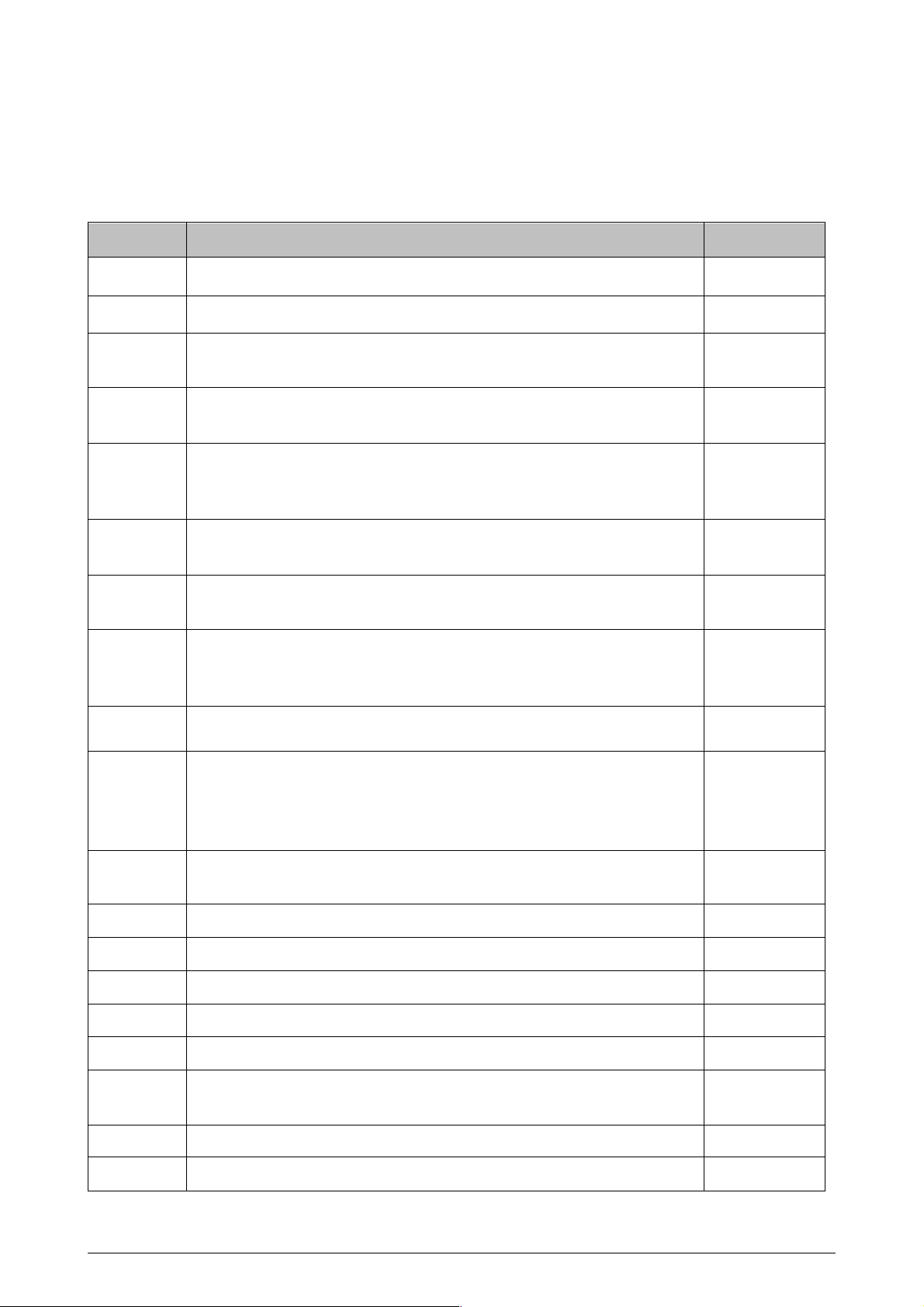

Table&of&Contents&

&

&

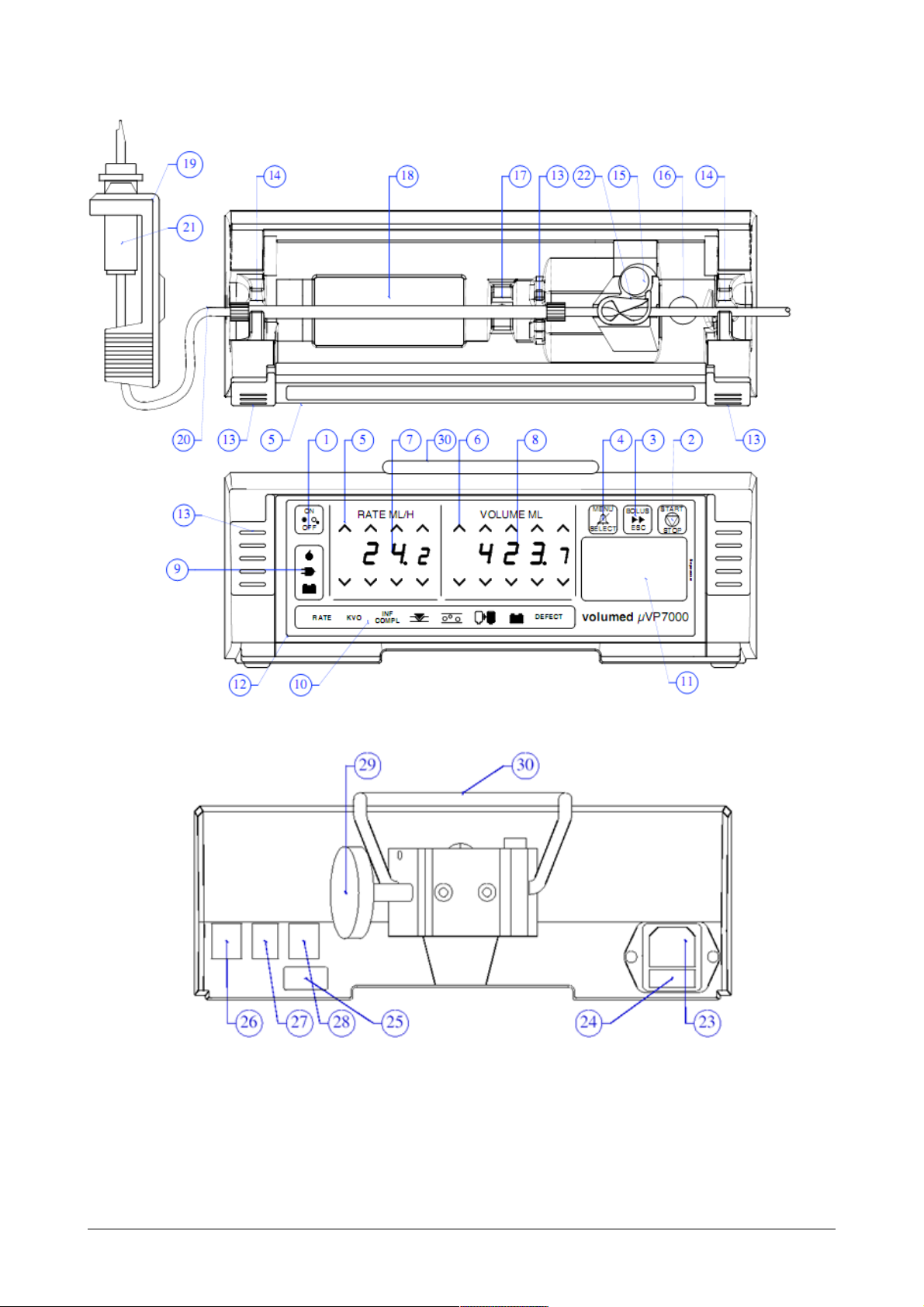

1!TECHNICAL DESCRIPTION................................................................................................... 4!

Control: ....................................................................................................................................4!

Power Supply:..........................................................................................................................4!

Software: ..................................................................................................................................5!

Specifications, instructions for use, warranty, performance data, EMC behaviour: ...............5!

2!SETUP MODE: ............................................................................................................................6!

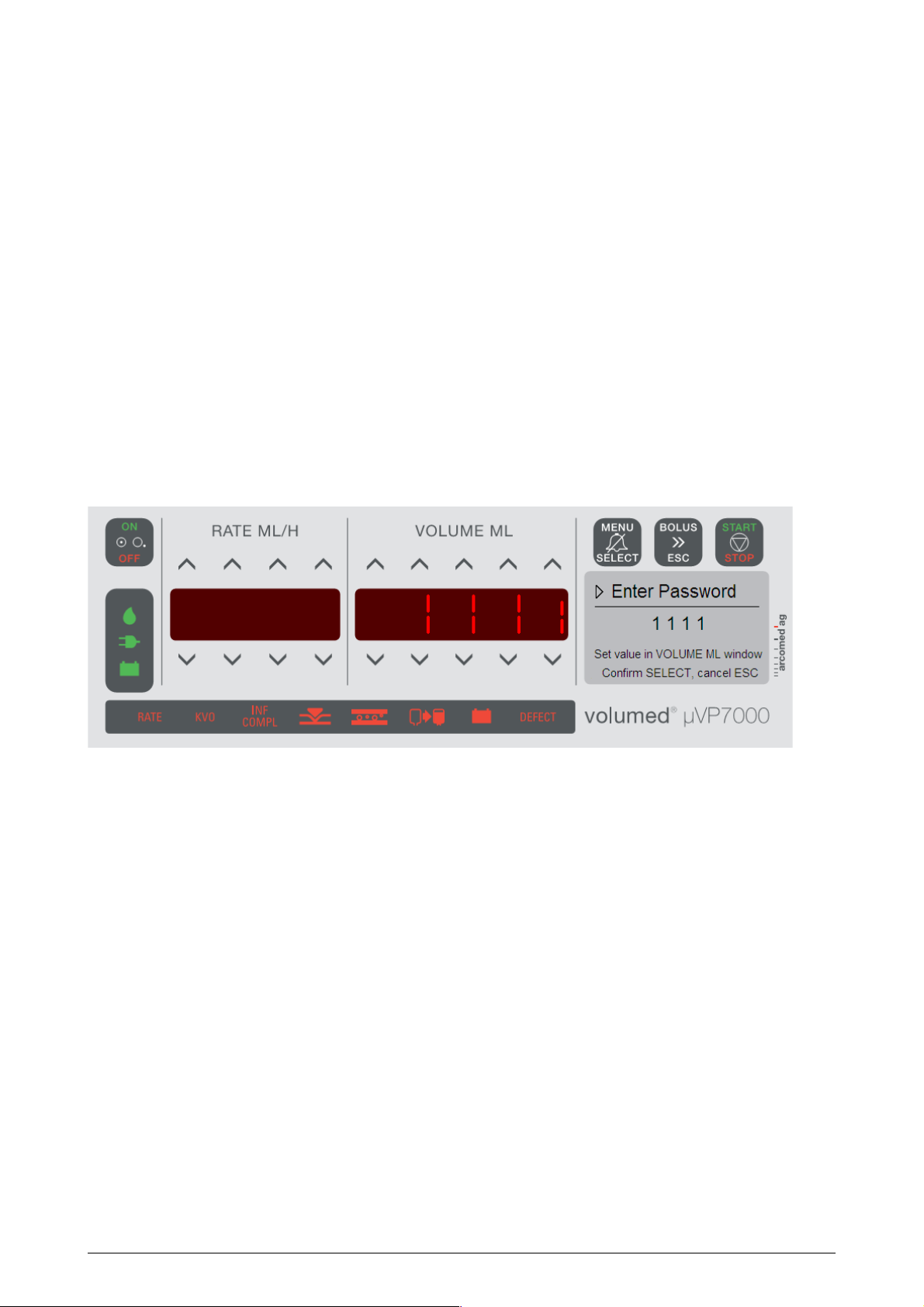

2.1!STARTING THE PUMP IN SETUP MODE ......................................................................................6!

2.2!DESCRIPTION OF PUMP SETUP...................................................................................................6!

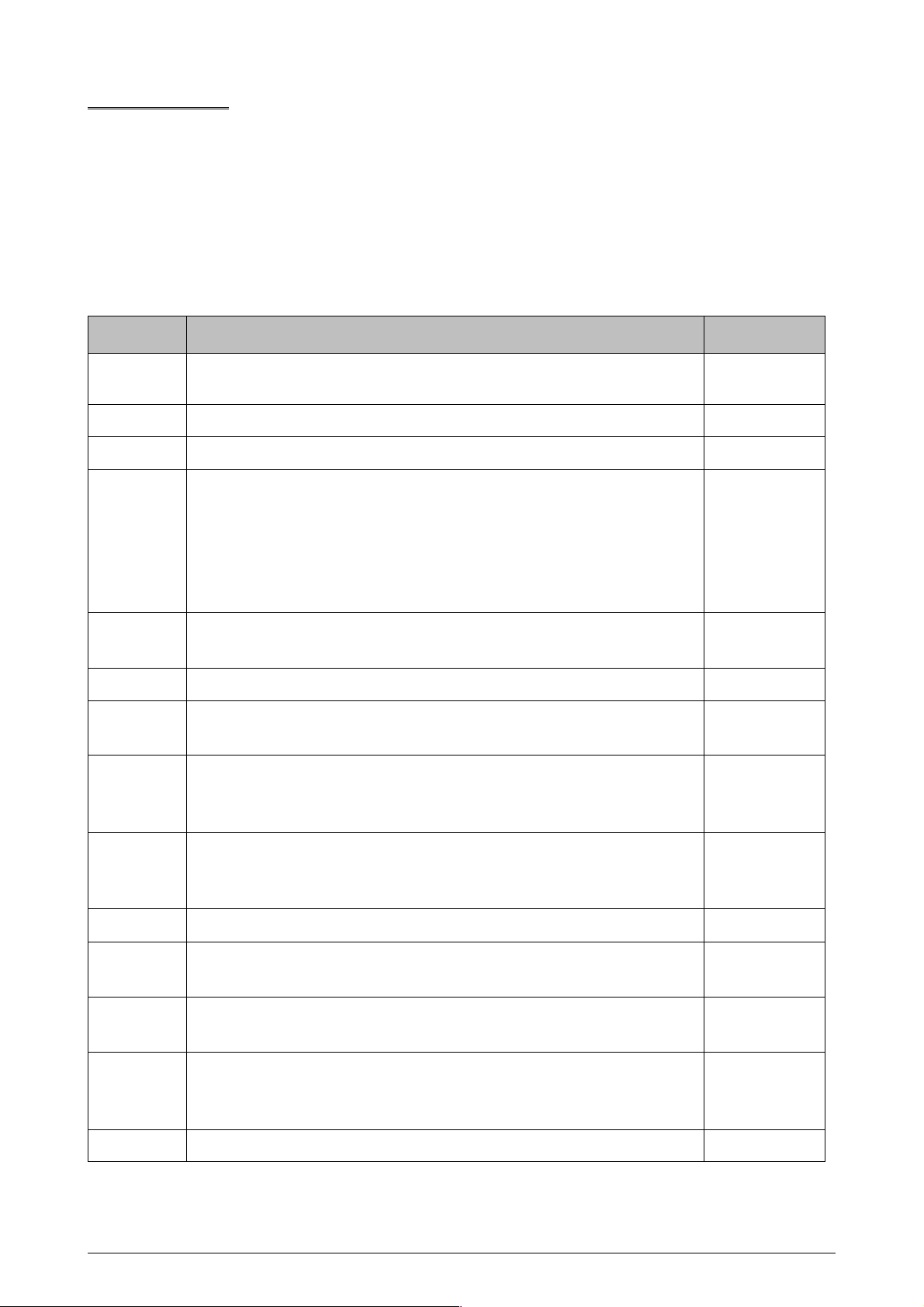

2.3!BASIC SETTINGS.......................................................................................................................7!

2.4!OPTIONAL SETTINGS ................................................................................................................8!

3!TROUBLE SHOOTING ...........................................................................................................10!

4!DEFECT ALARMS ...................................................................................................................14!

4.1!MEANING OF ERROR CODES: ..................................................................................................15!

4.2!WATCH-DOG ON MAINPCB:...................................................................................................17!

5!REPAIRS .................................................................................................................................... 18!

5.1!REPLACEMENT OF MAIN PCB................................................................................................18!

5.2!DISMANTLING THE DOOR.......................................................................................................20!

5.3!CHANGING DISPLAY PCB AND FRONT FOIL ..........................................................................22!

5.4!DISMANTLE THE PUMP BLOCK ...............................................................................................24!

5.5!REPLACEMENT OF PRESSURE SENSOR ....................................................................................25!

5.6!REPLACEMENT OF UPSTREAM OCCLUSION PRESSURE SENSOR ..............................................26!

5.7!REPLACEMENT OF STOP-FLOW MECHANISM ..........................................................................28!

5.8!REPLACING THE PERISTALTIC COVER ....................................................................................32!

5.9!REPLACEMENT OF PB BACK PLATE AND SPRINGS .................................................................34!

5.10!CHANGING THE AIR DETECTOR PLATES...............................................................................35!

5.10.1!Part A: Door Air Detector Plate: ..................................................................................35!

5.10.2!Part B: Front Housing Air Detector Plate.....................................................................36!

5.11!ADDITIONAL OPTIONS AND AMENDMENTS ...........................................................................37!

5.11.1!Stop flow counter plate ..................................................................................................37!

6!INITIALISATION AND UPDATES........................................................................................ 38!

6.1!RELEASE NOTE ......................................................................................................................38!

6.2!SW UPDATE...........................................................................................................................39!

6.3!SW UPDATE AFTER REPLACEMENT OF DISPLAY PCB..............................................................40!

6.4!SW UPDATE AFTER REPLACEMENT OF MAIN PCB. .................................................................41!

7!CALIBRATION ......................................................................................................................... 43!

7.3!DOOR PRESSURE ....................................................................................................................47!

8!MAINTENANCE ....................................................................................................................... 48!

9!DRAWINGS AND LAYOUTS .................................................................................................51!

10!HISTORY ................................................................................................................................. 52!

&