7

453272 ISS U 09.2004

1. Read the instructions before installing and starting the pump. Always follow

the guidelines for assembly in order to secure optimum operational reliability.

If in doubt, contact your local APV dealer.

Electrical Installation

2. Always check that the specifications of the motor and the motor control unit

are correct, particularly in operating environments where there may be a risk

of explosion.

3. Always ensure that all electrical installation is carried out by qualified staff.

4. Never hose down the electric motor directly with water or cleaning fluids.

5. Never dismantle the pump before the power supply to the motor has been

disconnected. The fuses should be removed and the cable disconnected

from the motor.

6. Pumps should only be installed, disassembled, repaired and assembled by

personnel trained in servicing of APV pumps, or by APV fitters.

For further information, please contact your local APV dealer.

Personal Injury

7. Never start the pump before the coupling guard between pump and motor

has been securely fitted.

8. There are rotating parts in the pump. Never put hands or fingers into a pump

while it is in operation..

9. Never touch the gearbox of the pump as it can become very hot.

10. Never touch the rotor case during operation. If the pump is being used for

hot fluids the rotor case may become very hot.

11. Always ensure that all pipe connections have been fitted and tightened

properly before the pump is started. If the pump is used for hot and/or

hazardous liquids, special care must be taken. In such cases, follow the local

regulations for personal safety when working with these products.

12. Never dismantle the pump until the isolating valves on the suction and

discharge side have been closed and the immediate pipe system has been

drained. If the pump is used for hot and/or hazardous fluids, special

precautions must be taken. In such cases follow the local regulations for

personal safety when working with these products.

Pump damage

13. Always remove assembly tools from the pump before starting it up.

14. Always ensure that no debris of any kind is present in the pump.

15. Always ensure that the pump is filled with liquid before it is started.

16. Always ensure that the pump and the motor shafts are properly aligned .

17. Always ensure that the suction and discharge valves isolating the pump are

fully open before starting the pump.

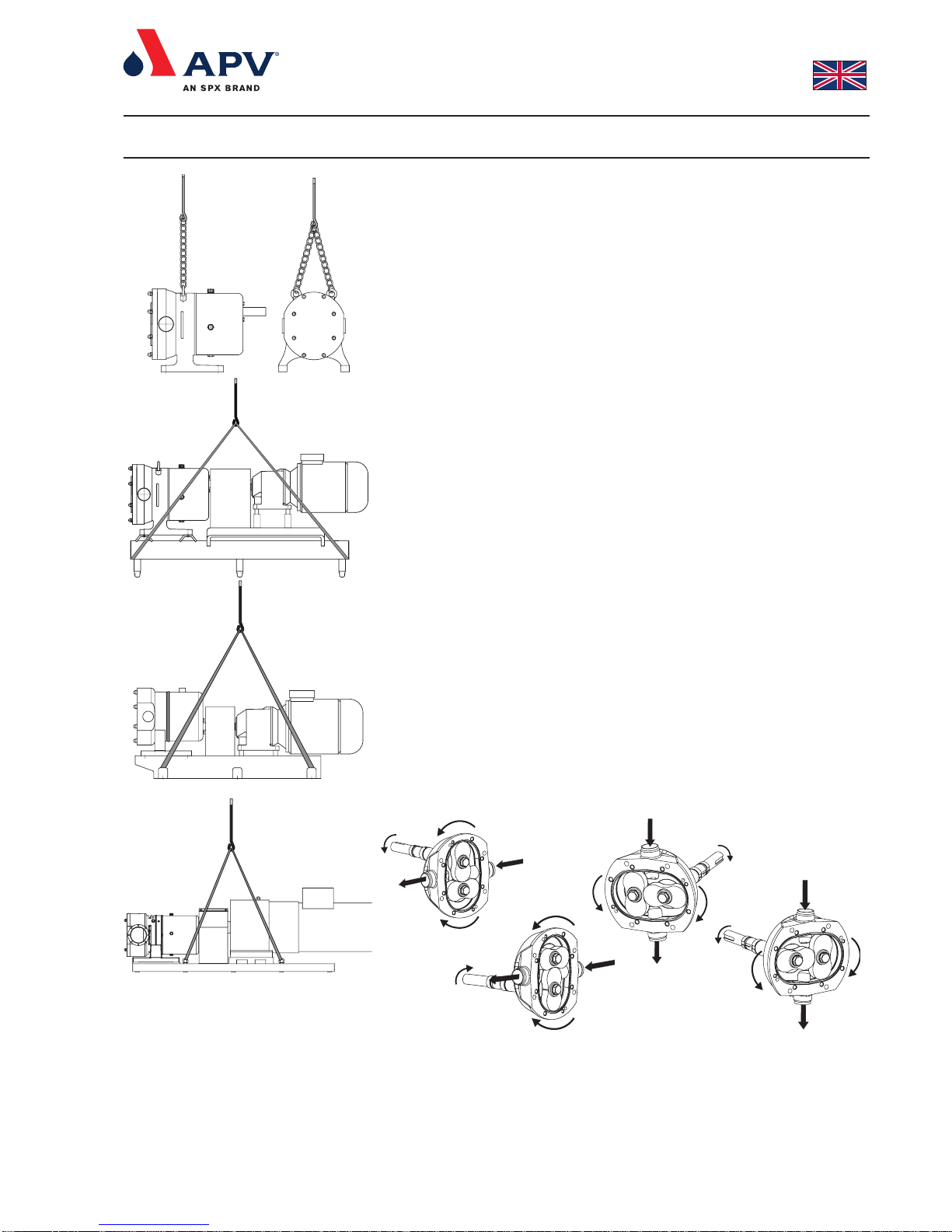

18. Always use securely fitted lifting straps when lifting the pump with a hoist or

similar lifting gear. Check whether there are any special lifting instructions.

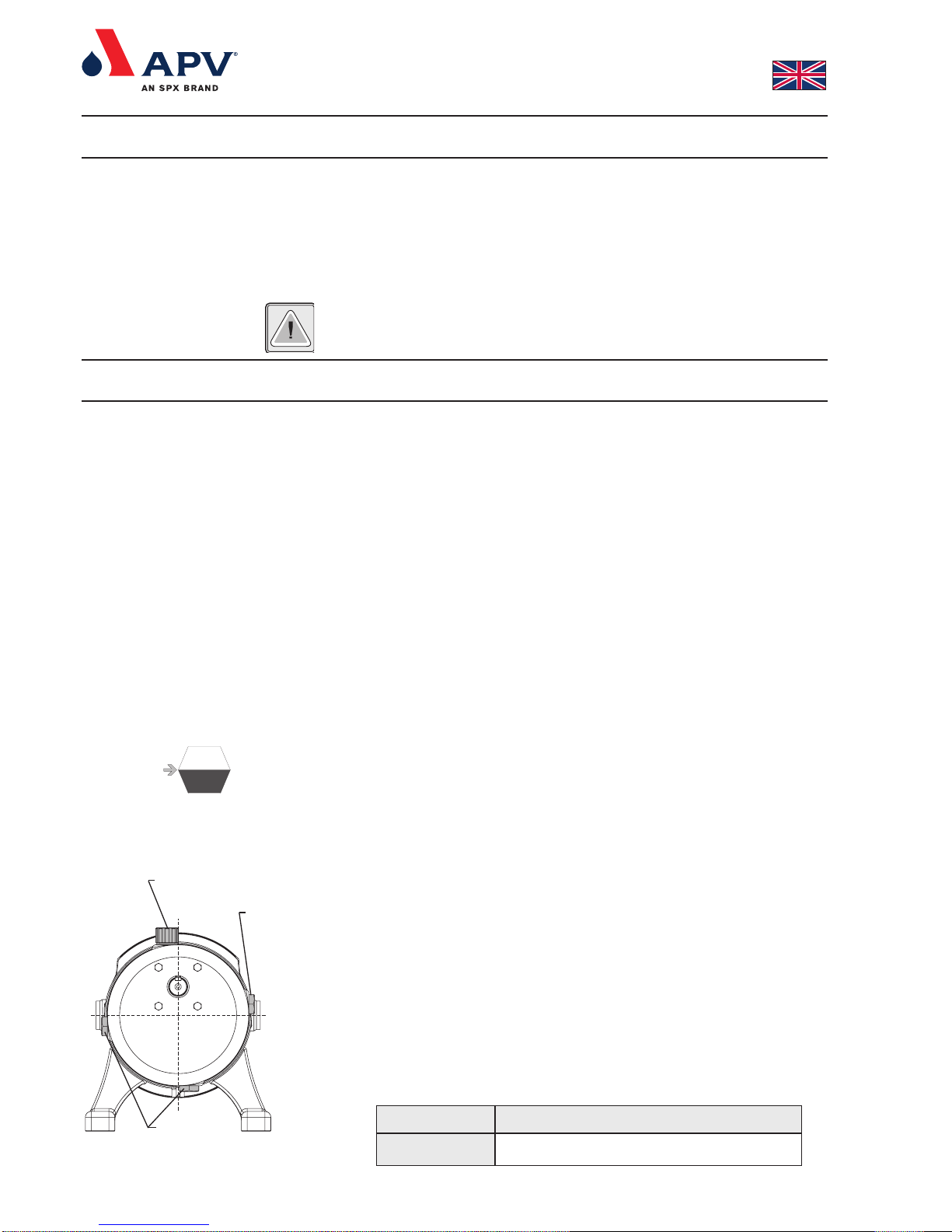

19. Always ensure that the gearbox case is filled with an APV recommended

gear oil to the appropriate level.

20. Never close or obstruct the outlet of the pump as the pressure in the system

will increase above the specified maximum pressure of the pump and cause

damage to the pump.

21. Never drop parts - especially rotors and front covers - on the floor.

22. Never exceed the maximum temperature specified on the pump nameplate.

23. Never exceed the maximum allowable pressure specified below:

Max. 33 bar: DW6 and DW7

Max. 28 bar: DW5

Max. 23 bar: DW2; DW3 and DW4

Max. 18 bar: DW1

These pressures apply for water at 20°C.

The differential pressure must not exceed the pressure stated on the nameplate.

0. Warnings