GENERAL

Introduction

This manual containsthe equipment operating procedures as well as additional information needed

to

help

the operator keep the equipment in properworking order. Study and follow the instructions carefully. A

planned maintenance program isincluded inthis manual; adhering

to

the programwill result in betterequip-

ment performance and longerequipment life. Proper diagnosis of a problem is the

most

important step

to

satisfactory repair; therefore. a troubleshooti.ng table is included.

Understanding

the

Diesel Engine

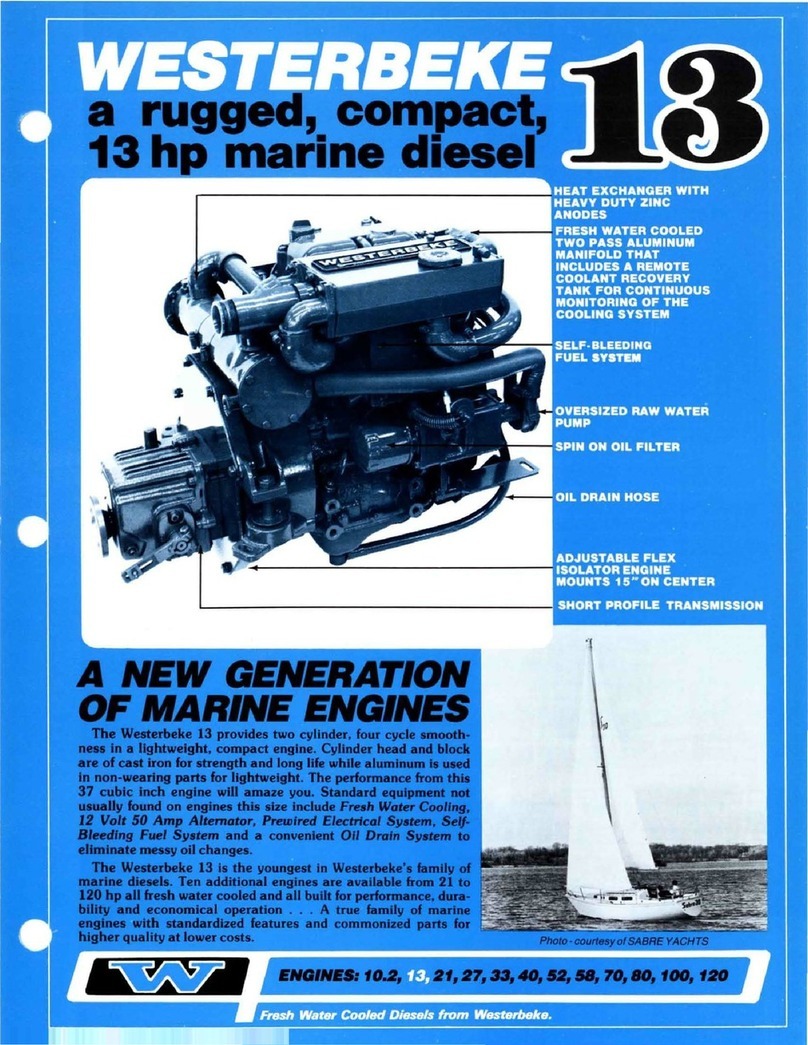

The diesel engine closely resembles the gasoline engine, since the mechanism is essentiallythe same. The

cylinders are arranged above a closed crankcase;

the

crankshaft is ofthe same general

type

as that of a

gasolineengine; and thediesel engine hasthe same

type

ofvalves. camshaft, pistons, connecting rods, and

lubricating system. ·

Therefore,

to

a greatextent, adiesel enginerequires the same preventive maintenanceasa gasolineengine.

The

most

importantfactors are properventilation and proper maintenance

of

the fuel, lubricating and cool-

ing systems. Replacement offuel and lubricating filter elements at the time periods specified is a must, and

frequent checking for contamination (that

is,

water, sediment,

or

algae) in the fuel system is also essential.

Anotherimportantfactoristhe useof

the

same brand

of

highdetergentdiesel lubricatingoildesignedspecifi-

cally fordiesel engines. Be careful

not

to

put gasoline inthe diesel fuel tank(s). Gasoline does nothavethe

same lubricating qualities asdiesel fuel; consequently, gasoline inthefuel lineswill damage components in

the fuel lift

pump

assembly, fuel injection pump and injectors.

The diesel engine does differfrom the gasoline engine, however, in its handling and firing

of

fuel. The car-

buretor and ignition systems are

done

awaywith and in their place are

two

components -thefuel injection

pump

and

the

fuel injectors.

Ordering

Parts

When contacting yourWesterbeke dealer, partsdistributor,

or

the factory concerning

your

Westerbeke unit,

alwaysprovidetheengine'smodel and serial number, andtransmission numberas

they

appearonthe black

and silver 'Westerbeke" plate which is mounted on the engine's exhaust manifold. When ordering parts for

your Westerbeke engine, be sure

to

insist upon Westerbeke factory packaged parts, because ''will fit''

or

generic parts are frequently notmade

to

the same specifications as original equipment.

Note that component locations in the manual are referenced from the front

of

the engine which is the pul-

ley/drive belt end. (The flywheel/transmission end is the rear end.) Left and right sides are determined

by

theengine; imagine straddling the engine and facing in the same direction as the front

of

the engine: the left

side is at

your

left, the right side is

your

right

·

Westerbeke engines and generator sets are thoroughly checked and given a final run undervarious load

conditions before leaving the factory. Test running the engine ensure depenqable operation. long service,

and a satisfied owner.

care

at

the

factory during assembly, and thorough testing, have resulted in a Westerbeke diesel engine

capable

of

manythousands

of

hours

of

dependable service. However, whatthe manufacturercannot con-

trol is the treatmentthe unit receives in thefield. That part is

up

to

the owner/operator.

Westerbeke Diesel

Engines

4

I