BWS1500 Simple Install Guide 2

175 gal.

storage

tank

shown

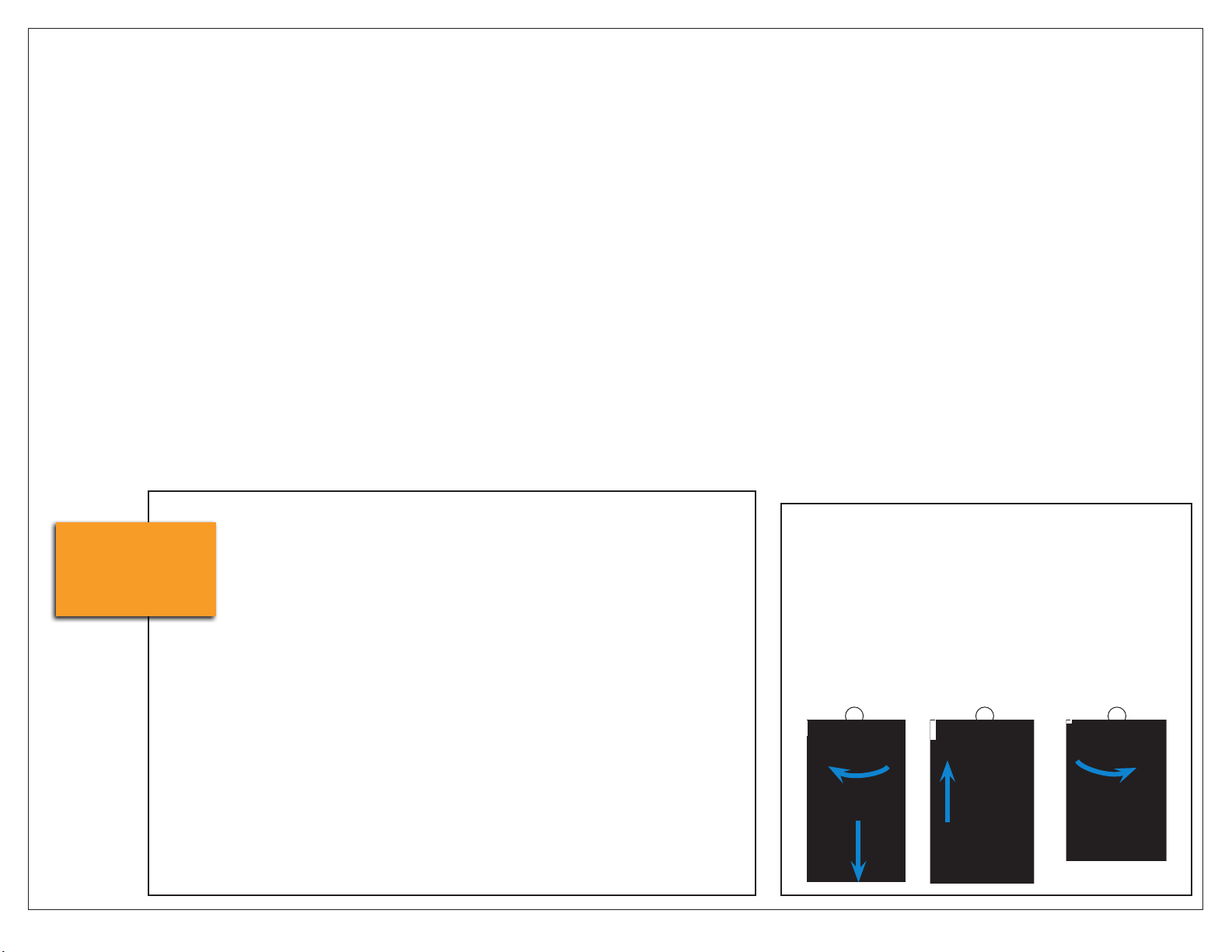

Completed

BWS1500 High

Flow Installation

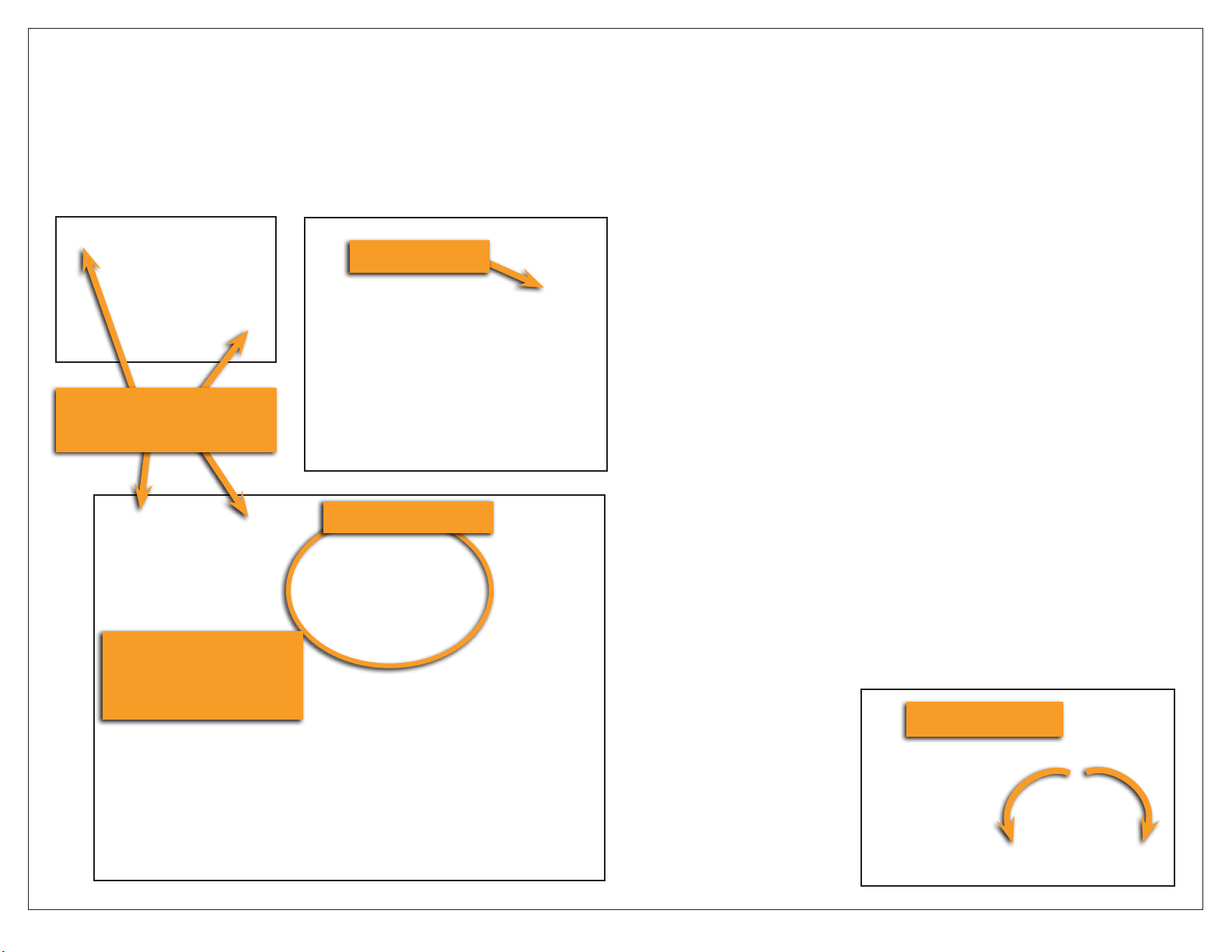

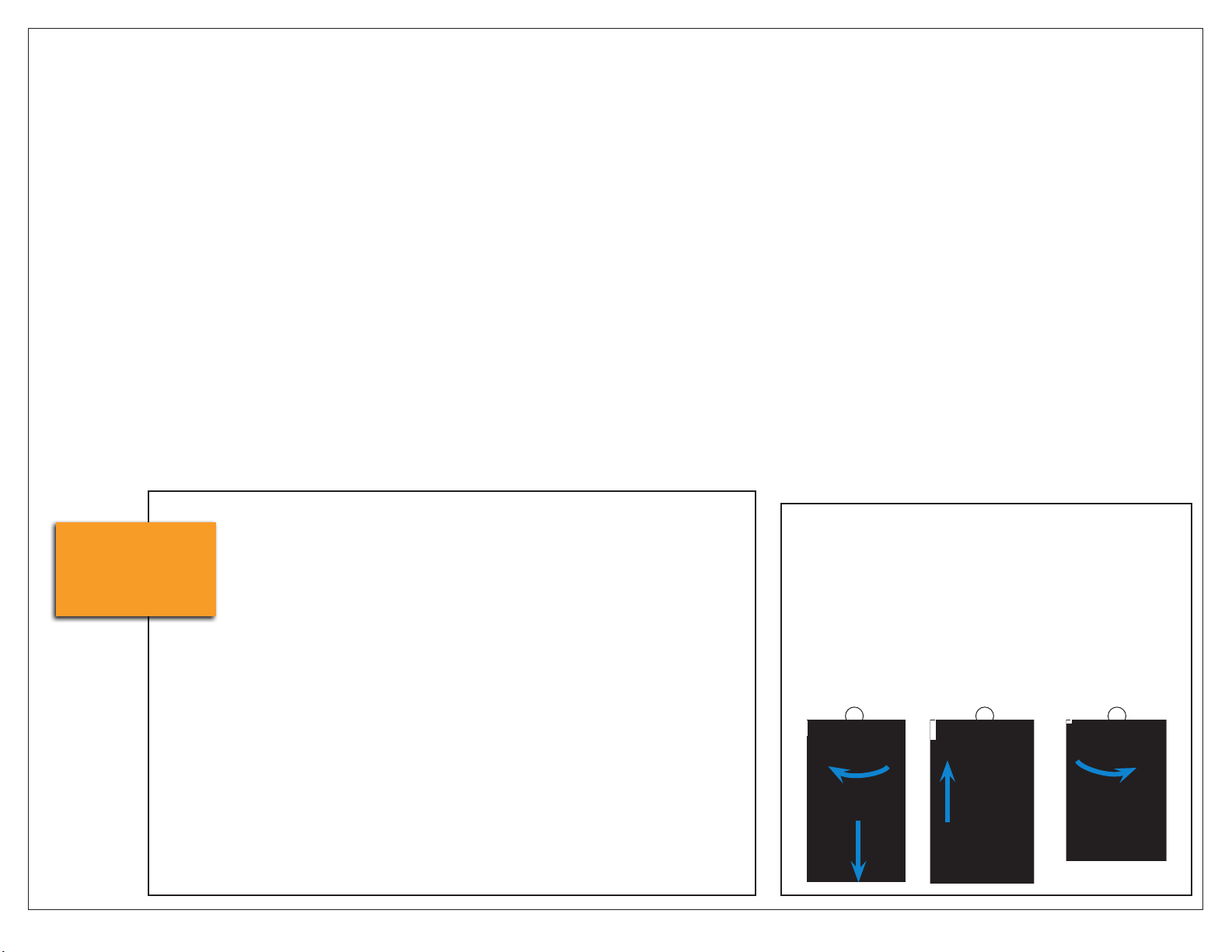

Installing or Replacing QT Cartridges

NOTE: Before installing or replacing QT Cartridges, make sure to remove

the plugs in the QT heads.

1. Close feed water valve.

2. Twist and pull down to remove cartridges.

3. Align the upward-pointing arrow on the new cartridge with the upward-

pointing arrow on the head. Push cartridge up into head until it stops.

4. Turn to right until it stops. NOTE: labels might not always face forward.

5. Open feed water valve.

234

System must be installed indoors

and easily accessed for service and

maintenance.

Water supply is cold water only, at a

minimum of 45 psi, maximum of 80 psi.

Distribution plumbing from the system

to equipment location(s) should be

minimum ¾” nominal. Hose, PEX or

other non-metal pipe is recommended.

Cut tubing and hoses to an appropriate

length and avoid loops or kinks in

tubing. Do not cut tubing with wire

crimpers or dikes. Route and secure

lines in an orderly manner.

Installation must conform to all local

codes and regulations.

Equipment layout:

Take time to visualize the nal

placement of equipment. Hose, tubing

and electrical connections will be

made between the Processor, Storage

Tank, RP Pump, Buffer Tank and the

distribution plumbing.

Consider the placement of components

in relation to the utilities (described

below), and allow easy access for

operation and service. For example,

make certain that an operator can see

and access the Emergency Bypass

Valve on the left side of the Processor;

and that the power cords from the

Processor and RP Pump can be routed

to the power outlet.

Utility requirements:

Water Supply – A minimum ½”

dedicated water supply line* with ½”

NFPT full-ow ball valve is required

within 6 feet of the processor. When

possible, locate the supply valve to

the left of the processor and install a

pressure gauge.

Drain – A drain with a capacity of 4

gallons per minute ow is required

within 4 feet of installation location.

Power – Two 120 VAC electrical outlets

are required; one for the Processor

and one for the RP Pump.

*NOTE: A dedicated supply line is a

water line run directly from a main

water source. It does not branch out

and is uninterrupted along its path.

vGeneral Information