Aqu@Scop Advance DCI 6 Manual

English Français EspañolDeutsch Italiano

IOM ADVANCE 01-N-3GB

Part number / Code / Teil Nummer / Codice / Código : 3990608GB

Supersedes / Annule et remplace / Annulliert und ersetzt /

Annulla e sostituisce / Anula y sustituye : IOM ADVANCE 01-N-2GB

3.5 kW

Ü

18 kW

Aqu@Scop Advance DCI

6 ÷ 16

Air-water Heat Pump

Pompe à Chaleur air-eau

Wärmepumpe Luft-Wasser

Pompa di Calore aria-acqua

Bomba de Calor aire-agua

Installation and maintenance manual

Manuel d’installation et de maintenance

Installations- und Wartungshandbuch

Manuale di installazione e di manutenzione

Manual de instalación y de mantenimiento

IOM ADVANCE 01-N-3

Part number / Code / Teil Nummer / Codice / Código : 3990608

Supersedes / Annule et remplace / Annulliert und ersetzt /

Annulla e sostituisce / Anula y sustituye : IOM ADVANCE 01-N-2

INSTALLATION INSTRUCTION

NOTICE D’INSTALLATION

INSTALLATIONSHANDBUCH

ISTRUZIONI INSTALLAZIONE

INSTRUCCIONES DE INSTALACIÓN

2

CONTENTS

1. GENERAL RECOMMENDATIONS................................................................................................................................3

1.1. SAFETY DIRECTIONS .................................................................................................................................................................................... 3

1.2. WARNING.................................................................................................................................................................................................... 3

1.3. EQUIPMENT SAFETY DATA ............................................................................................................................................................................ 4

2. INSPECTION AND STORAGE .....................................................................................................................................5

3. WARRANTY................................................................................................................................................................5

4. CONTENTS OF PACKAGE ..........................................................................................................................................5

5. PRODUCT PRESENTATION .........................................................................................................................................5

6. ACCESSORIES............................................................................................................................................................6

7. DIMENSIONS.............................................................................................................................................................6

8. HANDLING................................................................................................................................................................6

8.1. NET WEIGHT................................................................................................................................................................................................ 6

9. TECHNICAL SPECIFICATIONS ....................................................................................................................................7

9.1. PHYSICAL CHARACTERISTICS........................................................................................................................................................................ 7

9.2. ELECTRICAL CHARACTERISTICS..................................................................................................................................................................... 7

9.3. OPERATING LIMITS....................................................................................................................................................................................... 7

10. REFRIGERATION AND HYDRAULIC DIAGRAM..........................................................................................................8

11. INSTALLATION.........................................................................................................................................................8

11.1. SITING THE INSTALLATION.......................................................................................................................................................................... 8

11.2. CLEARANCE ............................................................................................................................................................................................... 9

11.3. ATTACHMENT TO THE GROUND ................................................................................................................................................................ 9

12. HYDRAULIC LINKS.................................................................................................................................................10

12.1. GENERAL RECOMMENDATIONS............................................................................................................................................................... 10

12.2. STANDARD CIRCUITS................................................................................................................................................................................ 11

12.3. ANTI-FREEZE PROTECTION....................................................................................................................................................................... 13

12.4. WATER TREATMENT WARNING.................................................................................................................................................................. 13

12.5. CONNECTION TO THE CENTRAL HEATING LOOP.................................................................................................................................... 14

12.6. HEAT INSULATION.................................................................................................................................................................................... 14

12.7. FILLING THE SYSTEM WITH WATER............................................................................................................................................................ 14

12.8. WATER FLOW CONTROLLER..................................................................................................................................................................... 14

12.9. DETERMINING WATER FLOW .................................................................................................................................................................... 15

13. WIRING DIAGRAM AND LEGEND..........................................................................................................................16

13.1. WIRING DIAGRAM.................................................................................................................................................................................... 16

13.2. LEGEND................................................................................................................................................................................................... 16

14. ELECTRICAL CONNECTIONS .................................................................................................................................18

14.1. CONNECTIONS....................................................................................................................................................................................... 19

15. COMMISSIONING .................................................................................................................................................20

15.1. PRE-START CHECK LIST ............................................................................................................................................................................. 20

16. REGULATION......................................................................................................................................................... 21

16.1. USER INTERFACE ...................................................................................................................................................................................... 21

16.2. PRINCIPLE ................................................................................................................................................................................................ 25

17. STARTING THE APPLIANCE.................................................................................................................................... 27

17.1. SIMPLIFIED START-UP PROCEDURE ............................................................................................................................................................ 27

18. AQU@SCOP ADVANCE DCI EMERGENCY OPERATION SWITCH............................................................................30

19. DOMESTIC HOT WATER.........................................................................................................................................30

19.1. CONNECTION TO THE CENTRAL HEATING LOOP.................................................................................................................................... 30

19.2. ELECTRICAL CONNECTIONS.................................................................................................................................................................... 31

19.3. DOMESTIC HOT WATER PRODUCTION MODES........................................................................................................................................ 31

20. OPERATING CHECK LIST........................................................................................................................................32

20.1. GENERAL ................................................................................................................................................................................................. 32

20.2. OPERATING VOLTAGE: ............................................................................................................................................................................. 32

20.3. CONTROL................................................................................................................................................................................................ 32

20.4. FAN & DRIVE............................................................................................................................................................................................. 32

20.5. COMPRESSOR AND REFRIGERATION SYSTEM ........................................................................................................................................... 32

20.6. FINAL CHECK........................................................................................................................................................................................... 32

21. FINAL TASKS..........................................................................................................................................................32

22. IN CASE OF WARRANTY - MATERIAL RETURN PROCEDURE...................................................................................32

23. ORDERING SERVICE AND SPARE PARTS ORDER.....................................................................................................32

24. MAINTENANCE .....................................................................................................................................................33

24.1. REGULAR MAINTENANCE ......................................................................................................................................................................... 33

24.2. GENERAL INSPECTION............................................................................................................................................................................. 33

24.3. REFRIGERATION CIRCUIT.......................................................................................................................................................................... 33

24.4. ELECTRICAL SECTION............................................................................................................................................................................... 33

24.5. SERVICING CHECKLIST............................................................................................................................................................................. 34

24.6. RESET SAFETY DEVICE............................................................................................................................................................................... 34

25. LIST OF SETTINGS..................................................................................................................................................35

26. ALARM LIST AVAILABLE ON THE AQU@SCOP ADVANCE DCI DISPLAY .................................................................38

3

1. GENERAL RECOMMENDATIONS

The purpose of this Manual is to provide users with instructions for installing, commissioning, using and maintaining

the units.

It does not contain the complete description of all the maintenance operations guaranteeing the unit’s long life and

reliability. Only the services of a qualified technician can guarantee the unit’s safe operation over a long service life.

Please read the following safety precautions very carefully before installing the unit.

1.1. SAFETY DIRECTIONS

Follow the safety rules in forces when you are working on your appliance.

The installation, commissioning and maintenance of these units should be performed by qualified personnel having

a good knowledge of standards and local regulations, as well as experience of this type of equipment.

This appliance has not been designed for use by persons (including children) with reduced physical, sensorial or

mental faculties or by persons without any experience or knowledge of heating systems, unless they act under the

safety and supervision of a responsible person or have received prior training concerning the use of the appliance.

Children should be supervised to ensure that they do not play with the appliance.

The unit should be handled using lifting and handling equipment appropriate to the unit's size and weight.

Any wiring produced on site must comply with the corresponding national electrical regulations.

Make sure that the power supply and its frequency are adapted to the required electric current of operation, taking

into account specific conditions of the location and the current required for any other appliance connected to the

same circuit.

The unit must be EARTHED to avoid any risks caused by insulation defects.

It is forbidden to start any work on the electrical components if water or high humidity is present on the installation site.

1.2. WARNING

Cutoff power supply before starting to work on the appliance.

When making the hydraulic connections, ensure that no impurities are introduced into the pipe work.

The manufacturer declines any responsibility and the warrantly becomes void if these instructions

are not respected.

If you meet a problem, please call the Technical Department of your area.

If possible, assemble the compulsory or optional accessories before placing the appliance on its final location. (see

instructions provided with each accessory).

In order to become fully familiar with the appliance, we suggest to read also our Technical Instructions.

The information contained in these Instructions are subject to modification without advance notice.

POWER SUPPLY MUST BE

SWITCHED OFF

BEFORE STARTING WORK IN

THE ELECTRIC

CONTROL BOX

4

1.3. EQUIPMENT SAFETY DATA

Safety Data R410A

Toxicity Low

In contact with skin Skin contact with the rapidly evaporating liquid may cause tissue chilblains. In case of skin contact

with the liquid, warm the frozen tissue with water and call a doctor. Remove contaminated clothing

and footwear. Wash the clothing prior to re-use.

In contact with eyes Vapours have no effect. Liquid splashes or sprays may cause freeze burns. In these cases rinse your

eyes with running water or with a solution for eye lavages for at least 10 minutes. Immediately

apply to a doctor.

Ingestion In this case, burns may result. Do not attempt to make the patient vomit. If the patient is conscious,

rinse the mouth with water. Call a doctor immediately.

Inhalation In case of inhalation, move the patient to an area with fresh air and provide oxygen if ne-

cessary. Perform artificial respiration if the patient has stopped breathing or lacks air. In

case of cardiac arrest, perform external cardiac massage. Call a doctor immediately.

Further Medical Advice Exposure to high concentrations can be dangerous for individuals with cardiac problems, as the

presence of catecholamines such as adrenalin in the bloodstream may lead to increased arrhyth-

mia and possible cardiac arrest.

Occupational exposure

limits

R410A: Recommended limits: 1,000 ppm v/v 8 hours TWA.

Stability Stable product

Conditions to avoid Increased pressure due to high temperatures may cause the container to explode. Keep out of

the sun and do not expose to a temperature >50°C.

Hazardous reactions Possibility of dangerous reactions in case of fire due to the presence of F and/or CI radicals

General precautions Avoid the inhalation of high concentrations of vapours. The concentration in the atmosphere

shall be kept at the minimum value and anyway below the occupational limits. Since vapours

are heavier than air and they tend to stagnate and to build up in closed areas, any opening for

ventilation shall be made at the lowest level.

Breathing protection In case of doubt about the actual concentration, wear breathing apparatus. It should be self-

contained and approved by the bodies for safety protection.

Storage Preservation Refrigerant containers shall be stored in a cool place, away from fire risk, direct sunlight and all

heat sources, such as radiators. The maximum temperature shall never exceed 50°C in the storage

place.

Protection clothes Wear boots, safety gloves and glasses or masks for facial protection.

Behaviour in case of

leaks or escapes

Never forget to wear protection clothes and brething apparatus. Isolate the source of the leakage,

provided that this operation may be performed in safety conditions. Any small quantity of

refrigerant which may have escaped in its liquid state may evaporate provided that the room is

well ventilated.In case of a large leakage, ventilate the room immediately. Stop the leakage with

sand, earth or any suitable absorbing material. Prevent the liquid refrigerant from flowing into

drains, sewers, foundations or absorbing wells since its vapours may create an asphyxiating

atmosphere.

Disposal The best procedure involves recovery and recycle. If this is not possible, the refrigerant shall be

given to a plant which is well equipped to destroy and neutralise any acid and toxic by-product

which may derive from its disposal.

Combustibility features R410A: Non-inflammable at ambient temperatures and atmospheric pressures.

Containers If they are exposed to the fire, they shall be constantly cooled down by water sprays.

Containers may explode if they are overheated.

Behaviour in case of fire In case of fire wear protection clothes and self-contained breathing apparatus.

5

2. INSPECTION AND STORAGE

At the time of receiving the equipment carefully cross check all the elements against the shipping documents in order

to ensure that all the crates and boxes have been received. Inspect all the units for any visible or hidden damage.

In the event of shipping damage, write precise details of the damage on the shipper’s delivery note

and send immediately a registered letter to the shipper within 48 hours, clearly stating the damage

caused. Forward a copy of this letter to the manufacturer or his representative.

Never store or transport the unit upside down. It must be stored indoors, completely protected from rain, snow etc.

The unit must not be damaged by changes in the weather (high and low temperatures). Excessively high temperatures

(above 60 °C) can harm certain plastic materials and cause permanent damage. Moreover, the performance of

certain electrical or electronic components can be impaired.

3. WARRANTY

The units are delivered fully assembled and tested.

Any modification to the units without the manufacturer’s prior approval, shall automatically render the warranty

null and void.

The following conditions must be respected in order to maintain the validity of the warranty:

²Commissioning shall be performed by specialised technicians from technical services approved by

the manufacturer.

²Maintenance shall be performed by technicians trained for this purpose.

²Only Original Equipment spare parts shall be used.

²All the operations listed in the present manual shall be performed within the required time limits.

THE WARRANTY SHALL BE NULL AND VOID IN THE EVENT

OF NON-COMPLIANCE WITH ANY OF THE ABOVE CONDITIONS.

1 HEAT Pump Aqu@Scop Advance DCI

1 Documentation pouch

4 Anti-vibration pads

1 Water filter kit

1 stop cock

The distinguishing feature of this Aqu@Scop Advance DCI Air/water heat pump range is its power variation

capability, provided by its inverter compressor technology.

This technology provides remarkable "power output / heating requirement" adaptability. Depending on the heating

power demand and the working temperature of the heat emitters, the regulator of the Aqu@Scop Advance DCI

chooses the compressor frequency to be used.

4. CONTENTS OF PACKAGE

5. PRODUCT PRESENTATION

6

SEE APPENDIX

6. ACCESSORIES

²Set of stop cocks with pressure tap

²Set of 2 flexible pipes (length 1m)

²Hydraulic connection kit

²Water flow adjustment kit (requires the stop cocks with pressure take-off kit)

²Domestic Hot Water (DHW) tank

²3 way valve Domestic Hot Water tank

²140 litre buffer tank

²Anti-vibration pads

²6 kW in-line electric heater (compatible with the boiler back-up version)

²Wired programmable ambiance terminal

²Wireless programmable ambiance terminal

Take care to avoid any rough handling or impacts when unloading and moving the appliance. Only push or pull

the appliance by its base. Place a safety wedge between the unit base and the fork lift truck to avoid damaging

the unit’s structure and casing.

Transit holes

Ø30mm

The handles present on the appliance's panels are intended for the removal/refitting of the latter and must not be

used for handling the complete appliance (too heavy to be supported by the panels).

Wedge required along the

entire length of the unit.

6 12 16

125 190

7. DIMENSIONS

8. HANDLING

8.1. NET WEIGHT

7

9. TECHNICAL SPECIFICATIONS

9.1. PHYSICAL CHARACTERISTICS

9.2. ELECTRICAL CHARACTERISTICS

This equipment contains fluorinated gas with greenhouse gas effects covered by the Kyoto agreement.

9.3. OPERATING LIMITS

20

25

30

35

40

45

50

55

60

65

70

-25 -20 -15 -10 -5 0 5 10 15 20 25

Outlet water temperature (°C)

Outdoor air temperature (°C)

Aqu@scop

Advance DCI

Aqu@scop

Advance DCI-R

Aqu@Scop Advance DCI heat pumps have a wide power range.

When heating requirements are low and when the necessary starting temperature is low, the Aqu@Scop Advance DCI

operates at reduced power. Otherwise the Aqu@Scop Advance DCI uses a higher power rating to supply the

heating needs up to the selected point.

The outlet water temperature is automatically adjusted to the water rule (heating curve) up to a maximum temperature

of 55° C.

6 12 16

REFRIGERANT

Type R410A

Factory charge g SEE NAME PLATE

HYDRAULIC LINKS

Inlet water gas 1" Female

Outlet water gas 1" Female

WATER FLOW

Nominal l/h 1100 1850 2600

Minimum l/h 850 1300 1500

Maximum l/h 1500 2300 3100

FANS

Number of fan 1 2

ACOUSTIC PRESSURE

Acoustic pressure dB(A) 63.5 65 65.5

6 12 16

SUPPLY VOLTAGE 230V / 1 Ph / 50Hz

Maximum current (without electric heater) A 18 26 27

Maximum current (with electric heater) A 37 58 59

FULL HEATING CAPACITY

8

SEE APPENDIX

The unit is not designed to withstand weights or stresses from adjacent equipment, pipe work or

constructions. Any foreign weight or stress on the unit structure could lead to a malfunction or a

collapse with dangerous consequences for personnel and property. In such an event, the warranty

shall be null and void.

Unit operation depends on air temperature. Any recycling of air extracted by the fan lowers the air intake

temperature across the exchanger fins and alters the standard operating conditions.

The outdoor unit must be installed outdoors with sufficient surrounding clearance to enable unobstructed air

circulation through the appliance and access for maintenance work.

In the case of the unit being sited in areas exposed to high winds, you must avoid the wind hitting the fan blowing

surface areas directly to avoid any risk of recycling cooled air. Strong wind can disrupt exchanger ventilation and

create de-frosting problems.

The arrows show the direction of air circulation through the appliance. (Refer to Fig. § Floor location).

Depending on temperature and outdoor air humidity conditions, water vapour contained in the air can condense

on the finned heat exchanger and even form ice under low outdoor temperature conditions (around < 5°C). This

condensate water and defrosted water runs off via outlets provided under the exchanger. To assist drainage and

to prevent frozen water remaining in the appliance in winter, we recommend that the unit is installed at a height

of around 10cm off the ground and placed on plastic blocks or other suitable supports (damper feet proposed as

an accessory). In this way, condensate and defrosted water can run off freely and be absorbed into the ground or

channelled to a basin built under the appliance in order to protect the environment.

In areas where outdoor temperatures fall below 1°C, the system can be equipped with a condensate anti-freeze

protection system (e.g. a heated pipe sheath).

To reduce the noise level, our machines are equipped with quiet fans and a soundproofed compressor.However,

noise levels can be reduced even further by following a few installation precautions:

²Do not install the appliance near a bedroom window. Avoid locating the appliance in a corner

(increased reverberated noise).

²Install the rubber pads supplied or anti-vibration pads (available as an option) under the appliance.

²Use flexible hoses (available as options) for connections between the appliance and the mains water

network.

²Do not join the concrete slab supporting the appliance to the structure of the dwelling (structure-

borne noise transmission)

10. REFRIGERATION AND HYDRAULIC DIAGRAM

11. INSTALLATION

11.1. SITING THE INSTALLATION

11.1.1. PREVAILING WIND

11.1.2. CONDENSATE WATER MANAGEMENT

11.1.3. HOW TO REDUCE NOISE POLLUTION

9

11.2. CLEARANCE

REF. DIMENSION

A 800mm

B 500mm

C 500mm

D 400mm

E 800mm

F 100mm

The unit location dimensions are indicated on the figure below. A slope of 1 cm/m should be created to assist

rainwater drainage.

Vibration dampers must be fitted during installation to overcome any risks of vibration being transmitted due to

direct contact with a rigid support surface.

THE UNIT MUST NEVER BE

INSTALLED ON A WALL BRACKET.

The appliance must be sited on a level and solid floor and preferably on a masonry surface.

When choosing the location for the appliance, take care to leave sufficient free clearance on all sides to ensure

easy access for maintenance work. The minimum free clearance dimensions indicated must be observed to ensure

both proper system operation and allow access for maintenance and cleaning.

A

BD

E

CF

349

1192.6

1%

AIR FLOW

11.3. ATTACHMENT TO THE GROUND

10

12. HYDRAULIC LINKS

When choosing and installing water pipes, you must consult and observe all current local standards, regulations

and instructions.

12.1. GENERAL RECOMMENDATIONS

²You must design the pipe network with the minimum number of bends and keep the number of

changes in height to the strict minimum. This will reduce installation costs and ensure optimum system

performance. The pipe network must include:

²A vibration elimination system (e.g.: link hoses available as an accessory) on all pipes connected to

the appliance in order to reduce vibrations and noise transmitted to the building fabric.

²Stop cocks to isolate the hydraulic circuit during maintenance.

²Manual or automatic bleed valves at the highest point on the water circuit.

²A suitable system for maintaining water pressure in the circuit (all Aqu@Scop Advance DCI models

have an internal expansion tank).

²The installation of thermometers and pressure gauges on the heat exchanger inlet and outlet to

facilitate day-to-day controls and system maintenance.

When installing Aqu@Scop Advance DCI appliances in existing water circuits, a sludge trap and a removable

mesh filter should be installed upstream of the appliance.

To avoid all risks of foreign object ingress and to preserve the performance of the machine, IT IS

NECESSARY TO INSTALL THE WATER FILTER ACCESSORY (supplied) at the inlet of the machine.

To ensure that the system operates correctly you must use suitably sized and properly routed pipes for the hydraulic

links between the Heat pump and the mains network.

The volume of water in the installation must be sufficient to avoid short defrosting cycles and to operate without

any loss of comfort. To ensure the Aqu@Scop Advance DCI functions efficiently, available installation water

volume must be:

12.1.1. EXPANSION TANK

Aqu@Scop Advance DCI units are equipped with an expansion tank with the following volumes and pre-

pressurisation pressures:

6 12 16

Volume l 3 5

Pre-pressurisation pressure bar 0.5 2

It is important to make sure that the pressure in the water supply system is sufficient to enable the installation to be

filled correctly. It is necessary to ensure that the expansion tank is sufficiently large for the installation.

1. Check of the required volume

2. Adjustment of the pressurisation pressure

6 12 16

available water volume l 140 190 250

When water circulation through heat emitters can be interrupted (thermostatic radiator valves closed) or the heating

supply halted, you must ensure that:

²The heat pump maintains its nominal water flow.

²The heat pump works in a loop with a useful volume that complies with the required minima.

The use of a 3-speed circulation pump enables water flow through the appliance to be adapted to pressure losses

in the system. Pump delivered set to position MV for model 6 and to GV for models 12 and 16). Refer to water

flow graph.

12.1.2. ANTI-CLOGGING PROTECTION

12.1.3. MINIMUM HEATED WATER VOLUME REQUIREMENTS – BUFFER TANK.

11

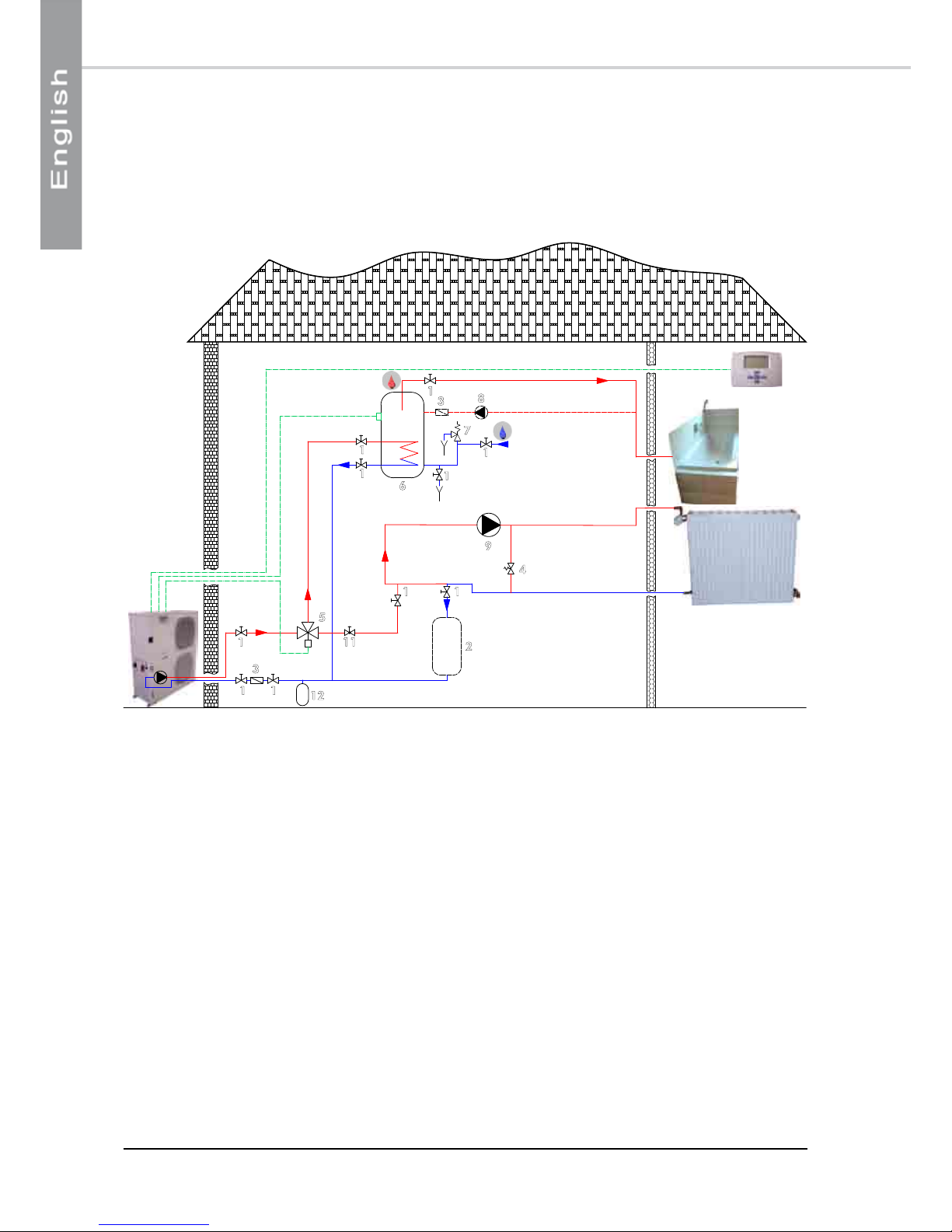

Layout 1: underfloor heating application without individual room regulation

This layout is recommended when the Aqu@Scop Advance DCI water flow is continuous and close to the nominal

value (no thermostatic valves).

The buffer tank (2) provides extra circulating water volume to maintain the minimum volume.

12.2. STANDARD CIRCUITS

1

3

2

1 1

1

1

11

3

1

5

6

7

8

1

1

12

1. Stop cocks

2. Buffer tank (optional)

3. Filter or sludge trap

4. Relief valve

5. 3-way valve – Domestic Hot Water

6. Domestic Hot Water tank

7. Safety devices

8. Recycling circulation pump (optional)

9. Circulation pump

10. Mixing tank

11. Flow regulating valve

12. Additional expansion tank (if required)

This drawing is not applicable to Aqu@Scop Advance DCI 16 if heating water circuit pressure drop

is higher than 20kPA.

12

Layout 2: underfloor heating application without individual room regulation

This layout is recommended for heating installations with wide operating water flow variations (radiator thermostatic

valves present in the system). We strongly recommend including the buffer tank (2) as it guarantees that the heating

loop capacity is higher than the minimum volume when the maximum number of thermostatic valves are closed.

The flow regulating valve (11) is used to balance the flow in heating mode and domestic hot water production

mode to always ensure optimum Aqu@Scop Advance DCI operation.

1

3

2

4

1 1

1

1

11

3

1

5

6

7

8

9

1

1

11

12

13

12.3. ANTI-FREEZE PROTECTION

We recommend that the installation is protected against freezing by adding anti-freeze.

The chart below indicates the concentration of anti-freeze to be used relative to the minimum outdoor temperature

reached.

Using untreated or inadequately treated water in this appliance can lead to a build-up of limescale,

algae or sludge deposits and cause corrosion and erosion. As the manufacturer is not aware of

the components used in the hydraulic network, or of the quality of water used, the installer or the

owner should contact a specialised water treatment company. This issue is particularly important

and every care should be taken to ensure that circuit water is properly treated in order to avoid

problems associated with incorrect water distribution. A clogged water network will systematically

lead to premature wear of the appliance's components.

Layout 3: radiator application or underfloor heating application with individual room regulation

This layout is also recommended for heating installations with wide operating water flow variations (radiator

thermostatic valves present in the system). Minimum system volume is guaranteed by a mixing tank (10). Take care

when calculating the volume of water in the installation and only take account of 50% of the mixing tank's volume.

Example: For a useful volume of 100 litres the actual mixing tank volume will be 200 litres.

The flow regulating valve (11) is used to balance the flow in heating mode and domestic hot water production

mode to always ensure optimum Aqu@Scop Advance DCI operation.

1

3

10

4

1 1

1

11

3

1

5

6

7

8

9

11

1

1

1

11

12

The mixture considerably alters the installation's performances, particularly in terms of pressure losses.

Concentration propylene glycol % 10 20 30

Minimum outdoor temperature °C -3 -7 -13

12.4. WATER TREATMENT WARNING

14

12.5. CONNECTION TO THE CENTRAL HEATING LOOP

You must check water tightness and the cleanliness of the installation before connecting the Aqu@Scop Advance DCI.

For the Aqu@Scop Advance DCI's WATER INLET and OUTLET connections, you must install manual stop

cocks with the same diameter as the main pipe work. This will enable maintenance work to be carried out on the

Aqu@Scop Advance DCI without having to bleed the entire system.

A link valve with pressure tap kit is available.

The Aqu@Scop Advance DCI must be protected by a water filter. Connect this subassembly to the water inlet

of the unit, taking care to maintain the strainer of the water filter downwards. A sludge trap should be fitted in the

event of high sludge build-ups.

WARNING!

Take care not to damage the hydraulic pipe links by applying too much tightening pressure.

Use a second wrench to compensate for the tightening torque.

You should always use a counter-wrench for tightening valves.

12.6. HEAT INSULATION

To guarantee proper energy efficiency and compliance with current standards, water pipes passing through

uninhabited zones should be properly lagged to retain heat.

To achieve correct insulation with conductivity of 0.04 W/mK, lag the pipes with insulating material with a radial

thickness between 25mm and 30 mm.

12.7. FILLING THE SYSTEM WITH WATER

All installation works must be completed and the system cleaned and drained, before filling the water circuit in

accordance with current best practices. The system should be filled to obtain a service pressure not exceeding 2.5

bars.

The water supply should come either from the mains network or from the Heat Pump or from any other point on

the installation.

Check that the automatic bleed valve operates correctly.

You must completely bleed the circuit of all air to ensure efficient operation.

Close the inlet water valve once the hydraulic circuit is filled correctly.

12.8. WATER FLOW CONTROLLER

A paddle type water flow controller is fitted to the water circuit connected to the condenser. The purpose of this

safety component is to ensure that a minimum water flow is established before the unit is started up.

The appliance is equipped with a set of safety devices including a safety valve set at 3 bars and a manual pressure

relief valve.

THE MANUFACTURER'S WARRANTY IS VOID IF THE FILTER SUPPLIED WITH THE

Aqu@Scop Advance DCI IS NOT INSTALLED TO PROTECT THE APPLIANCE

15

12.9. DETERMINING WATER FLOW

²P1 = Aqu@Scop Advance DCI outlet

water pressure.

²P2 = Aqu@Scop Advance DCI inlet water

pressure.

Reminder:

1bar = 100kPa = 10m water column

AVAILABLE PRESSURE = P1-P2

WATER FLOW CALCULATION GRAPH

Pump output (flow) is adjustable in relation to the system's pressure losses, by means of the internal pump speed

selector.

SEE APPENDIX

P1

P2

WATER

OUTLET

WATER INLET

(RETURN)

When you have measured the available pressure, expressed in

kPa, refer to the graph corresponding to the appliance installed

and read the flow value at the point where the pressure value

crosses the speed curve for the pump.

To ensure that the Aqu@Scop Advance DCI operates properly and to attain the required outlet water

temperatures, the water flow through the appliance has to be within specifications. The water flow through the

Aqu@Scop Advance DCI can be controlled and regulated by measuring the difference between:

²Both the outlet water and inlet water pressures.

12.9.1. METHOD BASED ON WATER

PRESSURES

12.9.2. WATER FLOW REGULATION

16

13. WIRING DIAGRAM AND LEGEND

N 776

13.1. WIRING DIAGRAM SEE APPENDIX

Connection to the QG main disconnect switch

230V +/-10% 50Hz

²L : phase

²N : neutral

²: ground

This supply comes from a CIRCUIT BREAKER or a FUSE HOLDER equipped with aM type fuses supplied by the

installer. Fuse sizes are indicated on the charts on the following page.

The appliance's electrical installation and wiring must comply with the country's current standards.

SE3870 Aqu@Scop Advance DCI 6 Control 1-Phase 230V +/-10% 50Hz

SE3869 Aqu@Scop Advance DCI 6 Power 1-Phase 230V +/-10% 50Hz

SE3872 Aqu@Scop Advance DCI 12/16 Control 1-Phase 230V +/-10% 50Hz

SE3871 Aqu@Scop Advance DCI 12/16 Power 1-Phase 230V +/-10% 50Hz

SE3888 Aqu@Scop Advance DCI R 6 Control 1-Phase 230V +/-10% 50Hz

SE3887 Aqu@Scop Advance DCI R 6 Power 1-Phase 230V +/-10% 50Hz

SE3884 Aqu@Scop Advance DCI R 12/16 Control 1-Phase 230V +/-10% 50Hz

SE3883 Aqu@Scop Advance DCI R 12/16 Power 1-Phase 230V +/-10% 50Hz

QG : Main cut-out switch

M1 : Compressor

FM1 : Internal safety device of the refrigeration

compressor

RV : 4-way cycle changeover valves

RAG : Anti-freezing protection electric resistance

FFC : Control circuit protection fuse

T1 : Ambience terminal 230/24V power supply

transformer

FER : Ferrite

LF : Supply filter

HF : Heater supply filter

CD : Compressor driver

CC : Coil

µPC : Controller

FFT : T1 transformer protection fuse (24V secondary

circuit)

EEV : Electronic pressure relief valve

ST1(EWT) : Entering water temperature

ST2(LWT) : Leaving water temperature

ST3(OCT) : Outdoor coil temperature

ST4(OAT) : Outdoor air temperature

ST5(CDT) : Compressor discharge temperature

ST6(CST) : Compressor suction temperature

ST8(DHWT) : Domestic hot water temperature (option)

ST9(DZLWT) : Dual-zone leaving water temperature

(option)

13.2. LEGEND

13.2.1. POWER SUPPLY

13.2.2. WIRING DIAGRAM KEY DESCRIPTIONS

13.2.2.1. POWER

13.2.2.2. COMMAND AND REGULATION

17

13.2.2.3. VENTILATION - FAN

13.2.2.4. WATER CIRCUIT

* These values are provided for information purposes only and must be checked and adjusted in relation to currently

applicable standards. They vary depending on the type of installation and the choice of conductors.

OF1 : Lower air exchanger fan motor

OF2 : Upper air exchanger fan motor

FOF1 : OF1 motor internal safety

FOF2 : OF2 motor internal safety

EP : Evaporating pressure transducer

HP1/2 : Automatic reset high pressure switch

CF : Fan motor speed controller

K2 : Start-up relay

COF1: OF1 motor capacitor

COF2: OF2 motor capacitor

KOF1 : OF1 fan motor relay

KOF2 : OF2 fan motor relay

FS : Water flow switch

WP : Water pump

KWP : WP water pump relay

CWP : Water pump capacitor

FFEH1 : Power circuit protection fuse (stage 1)

FFEH2 : Power circuit protection fuse (stage 2)

KEH1 : Heater element power relay (stage 1)

KEH2 : Heater element power relay (stage 2)

FCM : Heater safety device with manual reset

FCA : Heater safety device with automatic reset

KFCM: Power cut-off contactor (controlled by the "safety

device with manual reset")

EH : Heater elements

EMH : Back-up heating switch

Supply voltages 230V +/-10% 50Hz

Aqu@Scop Advance DCI Aqu@Scop Advance DCI R

6 12 16 6 12 16

General protection fuse rating aM type

(not supplied) 40A 63A 63A 25A 32A 32A

Fuse ratings

FFC aM type 4A 4A 4A 4A 4A 4A

FFEH1 Gg type 10A 10A 10A / / /

FFEH2 Gg type 10A 20A 20A / / /

FF T type T 0.6A 0.6A 0.6A 0.6A 0.6A 0.6A

Contactors and power relays

KFCM 12A 12A 12A / / /

K5 30A 30A 30A / / /

K6 30A 30A 30A / / /

WP2 : Water pump N°2

DHWV : Domestic hot water valve

DHWEH : Domestic hot water electric heater

DHWWP : Domestic hot water pump

DZWP : Dual-zone water pump (zone 1)

BOILER : Hot water boiler

BRV : Boiler relief valve

ON/OFF : Remote ON/OFF switch

DAY/NIGHT : DHW off-peak hours switch

EJP : Off-peak days switch

13.2.2.5. ELECTRIC HEATER

13.2.2.6. OPTIONS

13.2.3. FUSE VALUES, NOMINAL CURRENT OF CONTACTORS AND POWER RELAYS

18

14. ELECTRICAL CONNECTIONS

WARNING

Before carrying out any work on the equipment,

make sure that the electrical power supply is

disconnected and that there is no possibility

of the unit being started inadvertently.

Non-compliance with the above instructions

can lead to injury or death by electrocution.

The electrical installation must be performed by a fully qualified electrician, and in accordance with local electrical

standards and the wiring diagram corresponding to the unit model.

Any modification performed without our prior authorisation may result in the unit’s warranty being declared null

and void.

The power supply cable section must be sufficient to provide the appropriate voltage to the unit’s power supply

terminals, both at start-up and under full load operating conditions.

The power supply cable shall be selected in accordance with the following criteria:

1. Power supply cable length.

2. Maximum unit starting current draw – the cables shall supply the appropriate voltage to the unit

terminals for starting.

3. Power supply cables’ installation mode.

4. Cables’ capacity to transport the total system current draw.

Short circuit protection shall be provided. This protection shall comprise fuses or circuit breakers with high breaking

capacity, mounted on the distribution board.

If the local control includes a remote ambient terminal, it shall be connected with shielded cable and shall not

pass through the same conduits as the power supply cables as the voltages induced may create reliability faults in

the unit’s operation.

WARNING!

On-site wiring must be performed in accordance with the wiring diagram present in the appliance's

electrical connection box.

Mains power supply cables to the appliance must have copper conducting cores and be sized in

compliance with currently applicable IEC standards.

The installer must make sure that the installed power, the amperage and type of the protections and

the cross-section of the cables are sufficient to avoid an overload, and tripping of the installation

to protection mode.

The appliance must be grounded via a terminal block located inside the electrical connection box.

The power supply must not fluctuate by more than 10 %.

This manual suits for next models

2

Table of contents

Popular Heat Pump manuals by other brands

Nova Booster

Nova Booster Swimming Pool Heat Pump User & service manual

Electra

Electra PXD 25 DCI Service manual

Daikin

Daikin EHVZ08S18DA6V7 installation manual

Glen Dimplex

Glen Dimplex LIK 8TES Installation and operating instruction

Ingersoll-Rand

Ingersoll-Rand ENL 5 Instructions for installation and operation

Bryant

Bryant EVOLUTION V 288BNV owner's manual