C6.1.6/1108-0509/E

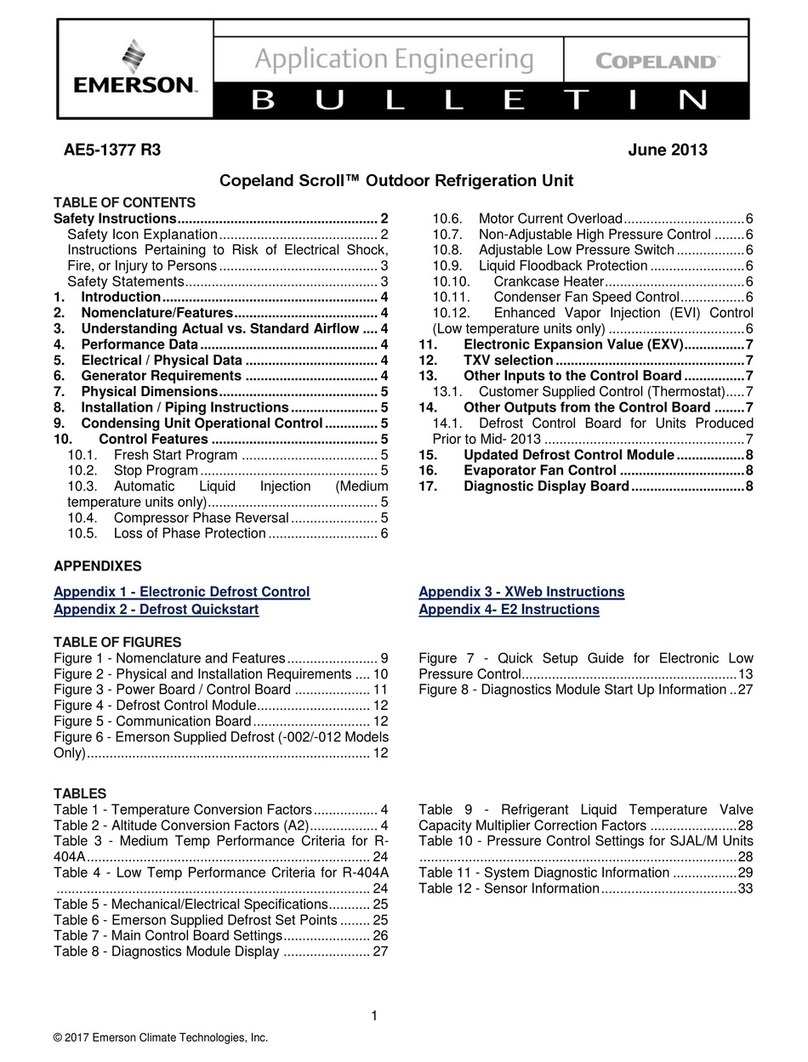

1 Safety instructions............................................................................................ 1

1.1 Icon explanation.................................................................................................................1

1.2 Safety statements ..............................................................................................................1

1.3 General instructions...........................................................................................................2

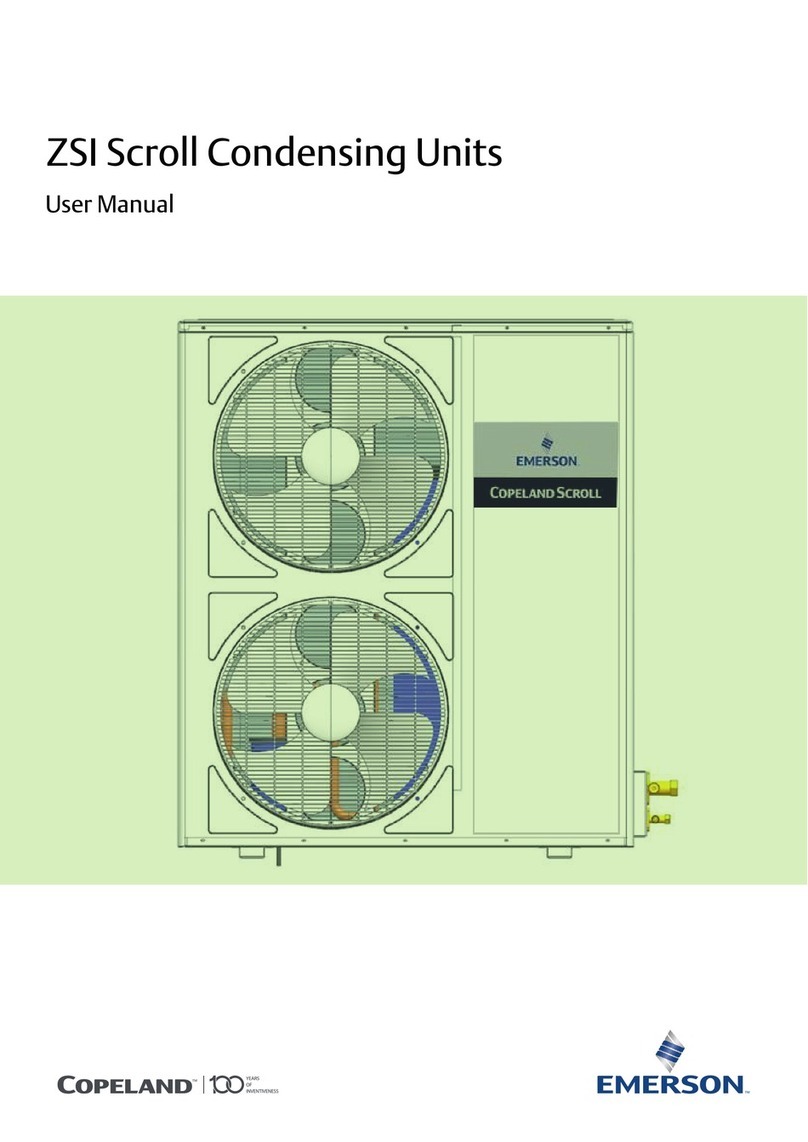

2 Product description .......................................................................................... 3

2.1 Common information about Copeland EazyCool™ZX condensing units.........................3

2.2 About this guideline............................................................................................................3

2.3 Product range ....................................................................................................................3

2.4 Product nameplate.............................................................................................................3

2.5 Nomenclature.....................................................................................................................3

2.6 Application range...............................................................................................................4

2.6.1 Qualified refrigerants and oils ................................................................................4

2.6.2 Application limits.....................................................................................................4

2.7 Main component description..............................................................................................4

2.7.1 Compressor............................................................................................................4

2.7.2 Condenser fan(s)....................................................................................................4

2.8 Electronic board control and operating features................................................................5

2.8.1 Electronic board features .......................................................................................5

2.8.2 Electronic board description...................................................................................6

2.8.3 Diagnostic signal ....................................................................................................7

2.9 Compressor / Unit setting ..................................................................................................8

2.10 Compressor motor protection ............................................................................................9

2.11 Compressor pressure protection .......................................................................................9

2.11.1 High pressure.........................................................................................................9

2.11.2 Low pressure..........................................................................................................9

2.12 Other inputs to the board...................................................................................................9

2.12.1 Customer-supplied control (thermostat).................................................................9

2.12.2 Case temperature controller.................................................................................10

2.12.3 Condenser coil & ambient air thermistors ............................................................10

2.13 Other outputs from the electronic board..........................................................................10

2.13.1 Liquid line solenoid valve (not supplied) ..............................................................10

2.13.2 Defrost heater contactor coil (not supplied) .........................................................11

2.13.3 Evaporator fan contactor coil (not supplied).........................................................11

2.14 Dimensions in mm ...........................................................................................................11

3 Installation....................................................................................................... 13

3.1 Condensing unit handling ................................................................................................13

3.1.1 Transport and storage..........................................................................................13

3.1.2 Weights.................................................................................................................13

3.2 Electrical connection........................................................................................................13

3.2.1 Power supply connections....................................................................................13