APRILIA RSV4 1100 Factory 2021 User manual

Other APRILIA Motorcycle manuals

APRILIA

APRILIA MX 125 - ED01 2004 User manual

APRILIA

APRILIA RSV MILLE - DEALER INSTRUCTION SHEET 2004 User manual

APRILIA

APRILIA HABANA 125 - PART1 User manual

APRILIA

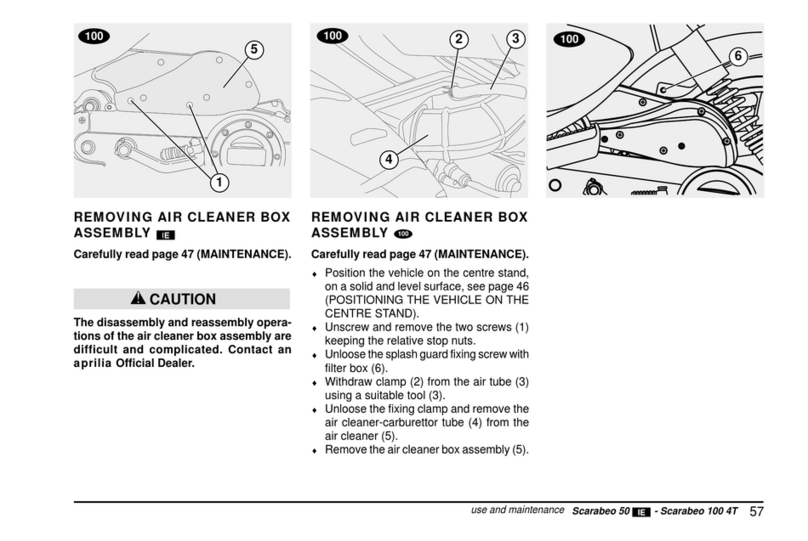

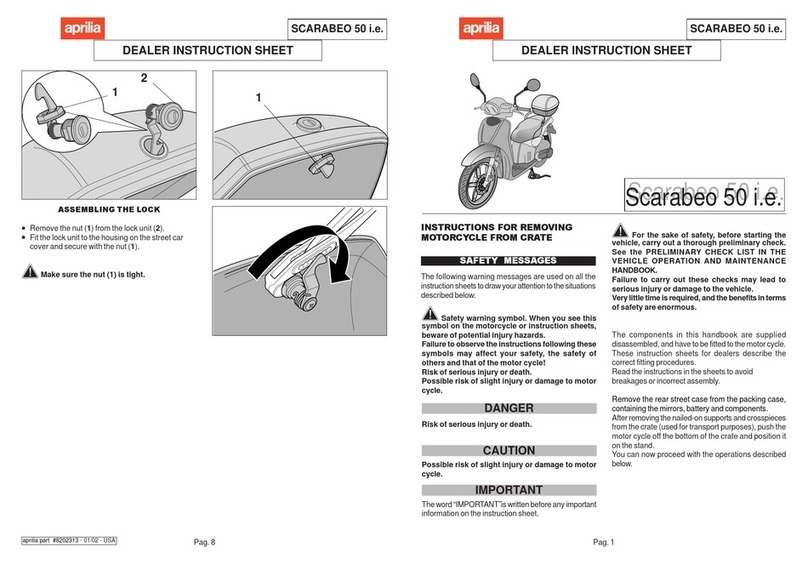

APRILIA SCARABEO 50 IE - 06-2001 PART8 User manual

APRILIA

APRILIA ETV MILLE CAPONORD ABS - 2003 User manual

APRILIA

APRILIA SPORTCITY ONE 50 2T User manual

APRILIA

APRILIA MOJITO 150 - 2006 User manual

APRILIA

APRILIA SPORTCITY ONE 50 4T User manual

APRILIA

APRILIA SL MILLE - 2000 User manual

APRILIA

APRILIA SR 50 User manual

APRILIA

APRILIA RS 125 - 1996 User manual

APRILIA

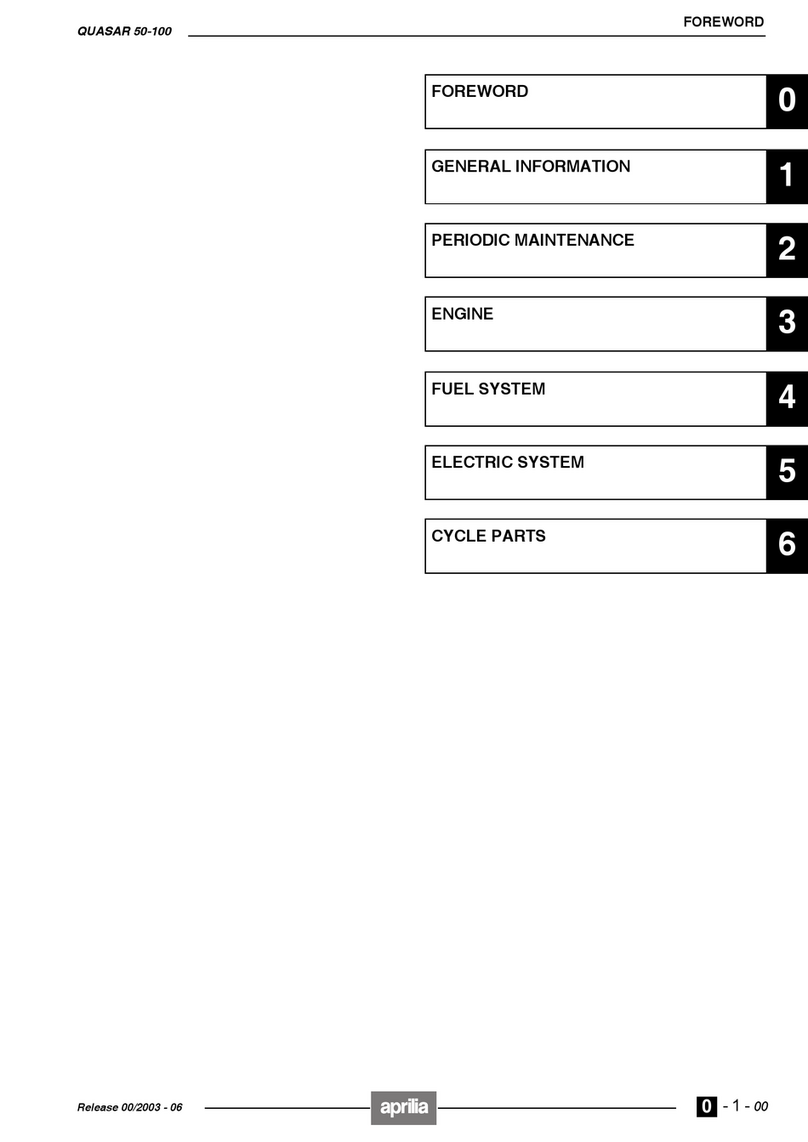

APRILIA QUASAR 50 User manual

APRILIA

APRILIA PEGASO 650 IE - PART2 01-2001 User manual

APRILIA

APRILIA SR 50 - 2000 User manual

APRILIA

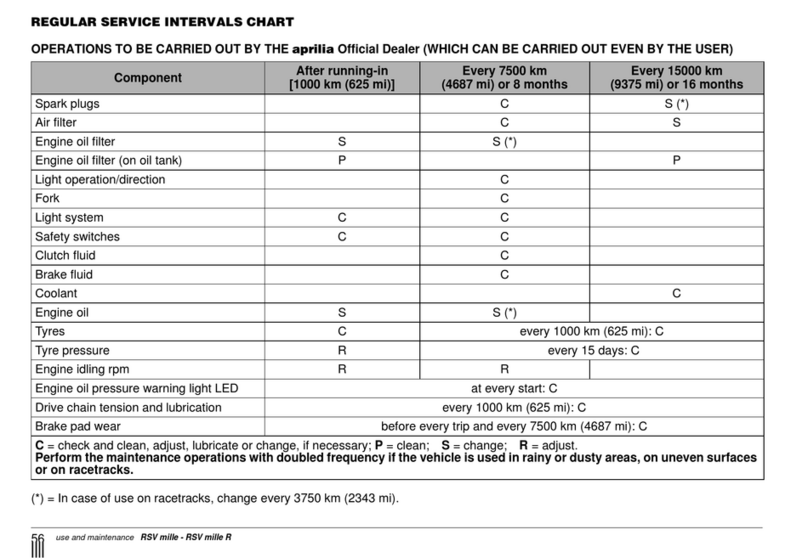

APRILIA RSV MILLE - REGULAR SERVICE User manual

APRILIA

APRILIA AM5 H2O AUTOMIX User manual

APRILIA

APRILIA SL MILLE Instruction manual

APRILIA

APRILIA SCARABEO 250 User manual

APRILIA

APRILIA RX 125 User manual

APRILIA

APRILIA SCARABEO 50 I.E - 2002 User manual