ASAHI PENTAX AL-M2 Series User manual

PENTAX

AUTOMATIC

LEVEL

/1L-A12

SERIES

gL-Aia

•

AL-MSc

•

/IL-AIgs

INSTRUCTION

MANUAL

(For

proper

operation

of

instrument)

Pentax

automatic

level

AL-M2

series

consist

of

a

variety

of

instruments

in

order

to

comply

with

a

wide

range

of

surveying

from

second

or

third

order

leveling

surveying

to

civil

engineering

requiring

high

accuracy.

Our

surveying

instruments

are

precise

in

function

and

precision

made.

Survey¬

ing

instruments

do

not

either

work

well

nor

become

of

value

unless

they

are

carefully

handled

and

operated.

For

the

instrument

to

work

efficiently

and

be

useful

for

long

time,

read

through

this

instruction

book.

Storage

This

instrument

should

be

stored

in

a

dry,

dust-proof

room,

which

does

not

have

a

big

temperature

range.

When

the

instrument

is

stored

for

a

long

time,

it

must

occasionally

be

taken

out

of

the

case

and

air

circulated

freely

around

the

instrument.

When

storage

or

transportation

temperature

is

extremely

different

from

the

working

temperature,

the

instrument

must

be

allowed

to

come

to

the

ambient

temperature.

Exposure

time

required

is

approximately

one

minute

per

one

degree

temperature

difference.

Transport

For

shipment,

the

instrument

should

be

packed

with

cushioning

material

with

reasonable

thickness

on

all

sides.

Insurance

coverage

is

recommended.

Vehicle

transportation

does

not

require

packing

but

movement

should

be

restricted

by

securing

it.

When

heavy

vibration

or

rough

travel

is

encountered,

it

is

recommended

that

the

instrument

be

secured

in

a

padded

box.

Checking

Before

measurement,

an

instrument

should

be

examined

according

to

this

instruction

book.

If

necessary,

the

instrument

should

be

adjusted.

Even

a

new

instrument

or

completely

repaired

instrument

needs

to

be

checked.

This

proce¬

dure

is

also

recommended

during

long

intervals

of

non-use

or

after

long

journey.

At

least

once

per

year,

or

more

often,

it

is

recommended

that

the

instrument

should

be

checked

by

a

qualified

Pentax

dealer.

Unpacking

When

removing

an

instrument

from

its

carrying

case,

pay

attention

to

how

it

is

positioned

so

that

it

can

be

returned

properly.

Grasp

the

instrument

securely

when

removing

or

returning

it

from

or

to

the

case.

Setting

up

When

installing

or

removing

the

instrument

on

or

from

the

tripod,

the

instru¬

ment

should

be

securely

held

with

one

hand

while

the

other

hand

manipulates

tripod

center

screw.

The

instrument

should

never

be

left

on

the

tripod

without

being

fastened

down.

Failure

to

carry

out

these

instructions

can

result

in

a

bad

accident.

Careful

operation

and

handling

of

the

instrument

in

accordance

with

these

instructions

and

plain

common

sense

will

provide

long

and

useful

service.

-

2

-

Contents

1.

Features.4

2.

Description

.5

3.

Equipment.6

4.

Specifications

.7

5.

Operation

□

Preparation

for

surveying

1)

Setting

up

the

tripod

.8

2)

Setting

up

the

instrument.8

3)

Leveling

.9

□

Observation

1)

Reticle

collimation.9

2)

Sighting

.

10

3)

Reading

the

staff.

11

HI

Surveying

1)

Leveling

.

11

2)

Stadia

survey.

12

3)

Angle

measurement.

13

6.

Maintenance

and

packing

□

Maintenance.

14

□

Packing

.

14

7.

Precaution.

15

8.

Inspection

and

adjustment

□

Circular

level.

15

□

Leveling

line

of

sight.

16

9.

Optional

accessories

□

Electric

illumination

[EP].

18

□

Parallel

plate

micrometer

[SM3].

19

□

Diagonal

eyepiece

[SBL1]

.

21

-

3

-

1.

Features

■

Easy

to

operate

due

to

simple

design,

and

compact

and

light

construction,

■

The

telescope

is

of

dust

-

and

water

resistance,

enabling

use

of

the

instru¬

ment

in

the

rain

or

tunnel

with

humidity.

■

Minimum

focus

distance

is

extremely

short,

0.8m.

Anallactic

optics

of

the

telescope

makes

stadia

surveying

easy

as

the

stadia

constant

is

0.

■

With

special

alloy

ribbon

with

long-established

reputation,

a

newly

developed

automatic

compensator

having

magnet

damper

is

of

wire-

suspension

type

and

provides

extremely

stable

surveying

results

even

under

unfavorable

conditions

such

as

vibration,

■

Optical

collimator

provides

fast

and

accurate

sighting.

■

Concurved

foot

plate

fits

domed

head

tripod

as

well

as

flat-head

tripod.

■

Adjustable

reflecting

prism

permits

operator

to

observe

the

circular

level

without

changing

his

operating

position,

thus

enabling

easy

confirmation

of

leveling.

■

Clampless

horizontal

drive

screw

equipped

with

knobs

on

both

ends

pro¬

vides

endless

movement

of

the

telescope.

■

AL-M2C

with

a

horizontal

circle

permits

horizontal

angle

measurement

as

well

as

angle

setting.

■

AL-M2S

equipped

with

a

glass

circle

graduated

down

to

10'

or

10c

permits

angle

measurement

with

higher

accuracy.

Fine-coarse

focussing

screw

provides

fast

and

accurate

focussing.

■

Electric

illumination,

parallel

plate

micrometer

and

diagonal

eyepiece

are

available

as

optional

accessories.

-

4

-

2.

Description

Collimator

Circle

rotation

ring

Circle

reading

window

(For

AL-M2C,

AL-M2S

only)

(For

AL-M2C

only)

-

5

-

3.

Equipment

[T]

Standard

Equipment

Instrument.1

Carrying

case

.1

Objective

cap

.1

Sunshade

.

1

Plumb

bob

(AL-M2C,

M25

only)

.1

Screw

driver

.1

Adjusting

pins.2

Brush.1

Rain

cover

.1

Silicone

cloth.1

[2]

Optional

accessories

Tripod

(TS-3)

Parallel

plate

micrometer

(SM3)

Electric

illumination

(EP)

Diagonal

eyepiece

(SBL1)

6

-

4.

Specifications

AL-M2

AL-M2C

ALM2S

■

Telescope

(Internal

Anallactic

Optics)

Image

Erecting

Magnification

32

x

Objective

aperture

45mm

Resolving

power

2.5"

Field

of

View

2.3%

(2.3m

at

100m

or

2.3

feet

at

100

feet)

or

1

°2Q'

Minimum

focus

distance

0.8m

Stadia

ratio

1

:

100

Stadia

constant

0

■

Automatic

Compensator

Range

±12'

Setting

accuracy

±0.3"

Standard

deviation

1

km

double

run

levelling

±1.0mm

■

Circular

level

Sensitivity

872mm

■

Horizontal

Circle

—

metal

glass

Diameter

—

100mm

88mm

Graduation

—

1°

or

1G

10'

or

10C

Reading

method

—

Index

Index

Least

Reading

—

Tor

1G

10'or

10c

Estimation

Reading

—

0.1°

or

0.1G

V

or

1c

■

Tripod

attaching

screw

Thread

5/8"

x

11

■

Dimensions

&

Weight

Length

254mm

Width

140mm

Height

137mm

Weight

2.1

Kgs/4.6

lbs

2.3

Kgs/5.0

lbs

■

Case

350

(L)

x

210

(W)

x

200

(H)

mm,

2.5

Kgs/55

lbs

Tripod

TS-3

1-1.7m

Length,

4.5

Kgs/9.9

lbs

7

—

5.

Operation

[T]

Preparation

for

surveying

1)

Setting

up

the

tripod

©

Prepare

the

tripod

having

a

center

locking

screw

with

5/8"x11

thread.

©

Dig

the

legs

firmly

into

the

ground

and

adjust

the

tripod

to

the

height

suitable

for

observation

when

the

instrument

is

mounted.

©

For

angle

measurement,

set

the

tripod

so

that

the

center

of

the

tripod

head

is

positioned

right

above

the

ground

point.

2)

Setting

up

the

instrument

©

Mount

the

instrument

on

the

tripod

head

and

secure

it

using

a

center

lock

screw.

{Fig,

4)

©

Suspend

the

plumb

bob

from

the

hook,

adjusting

the

length

of

the

string,

(for

angle

measurement)

©

Loosing

the

center

lock

screw,

move

the

instrument

with

the

tips

of

fingers.

Tighten

it

as

a

tip

of

plumb

bob

coincides

with

the

ground

point

(for

angle

measurement)

-

8

-

3)

Leveling

(D

Place

the

telescope

in

parallel

to

the

line

connecting

two

optionally

selected

leveling

screws,

and

turn

them

to

move

the

bubble

of

the

circular

level

at

a

position

even

to

the

left

and

the

right.

(Fig.

A)

■

Turn

the

two

leveling

screws

in

opposite

directions.

©

Turning

a

remaining

leveling

screw,

shift

the

bubble

to

the

center.

(Fig.

B)

CD

Make

sure

that

the

bubble

stays

at

the

center

of

the

circle

even

after

turning

the

telescope

180°.

■

See

arrows

in

Fig.

A

and

B

for

the

relation

between

the

direction

of

leveling

screw

rotation

and

the

bubble

shifting

direction.

■

If

the

bubble

is

out

of

the

center

in

(5),

"adjustment

of

the

circular

level"

on

page

15

is

needed.

[

2

]

Observation

1)

Reticle

collimation

©

Remove

the

objective

cap.

If

necessary,

attach

the

sunshade.

©

Directing

the

telescope

to

the

bright

background,

rotate

the

eyepiece

coun¬

terclockwise

to

draw

out

the

eyepiece

ring.

©

While

looking

into

the

eyepiece,

rotate

it

clockwise

until

the

cross

hair

of

the

reticle

comes

to

its

extreme

sharpness.

■

It

is

advisable

to

relax

when

looking

into

the

eyepiece.

An

intense

look

at

the

reticle

may

tend

to

cause

parallax

or

eye

fatigue.

-

9

-

Cross

hairs

Fig.

6

Field

of

view

2)

Sighting

©

Sight

the

telescope

at

the

object

looking

through

the

collimator.

©

Looking

into

the

eyepiece,

rotate

the

focussing

knob

until

the

object

be¬

comes

dearly

visible.

Make

sure

that

the

relation

between

the

object

and

the

cross

hair

does

not

change

even

when

you

move

your

eye

up

or

down¬

ward.

(Fig.

7)

■

If

parallax

exists

in

®,

the

relation

between

the

object

and

the

cross

hair

may

change.

This

may

cause

surveying

error.

Fig.

7

-

1

0

-

3)

Reading

the

staff

How

to

read

the

graduation

on

the

staff.

Reading

value

2.195m

■

Reading

of

the

staff

should

be

done

at

the

center

of

the

cross

hair

on

the

reticle.

[

3

]

Surveying

1)

Leveling

•

How

to

get

the

difference

in

height

and

the

elevation

Difference

in

height

(Ah)

^

backsight

(b)

-

foresight

(f)

Elevation

at

point

B

(he)

=

Elevation

at

point

A

(hA)

+

Ah

S

(1):

Staff

(I)

S

(IT):

Staff

(II)

I:

Instrument

B.S:

Backsight

(Staff

reading

at

the

point

where

eleva¬

tion

is

specified.)

F.S:

Foresight

(Staff

reading

at

the

point

where

elevation

is

unspecified.)

hA

Fig.

9

Datum

level

i

I

Difference

in

height

(AH)

=

£Ah

■

Set

the

instrument

at

almost

middle

of

two

staffs.

■

When

reading

the

staff,

try

to

get

least

reading

by

tilting

the

staff

back

and

forth

slightly.

■

For

more

precise

surveying,

use

the

double

run

method.

2)

Stadia

survey

Distance

from

the

instrument

to

the

staff

can

be

measured

by

the

stadia

hairs

visible

within

the

field

of

view

of

the

telescope.

■

To

measure

the

distance

is

easy

as

stadia

constant

is

0.

S:

Horizontal

distance

f

:

Difference

in

reading

between

of

upper

and

of

lower

stadia

lines

S=100

t

(A)

Fig.

11

(B)

-

1

2

-

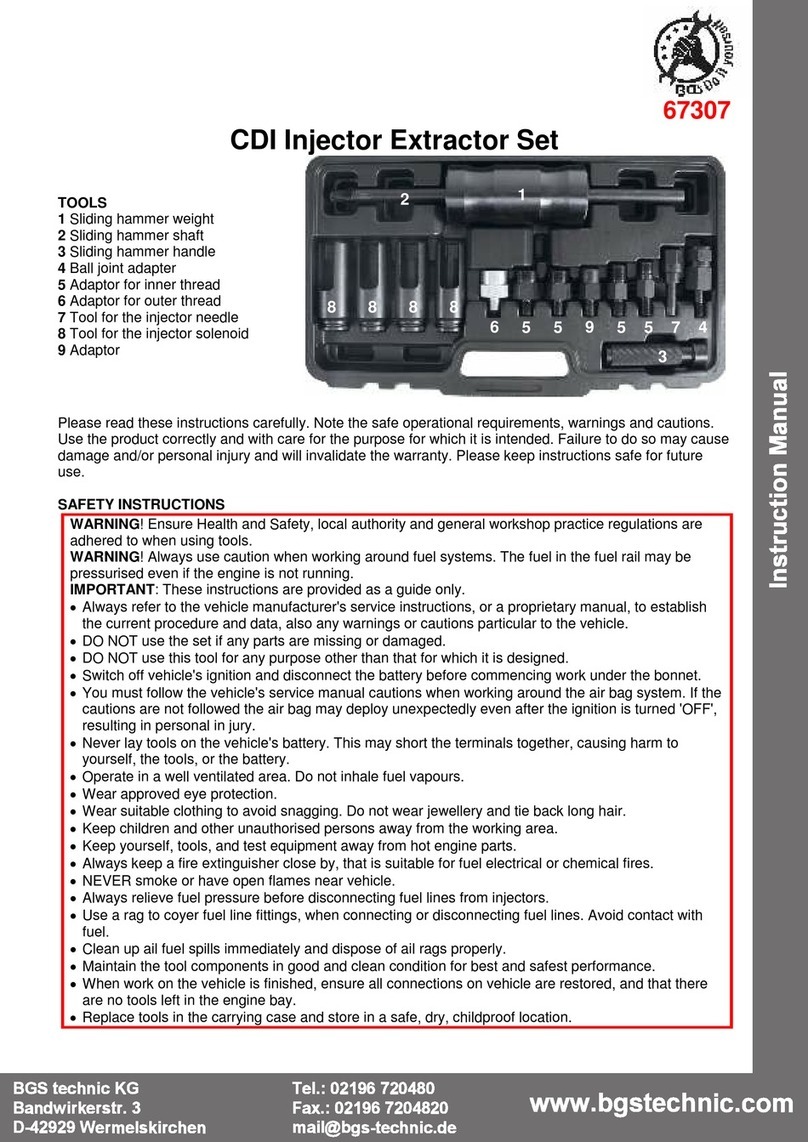

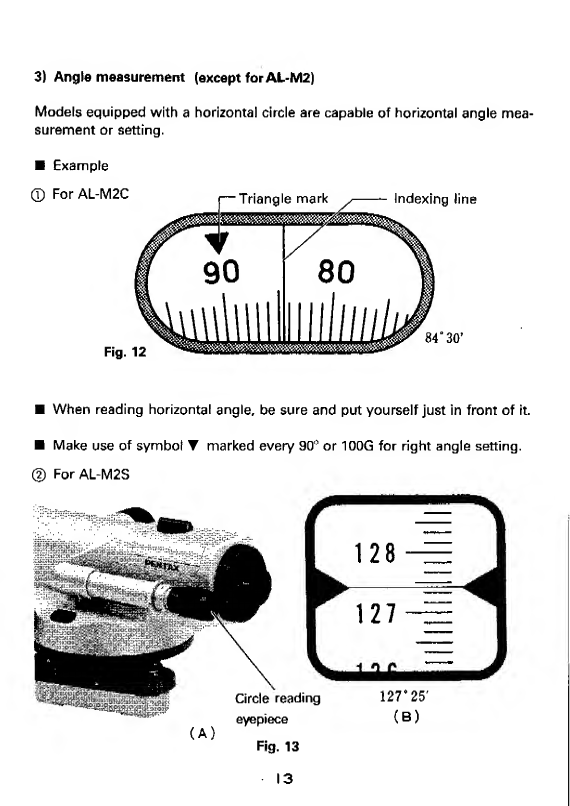

3)

Angle

measurement

(except

for

AL-M2)

Models

equipped

with

a

horizontal

circle

are

capable

of

horizontal

angle

mea¬

surement

or

setting.

■

Example

■

When

reading

horizontal

angle,

be

sure

and

put

yourself

just

in

front

of

it.

■

Make

use

of

symbol

T

marked

every

90°

or

100G

for

right

angle

setting.

©

For

AL-M2S

6.

Maintenance

and

packing

[T]

Maintenance

©

Clean

dust

or

water

from

the

instrument

and

then

put

it

back

to

the

case

after

using

it.

(2)

Brush

dust

off,

wipe

off

moisture

on

exposed

parts

with

a

soft

cloth.

<D

Wipe

off

the

moisture

on

the

surface

of

the

lenses

with

a

cotton

cloth,

using

light

pressure,

after

brushing

the

dust

off.

[

2

]

Packing

©

Gently

put

the

instrument

into

the

case,

facing

focussing

knob

toward

you.

©

Close

the

case

and

secure

the

latch.

7.

Precaution

O

Attach

the

sunshade

to

the

telescope

to

avoid

the

direct

sunlight

when

high

precise

survey

needed.

<0

Operate

the

instrument

carefully.

Do

not

apply

excessive

pressure

to

it.

O

Store

the

instrument

in

a

dry

place,

removing

dust

or

moisture

after

use

of

it.

O

Be

careful

not

to

subject

the

instrument

to

impact

or

vibration

during

trans¬

port.

O

When

moisture

or

disorder

is

found

inside

the

lens,

contact

your

dealer,

do

not

attempt

to

dismantle

the

instrument

by

yourself.

<0

When

any

malfunction

due

to

falling

down

or

some

other

cause

is

recog¬

nized,

contact

your

dealer,

do

not

attempt

to

forcibly

dismantle

the

instru¬

ment

by

yourself.

O

Check

all

parts

of

the

tripod

are

firmly

secured.

8.

Inspection

and

adjustment

[7]

Circular

level

1)

Inspection

©

Setting

the

instrument

on

the

tripod,

level

it

so

that

the

bubble

of

circular

level

is

positioned

at

the

center

of

the

circle.

(Refer

to

P.9

"Leveling".)

©

Turn

the

telescope

180°.

©

No

further

adjustment

is

necessary

if

the

bubble

stays

at

the

center

of

the

circle.

2)

Adjustment

©

if

the

bubble

moves

out

of

the

center

in

the

circle,

turn

the

leveling

screw

to

shift

the

bubble

halfway

back

after

taking

off

the

reflecting

prism.

(Fig.

A)

©

Shift

the

bubble

remaining

halfway

to

the

center

by

turning

adjustment

screws.

(Fig.

B)

©

Turn

the

telescope

180°

to

check

to

see

if

the

bubble

stays

at

the

center

of

the

circle.

®

Repeat

again

from

©

should

the

bubble

move.

-

15

■

When

doing

adjustment,

finish

screws

being

firmly

tightened.

[

2

]

Leveling

line

of

sight

Target

plate

Approx.

2m

1)

Inspection

(T)

Prepare

two

same

target

plates.

Setting

up

the

instrument

midway

between

two

walls

at

a

distance

of

50

to

100

meters,

level

it.

(Fig.

16(A))

(2)

Sighting

both

walls

alternately*

adjust

the

target

plates

to

the

height

so

that

readings

of

the

target

plates

are

identical,

and

secure

them

in

position.

(5)

Move

the

instrument

to

a

position

approx.

2

meters

from

one

target

plate

and

level

it.

(Fig.

16(B))

®

Read

both

target

plates.

(

5

)

No

adjustment

is

necessary

if

readings

of

both

target

plates

are

identical.

16

2)

Adjustment

©

Sight

the

farthest

target

plate

through

the

telescope.

(

2

)

Remove

the

eyepiece

cover,

rotate

the

reticle

adjusting

screw

using

the

adjusting

pin

and

adjust

the

reading

to

be

identical

to

that

of

the

nearest

target

plate.

(D

After

checking

that

correct

adjustment

has

been

made,

mount

the

eyepiece

cover

back

in

place.

Adjustment

screws

17

9.

Optional

accessories

[7]

Electric

illumination

[EP]

Electric

illumination

permits

surveying

work

in

a

tunnel

or

any

dark

place

by

way

of

illuminating

the

reticle.

Light

source

.

Green

LED

Power

supply

...

Two

1.5V

dry

batteries

(SUM-3)

(p

It

can

be

mounted

in

the

same

way

that

a

sunshade

is

attached

to

the

tele¬

scope

objective.

(

2

)

Turn

the

switch

on

and

adjust

brightness

by

rotating

illuminator

knob

while

looking

into

the

telescope.

■

Remove

battery

when

device

will

not

be

used

for

an

extended

period

as

extended

storage

may

cause

damage

to

the

device

due

to

leakage

of

battery

acid.

-

Electric

illumination

\T}

Parallel

plate

micrometer

[SM3]

Parallel

plate

micrometer

is

used

for

leveling

or

civil

engineering

work

requiring

precise

accuracy.

With

a

bright

microscale

etched

on

optical

glass,

it

provides

reading

down

to

0.1mm.

■

Use

the

instrument

with

wedge

type

reticle

for

use

of

the

parallel

plate

mic¬

rometer.

■

Replacement

of

the

reticle

if

your

instrument

is

equipped

with

ordinary

reticle

should

be

made

at

your

dealer.

■

Use

second

order

staff

or

equivalent

to

it,

not

ordinary

one.

Operation

(T)

Mount

the

parallel

plate

micrometer

horizontally

on

the

object

and

counter¬

weight

on

the

eyepiece

of

the

telescope,

respectively

and

secure

both.

(Fig.

19)

(

2

)

Turning

the

micrometer

knob,

accurately

put

the

staff

graduation

between

the

wedge-shaped

lines,

(Fig.

20)

(5)

Read

the

staff

<A|

and

microscale

(B}

.

micrometer

Fig.

19

-

19-

This manual suits for next models

3

Table of contents