4

INTRODUCTION

• MANUAL USE MODES

The section of this manual dedicated to the installation contains information for installers. For this reason we have used technical terms without

providing explanations which would be necessary for end users only.

THE INSTALLATION MUST BE CARRIED OUT BY AUTHORIZED AND SKILLED PERSONNEL ONLY. ARAG IS NOT RESPONSIBLE

FOR ANY OPERATION SPECIFIED IN THIS MANUAL CARRIED OUT BY UNAUTHORIZED OR UNSKILLED PERSONNEL.

• LIMITATIONS

The descriptions of the assembly phases refer to a "general" Virtual Terminal, so specic models will not be mentioned, unless a certain installation

procedure concerns exclusively one VT type.

• RESPONSIBILITY

The installer must carry out "workmanlike" installations and ensure to the end user the perfect operation of the whole system both with ARAG

components only and other brands' components.

ARAG always recommends using its components to install control systems.

The installer will be held responsible for any malfunction if he decides to use other brands' components even without actually changing the system

parts or harness.

The compatibility check with components and accessories of other manufacturers shall be carried out by the installer.

If the ARAG components installed together with other brands' components get damaged because of what stated above, no direct or indirect warranty

will be provided.

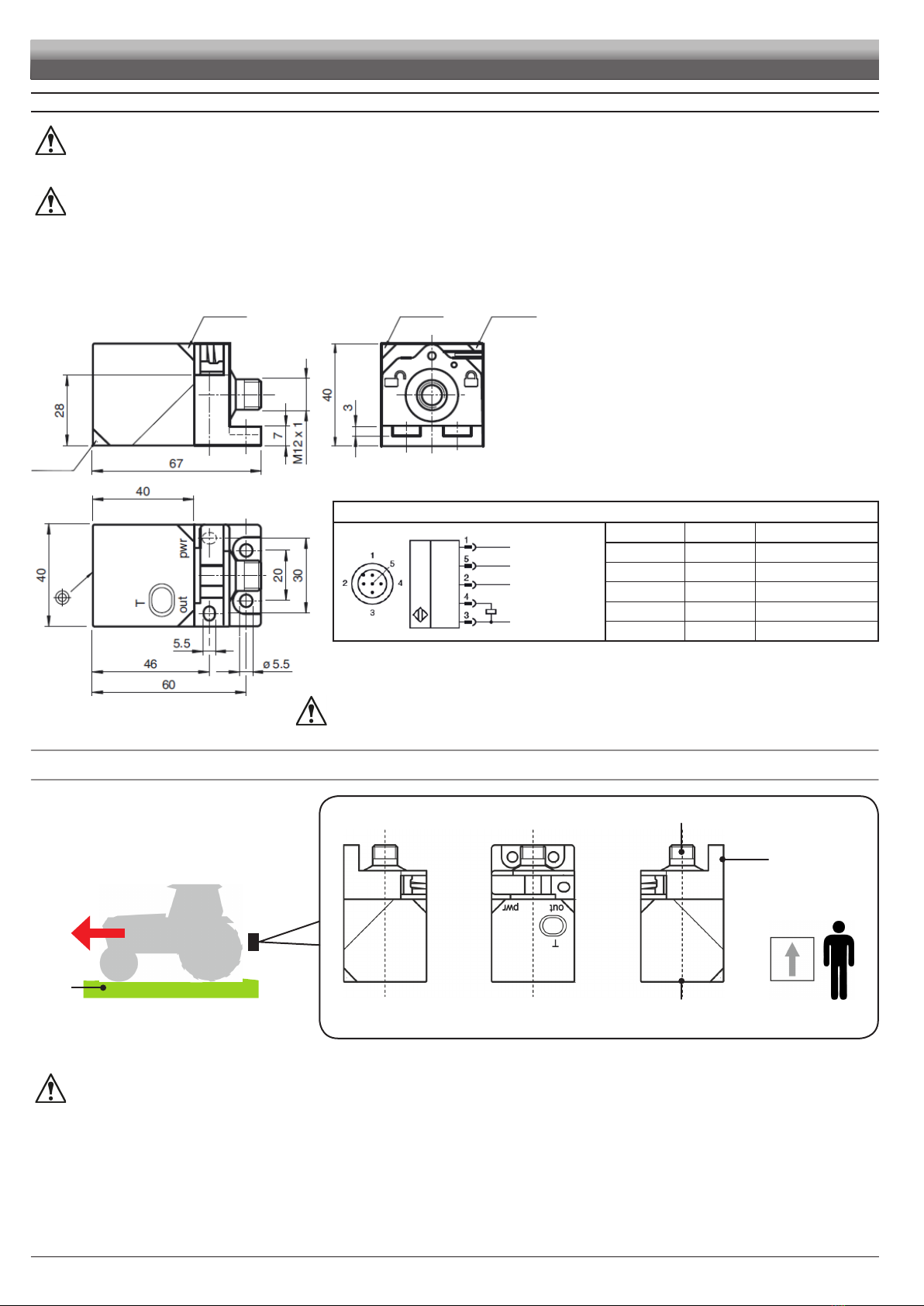

1 RISKS AND PROTECTIONS BEFORE ASSEMBLY

All installation works of IBX100 control unit, except the main connection (Refer to the manual supplied with IBX100 ISOBUS Hydraulic

- Chap. Settings > AUX conguration)must be done with battery disconnected, using suitable tools and any individual protection

equipment deemed necessary.

Use ONLY clean water for treatment tests and simulations: using chemicals during simulated treatment runs can seriously injure

persons in the vicinity.

DO NOT WORK NEAR THE BOOM WHILE THE BLC CONTROL SYSTEM IS IN OPERATION.

2 PRODUCT DESCRIPTION

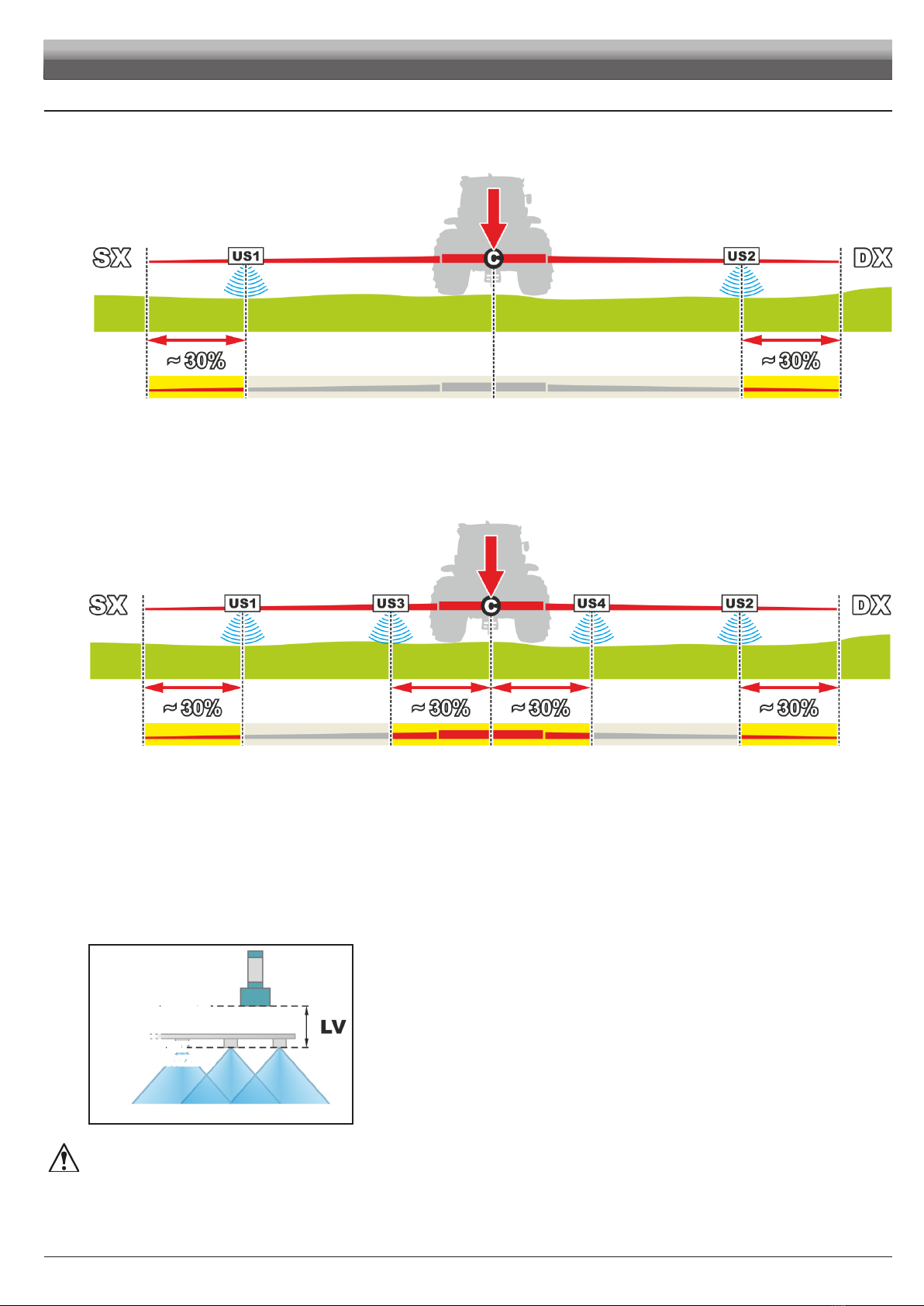

The BLC kit is the system for boom leveling control (BLC) that allows keeping the sprayer arm parallel to the eld orientation and managing its distance

from the ground through the dedicated control unit - IBX100 hydraulic control unit- so as to ensure an even spraying covering.

Since the BLC control is an hydraulic function of the machine, an IBX100 Hydraulic ISOBUS control unit is required.

The control unit could be previously installed to control other hydraulic functions on the machine.

If you do not have any control unit, order separately an IBX100 hydraulic control unit and the relevant connection cable.

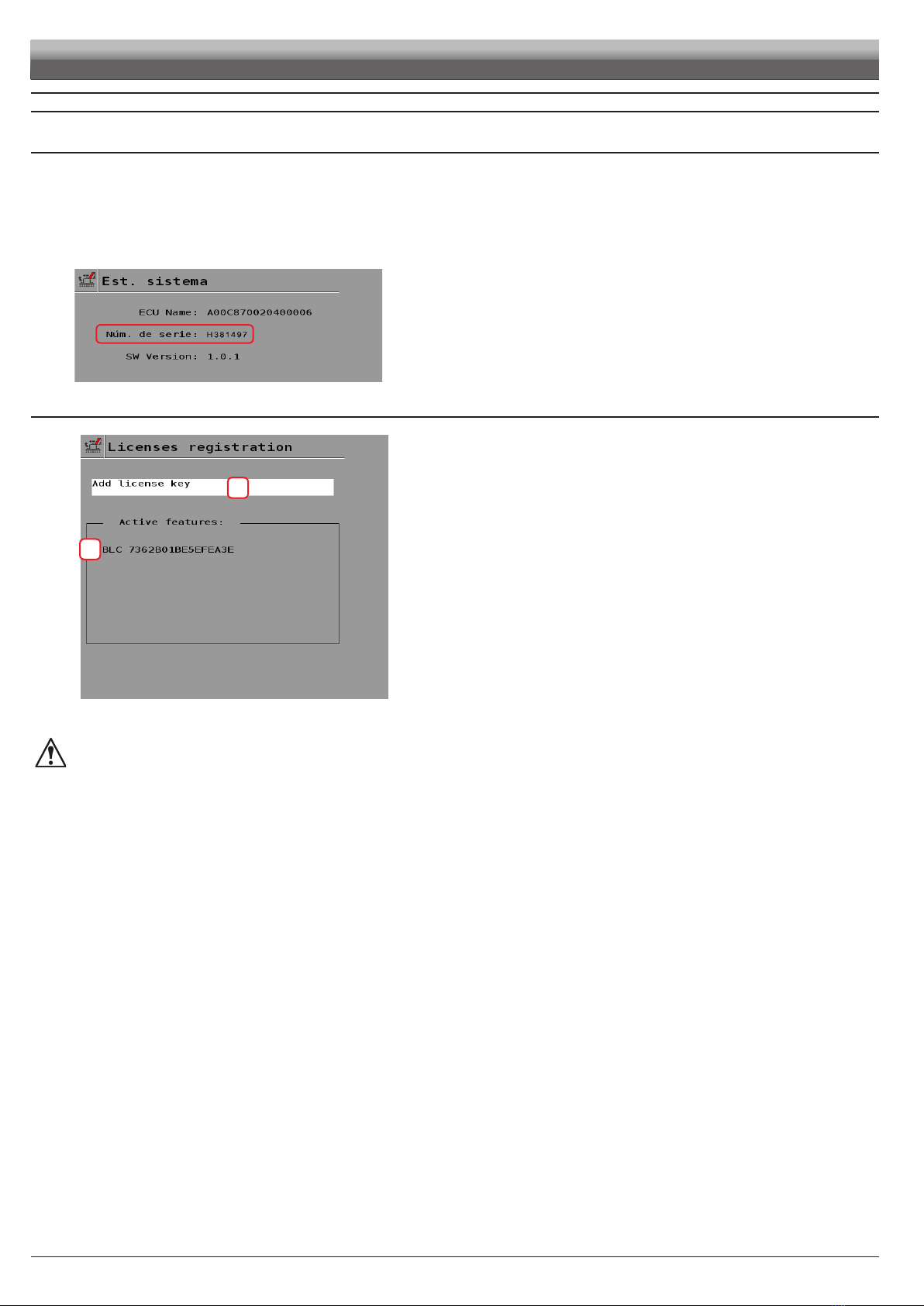

To enable IBX100 Hydraulic ISOBUS for the use of BLC, ask for the activation code to ARAG (“9.1.1 Activation procedure" on page 10).

3 INTENDED USE

The equipment you have purchased is a standard ISOBUS system compliant with ISO11783 to be applied to a crop spraying boom.

This device is designed to work on agricultural machinery for spraying and crop spraying applications.

The machine is designed and built in compliance with ISO 14982 standard (Electromagnetic compatibility - Forestry and farming

machines), harmonized with 2014/30/EU Directive.

4 PRECAUTIONS

• Do not aim water jets at the equipment.

• Do not use solvents or fuel to clean the case outer surface.

• Do not clean equipment with direct water jets.

• Comply with the specied power voltage (12 VDC).

• In case of voltaic arc welding, remove connectors from the device and disconnect the power cables.

• Only use ARAG genuine spare parts and accessories.

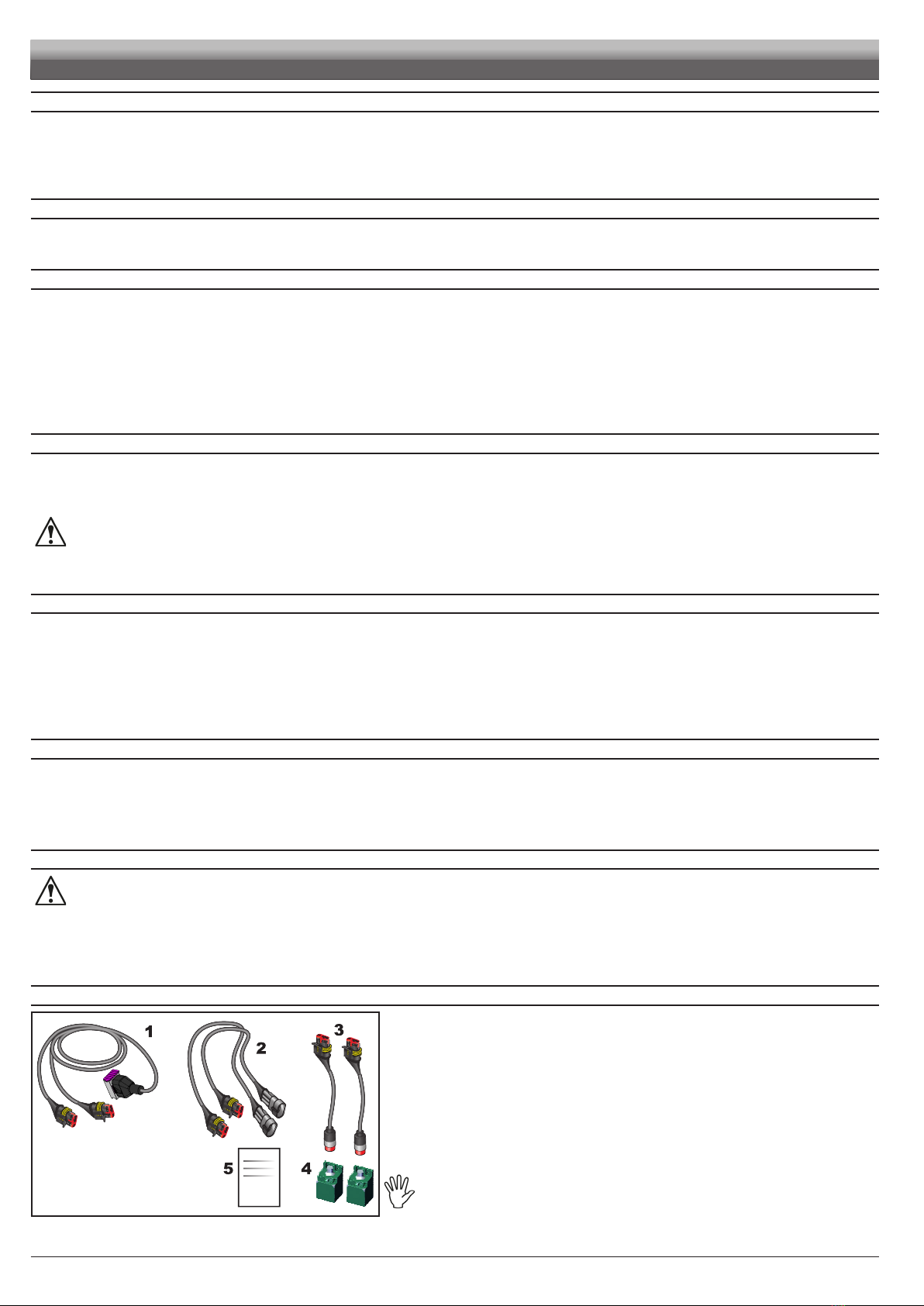

5 PACKAGE CONTENT

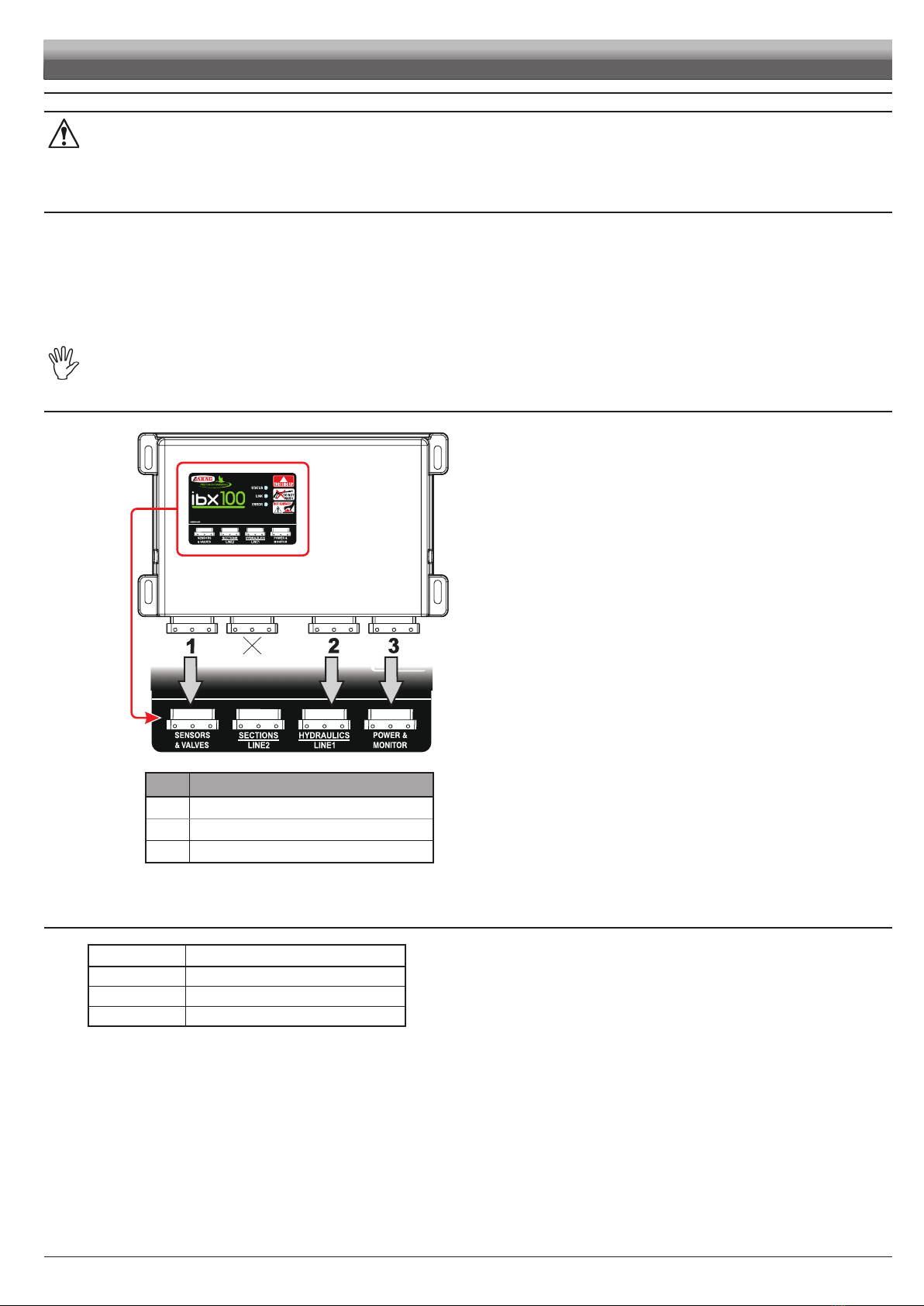

Fi g . 1

1Connection cable for sensors

2Extension for sensors - 5 m (no. 2)

3Adapter cables for ultrasonic sensors (no. 2)

4Ultrasonic sensors (no. 2)

5Purchase certication code

TO BE PURCHASED SEPARATELY:

• connection cable for IBX100 hydraulic control unit

TO BE PURCHASED SEPARATELY if not yet available on the existing system:

• IBX100 Hydraulic Isobus

• connection cable for hydraulic valves

• hydraulic valves for boom leveling

The kit supplied enables the BLC control function on an already existing system:

therefore, the mechanical and hydraulic components are supplied by the machine

manufacturer.