Arrow AR1012-B Use and care manual

Other Arrow Outdoor Storage manuals

Arrow

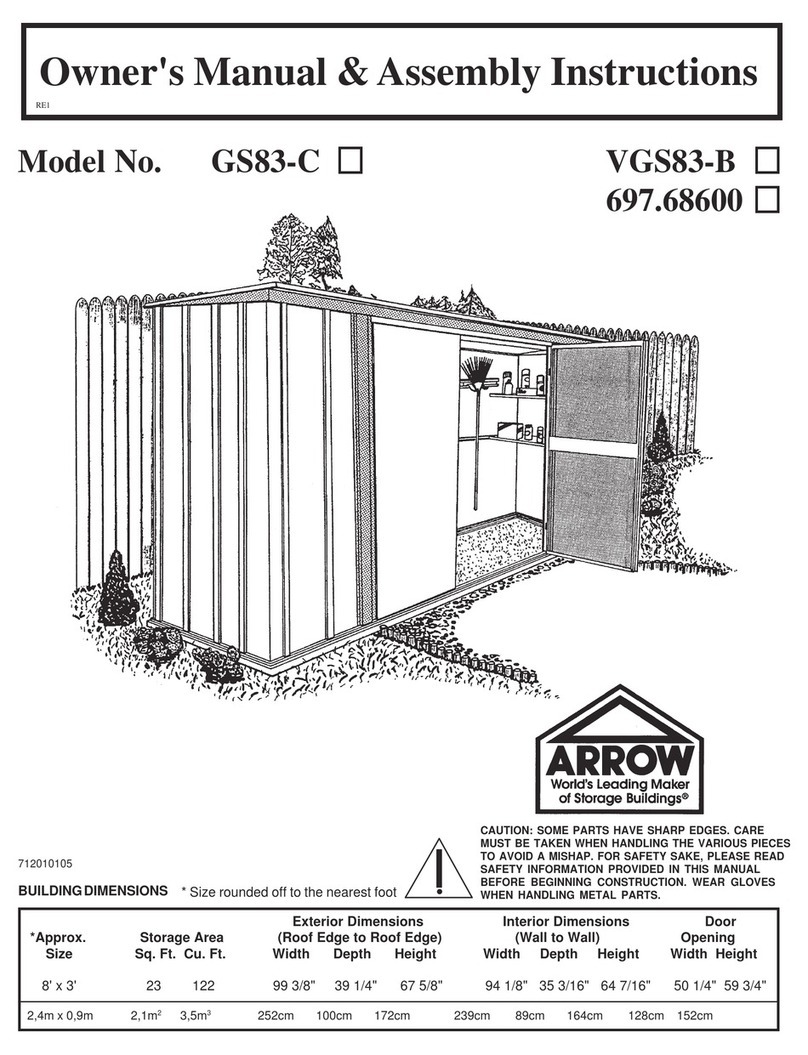

Arrow GS83C Use and care manual

Arrow

Arrow HM10867 Use and care manual

Arrow

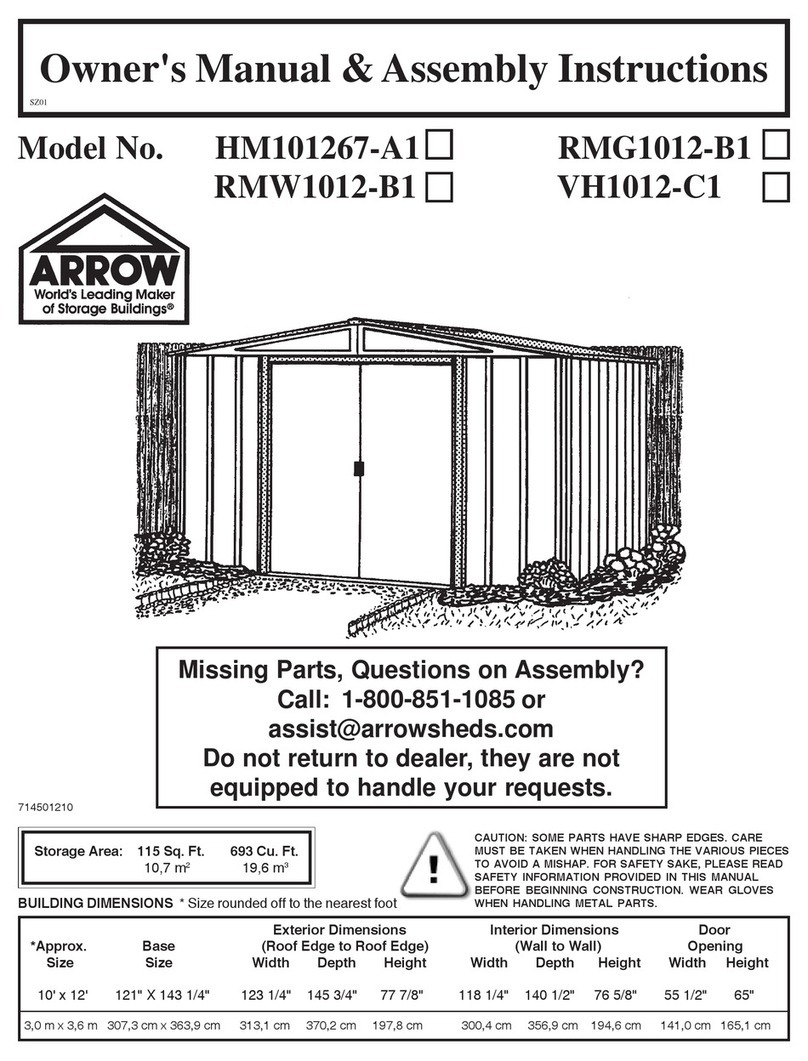

Arrow HM101267-A1 Use and care manual

Arrow

Arrow RH1014-C1 Use and care manual

Arrow

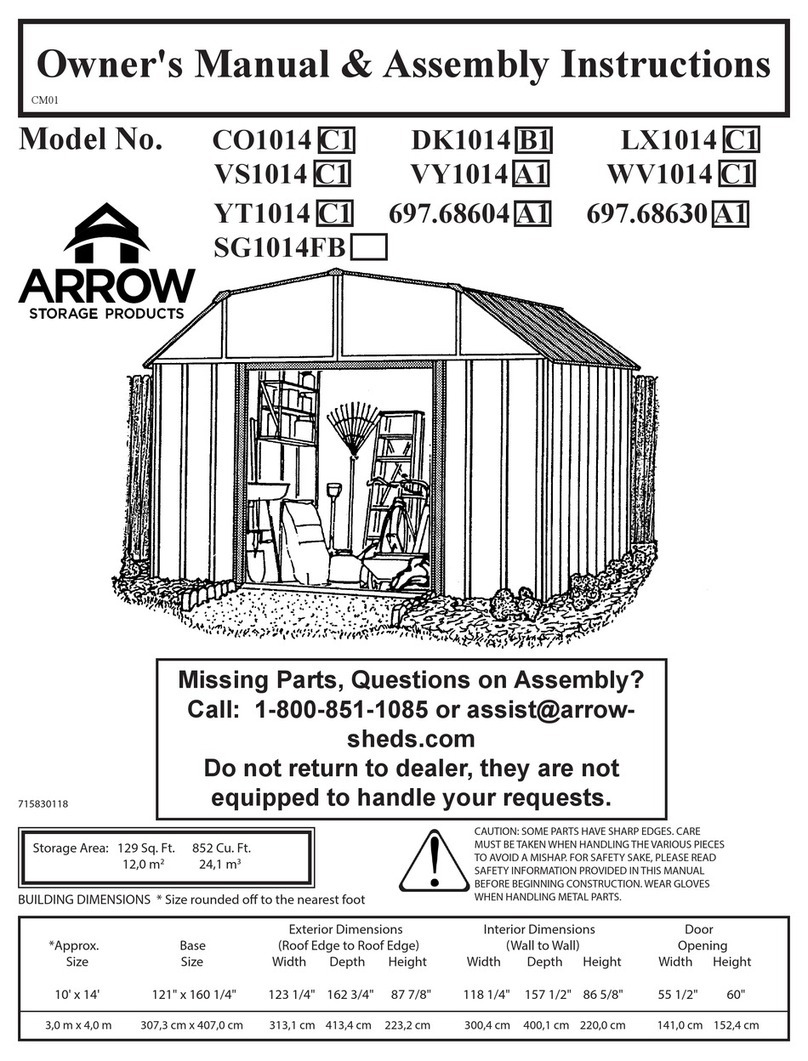

Arrow CO1014-C1 Use and care manual

Arrow

Arrow ED1012-B1 Series Use and care manual

Arrow

Arrow CLG1012CC Instructions for use

Arrow

Arrow CL72-A Use and care manual

Arrow

Arrow YT108M Series Use and care manual

Arrow

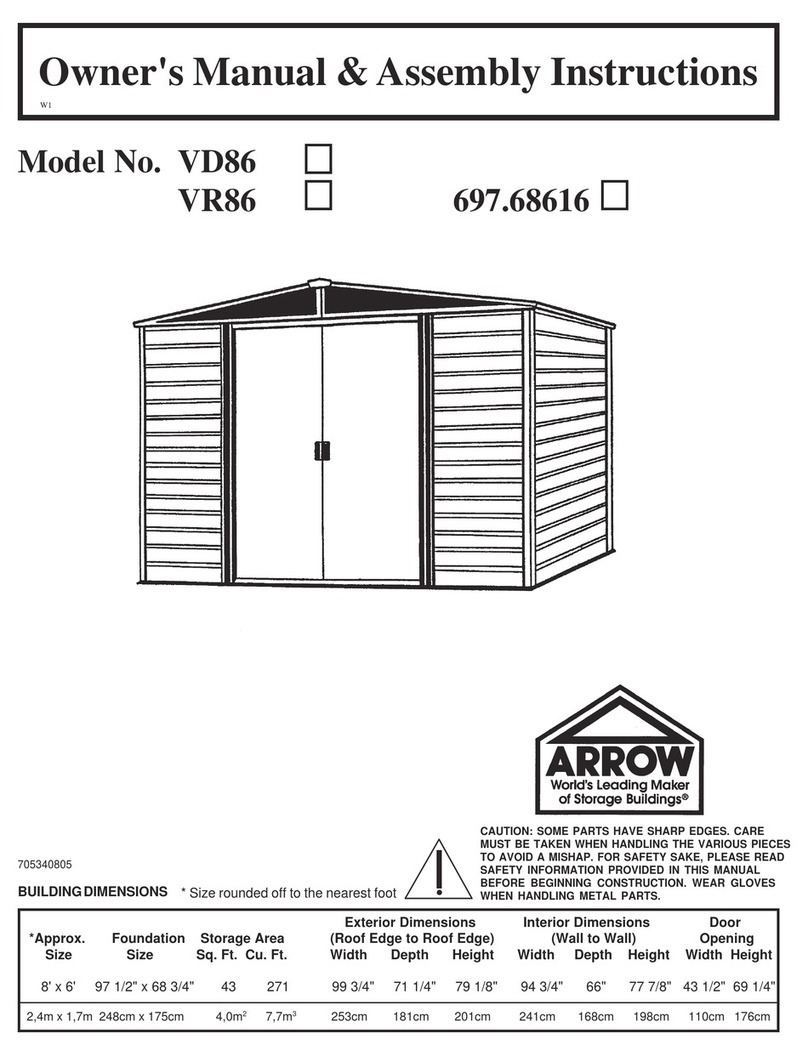

Arrow VD86 Series Use and care manual

Arrow

Arrow NP10867 Instructions for use

Arrow

Arrow SG1014FB Series Use and care manual

Arrow

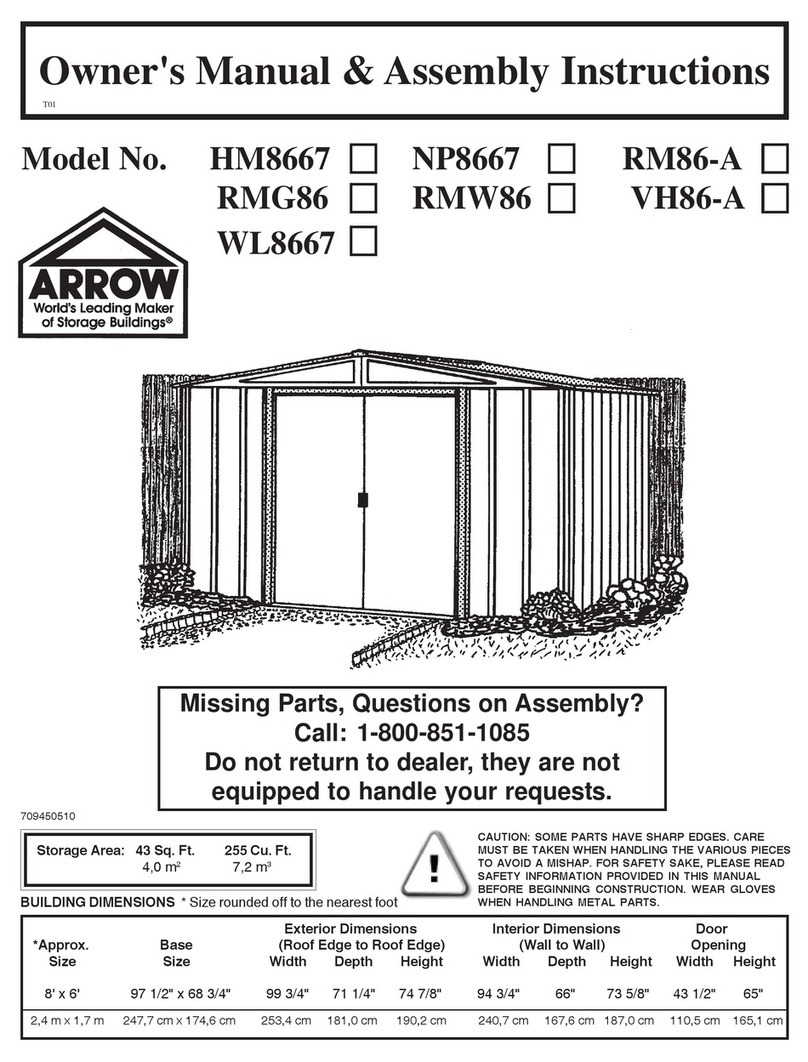

Arrow HM8667 Use and care manual

Arrow

Arrow FDN477 Use and care manual

Arrow

Arrow LW108LM Instructions for use

Arrow

Arrow ED1012 B1 Use and care manual

Arrow

Arrow CLG108CC Instructions for use

Arrow

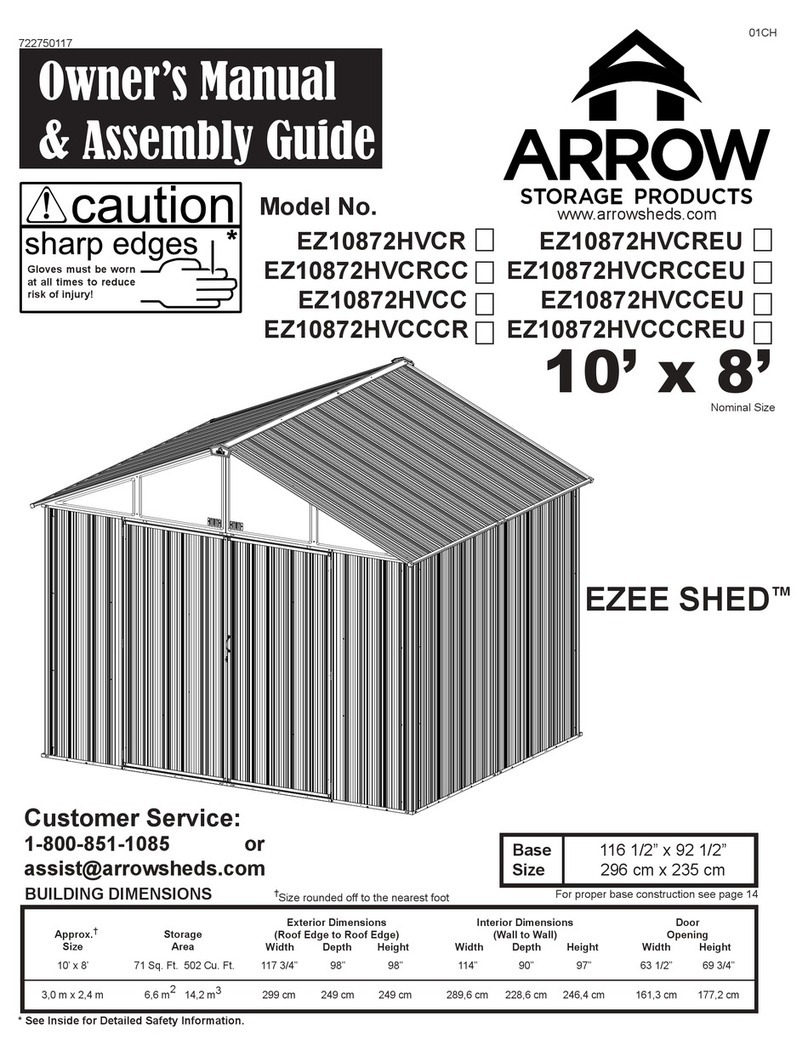

Arrow EZEE SHED EZ10872HVCR Instructions for use

Arrow

Arrow EH86-A Use and care manual

Arrow

Arrow SBS64 Instructions for use

Popular Outdoor Storage manuals by other brands

Lifetime

Lifetime 6418 owner's manual

rollaway container

rollaway container ARPCA24 manual

Duratuf

Duratuf Havelock Assembly instructions

X-METAL

X-METAL 4065 owner's manual

Outdoor Life Products

Outdoor Life Products FP2030 F Assembly instructions

Royalcraft

Royalcraft Faro 295L Storage Box Assembly instructions