1GENERAL PREFACTION ...........................................................................................................3

1.1 IDENTIFICATION MANUFACTURER’S DATA ....................................................................................3

2WARRANTY GENERAL RULES ...........................................................................................................4

3GLOSSARY OF THE USED TERMS......................................................................................................4

4RULES OF REFERENCE....................................................................................................................5

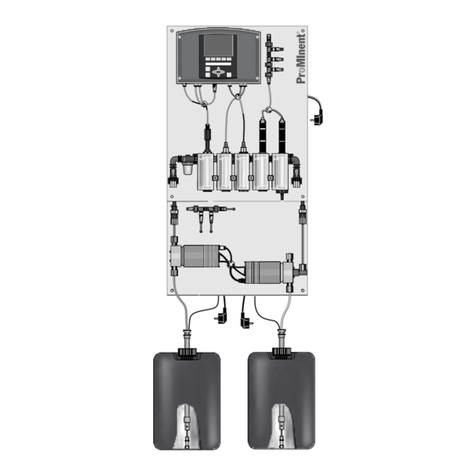

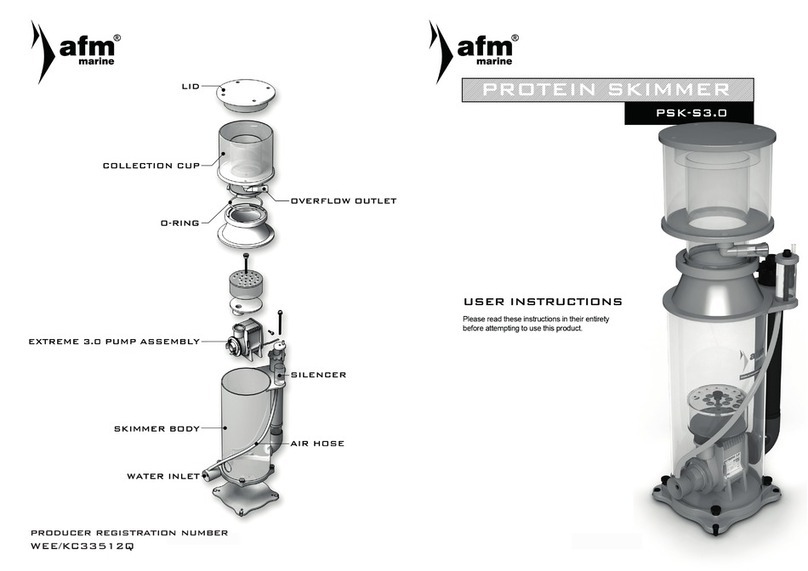

5EQUIPMENT DESCRIPTION...............................................................................................................5

5.1 PARTICULARS AND FUNCTION.....................................................................................................5

5.2 EQUIPMENT’S OVERALL VIEW .....................................................................................................5

5.3 STRUCTURAL DATA AND TECHNICAL CHARACTERISTICS ...............................................................6

5.4 EQUIPMENT’S TECHNICAL CHARACTERISTICS ..............................................................................6

6RISKS CONNECTED TO THE EQUIPMENT............................................................................................6

6.1 UNIVERSALITY...........................................................................................................................6

6.2 CONNECTED RISKS....................................................................................................................7

6.3 RISKS FOR AN INCORRECT USE...................................................................................................7

6.4 RESIDUAL RISKS........................................................................................................................7

7SIGNS STICKED ON THE EQUIPMENT.................................................................................................7

8TRANSPORT AND INTERNAL MOVING ................................................................................................8

9INSTALLATION ................................................................................................................................8

9.1 NORMAL WORKING ....................................................................................................................8

9.2 STORAGE..................................................................................................................................8

9.3 STARTING.................................................................................................................................9

9.4 REFILLING.................................................................................................................................9

9.5 FILTER CLOSING......................................................................................................................10

9.6 STARTING...............................................................................................................................10

9.7 WORKING................................................................................................................................10

9.8 FILTRATION.............................................................................................................................11

9.9 BACKWASH.............................................................................................................................11

9.10RINSING..................................................................................................................................11

9.11WASTE ...................................................................................................................................11

9.12CIRCULATION..........................................................................................................................11

9.13LOCK......................................................................................................................................11

9.14WINTER ..................................................................................................................................11

10 ORDINARY AND PREVENTIVE MAINTENANCE....................................................................................11

10.1UNIVERSALITY.........................................................................................................................11

10.2ORDINARY MAINTENANCE.........................................................................................................12

11 DRAINING.....................................................................................................................................12

12 PROHIBITIONS..............................................................................................................................13

13 MAINTENANCE OPERATION BOOK...................................................................................................13

14 COMPONENTS CARD..............................................................................................................14