5

Introduction

“Degaulle” Pool Water Treatment Principle

Vacuum negative pressure has been produced when the motor and pump running

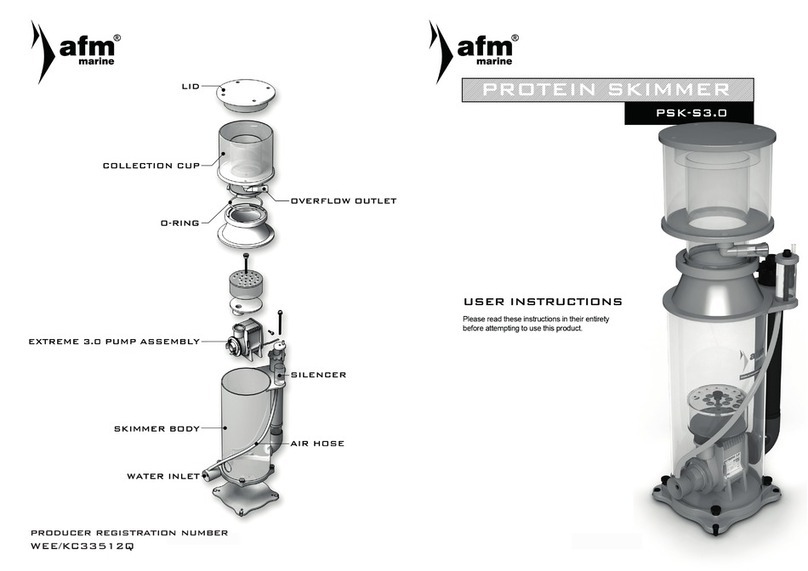

→Raw water will be drawn from skimmer opening on the side of the unit to the filter

basket (Water come into the basket from the surface to filter the leaves…)

→After basket filtered, water outgoing to the filter bag (5~15microns) for precision filtered

→After filtered by Bag filter, water will be discharged back to the pool

→”Degaulle”filtration system includes all traditional system functions

→It is efficiency, coupled with easy maintenance, will provide complete satisfaction.

“Degaulle”Pool Filtration System Features

1. High filtering capability: it can reach up to 5um.

2. Room saving: No operation room needed, it has the ABS, PP or PE housing instead

of the operation room. Nowadays, the earth for building is really expensive, so this

filter can be your best choice.

3. Pipe free: Our filter system does not need pipelines any more, so it can help with the

leakage problem.

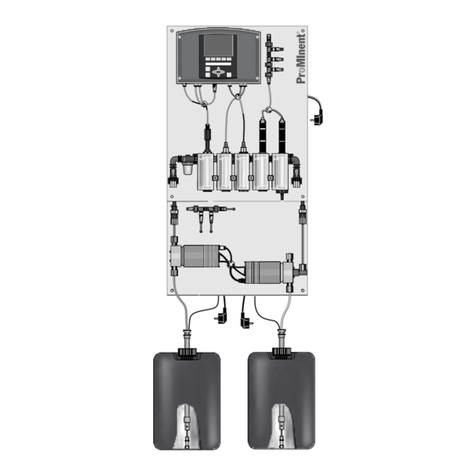

4. Auto chemical feeder: Chemicals can be sent to pool automatically once the motor

start, if you do not like to put chemicals to pool, switch off the valve.

5. Vacuum functions: This system has two vacuum functions. All dirt &debris can be

sucked into the skimmer basket or sucked through the vacuum pipe then out.

6. Massage functions: Our machine has turbo boost massage jet, something like

Jacuzzi. And air switch can be used to control the air bubble. And auxiliary jet can

assist the massage jet to strengthen the power of the water to massage.

7. Multiple functions: No underwater light, handrail, ladders, transformer, pump, sand

filter needed any more, etc.

8. Environmental &Reliable: We start this system for more than 6 years and have

thousands of successful cases in locally and overseas. And our machines are with

CE approvals already. Successfully exported to India, Singapore, Taiwan, France,

Turkey, Vietnam, Laos, and Cambodia…etc.

9. Warranty: We offer 2-year-limited warranty for our machine.

10. Professional technical supports: Our senior managers are with 22 years

experience in swimming pool filters, so we ensure you that we can help you with any

difficulties if needed and offer you our best services.

11. Corrosion Proof Housing: This machine is made out of PP material with the

functions of anticorrosion, watertight protection, scratches, cracks, tears proof etc...

12. Digital Control panel: Three groups working time setting, automatic and manual