Aquamatic Series

Page 6of 32

AquaTech-Pressmain Instruction Manual\Aquamatic Series AMV, AMF, HYAV

0.1.10 Any damage to equipment, pumpset, vessels, pipework or system components caused by

misapplication, mishandling or misuse could lead to Electric shock hazard, Burns hazard, Fire

hazard, Flooding hazard or cause injury to people or damage to property.

0.1.11 This equipment may contain moving/rotating parts that must remain guarded. Removal of or

missing guards could lead to serious personal injury.

0.1.12 Pressure vessels must never be disassembled whilst in use, they contain high pressure air/gas

charge which could cause injury to people or damage to property.

0.1.13 Pump motors with lifting eyes; the lifting eyes are only suitable for lifting motors NOT the

entire pump assembly. This could cause injury to people or damage to property.

0.1.14 Ensure the base/foundation/plinth/wall to which the equipment is to be attached is

sufficiently strong enough to carry the entire mass of the equipment including the water that

it will contain under worst-case fault conditions. E.g. fully saturated pressure vessel with no air

charge, break tank full to overflowing, etc. Failure to observe this could cause serious

mechanical damage/destruction resulting in injury to people or damage to property.

0.1.15 This equipment contains a fluid which may under certain circumstances leak/drip/spray fluid

(e.g. servicing, repair or malfunction). Ensure any fluid discharge will not cause damage to the

surroundings by taking appropriate action. E.g. install in a place that will not be damaged by

leakage or install in a bunded area with adequate drainage.

0.2 CAUTIONS FOR INSTALLATION

0.2.1 READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

0.2.2 The unit should only be installed/operated by a competent person; A competent person is someone

who is technically competent and familiar with safety practices and the hazards involved.

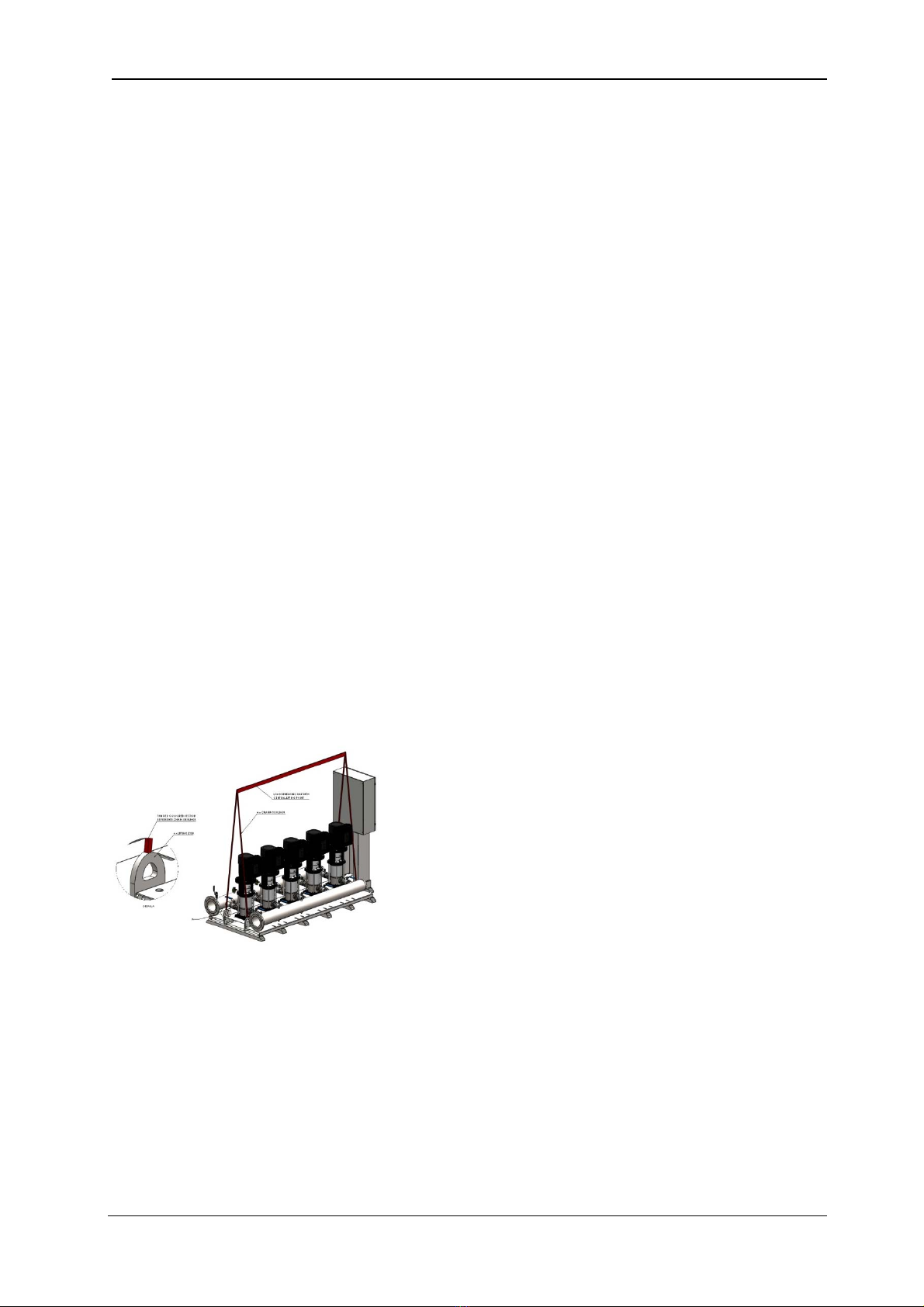

0.2.3 Do not lift the pumpset by pipework. Lift the pumpset by the container pallet using a

pallet/forklift or crane by passing strops underneath the skid using a spreader bar. Use built-in

lifting eyes on pump base where fitted, together with a spreader bar. Failure to utilise these

facilities will result in damage to the pumpset.

0.2.4 Store in a dry place to avoid damp conditions deteriorating the equipment.

0.2.5 Protect against dirt, damage and frost. It is absolutely essential that no foreign matter such as

pipe thread swarf, welding slag, grit or stones are allowed to enter the set. Debris of this type can

cause severe damage to the mechanical seals, diaphragms and impeller. Frost/freezing will

damage pumps/pipework and control panel components.

0.2.6 The equipment is only suitable for installation in a clean, dust free indoor environment, with

adequate protection from heat and frost, and sufficient ventilation to ensure cooling of the

motors. Ambient air temperature should be between 5 and 40 degrees centigrade, non-

condensating. Operation outside of these conditions could seriously damage the equipment. If

condensation in the motors is likely to occur, open the drain holes in the motor flange (where

fitted).

0.2.7 If the equipment were to be stored or taken out of service for a period of time (e.g. 1 week or

more), then we would recommend draining the equipment of all water/liquid (with due regard to

any local regulations) to prevent frost damage to components. When restarting is required we

would recommend commissioning by our authorised service agent.

0.2.8 Ensure the base/foundation/plinth/wall to which the equipment is to be attached has sufficient

mass compared to the equipment, in order to avoid noise/vibration transmission. E.g. the mass of

the base should be at least five times the mass of the equipment.

0.2.9 Ensure the electrical supply is the correct voltage, current, frequency and type for the

equipment supplied and that suitable circuit protection equipment is installed in the supply.

Incorrect electrical installation could be an electric shock/burns/fire hazard.

0.2.10 When accessing the control panel to make electrical connections adopt anti-static procedures

e.g. wear anti-static earthed wristband, to avoid risk of damaging the controller.

0.2.11 All products that are packaged to include Pressure vessel(s)/Hydraulic

Accumulator(s)/Expansion Vessel(s) are classed as “Assemblies” under the Pressure Equipment