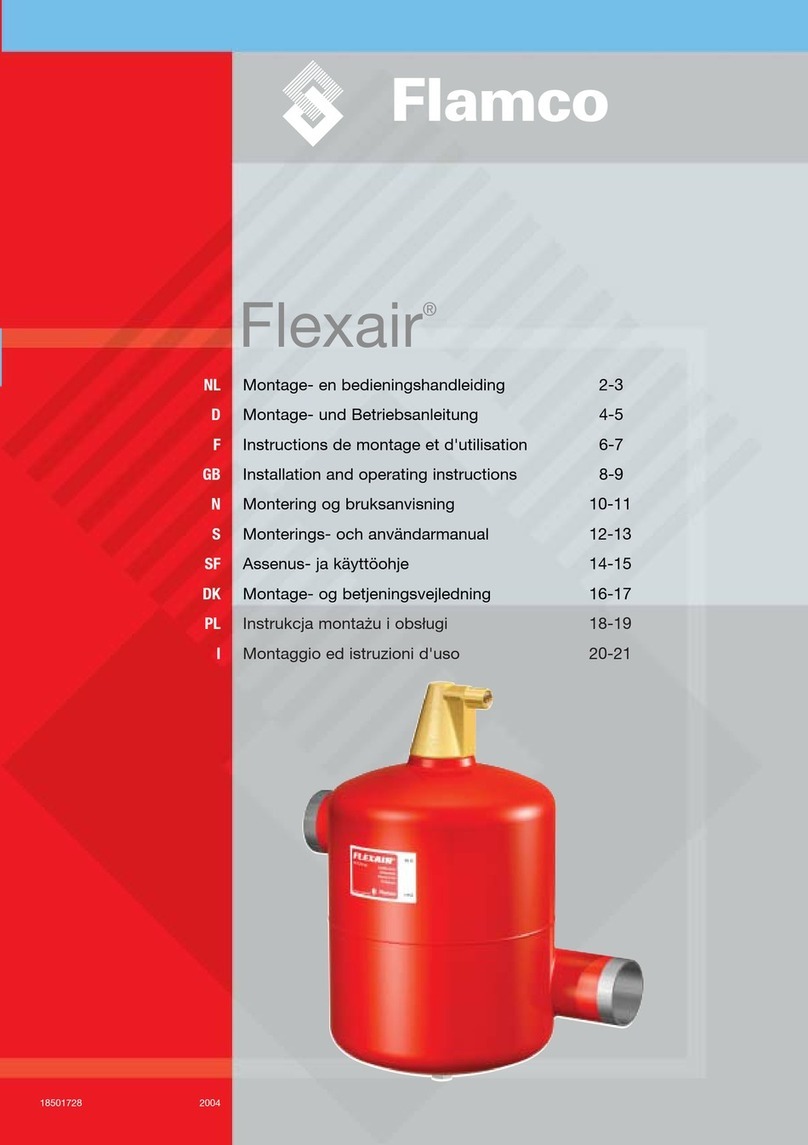

ELECTROMECHANICAL CONTROL PANEL

Page 8

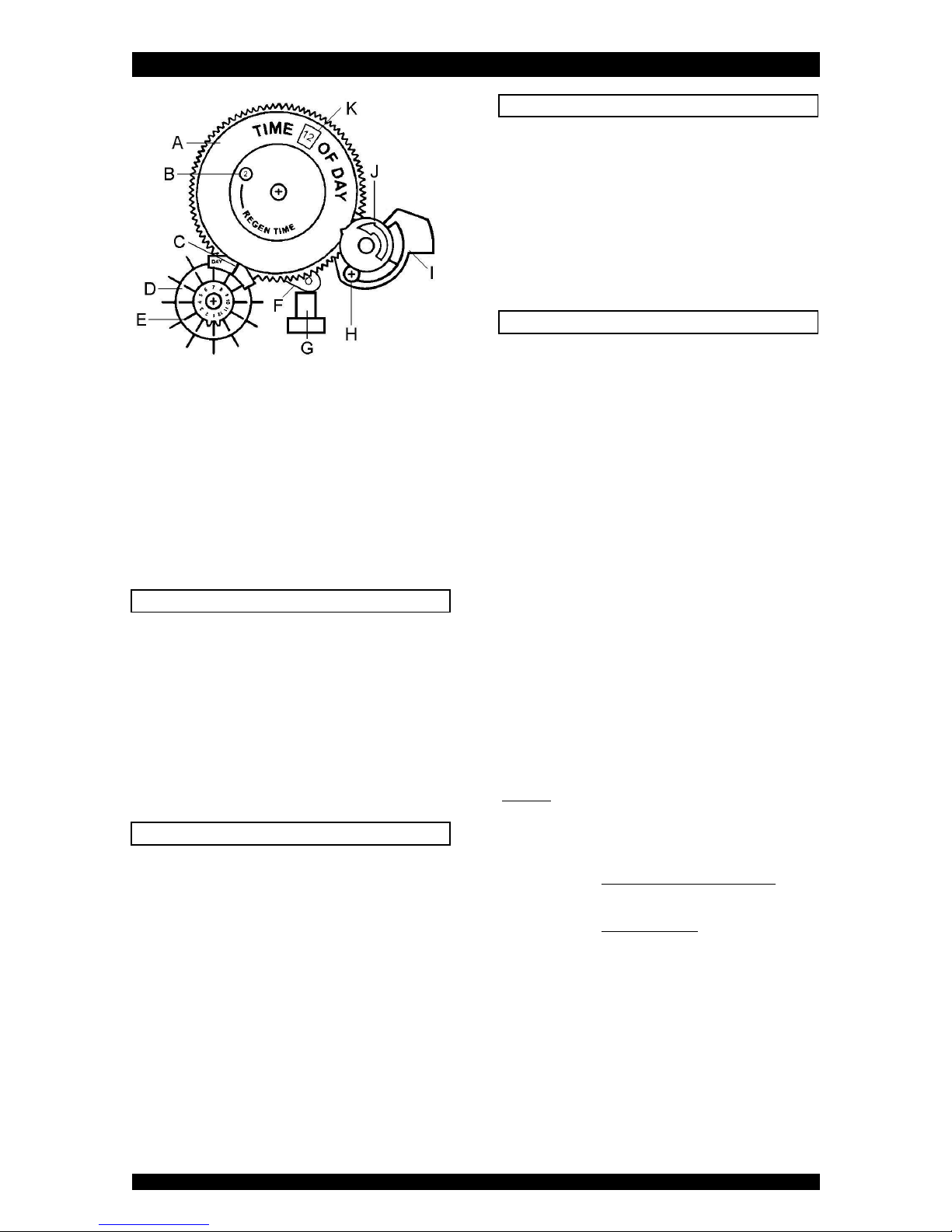

A clock plate

B time of regeneration window

C day indicator

D days skipper wheel

E skipper tabs

F actuator

G drain plunger

H locking screw

I brine/slow rinse section

J timer knob

K time of day window

POWER FAILURE

In the event of a power failure, the program will remain

unchanged, while the mechanical clock will stop;

consequently, in case of a power failure, the time of day

will not be maintained and will need to be set.

When the power failure occurs during the execution of an

automatic regeneration, the control valve will remain in

the regeneration position; when the power supply is re-

established, the control valve will resume the regeneration

from the point where it was interrupted.

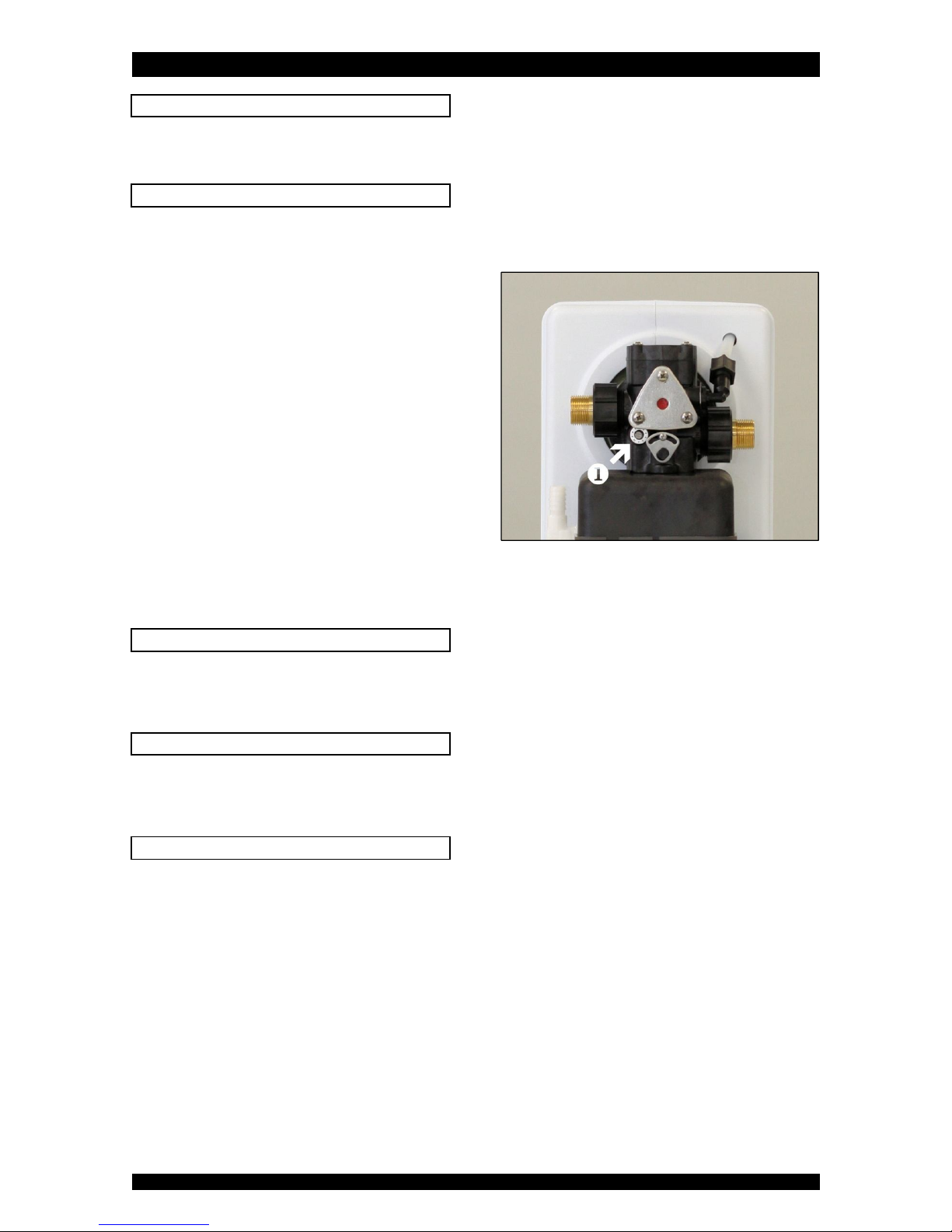

SERVICE / REGENERATION MODE

In service mode the drain plunger (G) will be closed. The

actuator (F) should NOT be visible.

In regeneration mode the drain plunger (G) will be pushed

down by the actuator (F). The actuator (F) will be visible.

The control valve can be reset to service mode at any time

by slowly turning the timer knob counter clockwise until

the drain plunger (K) is released again by the actuator (F).

MANUAL REGENERATION

It is possible to manually initiate a regeneration.

1. Push in the skipper tab (E) that is aligned with the day

indicator (C).

2. Turn the timer knob (K) counter clockwise, until the

time of day in the time of day window (L) equals the

time of regeneration in the time of regeneration

window (B).

3. The time of day and the skipper tab (E) must be reset,

when the regeneration is terminated.

PROGRAMMING INSTRUCTIONS

Before starting the programming sequence, make sure

that the control valve is in the service mode.

1. TIME OF REGENERATION:

Turn the clock plate (A) until the desired time of

regeneration appears in the time of regeneration

window (B).

2. TIME OF DAY:

Turn the timer knob (K) counter clockwise until the

correct time of day on the clock gear appears in

the time of day window (L).

3. REGENERATION FREQUENCY:

With all skipper tabs (E) pulled out, rotate the

skipper wheel (D) until day “1” is aligned with the

day indicator (C);

push in skipper tabs (E) which correspond with the

desired days of regeneration.

The regeneration frequency, i.e. the number of days of

service after which the system needs to be regenerated,

must be calculated, by dividing the nominal exchange

capacity of the system (see Technical Specifications) by:

1. the local water hardness,

2. the daily water usage.

Example:

Micro Budget 6

Water hardness = 19 °f

Water usage = 500 L/day = 0,5 m³/day

Regen freq. = nominal exchange capacity

water hardn. x daily water usage

= 31 m³x°f

19 °f x 0,5 m³/day

= 3,2 days

Regenerate every 2 days