Fundamental safety instructions

4

2.2 Organizational measures

The operating and assembly instructions must always

be at hand at the place of use of the machine.

In addition to the operating and assembly instructions,

observe and instruct the user in all other generally ap-

plicable legal and other mandatory regulations relevant

to accident prevention and environmental protection.

These compulsory regulations may also deal with

the handling of hazardous substances, issuing and/or

wearing of personal protective equipment, or trafc

regulations.

must be supplemented by instructions covering the

duties involved in supervising and notifying special

organizational features, such as job organization,

working sequences or the personnel entrusted with

the work.

Personnel entrusted with work on the machine must

have read the operating instructions and in particular

the chapter on safety before beginning work. Reading

the instructions after work has begun is too late. This

applies especially to persons working only occasionally

on the machine, e.g. during setting up or maintenance.

Check - at least from time to time - whether the per-

sonnel is carrying out the work in compliance with the

operating instructions and paying attention to risks

and safety factors.

For reasons of safety, long hair must be tied back or

otherwise secured, garments must be close-tting and

no jewellery may be worn, including rings. Injury may

result from being caught up in the machinery or from

rings catching on moving parts.

Use protective equipment wherever required by the

circumstances or by law.

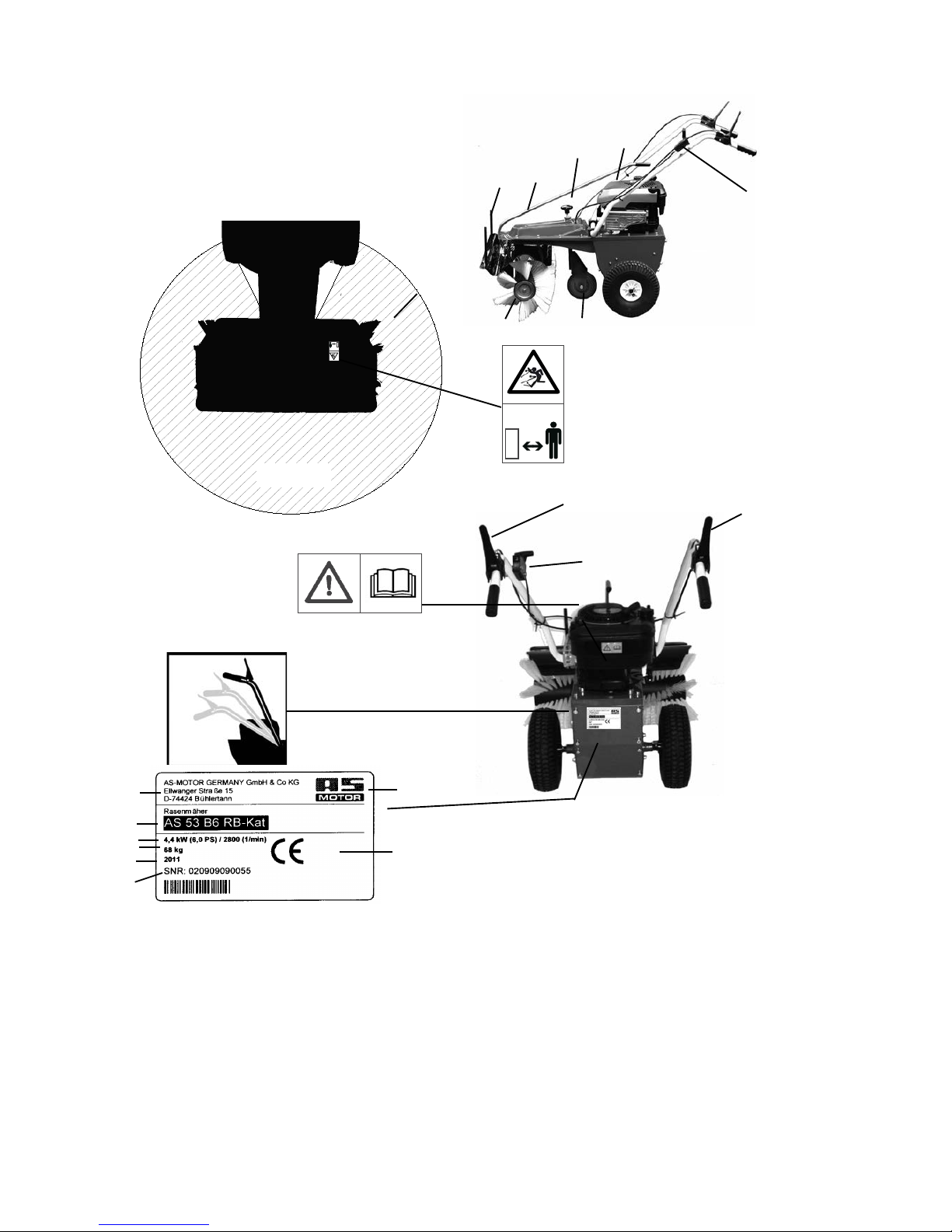

Observe all safety instructions and warnings attached

to the machine.

Make sure that safety instructions and warnings

attached to the machine are always complete and

perfectly legible.

In the event of safety-relevant modications or changes

in the behaviour of the machine during operation, stop

the machine immediately and report the malfunction

to the relevant specialized dealer.

Never make any modifications, additions or con-

versions which might affect safety without the

manufacturer’s approval. This also applies to the in-

stallation and adjustment of safety devices and valves

as well as to welding work on load-bearing elements.

Only use original spare parts from the manufacturer.

These meet technical requirements and include war-

ranty and guarantee claims. Adhere to prescribed inter-

vals or those specied in the operating and assembly

instructions for routine checks and inspections.

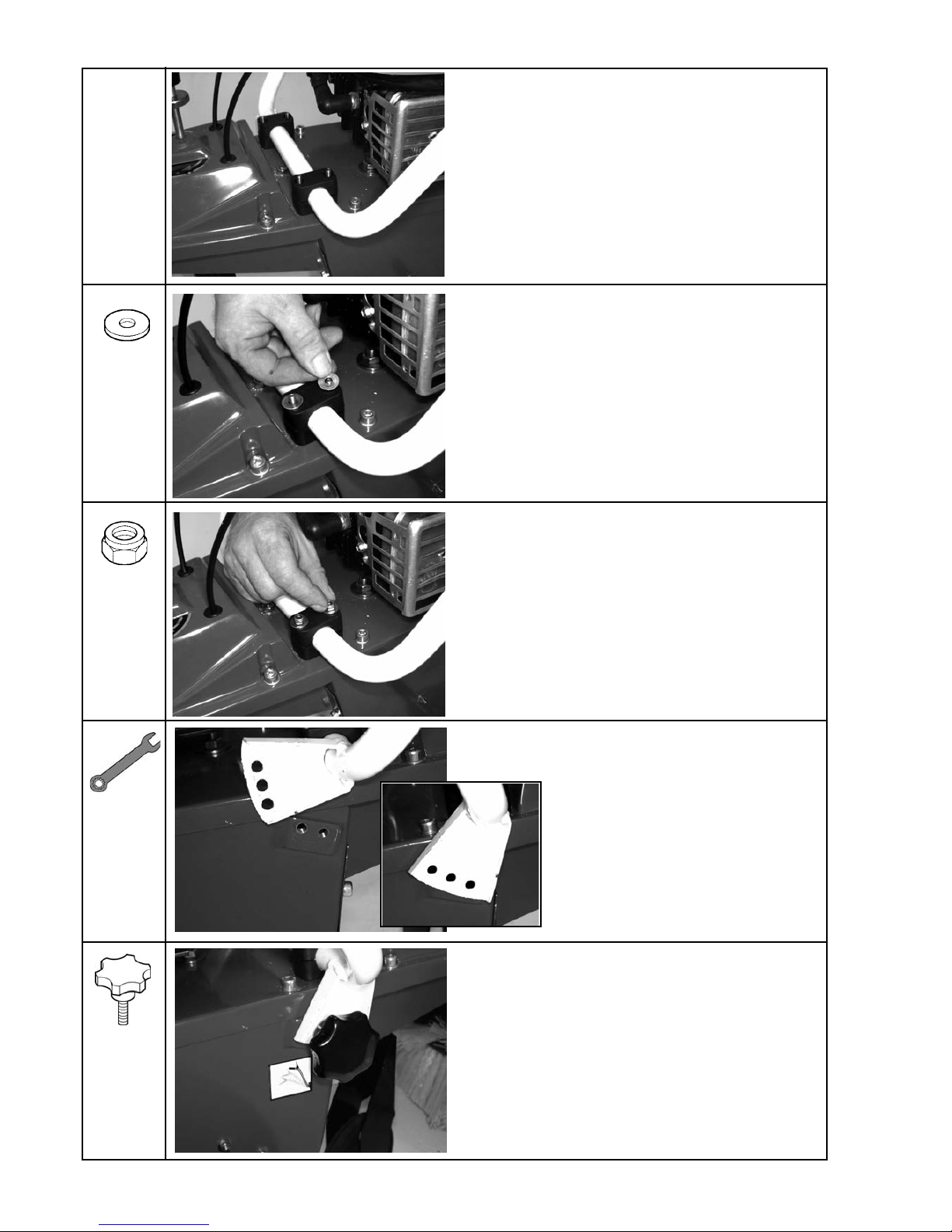

For the execution of maintenance work, tools and

workshop equipment adapted to the task on hand are

absolutely indispensable.

The personnel must be familiar with the location and

operation of re extinguishers.

Observe all re-warning and re-ghting procedures.

2.1 Designated use of the machine

The product has been built in accordance with state-

of-the-art standards and the recognized safety rules.

Nevertheless, its use may constitute a risk to life and

limb to the user or third parties, or cause damage to

the product and other material property.

The product must only be assembled in technically

perfect condition in accordance with its designated

use and the instructions set out in the operating and as-

sembly manual, and only by safety-conscious persons

who are fully aware of the risks involved in operating

the machine. Any functional disorders, especially

those affecting safety, should therefore be rectied

immediately.

The product is designed exclusively for tting to

machines approved by the manufacturer and for ac-

cessories approved by the manufacturer. Using the

machine for purposes other than those mentioned

above is considered contrary to its designated use. The

manufacturer/supplier cannot be held liable for any da-

mage resulting from such use. The risk of such misuse

lies entirely with the user. The machine is exclusively

intended for the private use.

Operating the machine within the limits of its designa-

ted use also involves observing the instructions set out

in the operating and assembly manual and complying

with the inspection and maintenance directives.

2 Fundamental safety instructions