Aquion M100-L082 User manual

AQ-OP-00010_E

Operations Manual

Battery Module Model M100-L082, M100-LS82

Aquion Energy, Inc.

www.aquionenergy.com

1 AQ-OP-00010_E

Table of Contents

1. General Information ................................................................................................................................. 3

1.1 About This Manual ............................................................................................................................. 3

1.2 Contact Information........................................................................................................................... 3

2. Product Information.................................................................................................................................. 3

2.1 AHI™ Battery Technology................................................................................................................... 3

2.2 M100-LS82 Overview ......................................................................................................................... 3

2.3 Physical Characteristics ...................................................................................................................... 3

2.4 Terminal Overview ............................................................................................................................. 4

2.5 Communications Overview ................................................................................................................ 4

3. Safety Information .................................................................................................................................... 4

3.1 General Safety Information................................................................................................................ 4

3.2 Electrical Hazards ............................................................................................................................... 4

3.3 Electrical Safety .................................................................................................................................. 5

3.4 Chemical Hazards ............................................................................................................................... 6

3.4.1 Gas Emissions.............................................................................................................................. 6

3.5 Mechanical Hazards ........................................................................................................................... 6

3.6 Transportation Hazards...................................................................................................................... 6

3.7 Weight Hazards .................................................................................................................................. 7

3.8 Environmental Considerations........................................................................................................... 7

3.9 Recycling and Disposal ....................................................................................................................... 7

4. Receipt of Equipment ............................................................................................................................... 7

4.1 Delivery Inspection............................................................................................................................. 7

4.2 Hidden Damage.................................................................................................................................. 7

4.3 Actions................................................................................................................................................ 7

5. Installation Procedures ............................................................................................................................. 8

5.1 Unpacking........................................................................................................................................... 8

5.2 Installation.......................................................................................................................................... 8

5.3 Battery Module Electrical Interfaces and Connections...................................................................... 8

5.4 Battery Module Wiring Diagrams.....................................................................................................10

5.5 Racking/Scaling Systems ..................................................................................................................11

5.6 Cabling Requirements ......................................................................................................................11

5.7 Ventilation Guidelines...................................................................................................................... 11

6. Operation ................................................................................................................................................12

6.1 Configuration and Operation Requirements ................................................................................... 12

2 AQ-OP-00010_E

6.2 Initial Charge .................................................................................................................................... 12

6.3 Discharge/Charge Cycles..................................................................................................................13

6.4 State of Charge.................................................................................................................................15

6.5 Record Keeping ................................................................................................................................ 16

6.6 Operational Records.........................................................................................................................16

6.7 Long-Term Storage........................................................................................................................... 16

6.8 Discharge Load Voltage from 100% SOC..........................................................................................17

6.9 Energy Efficiency ..............................................................................................................................18

6.10 Battery Monitoring System (BMS) ................................................................................................. 20

7. Warranty .................................................................................................................................................21

8. Technical Support and Troubleshooting.................................................................................................21

9. Disclaimers ..............................................................................................................................................21

Appendix A: Frequently Asked Questions...................................................................................................22

Appendix B: Operational Settings for Off-Grid Power Control Electronics.................................................25

B.1 Operational Settings for Off-Grid Power Control Electronics..........................................................25

B.1.1 Definitions................................................................................................................................. 25

B.1.2 Voltage Limits vs. Temperature ................................................................................................ 25

B.1.3 How to Charge Aquion Batteries ..............................................................................................25

B.1.4 Temperature Compensation..................................................................................................... 26

B.2 Off-Grid Device-Specific Settings by Manufacturer .........................................................................26

B.2.1 Morningstar .............................................................................................................................. 26

B.2.2 MidNite Classic.......................................................................................................................... 28

B.2.3 Outback..................................................................................................................................... 28

B.2.4 SMA Sunny Island...................................................................................................................... 29

B.2.5 Schneider Conext XW+............................................................................................................. 30

B.3 Grid-Tied/UPS Device-Specific Settings by Manufacturer ..............................................................30

B.3.1 MidNite Classic.........................................................................................................................30

B.3.2 Outback.................................................................................................................................... 30

B.3.3 SMA Sunny Island..................................................................................................................... 32

B.3.4 Schneider Conext XW+............................................................................................................. 32

B.3.5 Absorption Voltage vs. Charge Current, 30°C...........................................................................33

B.4 Reference Cycles for Lab Use .......................................................................................................... 33

3 AQ-OP-00010_E

1. General Information

1.1 About This Manual

This manual is intended to provide technical information and safe practices regarding receiving,

installing, operating, and servicing the Aquion Energy M100-L082 and M100-LS82 Battery Module. For

complete safety information, refer to the Safety Data Sheet (SDS) included with your product shipment.

NOTICE: Failure to follow the instructions in this document could result in fire, electric shock,

and/or other injury or damage.

1.2Contact Information

Aquion Energy, Inc.

32 39th Street

Pittsburgh, PA 15201

412.904.6400

www.aquionenergy.com

2. Product Information

2.1 AHI™ Battery Technology

Aquion Energy’s Aqueous Hybrid Ion (AHI™) batteries are optimized for stationary applications with

charge/discharge rates greater than 4 hours.

The batteries are designed to have extremely long cycle life at full depth of discharge with minimal

degradation, ability to stand at partial state of charge with minimal self-discharge or loss in function,

and extensive fault tolerance.

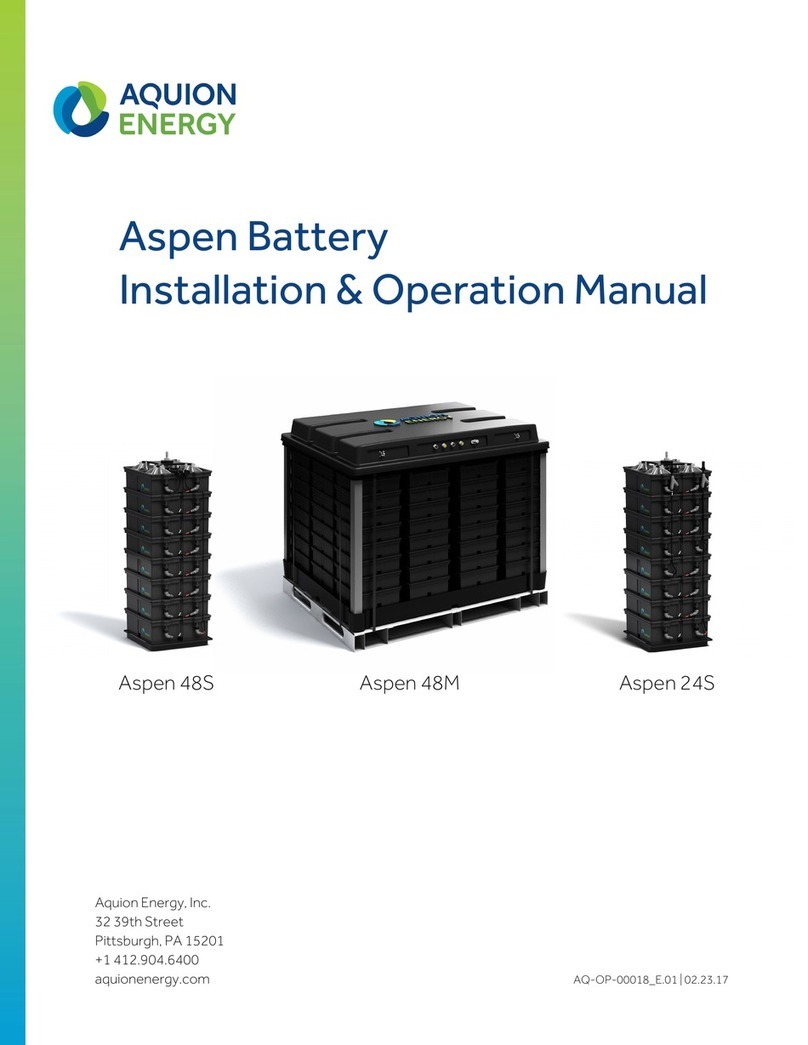

2.2 M100-LS82 Overview

Aquion Energy’s M100-L082 and M100-LS82 Battery Module (hereafter “Battery Module”) is a

palletized energy storage module that serves as a stand-alone system or as a building block for

larger systems.

The Battery Module is composed of twelve of Aquion Energy’s S20-008F Battery Stacks connected in

parallel. Battery Modules can be scaled in series or parallel for a wide range of stationary storage

applications.

For detailed specifications, please see the latest Product Specification Sheet, available on the Aquion

Energy Customer Portal at http://info.aquionenergy.com/customer-portal.

2.3 Physical Characteristics

For product physical characteristics and measurements, please see the latest Product Specification

Sheet (visit http://info.aquionenergy.com/customer-portal).

4 AQ-OP-00010_E

2.4 Terminal Overview

The Battery Module utilizes a standard Amphenol RADLOK pin, Part No. RL9-100-101, for each

terminal of the DC connection.

Connect to the Battery Module using Amphenol RADLOK connectors (not supplied by Aquion), part

numbers RL0-100-1-xxBK (Black) and RL0-100-1-xxRE (Red). The xx in these part numbers represents

the cable size, which should be determined from the data sheet for this part (see

http://www.amphenol-industrial.com/).

2.5 Communications Overview

For the VIS (Voltage/Current Sensor) installed on M100-LS82 units:

Network

Physical Layer

Protocol/Signal

Battery Monitoring System

Amphenol DeviceNet

CANopen*

Safety Interlock

Amphenol SineCo

24 Vdc

* The battery monitoring system CAN bus must be terminated with a 120 ohm CAN terminator.

3. Safety Information

3.1 General Safety Information

Service on the Battery Module should only be conducted by qualified individuals.

The Battery Module is designed to be UL recognized.

The UL recognition is in progress. Certification tests include:

oUL 1973-23 Vibration (S-line)

oUL 1973-24 Shock (S-line)

oUL 1973-26 Static Force

oUL 1973-27 Impact

oUL 1973-28 Drop Impact

oUL 1973-35 Salt Fog

3.2 Electrical Hazards

Never place foreign objects or tools in or on the unit as the metal parts of the battery terminals are

always live.

Electrical hazards exist in the voltage and current ranges that are found in battery systems and

associated electronics.

WARNING: Connecting AHI batteries in series can lead to dangerously high voltages.

Each Module is fused to 180 A max with 12 parallel 15 A fuses (one fuse per Stack). The maximum

rated current of the Module is below the maximum fuse rating to allow for internal energy

redistribution. If Modules are configured in series, we recommend system fuses of <180 A near the

system positive and negative terminals.

5 AQ-OP-00010_E

3.3 Electrical Safety

Each of the 12 parallel Battery Stacks that compose a Battery Module is equipped with a 1,000 V,

15 A fuse at the positive (+) lead.

Time Current Curve (15–30 A) for Littelfuse SPF Series Solar Fuses

1

The Battery Module is equipped with a ⅜”-16 grounding lug.

A properly sized ground wire, based on local code and regulations, should be connected to this

grounding lug and directly to the system DC ground.

1

Image adapted from Littelfuse®, POWR-GARD® Fuse Datasheet: SPF Series Solar Fuses. See

http://www.littelfuse.com/~/media/electrical/datasheets/fuses/solar-

fuses/littelfuse_fuse_solar_spf_datasheet.pdf.

6 AQ-OP-00010_E

A DC contactor is installed on the positive (+) lead of each Battery Module.

The DC contactor 24 V coil voltage is supplied externally by the system. Therefore, the DC contactor

operation can be easily integrated into a system-level emergency stop (ESTOP) system to break down

the series voltage to <59 Vdc (i.e., a single Module maximum open circuit voltage).

The DC contactor can be commanded open by the Battery Monitoring System (BMS) if certain alarm

limits are exceeded. However, there will be a 1-second (adjustable) warning signal sent by both

hardware and software before the Module contactor is opened. The hardware signal is a dry contact

signal on the Module 4-pin 24 V connector that can be sensed by the site controller. The software

signal is a MODBUS command sent from the BMS to the site controller.

3.4 Chemical Hazards

AHI battery materials are non-toxic and contain no chemical hazards.

Electrolyte spillage is not a concern with AHI batteries. The electrolyte is sodium-sulfate-based

saltwater with a neutral pH. In the unlikely event that electrolyte comes in contact with eyes or skin,

thoroughly wash out with water. Electrolyte residue on the battery terminal can be wiped away with

a cloth. A collection pan under the Module is not needed as the electrolyte will not leak during normal

operation, and any leaked electrolyte will not damage battery surfaces or equipment. Refer to the

SDS for additional information.

3.4.1 Gas Emissions

The battery may emit trace amounts of gas H2, O2, CO2, and CO during normal operation.

These gasses are not accumulated in hazardous quantities if the batteries are ventilated according to

the ventilation guidelines stipulated in this manual (see Section 5.7). The battery has passed UL

overcharge testing, which includes monitoring for toxic vapors and combustible vapor concentrations.

Overcharging the battery will result in venting of non-hazardous gas, primarily composed of H2, 02,

CO2, and CO, through the pressure relief valve.

3.5 Mechanical Hazards

The Battery Stack cases are intentionally flexible to accommodate compression of the electrode

stack and normal variations in internal pressure during operation.

A slight concave deformation in the sidewall of the Battery Stack case is not unusual, especially in new

batteries, and does not present an unsafe condition. A convex deformation, or bulge, projecting no

more than 10 mm from the sidewall of the battery is also not unusual and does not present an unsafe

condition. If a bulge projects more than 10 mm, the affected Battery Stack should be removed from

service, and Aquion Energy's technical support should be contacted.

3.6 Transportation Hazards

AHI battery products have no hazardous classifications and can be shipped as standard goods.

The AHI battery has also undergone International Safe Transit Association Testing for shock, vibration,

thermal shock, and altitude.

7 AQ-OP-00010_E

Battery Modules shall not exceed fifteen (15) degrees of tilt angle during transportation and

placement.

3.7 Weight Hazards

The Battery Module weighs 1,440 kg (3,175 lbs) and must be transported and handled with

appropriate precaution.

The use of forklift trucks and pallet jacks is recommended to move and position Battery Modules.

3.8 Environmental Considerations

Under normal conditions, AHI materials are contained and pose no known risk to persons or the

surrounding environment.

The product is not classified as environmentally hazardous.

3.9 Recycling and Disposal

AHI batteries are non-toxic, non-corrosive, and can be disposed of as ordinary trash or through

proper recycling channels.

Follow all local laws and regulations regarding disposal. Refer to Aquion Energy’s website at

http://www.aquionenergy.com/collection-recycling-waste-batteries for additional information.

4. Receipt of Equipment

4.1 Delivery Inspection

Immediately upon delivery, inspect all hard goods for signs of damage or tipping during transit.

This may be evidenced by damaged pallets or packaging. Immediately check the Tip-N-Tell indicator, if

one is included on the shipping container, and alert the carrier if the indicator has registered

tip. Thoroughly document all instances of product damage or tipping, and make a claim with the

carrier as soon as possible. Contact Aquion Energy for further support.

4.2 Hidden Damage

Within 10 days of receipt, a visual inspection must be performed.

If any damage is found, request an inspection by the carrier and file a hidden damage claim. Do not

delay visual inspection. Delaying this step may result in a loss of right of reimbursement for hidden

damages.

4.3 Actions

If, upon delivery, equipment appears to have been damaged or tipped, do not accept the shipment.

If you have accepted shipment and equipment in the shipment appears to have been tipped or

damaged, please contact your appropriate support representative. For technical support contact

information, please see Section 8, Technical Support and Troubleshooting.

8 AQ-OP-00010_E

5. Installation Procedures

5.1 Unpacking

Unpack Modules carefully and document any damage.

Battery Modules are permanently fastened to pallets. Fork trucks and pallet jacks can be used to

move and position Battery Modules.

5.2 Installation

AHI Battery Stacks are compressed and designed never to be dismantled.

WARNING: Do NOT attempt to disassemble Battery Stacks. Do NOT remove the nut on the

compression fixture on top of the Stacks in the Module. Battery Stacks have been compressed to

optimize battery performance. Releasing this load will void the product warranty and could result in

poor battery performance, permanent damage to Stack components, and/or injury.

Battery Modules should be positioned on flat, level ground appropriately rated for the weight of

the Module.

Battery Modules must not exceed fifteen (15) degrees of tilt angle for installation.

Do not stack Battery Modules on top of each other.

5.3 Battery Module Electrical Interfaces and Connections

J1

Module Negative (-) Battery Terminal

P/N: Amphenol RADLOK RL9-100-101

Mating P/N: Amphenol RADLOK Tubular Connector Black RL0-100-1-xxBK

PIN #

NAME

WIRE COLOR

DESCRIPTION

1

BATT-

Black

Module Battery Negative Terminal

J2

Module Positive (+) Battery Terminal

P/N: Amphenol RADLOK RL9-100-101

Mating P/N: Amphenol RADLOK Tubular Connector Red RL0-100-1-xxRE

PIN #

NAME

WIRE COLOR

DESCRIPTION

1

BATT+

Red

Module Battery Positive Terminal

9 AQ-OP-00010_E

J3

24V I/O IN

P/N: Amphenol SineCo MN41PW02Mxxx 4-pin MiniBOSS, male receptacle, external threads

Mating P/N: Amphenol SineCo MN47B4BC01Mxxx4-pin MiniBOSS Cordset

PIN #

NAME

WIRE COLOR

DESCRIPTION

1

24V_IO_NEG

Black

24V I/O negative

2

24V_IO_POS

White

24V I/O positive (for driving contactors)

3

INTLK_RLY_IN

Red

Interlock Relay In (Normally Open)

4

RLY_RTN_IN

Green

Interlock Relay Return In

J4

24V I/O OUT

P/N: Amphenol SineCo MN44PW02Mxxx 4-pin MiniBOSS, female receptacle, internal threads

Mating P/N: Amphenol SineCo MN47B4BC01Mxxx4-pin MiniBOSS Cordset

PIN #

NAME

WIRE COLOR

DESCRIPTION

1

24V_IO_NEG

Black

24V I/O negative

2

24V_IO_POS

White

24V I/O positive (for driving contactors)

3

INTLK_RLY_OUT

Red

Interlock Relay Out (Normally Open)

4

RLY_RTN_OUT

Green

Interlock Relay Return Out

J5

CAN IN

J5

CAN IN

P/N: Amphenol SineCo DeviceNet MN51PD01M005 Male Receptacle, external threads

Mating P/N: Amphenol SineCo DeviceNet MN57B4BD01Mxxxpatch cable

PIN #

NAME

WIRE COLOR

DESCRIPTION

1

CAN_GND

Bare

Isolated CAN ground

2

24V_LOGIC_POS

Red

24V Logic positive

3

24V_LOGIC_NEG

Black

24V Logic negative

4

CAN_H

White

CAN high signal

5

CAN_L

Blue

CAN low signal

J6

CAN OUT

P/N: Amphenol SineCo DeviceNet MN54PD01M005 Female Receptacle, internal threads

Mating P/N: Amphenol SineCo DeviceNet MN57B4BD01Mxxxpatch cable with 120 ohm terminator

(P/N P29319, Male).

PIN #

NAME

WIRE COLOR

DESCRIPTION

1

CAN_GND

Bare

Isolated CAN ground

2

24V_LOGIC_POS

Red

24V Logic positive

3

24V_LOGIC_NEG

Black

24V Logic negative

4

CAN_H

White

CAN high signal

5

CAN_L

Blue

CAN low signal

J7

EARTH GROUND LUG

P/N: Cooper Bussmann C1938

Mating P/N: Ground wire with 3/8" ring terminal

10 AQ-OP-00010_E

5.4 Battery Module Wiring Diagrams

M100-L082

M100-LS82

11 AQ-OP-00010_E

5.5 Racking/Scaling Systems

AHI Battery Modules are compatible with a variety of pallet racking solutions offered by vendors

around the world.

They are designed to be racked in standard pallet racking or drive-in, edge-loaded racking systems,

such as depicted in the image below. (The stand and dimensions shown are examples only. Actual

racking solutions may vary.)

For edge loading, the outer edges of the pallet shall be supported by at least 2 inches along the entire

length of the pallet.

Refer to your local regulations for proper load and seismic ratings.

5.6 Cabling Requirements

DeviceNet Thin

(MN57B4BD02Mxxx)

DeviceNet Thick

(MN57B4BD01Mxxx)

Maximum Path Length (ft)

48

240

5.7 Ventilation Guidelines

Per IBC and NFPA 1 guidelines, installations in enclosed spaces require ventilation equal to either

six (6) air changes per hour or ventilation at 1 cubic foot per minute (CFM) per square foot of room

size.

12 AQ-OP-00010_E

6. Operation

6.1 Configuration and Operation Requirements

The following system design configurations must be followed. Contact Aquion before attempting to

install a system outside of these parameters.

Battery Modules must be installed in a dry environment.

The Battery Module is IP2X rated. Direct exposure to water may cause shorting.

The unit may be installed in coastal regions with atmospheric salt.

Battery Modules must not be operated or stored under direct exposure to sunlight.

Prolonged exposure to ultraviolet light may damage the battery casing and reduce product lifetime.

Battery Modules may be stored at 0%–100% state of charge (SOC) without significant performance

loss.

For best results over long-term storage, Aquion recommends keeping the battery at ≤50% SOC (<48 V)

and ≤40°C.

Battery Modules must be operated in temperatures between -5°C and 40°C on a 24-hour average.

Operation above or below these limits will cause advanced degradation of the battery chemistry.

Battery Modules must be stored in temperatures between -10°C and 40°C.

Storage above or below these limits may cause permanent damage to the Battery Stacks.

Battery Modules must be kept between 30 and 59 Vdc after initial charge.

Operation or storage above or below these voltage limits will cause damage to the battery chemistry.

Battery Modules must be charged or discharged with less than or equal to 144 A of current.

There is a 15 A fuse on each individual Battery Stack, and internal Stack interactions may have up to

3 A of impact in high-rate conditions.

Battery Modules may be operated in systems up to 1,000 Vdc.

Battery Modules may be wired together in PARALLEL configurations of up to 12 Modules per inverter

or power control system.

A BMS100 is required for the M100-LS82 to operate properly. Please see the BMS100 operations

manual for more information.

6.2 Initial Charge

The Module should arrive with an initial voltage greater than 32 Vdc.

If the initial voltage is insufficient for charging power electronics, the Module can be charged using a

battery charging device within the operating limits of the Module as defined in the latest Product

Specification Sheet, available on the Aquion Energy Customer Portal at

http://info.aquionenergy.com/customer-portal.

13 AQ-OP-00010_E

Use only power supplies designed to charge storage batteries.

Most DC power supplies are not designed to charge batteries and lack sufficient reverse current

protection.

If the Modules are to be installed in a series configuration, it is important to match their states of

charge to be within 5% of each other.

Ideally, before Modules are connected in series they should be taken to full discharge 40 ±1 V at open

circuit. Aquion recommends that the parallel bussing operation be performed using circuit breakers in

a UL-approved battery combiner.

The high impedance of the AHI battery limits the short-circuit current of the battery.

Care must still be taken, however, when “live parallel bussing”batteries with unequal open circuit

voltages. The current created in this situation may still be sufficient to cause an arc or cause a fuse to

blow.

During its initial charge cycles, it is normal for the battery to accept more energy before it reaches

its max voltage.

This is the normal conditioning process that occurs in the battery. A specific conditioning procedure

does not need to be used.

6.3 Discharge/Charge Cycles

The AHI battery chemistry allows for long cycle life at high depth of discharge.

Based on the current results of Aquion’s ongoing, real-time test of production batteries, Aquion is

targeting a cycle life of 3,000 cycles at 100% depth of discharge to 80% retained capacity on all

commercial battery products.

The AHI battery chemistry can accept any charge or discharge profile or algorithm that respects the

operating limits defined in the Product Specification Sheet, available on the Aquion Energy Customer

Portal at http://info.aquionenergy.com/customer-portal. For example, the battery can accept

charging up to the recommended current limit as long as the upper voltage limit is not exceeded.

14 AQ-OP-00010_E

Aquion batteries can be charged using the same type of three-stage profile used for lead acid

batteries.

Though not strictly correct for the AHI chemistry, the lead acid terminology (bulk, absorption, float) is

included for clarity. Unlike lead acid, AHI batteries do not require a float voltage, but one is included

to maintain a full state of charge.

Aquion batteries should be charged using the following set points:

Max Current........................................................................................................................144 A/Module

Max (Absorption) Voltage..............59 V at 60 A and 30°C average charge, or use table in Section B.1.2

(Absorption) Time at Max V............................................................................................................1 hour

Float Voltage......................................................54.4 V, or 52.8 V if holding for >4 hours (UPS/grid-tied)

Recommended charge profile

15 AQ-OP-00010_E

Charging the battery to 100% SOC daily or periodically is not required to maintain battery life.

The AHI battery chemistry can be maintained at a partial or low state of charge indefinitely.

The Module can be discharged within its operating limits as well, as defined in Product Specification

Sheet, available on the Aquion Energy Customer Portal at http://info.aquionenergy.com/customer-

portal.

The AHI battery is designed for long duration charge and discharge. The battery’s high impedance

causes its voltage response to high current levels to be higher than lead acid or lithium ion battery

solutions of equivalent capacity. The supplemental charger settings (i.e., generator- or grid-tie) may

need to be adjusted so that at low battery state of charge, high inrush loads will not trigger a low

battery fault condition in the power electronics.

6.4 State of Charge

16 AQ-OP-00010_E

6.5 Record Keeping

Aquion Energy recommends maintaining proper system documentation records.

These include a single line diagram of the complete system and a log documenting system settings

(inverter, charge controller, charge voltages, etc.).

Record

Description

Frequency

single line system diagram

complete AC and DC system diagram

at installation or upon change

system component settings

charge voltage and current settings

at installation or upon change

6.6 Operational Records

Aquion Energy recommends maintaining proper and regular operating records.

These include battery temperatures, maximum and minimum operating voltages, and maximum

currents. Module-based systems that include the optional Aquion Energy BMS log this data

automatically.

Measurement

Description

Frequency

average battery temperature

daily average temperature

logged every 24 hours

minimum battery voltage

daily minimum voltage

logged every 24 hours

maximum battery voltage

daily maximum voltage

logged every 24 hours

maximum battery current

daily maximum current

logged every 24 hours

6.7 Long-Term Storage

If the Battery Module is to be stored for an extended period of time, remove all signal and power

connections to prevent unintended self-discharge and undetected ground faults.

Keep any grounding in place.

17 AQ-OP-00010_E

6.8 Discharge Load Voltage from 100% SOC

Load Voltage vs. State of Charge

SOC (%)

Discharge Current

24 A

48 A

72 A

96 A

118.8 A

0

30.00 V

30.00 V

30.00 V

30.00 V

30.00 V

5

43.04 V

39.40 V

36.42 V

34.40 V

33.28 V

10

44.92 V

41.52 V

38.67 V

36.61 V

35.28 V

15

45.64 V

42.50 V

39.85 V

37.89 V

36.54 V

20

46.19 V

43.16 V

40.64 V

38.74 V

37.41 V

25

46.66 V

43.67 V

41.24 V

39.38 V

38.04 V

30

47.10 V

44.23 V

41.73 V

39.91 V

38.40 V

35

47.49 V

44.65 V

42.17 V

40.35 V

38.85 V

40

47.85 V

45.03 V

42.56 V

40.74 V

39.22 V

45

48.17 V

45.38 V

42.90 V

41.08 V

39.57 V

50

48.47 V

45.70 V

43.24 V

41.41 V

39.89 V

55

48.74 V

46.01 V

43.55 V

41.70 V

40.20 V

60

48.99 V

46.30 V

43.83 V

42.00 V

40.49 V

65

49.22 V

46.58 V

44.12 V

42.29 V

40.78 V

70

49.46 V

46.86 V

44.42 V

42.60 V

41.10 V

75

49.73 V

47.18 V

44.73 V

42.92 V

41.41 V

80

50.09 V

47.54 V

45.08 V

43.28 V

41.81 V

85

50.60 V

48.03 V

45.53 V

43.72 V

42.27 V

90

51.27 V

48.67 V

46.08 V

44.28 V

42.81 V

95

52.11 V

49.46 V

46.81 V

45.00 V

43.48 V

100

55.99 V

53.85 V

51.40 V

49.50 V

48.22 V

18 AQ-OP-00010_E

6.9Energy Efficiency

Energy efficiency is determined by running a symmetric charge-discharge cycle, bounded by time or

voltage, and using the equation

𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 = 𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒 𝑒𝑛𝑒𝑟𝑔𝑦 𝑐ℎ𝑎𝑟𝑔𝑒 𝑒𝑛𝑒𝑟𝑔𝑦 ∗ 100%

⁄

Thus, for a given rate and temperature:

𝑚𝑎𝑥 𝑑𝑖𝑠𝑐ℎ𝑎𝑟𝑔𝑒 𝑒𝑛𝑒𝑟𝑔𝑦 = 𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 ∗ 𝑐ℎ𝑎𝑟𝑔𝑒 𝑒𝑛𝑒𝑟𝑔𝑦

or

𝑒𝑛𝑒𝑟𝑔𝑦 𝑎𝑣𝑎𝑖𝑙𝑎𝑏𝑙𝑒 = 𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 ∗ 𝑒𝑛𝑒𝑟𝑔𝑦 𝑖𝑛

Energy Efficiency vs. Charge Rate

Ambient

Temperature

Current

24 A

48 A

72 A

96 A

118.8 A

10°C

89.70%

81.04%

73.30%

66.46%

61.00%

30°C

90.50%

82.48%

75.02%

67.78%

62.35%

40°C

90.06%

81.74%

74.06%

67.03%

61.15%

19 AQ-OP-00010_E

The energy efficiency of Aquion Energy’s AHI battery does not significantly change with state of

charge.

Energy Efficiency vs. Condition

Condition

Current

24 A

48 A

72 A

96 A

118 A

10°C, 20% SOC

89%

80%

73%

66%

60%

10°C, 40% SOC

90%

81%

73%

66%

61%

10°C, 60% SOC

90%

81%

74%

67%

--

10°C, 80% SOC

89%

80%

72%

--

--

30°C, 20% SOC

90%

82%

74%

67%

62%

30°C, 40% SOC

91%

82%

75%

68%

62%

30°C, 60% SOC

91%

83%

75%

68%

63%

30°C, 80% SOC

91%

83%

75%

69%

--

40°C, 20% SOC

90%

81%

74%

67%

60%

40°C, 40% SOC

90%

82%

74%

67%

61%

40°C, 60% SOC

91%

82%

74%

67%

--

40°C, 80% SOC

91%

82%

75%

68%

--

This manual suits for next models

1

Table of contents

Other Aquion Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Trojan

Trojan GC2 48V quick start guide

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual