8

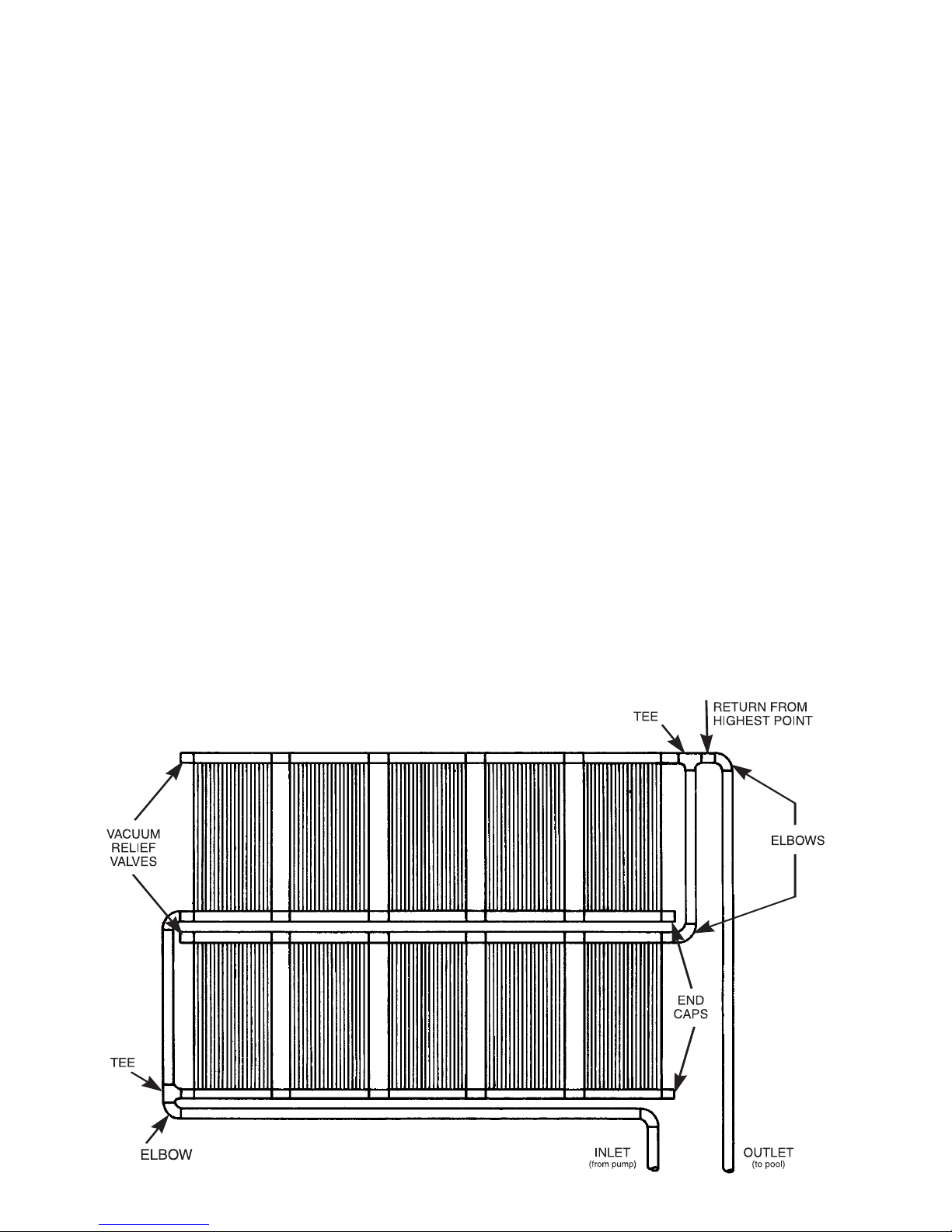

Manual Systems

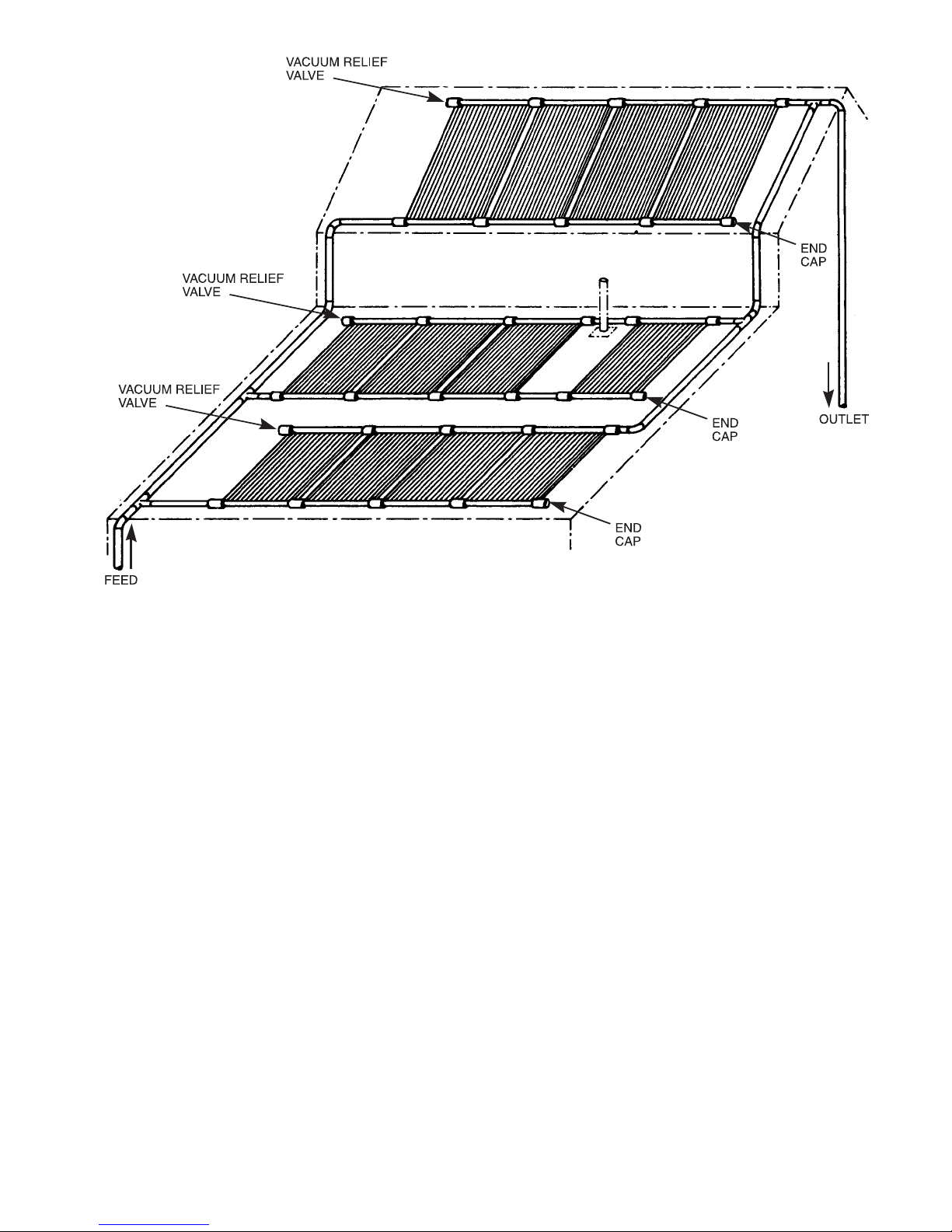

Some systems can employ a manual control valve to con-

trol the flow of water thru the solar collectors, although this

may reduce the overall heating capacity of the system.

The manual control valve usually consists of a non-posi-

tively sealed 3-way valve as shown in Diagram 10. Water

continuously flows through the solar collectors when the

filter pump is on, but can be diverted manually by the pool

owner if the pool becomes too warm or during extended

cloudy weather. During a threat of freezing conditions it

can also be diverted, by first shutting off the pool pump,

allowing the collectors to drain, diverting the 3-way manu-

al valve to the “bypass collector” position and shutting the

isolation valves on the collector feed and return lines. A

lower end cap on the collectors or any of the connecting

hoses can be removed to make sure there is no standing

water in the collectors. The filter pump can then be re-

started to allow for normal pool filtration.

During normal operation of the system when the 3-way

valve is in the ‘bypass collector’ position all the water in the

collectors should drain back through the 3-way valve (non-

positively sealed) when the filter pump shuts off. An alter-

nate way to protect against sudden freezes can be accom-

plished by running a bypass line (1/8”-1/4”, 3-6mm)

between the collector feed and return line above the isola-

tion valves, if any. It is possible that a small amount of water

may be present in the collectors when a non-positively

sealed 3-way valve is used and the filter pump is on. If a

positively sealed 3-way valve is used, a bypass line as men-

tioned above is mandatory to allow for collector drainage.

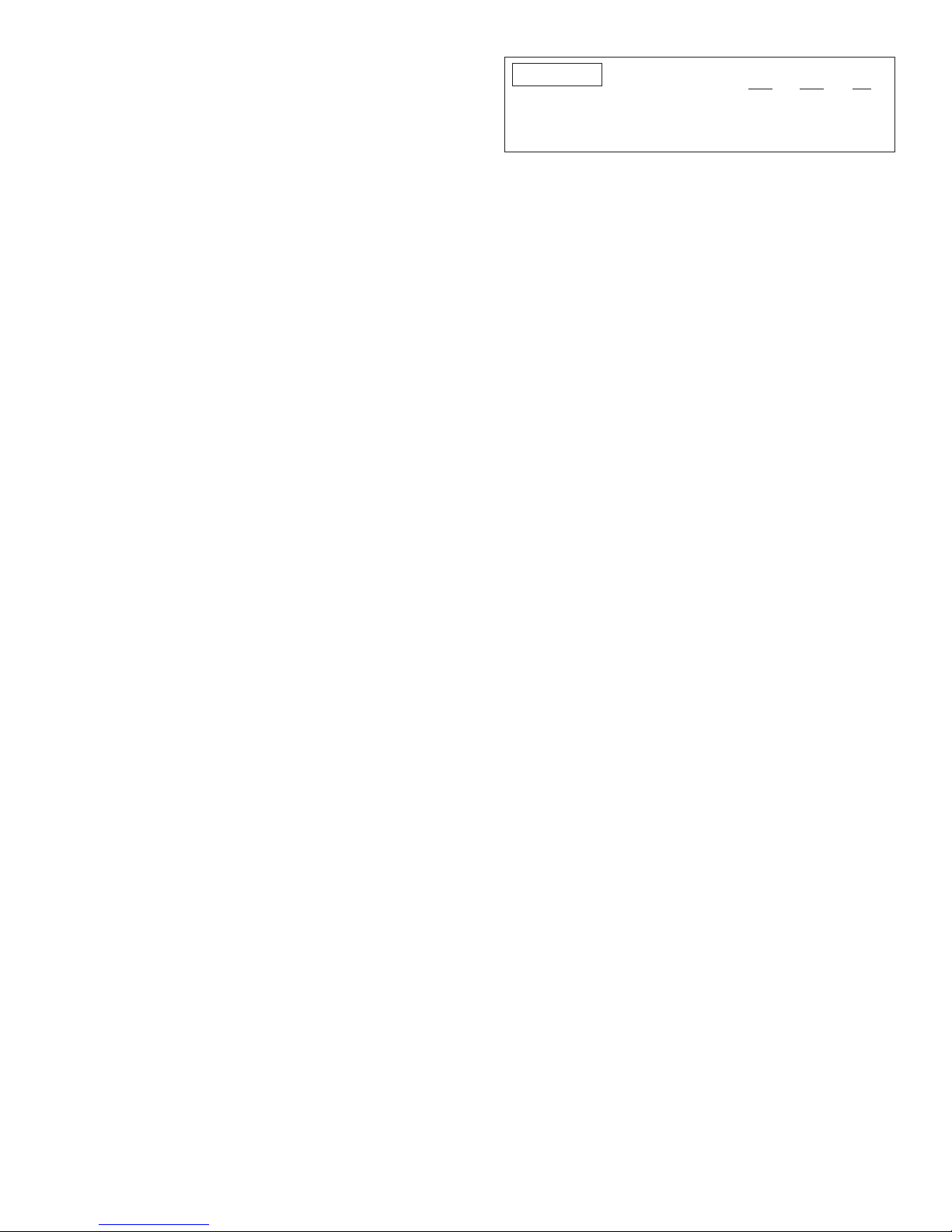

AUTOMATIC CONTROL SYSTEMS

The performance of a solar pool heating system can be

improved with the use of an electronic control and motor-

ized 3-way valve. The control activates the motorized

valve and either sends water thru the collectors for heating

(or nocturnal cooling) or automatically bypasses the collec-

tors when the pool is warm enough or insufficient sunlight

is available. Refer to the manufacturer’s instructions

included with the automatic control you use.

Other Equipment

Some pools employ an automatic pool cleaner.This

should be plumbed before the control valve to assure

positive flow to the cleaner at all times. If the pool uses

an automatic chlorinator,this should be plumbed after

the outlet tee on the return to the pool.

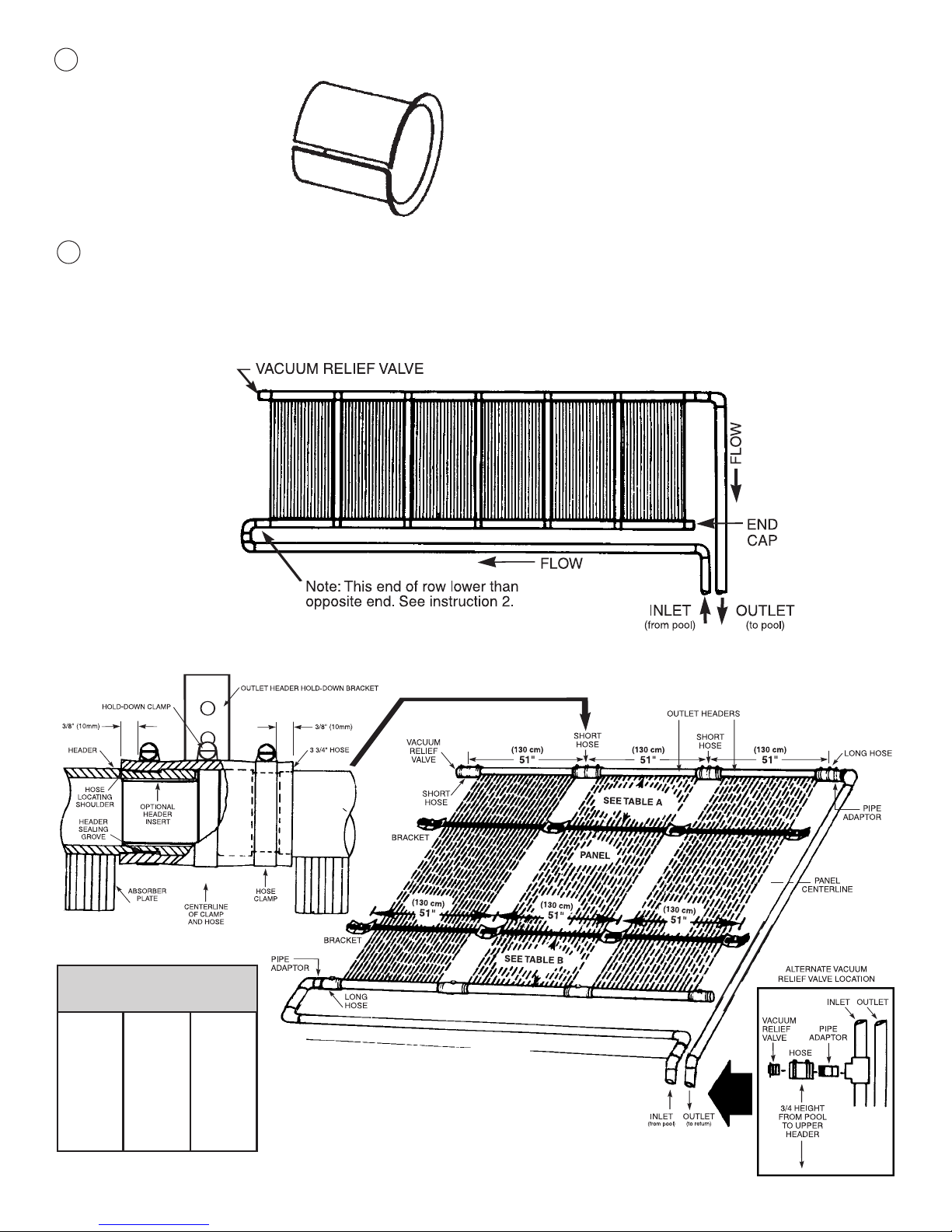

Flow Rates

In order to receive optimum results from Aquatherm

Industries collectors, the following recommended flow

rates and number of collectors per row should be followed.

When the system is running, all the collectors should feel

uniformly cool to the touch, and there should be no resid-

ual air left in the pool return lines. If either of these two

conditions persist, chances are that the flow rates thru

the collectors are inadequate or the system is not prop-

erly balanced. A flow meter can be installed in the col-

lector feed line to check on the flow rate. If the flow rates

are within the limits as shown in Table B, then the sys-

tem may not be properly balanced, especially with sys-

tems requiring multiple banks of collectors. Refer to the

following section on Special System Layouts.

If the flow rate is below the minimum as shown in the

table above, then the pool pump horse power or pipe

size should be increased, or a booster pump installed in

some cases. If the long hoses on the inlet and outlet pip-

ing connections “suck in”, then slip a piece of 1 1/2”

(50mm) pipe into the hose to prevent this. And also, if

the flow rate is excessive (more than 10 GPM/(37.9l)

collector), or if the system pressure is greater than 30

psi, a bypass line should be installed between the col-

lector feed and return lines above the 3-way valve to pre-

vent problems with the collectors and connection hoses.

If there is residual air in the pool return lines and the col-

lectors do feel cool to the touch, refer to the section con-

cerning the vacuum relief valve test on page 10.

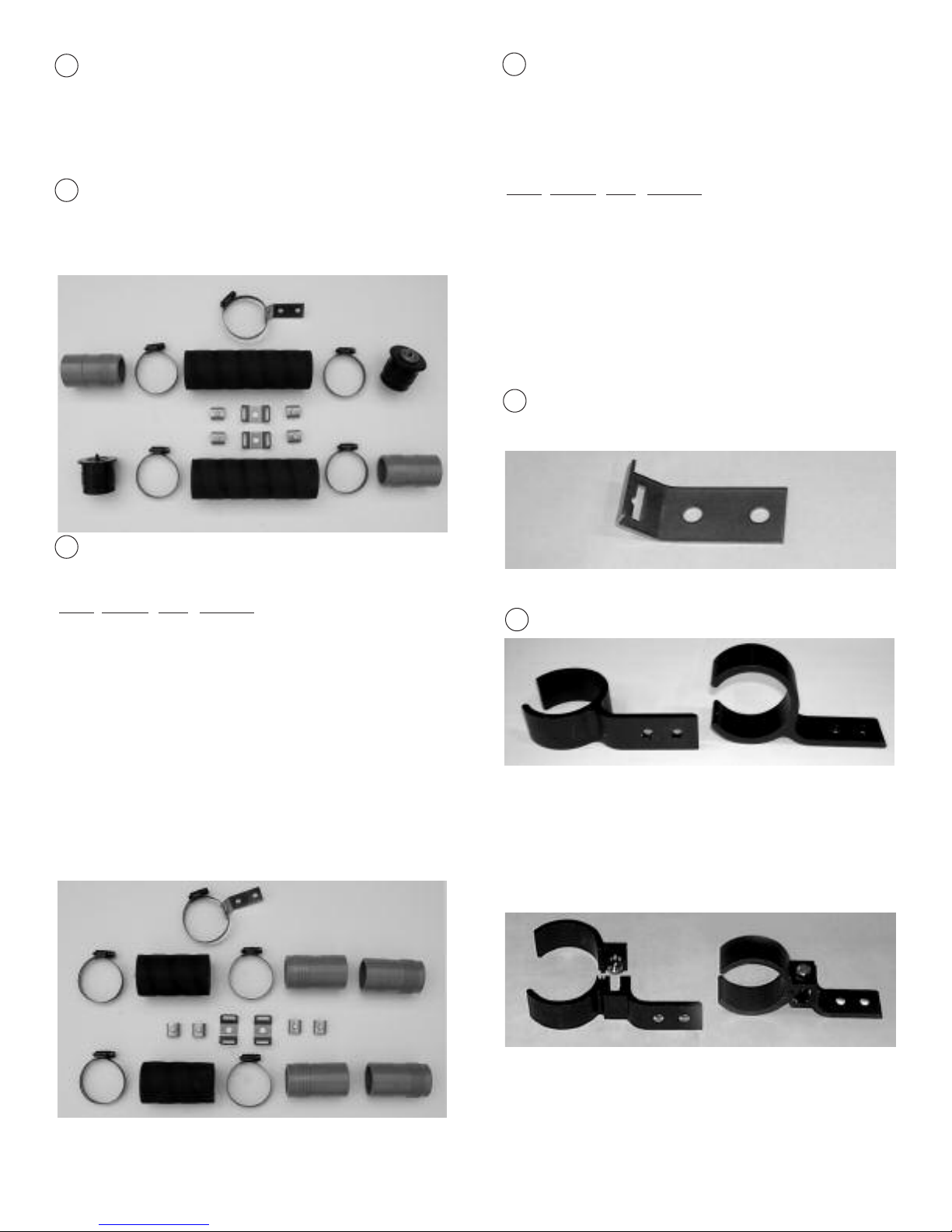

Optional Isolation Valves

Isolation valves may be installed in the collector piping

so that the pool may be operated while the collectors are

being serviced or during freezing weather. Install a man-

ually operated ball valve in the collector inlet line and a

check valve on the collector return line. Both valves,

available in the Optional Supplemental System

Isolation Kit (Part #12033-1) are made to accept either

11/2” or 2” PVC pipe. Make sure that the arrow on the

check valve is pointing away from the collectors, and that

the ball valve and check valve are located close to the

control valve and outlet ‘T’, respectively.For further pre-

cautions in warm climates where pools are operated

year round and periodic freezes can occur, a bypass line

(small diameter tubing) can be located above the ball

and check valve so as to prevent any accidental trapping

of water in the collectors by the pool owner. To make

sure no water is left in the collectors for servicing or dur-

ing freezes, remember that the pool pump should be

shut off, allowing the collectors to drain naturally, before

the optional isolation valves are used.

COLLECTOR SIZE

4x12 4x10 4x8

Recommended flow rate per collector, gpm/

l

5.0/18.9 4.0/15.1 3.25/12.5

Minimum flow rate per collector, gpm/

l

3.0/11.4 2.5/9.5 2.0/7.6

Maximum # collectors per row 10 12 14

Table B