ARVEN OP Series User manual

SUBMERSIBLE MOTOR OP 4”

OPERATING INSTRUCTION

CONTENTS

1.00 Introduction

1.01 Warranty

1.02 Description of motor

1.03 Trasport and installation

1.04 Thechnical particulars

,GHQWLÀFDWLRQSODWH

1.06 Generaly safety precatuions

1.07 Operating conditions

2.00 Installation

2.01 Start-up

3.00 Maintenance and service

4.00 Spare parts

5.00 Descriptions of symbol

1.00 INTRODUCTION

This brochure gives important information con-

cerning the installation,use and maintenance

of the motors. The contents of this brochure

refer to the standard product, and presented

in the sales documentation. Please refer to the

sales contract for the futures of variants and

special version. Always specify the exact type

of motor and code when requesting our Sales

and Service Department for technical informa-

tion spare parts. For any instruction,situations

and event not covered in this brochure or in

the sales documentation, please conctact

the nearest Technical Assistance Center.

Read this manual carefully before installing and

using the product.

The manufacturer shall not be held directly or

indirectly liable for any negligence or failure

to observe the instructions given in this bro-

chure, nor for any damage caused by faulty

installation and/or improper use of the motor.

At the time of purchase, check that the mo-

tor is intact and complete. Any complaints

shall have to be presented in writing within

seven (7) days of receving the motor.

1.01 WARRANTY

The manufacturer guarantees its products for

a period of twelve (12) months from the date

of purchase. This warranty is onlyexpressed

in the repair or replacement free of charge of

those parts that after careful examination by

the manufacturer turn out to be defective. War-

ranty excluding all liability for direct or indirect

damage, is considered to be restricted to ma-

terial defects inly (excluding electrical parts)

and ceases to have effect if the parts returned

anyhow turn out to have been dismantled.

tampered with, or repaired outside the fac-

tory. Returned equipment, even if in warran-

ty, shall have to be shipped with freight paid.

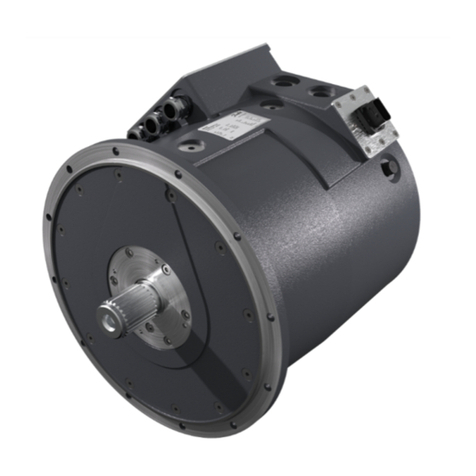

1.02 DESCRIPTION OF MOTOR (Fig.1)

1) Electric cable

2) Double ends studs, washer and nuts

,GHQWLÀFDWLRQVSODWH

The 4OS range comprises a number of 4”

submersible motors with stator and rotor in coo-

OLQJÀOOLQJÁXLGVXLWDEOHIRUXVHZLWKIRRGVWXIIV7KH

ÁDQJHFRQQHFWLRQVL]HPHHWV1(0$VWDQGDUGV

Each motor includes a cable with removable

connector.

1.03 TRASPORT AND INSTALLATION

The motor is supplied completely with a power

supply cable, in sturdy cardboard boxes suitable

for transportation and storage. It is advisable, in

thecaseofstorage,nottoexceedastackof4units.

Before installation, carefully read this bro-

chure and especially the safetyprecau-

tions described in paragraph 1.06. Pay at-

tention to the danger sign marked in this

brochure wich highlights a potential danger.

3

1.04 TECHNICAL PARTICULARS

MOTOR

TYPE

POWER H

mm

WEIGHT

Kg

kW Hp

OPM00750 0.55 0.75 381.5 8.5

OPT00750 386.5 8

OPM01000 0.75 1.0 401.5 9.4

OPT01000 406.5 9

OPM01500 1.1 1.5 432.5 10.7

OPT01500 442.5 10.4

OPM02000 1.5 2.0 472.5 12.6

OPT02000 482.5 12.1

OPM03000 2.2 3.0 585 17.3

OPT03000 560 16.9

OPT04000 3.0 4.0 635 20

OPT05500 4.0 5.5 684 22.3

OPT07500 5.5 7.5 804 27.9

OPT10000 7.5 10 919 33.6

4

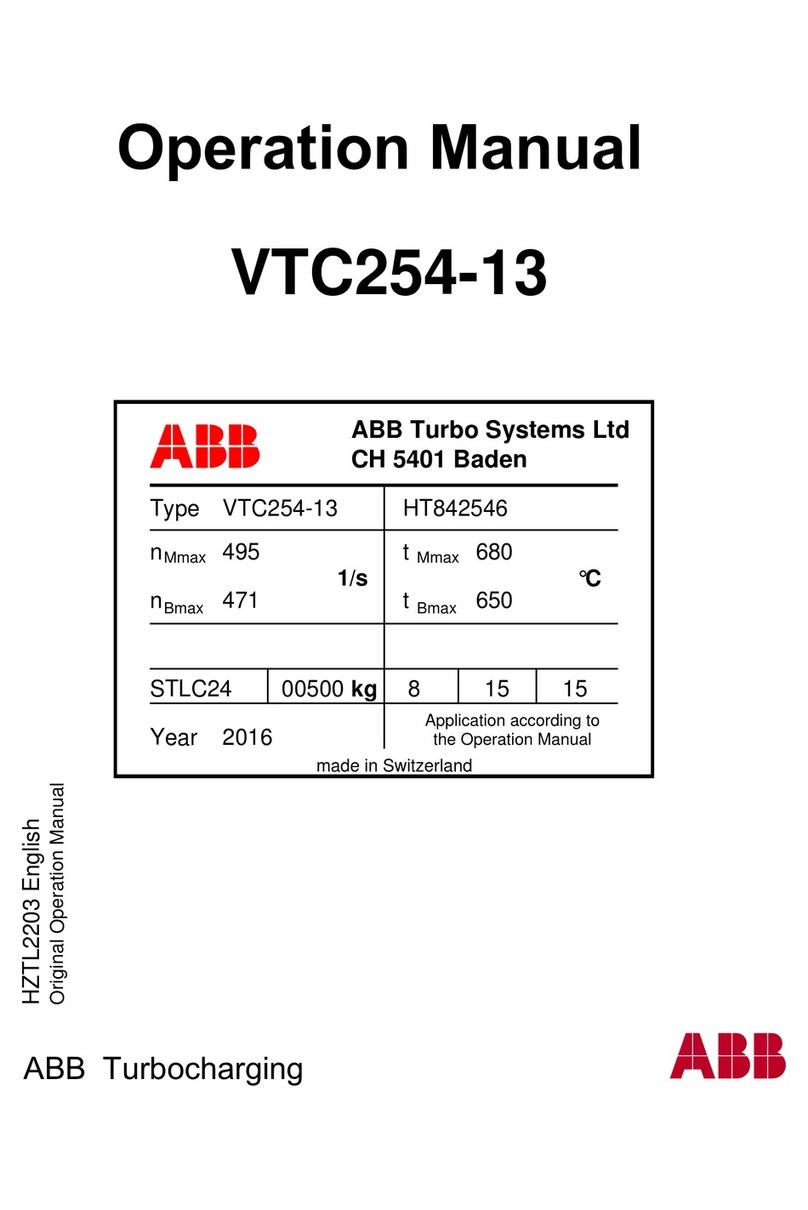

1.05 IDENTIFICATION PLATE

1 Type of motor

2 Manufacturing date

3 Rated voltage

4 Protection class

5 Rated power in kW

6 Rated power in Hp

7 Frequuncy

8 Rated current

9 Power factor

10 Phase

11 Rated speed

12 Starter capacitor capacity

13 Capacitor voltage

14 Maximum ambient temperature

15 Class of insulation

16 The weight of the motor

17 Code

18 Maximum thrust load

19 Service factor

20 Symbol RAEE

1.06 GENERAL SAFETY PRECAUTIONS

When using electrical equipement, it is ne-

cessary to take the appropriate safety pre-

JH\[PVUZ [V YLK\JL [OL YPZR VM ÄYL LSLJ[YPJHS

shock, and injury to person. Therefore, before

using the equipement, carefully read and me-

morize the following safety instructions. After

reading, keep this brochure with care. The ma-

nufacturer shall not be heald liable for any non-

observance of the safety and accident-preven-

tion instructions described in this brochure.

- Keep the work area clean and tidy. Untidy areas

and environments make accidents more likely.

- Before starting work, become familar with the

control devices and their functions.

- Do not subject the equipment to work it could

not reasonably support.

- Operate only with good lighting, in a safe po-

sition free from hindrances.

- When handling the motor use suitable lifting.

- Equipment in conformity with the safety regu-

lations, and wear safety shoes and gloves.

- Never handle the equipement by pulling in its

power cable.

- Use only cables of allowed lenght, marked

and with suitable cross-sections.

- Protect the cable from high temperature, lubri-

ÄJHU[ZHUKZOHYWJVYULYZ

- During the installation operations, pay atten-

tion to hanging loads and follow the correspon-

ding safety instructions.

- Make the control panel and the electrical sy-

stem in accordance with current regulations.

- It is essential to use skilled personnnel since

motor are machines that due to their type of in-

stallations and starting to require precise tech-

nical knowledge.

1.07 OPERATING CONDITIONS

-Liquids in wich the motor can operate

This motor can be used in cold water. Do not

use this motor with corrosive or explosive li-

quids, or particularly dirty or hard water (impuri-

ties may deposit on the outer casing).

-Water temperature

Minimum water temperature is 0°C

Maximum water temperature is +35°C as long

HZ[OL ÅV^YH[LVM [OL^H[LY HYV\UK[OLTV[VY

does not fall below 0.16m/s

5

-Cooling the motor

To ensure the motor is correctly cooled, make

sure the plowrate of the water around the outer

casing is at least 0.16m/s when positioning the

motor in wells or tanks.

-Installation position

All the motors in the range can be installed

vertically.

Motors up to 2.2 kW power can be installed

horizontally.

-Depth of immersion

The maximum depth of immersion for all motors

is 150m.

-Power supply requirements

Make sure the supply voltage and frequency

match yhose indicated on the rating plate of the

motor.

The motors can generally work at the following

supply voltage tolerances.

f UN

Hz ~ V ± %

50 1 220V ± 10%

50 3 220V ± 10%

50 3 380V ± 10%

-Number of starts per hour

To get the best operation and longest service

life out of your motor and pump, the maximum

number of starting times is not more than 30

times.

-Compatible pumps

Make sure the motor is compatible with the

pump.

Incompatible combinations may cause pro-

blems.

In particular, before coupling the motor to the

pump check that:

-the power of the pump to couple to the motor

is less than or equal to that of the motor.

- the supply voltage and frequency match those

PUKPJH[LKVU[OLPKLU[PÄJH[PVUWSH[LVM[OLTV-

tor.

-the motor and pump shafts turn freely.

-Motor powered by a frequency converter

Only specially ordered motors can be powered

with a frequency converter.

If the motor is combined with a frequency con-

verter, downgrade power by 10% and make

sure never exceed the rated input frequency of

the motor.

To ensure the motor is properly cooled, the mini-

T\T^H[LYÅV^YH[LH[[OLTPUPT\TMYLX\LUJ`

VM\ZLT\Z[LX\HS[V[OLTPUPT\TÅV^YH[LPUKP-

cated in the previous points.

2.00 INSTALLATION

Installation must be done by competent and

authorized operators.

During installation,apply all the safety pro-

visions issued by the competent bodies in

the country of use and dictated by common

sense.

Before installing the motor, read this instruc-

tions manual and the one supplied the pump

or electric pump to wich the motor will be cou-

pled. Keep both manuals with care.

Use suitable equipment and protective devices.

-Selecting the electrical panel

Motors must be suitably protected against

overloads and short circuits.

The following starting systems can be used:

direct, impedance, autotransformer, soft-start.

Make sure the panel power ratings match those

of the pump. Incompatible combinations may

cause faults and fail to fully protect the motor.

Before installing, carefully read the instructions

supplied with the electrical panel.

6

- Pump connections

Before connecting the motor to the pump, read

this instructions manual and the one supplied

with the pump or electric pump to wich the mo-

tor will be coupled.

Keep both manuals with care.

-Installing the motor in a well or tank

Follow the instructions in the pump or electric

pump brochure.

When installing the electric pump vertically,

make sure the motor does not rest on the bot-

tom of the well ot tank.

When installing the electric pump horizontally,

make sure the motore does not rest on the bot-

tom of the tank.

2.01 START-UP

Follow the instructions in the pump or electric

pump manual

-Electrical connections to the electric pump

Electrical connections may only be performed

I`HX\HSPÄLKPUZ[HSSLY PUJVTWSPHUJL^P[OJ\Y-

rent regulations.

Make sure that the supply voltage and fre-

quency are compatible with the electrical panel.

The relative information is shown on the motor

PKLU[PÄJH[PVUWSH[LHUKPU[OLKVJ\TLU[ZZ\W-

plied with the panel. Provide suitable short cir-

cuit protection on the supply line.

Before proceeding, make sure that all the con-

nections (even if they are potential-free9 are

voltage-free.

UnlesZV[OLY^PZLZWLJPÄLKPUSVJHSI`SH^Z[OL

Z\WWS`SPULT\Z[ILÄ[[LK^P[O!

- a short circuit protection device.

- a high sensitivity residual current circuit brea-

ker (30mA) for addictional protection from elec-

[YVJ\[PVUPUJHZLVMPULMÄJPLU[NYV\UKPUN

- a general switch with a contact aperture of at

least 3 millimiters.

Ground the system in compliance with current

regulations.

Single-phase version

Connect the electric pump to a supply line via

a suitable electrical control panel containing the

overload protection and the capacitor.

Refer to the wiring KPHNYHTPUÄN\YLHUK[OL

documentation supplied with the electrical pa-

nel.

Refer to the motor rating plate for the capacity

of capacitor.

Install the electrical panel in a sheltred area.

Figure 2: Single-phase wiring diagram

Three-phase version

Connect the electrical pump to a supply line via

a suitable electrical control panel.

Install the electrical panel in a sheltered area.

Refer to the documentation supplied with the

electrical panel.

For connections to any external control follow

the instructions supplied with these devices.

7

3.00 MAINTENANCE AND SERVICE

Before proceeding, always make sure the motor

is disconnected from the supply line.

Maintance operations may only be performed

I` L_WLY[Z HUK X\HSPÄLK WLVWSL <ZL Z\P[HISL

equipment and protective devices. Observe all

accident prevention regulations.

Do not attempt to disconnect the connector

from the motor hand cable.

This may only be done by authorised personnel.

Only use original spare parts to replace faulty

components.

The motor does not require any scheduled rou-

tine maintenance.

Users wishing to prepare a maintenance sche-

dule should bear in mind that maintenance

cycle depends on the conditions of use.

For any requirements, please contact our Sales

and Service Department.

4.00 SPARE PARTS

Always specify the exact type of motor and

code when requesting our Sales and Assistan-

ce Service for technical information or spare

parts.

Only use spare parts to replace faulty compo-

nents. Unsuitable spare parts may cause the

product to work incorrectly and cause hazards

for people and property.

For further information, please contact our Sa-

les and Service Department.

5.00 DESCRIPTIONS OF SYMBOL

Read this brochure carefully

before proceeding

Electric shock failure to observe

this warning may result in the

electric shock

Warning sign indicates a potential

hazard

Arven S.r.l.

Via Artigiani n°10

25030 Maclodio - Brescia Italy

Tel. +39.030.9973973

Fax +39.030.9973975

www.Arven.it

0940.ARV0005.00

Ed. 04/2019_00

This manual suits for next models

14

Table of contents