WWW.ARISTOCRAFT.COM4

Live Steam Trains should not be used by anyone under the age of 14. This is not a

toy, and while not any more dangerous then the use of a stove while boiling water

for a cup of tea, it does take some common sense and the ability to make rational

actions if something doesn’t work as prescribed.

Hot water is scalding and must be treated as such, so do not open a pressurized

locomotive water tank until it has cooled sufficiently. To do so would create a reac-

tion much like opening an auto’s radiator cap under full pressure. DON’T do this.

Do not smoke when filling the butane into the tender. This is a flammable material

and is similar to the situation when relighting a gas stove burner when the pilot light

goes out.

Use only distilled water, available at supermarkets and drugstores widely, as regu-

lar water has contaminates that could eat away at your copper boiler. This is espe-

cially true if you do not thoroughly drain the water from the boiler after each use.

The Aristo-Craft Live Steamer has a drain cock to allow you to do just that.

Do tighten the hose to the boiler of the locomotive prior to adding the butane mate-

rial to the input in the tender.

Do not use boiling water in the supplemental hot water bath for the butane tank. It’s

not necessary and could cause handling problems with the scalding water. If you

like you can drain this hot bath water after steam-up and before you actually begin

running. This will provide a fresh hot water bath for the running period after the

water has reached the starting pressure.

Do not run your loco without proper steam oil that is formulated for the super-hot

conditions of running a steam locomotive. This is not included, but is available from

where you purchased your loco.

Do not overfill your boiler beyond the two cups of distilled water (500 ml total).

Live Steam Operation Safety

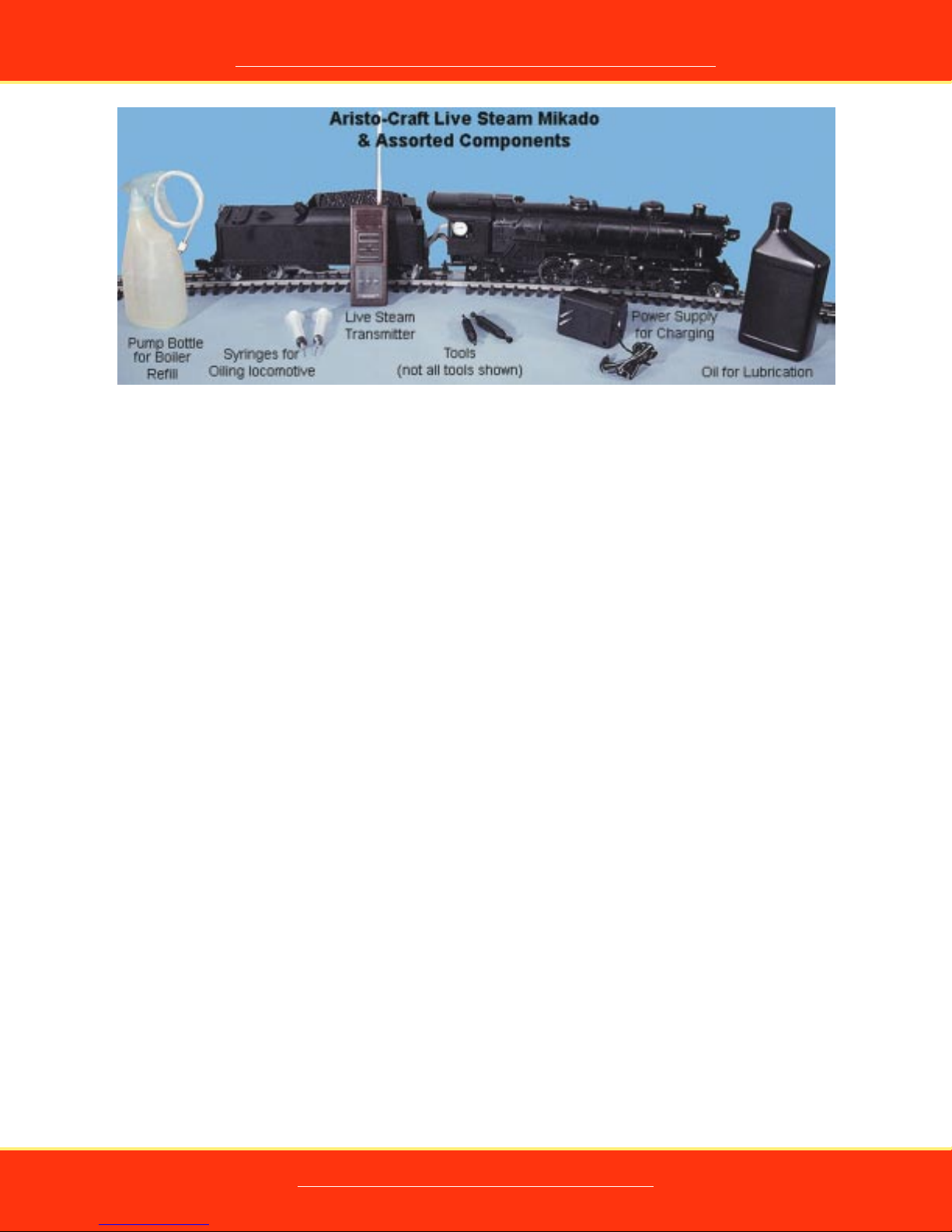

Please read all of these warnings very carefully before using your Aristo-Craft Live

Steam Mikado for the first time!