ARDEN Heat Pumps Pty

3.1.8. Linkage control ......................................................................................................42

3.1.9. Refrigerant recovery function................................................................................43

3.1.10. Expiry date password setting...............................................................................43

3.1.11. Electric heating control EH1/gas control signal output........................................43

3.1.12. Heating auxiliary electric heater EH2...................................................................44

3.1.13. Unit auxiliary pump P_c.......................................................................................45

3.1.14. Hot water three-way valve SV1............................................................................45

3.1.15. Air conditioning three-way valve SV2..................................................................45

3.1.16. Air conditioner secondary water pump P_b (secondary system) ........................46

3.1.17. Heat source hot water pump P_e........................................................................46

3.1.18. Heat source heating water pump P_f..................................................................47

3.1.19. winter frost protection ........................................................................................47

3.1.20. Host water flow switch protection ......................................................................48

3.1.21. Protection against excessive temperature difference between inlet and outlet

pipes 49

3.1.22. High voltage protection.......................................................................................50

3.1.23. Low voltage protection........................................................................................50

3.1.24. Exhaust temperature too high protection ...........................................................50

3.2. Display and operation of the wire controller....................................................................51

3.2.1. Wire controller interface display and operation....................................................51

3.2.2. Setting and operation of climate temperature curve.............................................55

3.2.3. Setting and operation of unit tooling number.......................................................57

3.2.4. Network connection method and display of multiple units...................................58

3.2.5. Operation method of unit status parameter query ...............................................59

3.2.6. Factory parameter setting method........................................................................61

3.2.7. Reset......................................................................................................................63

3.2.8. *Touch screen controller operation.......................................................................64

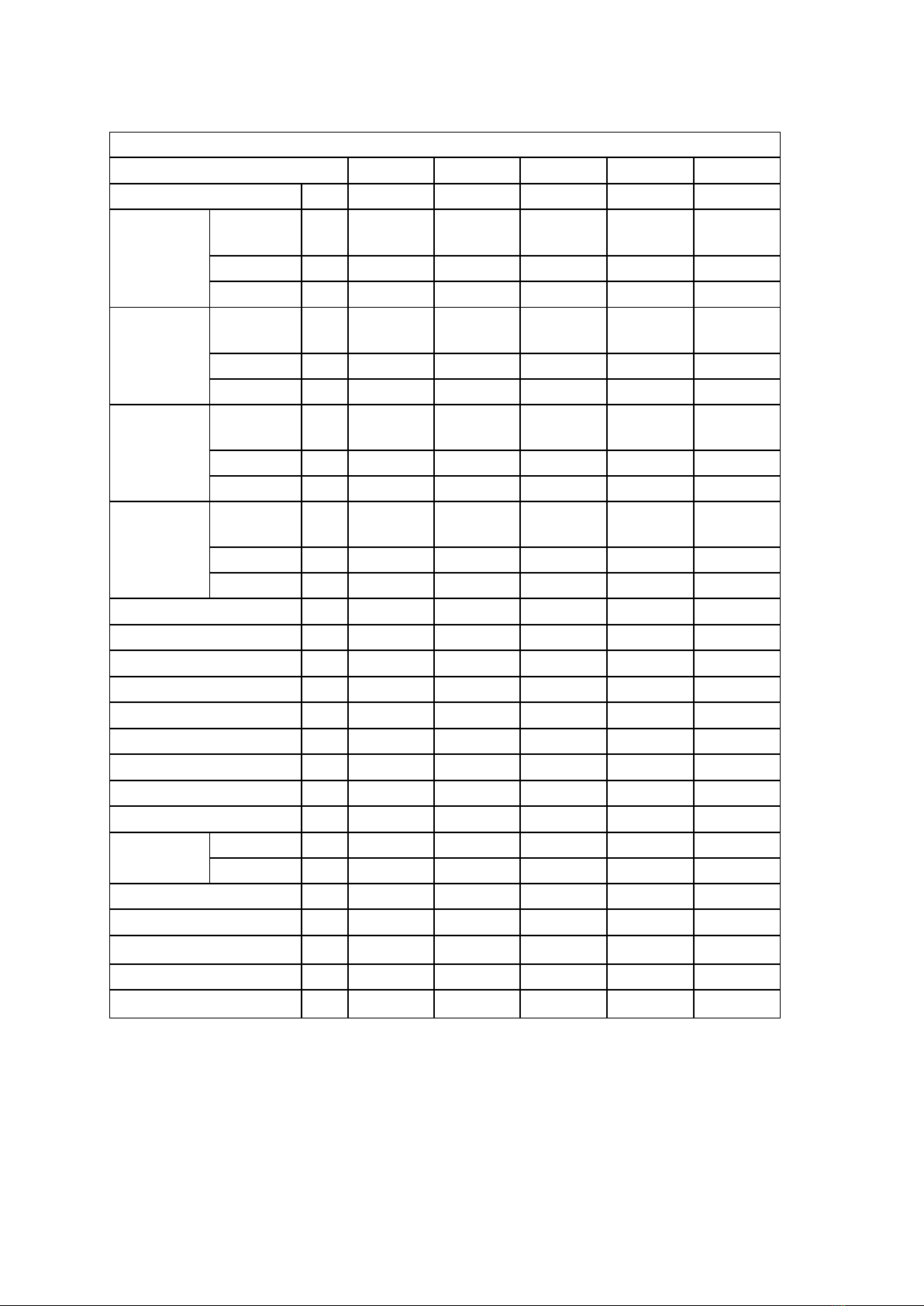

L parameter setting table.................................................................................................80

P parameter setting table................................................................................................81

3.3. Setting method of pump flow range setting value ...........................................................85

3.4. Outdoor unit electric control box layout ..........................................................................85

3.4.1. BLN-006TC1...........................................................................................................85

3.4.2 BLN-012TC1............................................................................................................86

3.4.3. BLN-006TC1/ BLN-012TC1/ BLN-018TC1 ...............................................................86

3.4.4. BLN-012TC3...........................................................................................................87

3.4.5. BLN-018TC3...........................................................................................................87

3.1.6. BLN-012TC3/BLN-018TC3 ......................................................................................88

3.5. Host unit port definition diagram.....................................................................................88

3.5.1. Main control board port definition diagram (AP1) ................................................88

3.5.2. Port Definition Diagram of Water Pump Expansion Board (AP3)...........................89

3.5.3. Port definition diagram of switching power supply (AP4)......................................91

3.5.4. DC fan board port definition diagram (AP5) ..........................................................92

3.5.5. Compressor driver board port definition diagram (AP4) .......................................92

3.6. Fault code and fault reason..............................................................................................94