Table of contents

3

Table of contents

1 About this manual

1.1 Record of changes ............................................................................................. 5

1.2 How to work with the manual ............................................................................. 5

1.3 Terms and abbreviations.................................................................................... 5

1.4 Safety symbols and descriptions used in this manual........................................ 6

2 Safety

2.1 Intended use ...................................................................................................... 7

2.2 Personnel qualification ....................................................................................... 7

2.2.1 Electrical installation .............................................................................. 7

2.2.2 Maintenance .......................................................................................... 7

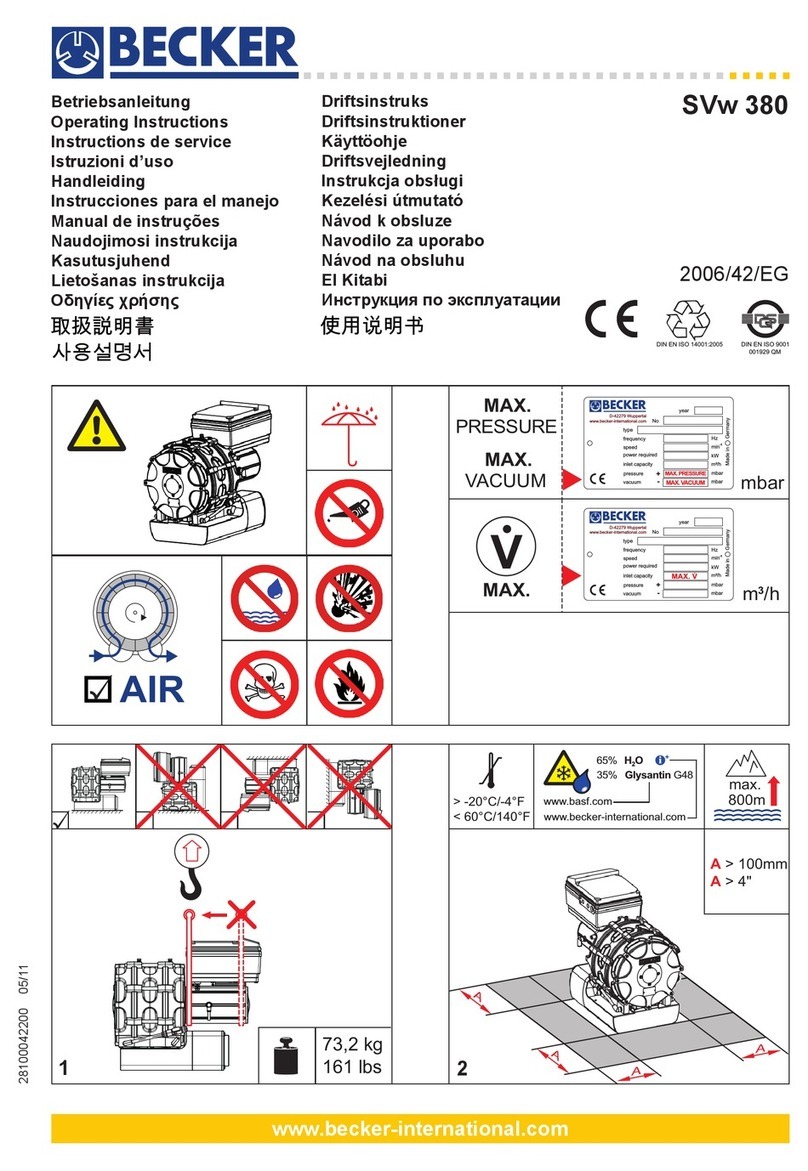

2.3 Safety label on the product ................................................................................ 7

2.4 Safety instructions.............................................................................................. 8

2.5 Declaration of conformity ................................................................................... 8

3 Warranty

3.1 Warranty period.................................................................................................. 9

3.2 Applicability ........................................................................................................ 9

3.3 Warranty on wear parts ...................................................................................... 9

3.4 Not covered by warranty .................................................................................... 9

3.5 Modifications or repair without permission ......................................................... 9

3.6 Reporting............................................................................................................ 9

3.7 Delivery of the product ..................................................................................... 10

3.8 Restriction ........................................................................................................ 10

3.9 Result damage ................................................................................................. 10

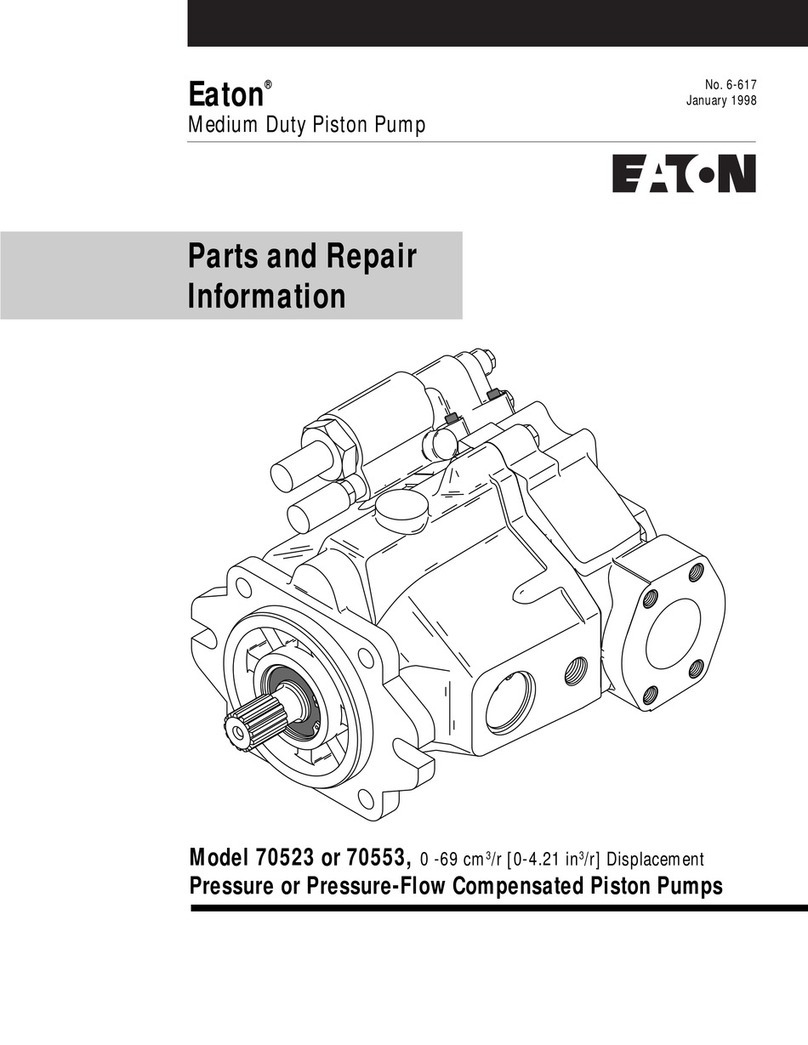

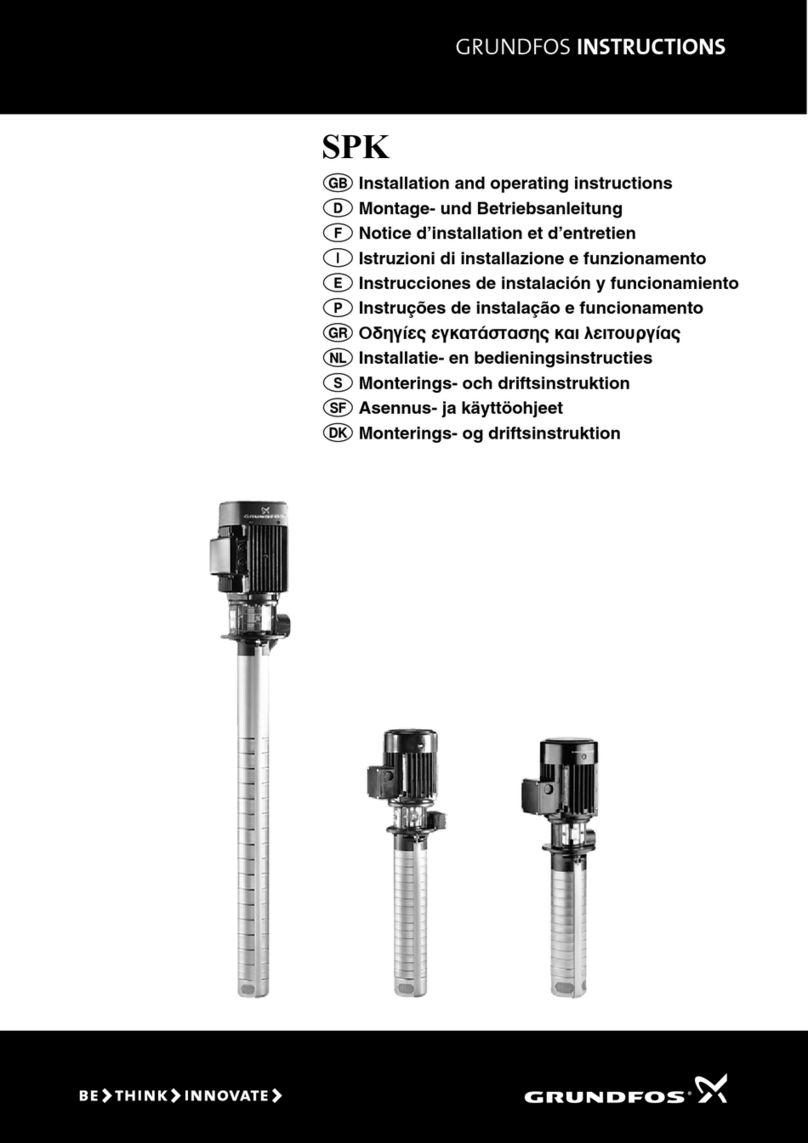

4 Description

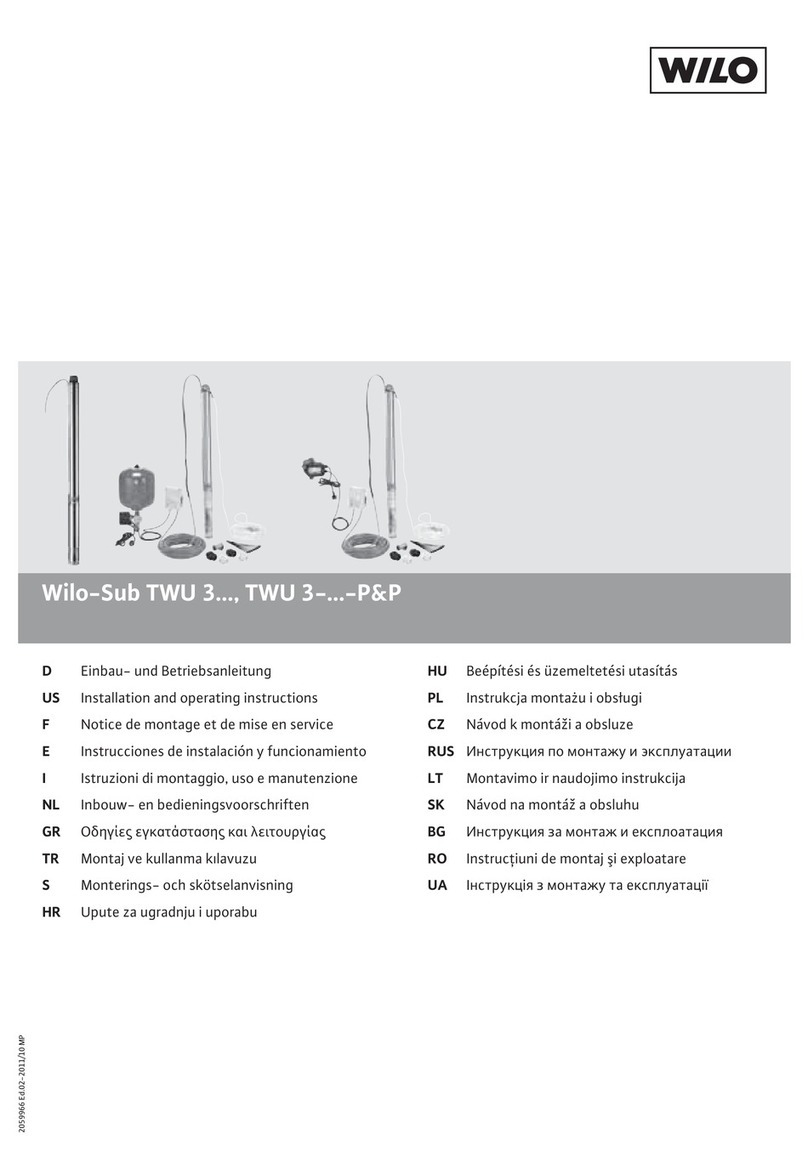

4.1 Overview .......................................................................................................... 11

4.2 Available options .............................................................................................. 12

4.3 Pump identification plate .................................................................................. 13

4.4 Product identification code ............................................................................... 13

4.5 Construction data mechanical seals ................................................................ 14

4.5.1 SealPro series ..................................................................................... 14

4.5.2 HD series............................................................................................. 14

4.5.3 Seal limitations .................................................................................... 15

5Installation

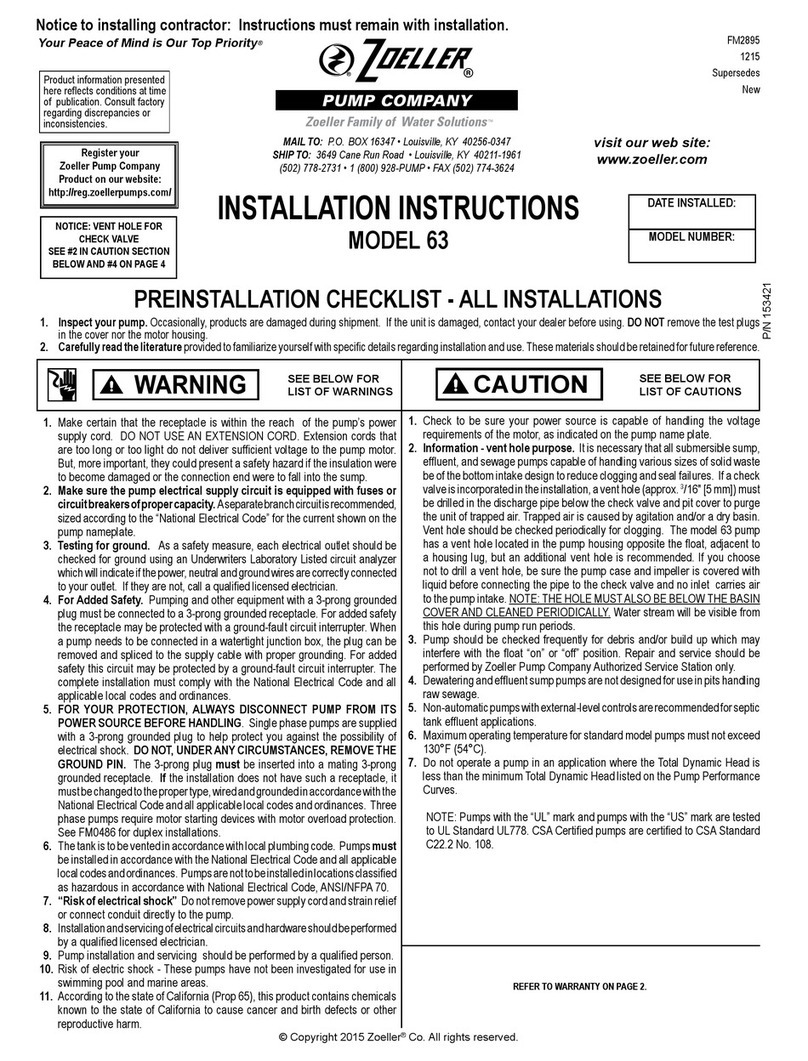

5.1 Before installation............................................................................................. 16

5.1.1 General instructions to prepare the product ........................................ 16

5.1.2 Filling the bearing assembly with oil (no. 42b only) ............................. 17

5.2 Installation of the piping ................................................................................... 18

5.2.1 General instructions to prepare the piping........................................... 18