HBE SOFTEX Service manual

1. FUNCTIONAL DESCRIPTION

The Softex® coupling is a torsionally flexible, puncture-

proof three part claw coupling.

Due to the elastic gear ring, it enables to dampen im-

pacts, torsional vibrations, as well as noises.

Furthermore, the gear ring has a high resistance, elastici-

ty as well as good resistance to oils, greases, a variety of

solvents, ozone and influences of the weather.

Due to the construction of the coupling (hub / elastic

gear ring / hub), an angular resp. a radial misalignment

of the shafts to be connected as well as expansions will

be compensated.

The operating temperatures are between -50°C and

+120°C, depending on the type of gear ring. Short term

temperature peaks up to +150°C are admissible.

MATERIALS

Cast Iron (GG)

Spheroidal Cast Iron (GGG)

Steel (St)

Stainless Steel (VA)

Sinter Steel (S)

Type:

Clamping Hub (for splines)

OPERATING AND MOUNTING

INSTRUCTION SOFTEX®

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

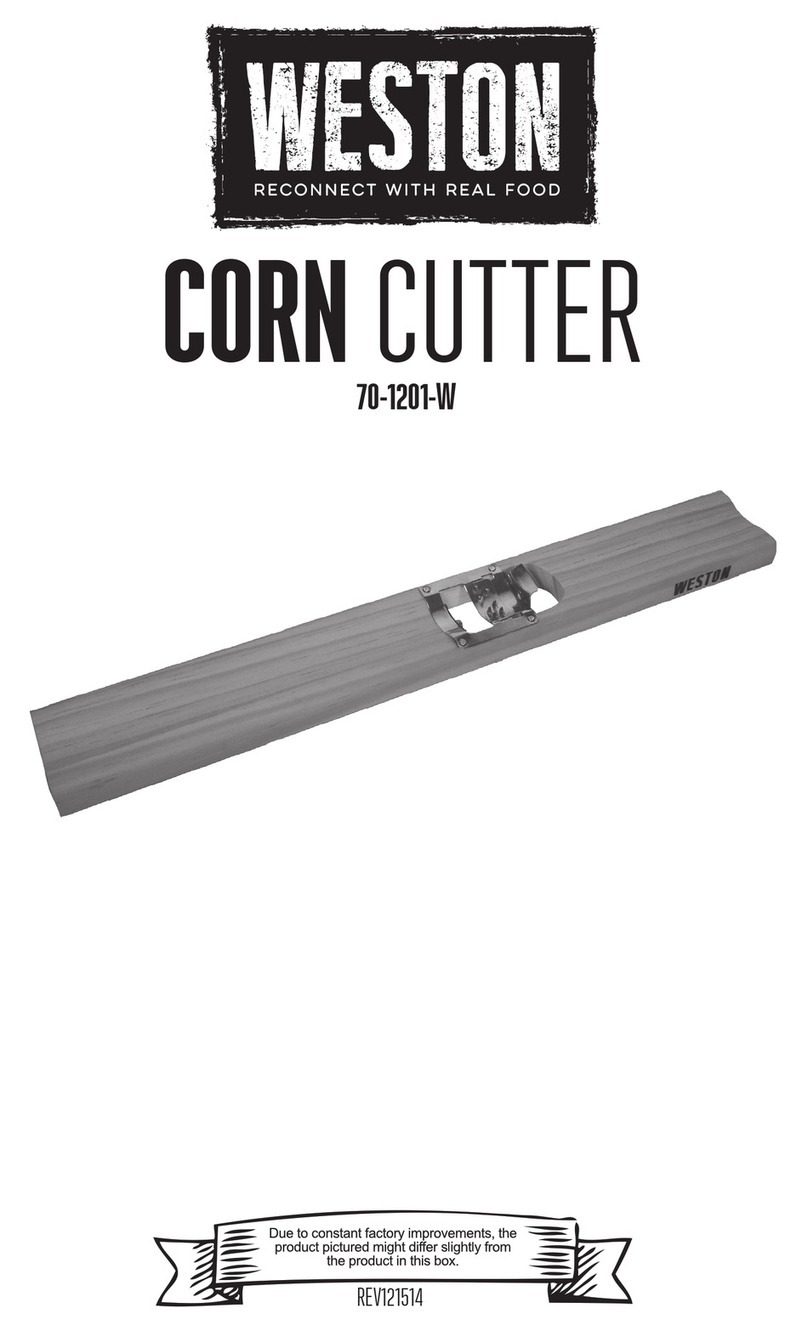

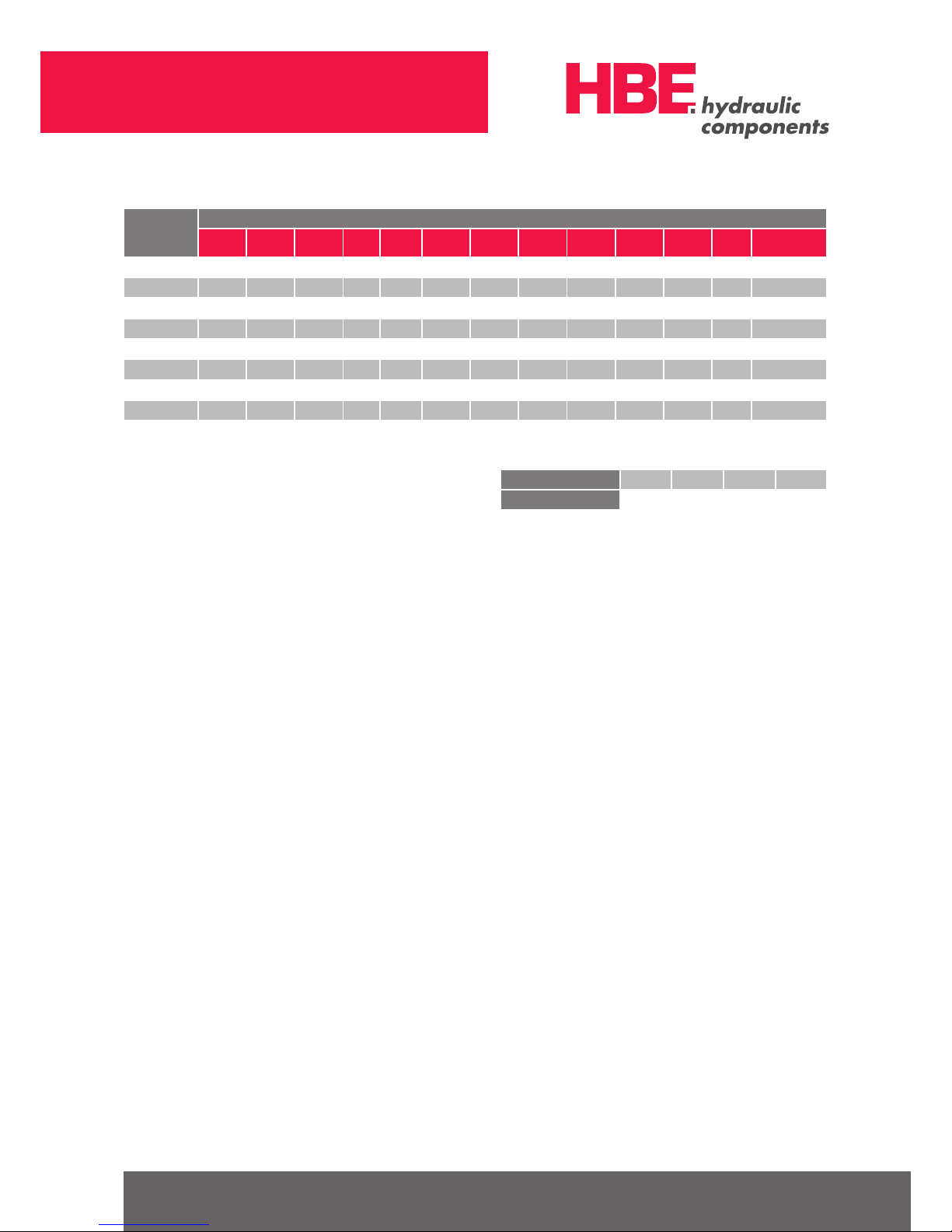

2. TECHNICAL DATA

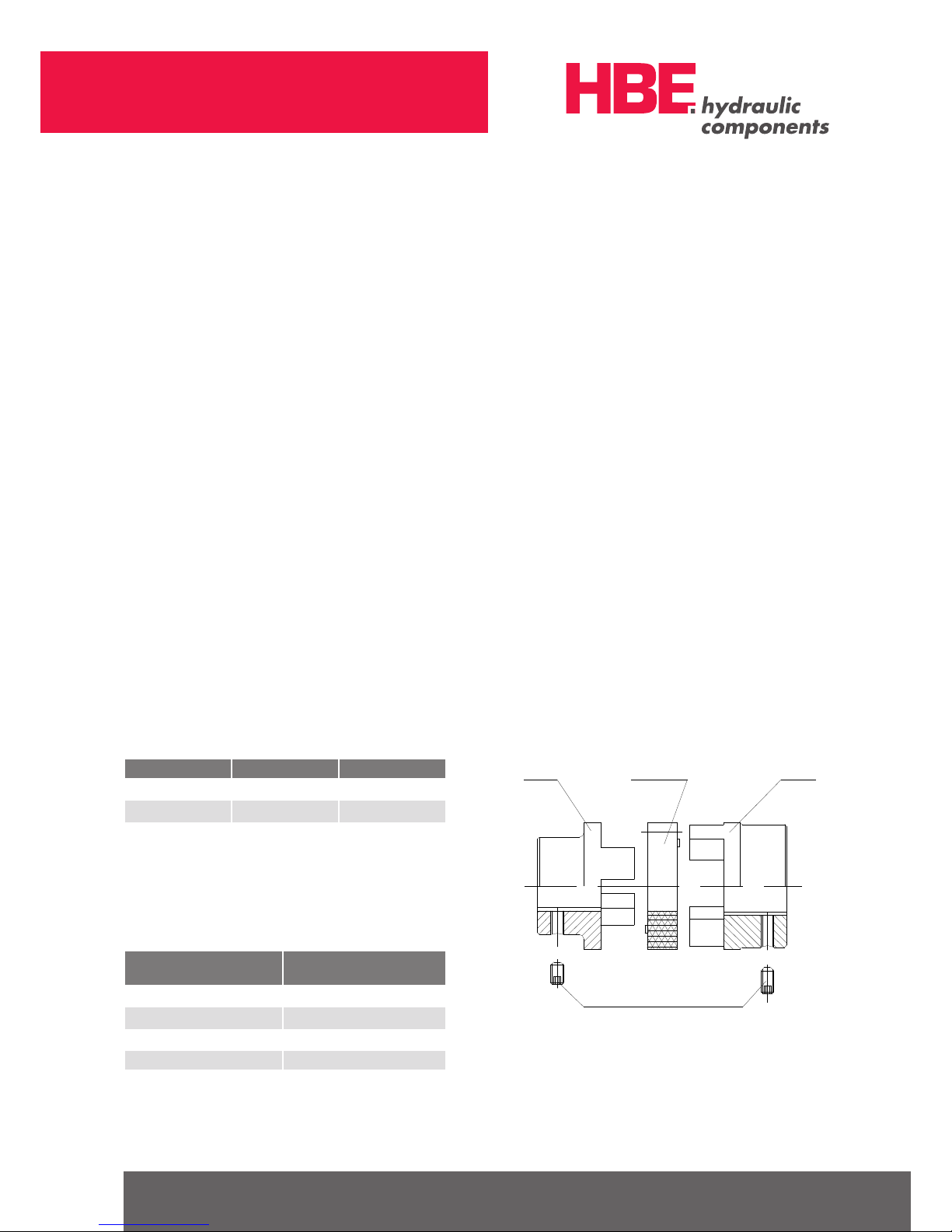

E

b s

L

Zahnkranz

L 1

s

Ø

A Ø

B

Ø

d 1

Nabe

AG

Ø

d

h

L 2

Ø

B1

Nabe

B

G

Ø

d 2

f 1 M

øA

øB

ød1

ødh

ød2

øB1

Hub Hub

Gear Ring

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

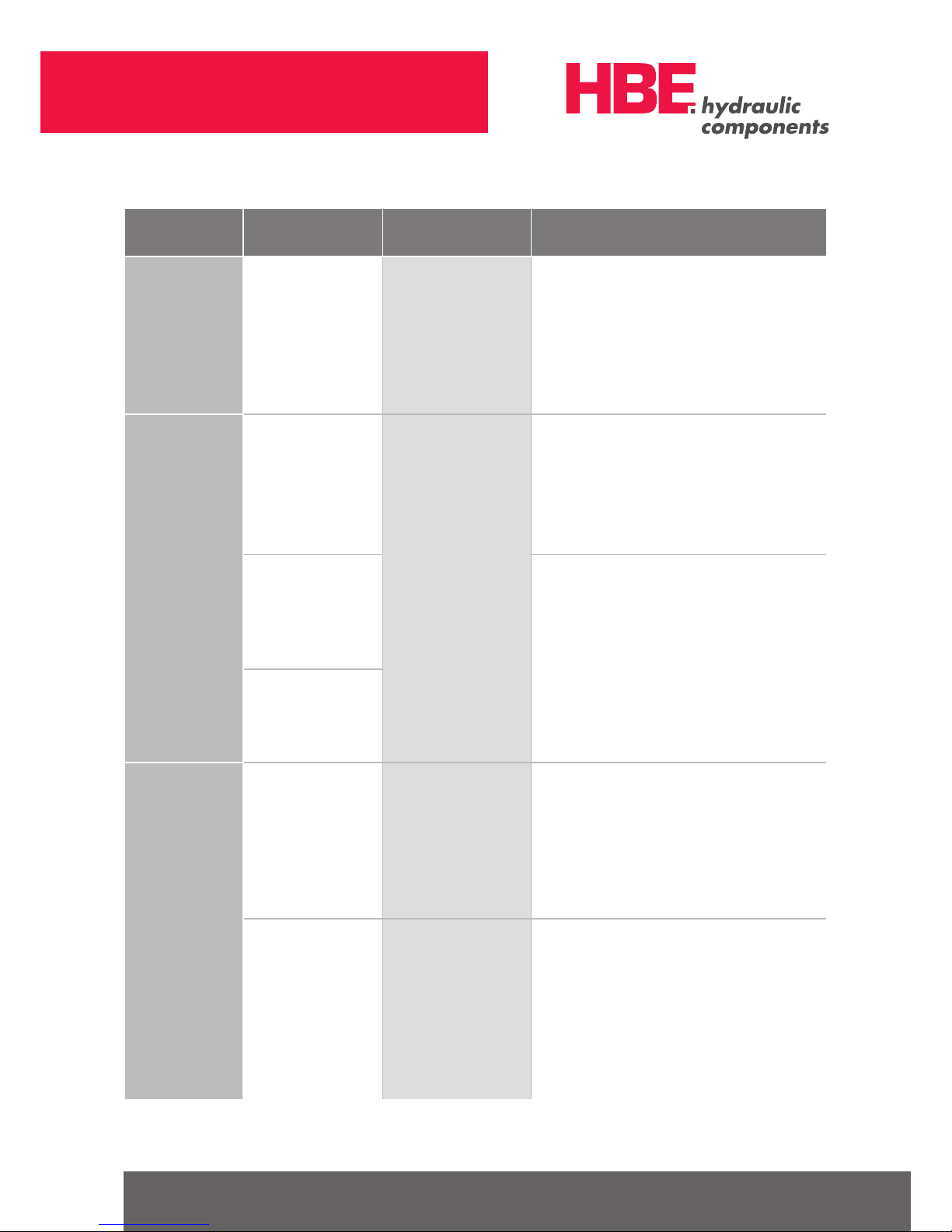

TYPE HARDNESSES OF

GEAR RING

BORES DIMENSIONS

mm

NOMINAL TORQUE

Nm

FINISH

BORE

d 1

FINISH

BORE

d 2

A B B1L

L1

+

L2

E s b G dh g f f1 M

92 Sh A

95 Sh A

98 Sh A

64 Sh D

min

max

min

max

14/16 7. 5 -12. 5 - - 4 16 30 - - 35 11 13 1.5 10 -10 M4 5 5 M3

19/24 10 -17 - - - 6 24 40 - - 66 25 16 212 -18 M5 10 12 M6

24/30 35 -60 75 - - 8 32 55 - - 78 30 18 214 -27 M5 10 14 M8

28 / 3 8 95 -160 200 - - 10 38 65 - - 90 35 20 2.5 15 -30 M6 15 15 M8

38 / 4 5 190 -325 405 14 38 40 45 80 66 78 114 45 24 318 37 38 M8 15 20 M10

42/ 5 5 265 -450 560 16 42 45 55 95 75 93 126 50 26 320 40 46 M8 20 20 M10

48 / 60 310 -525 655 19 48 50 60 105 85 103 140 56 28 3.5 21 45 51 M8 20 30 M10

5 5 / 70 375 -625 825 22 55 60 70 120 98 118 160 65 30 422 52 60 M10 20 25 M12

6 5 / 75 625 900 -1175 25 65 70 75 135 115 132 185 75 35 4.5 26 59 68 M10 20 30 M12

75/90 975 150 0 -2400 30 75 80 90 160 135 158 210 85 40 530 65 80 M10 25 30 M16

90/100 2400 3600 -4500 - - 45 100 200 -170 245 100 45 5.5 34 81 100 M10 25 30 M20

100/110 3300 4950 - - - - 45 110 225 -180 270 110 50 638 89 113 M12 30 - -

110/125 4000 6000 - - - - 60 125 255 -200 295 120 55 6.5 42 96 127 M16 35 - -

125/145 5000 7500 - - - - 60 145 290 -230 340 140 60 746 112 147 M16 40 - -

FLANGE HUB

Z=Anzahl ØG

Z = Anzahl ØG

b

L

l 1

s

Ød

ØA

ØD 1

ØD 2

ØF

ØA 1

ØG

l 2

H7

90/100 FA

nur bei Ausführung

2x M12 durchgehend

Types 75/90 – 90/100 FA Types 28/ 38 – 65/75 FA

Z= Quantity øG

Z= Quantity øG

øA

øD1

øD2 H7

ød

øF

øA1

øG

2x M12 through only

in case of type

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

TYPE DIMENSIONS mm

A A1L L1s b F l2D1D2d G Z

28 / 38 FA 100 65 2 7. 5 10 2.5 15 39 1.5 80 65 30 7 6

38 / 45 FA 115 80 31 10 318 48 1.5 95 80 38 7 6

42/ 55 FA 140 95 35 12 320 57 2115 95 46 9 6

48 / 60 FA 150 105 36.5 12 3.5 21 63 2125 105 51 9 8

55 / 70 FA 175 120 42 16 422 74 2145 120 60 11 8

65 / 75 FA 190 135 46.5 16 4.5 26 83 2160 135 68 11 10

75 / 90 FA 215 160 54 19 530 98 2.5 185 160 80 14 10

90 / 100 FA 260 200 59.5 20 5.5 34 122 3225 200 100 14 12

THREAD M6 M8 M10 M12

TORQUE Nm 14 35 69 120

3. INDICATIONS

3.1 GENERAL INDICATIONS

Before initial operation, the installation instructions must

be read carefully. Please pay attention to the security

and warning indications. The Softex® coupling is appro-

ved for application in hazardous areas.

Please pay special attention to the indications and

prescriptions concerning security (Item 6). This operating

and mounting instruction is part of the delivery extent and

must be kept carefully.

Tightening torque for the fixing screws DIN 912 – 10.9

3.2 WARNING AND INDICATION SIGNS

Passages with following indications must be especially

paid attention to.

DANGER ! Danger of injury for persons

ATTENTION! Engine trouble possible

INDICATION! Important items

CAUTION! Indications to protection in

hazardous areas

3.3 INDICATIONS OF RISKS

DANGER!

Due to the high risk of injury by rotating parts, you

must ensure that the complete system is protected

from accidental activation during mounting, service

and maintenance. Please imperatively pay attention

to the following safety information:

• During all activities with and at the coupling, please

especially pay attention to the safety regulations.

• Before starting the activities at the coupling, the power

unit must be switched off.

• The power unit must be protected from unintentional

switching on by labels or removing of the protector.

• The unintentional contact of a running coupling must be

prevented by appropriate safety devices.

• In case of operating couplings please pay attention to

a sufficient safety clearance.

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

3.4 USAGE

The following items must be paid attention to before

mounting, operation or service of the coupling.

• The operating and mounting instructions are to be read

imperatively.

• Operations must only be made by qualified personnel.

The coupling must only be applied in accordance to its

corresponding technical data. Constructional changes of

the coupling parts without any permission by the manufac-

turer are illegal and result in loss of warrenty.

4. STORAGE

Due to the corrosion protection which must not be da-

maged, the coupling can be stored for approx. 6 – 12

months at a dry place.

The gear rings (Polyurethane) keep their qualities in case

of a corresponding storage for approx. 5 years.

ATTENTION!

It must be ensured that there is no condensation in

the storage rooms. A relative humidity of less than

65 % is favourable.

Furhtermore, please ensure that there are no ozone

generating devices, such as illuminants or high

voltage devices in the storage rooms.

5. MOUNTING

5.1 MOUNTING OF COUPLING

Basically, the coupling is supplied in component parts.

Before mounting, the coupling must be checked for com-

pleteness.

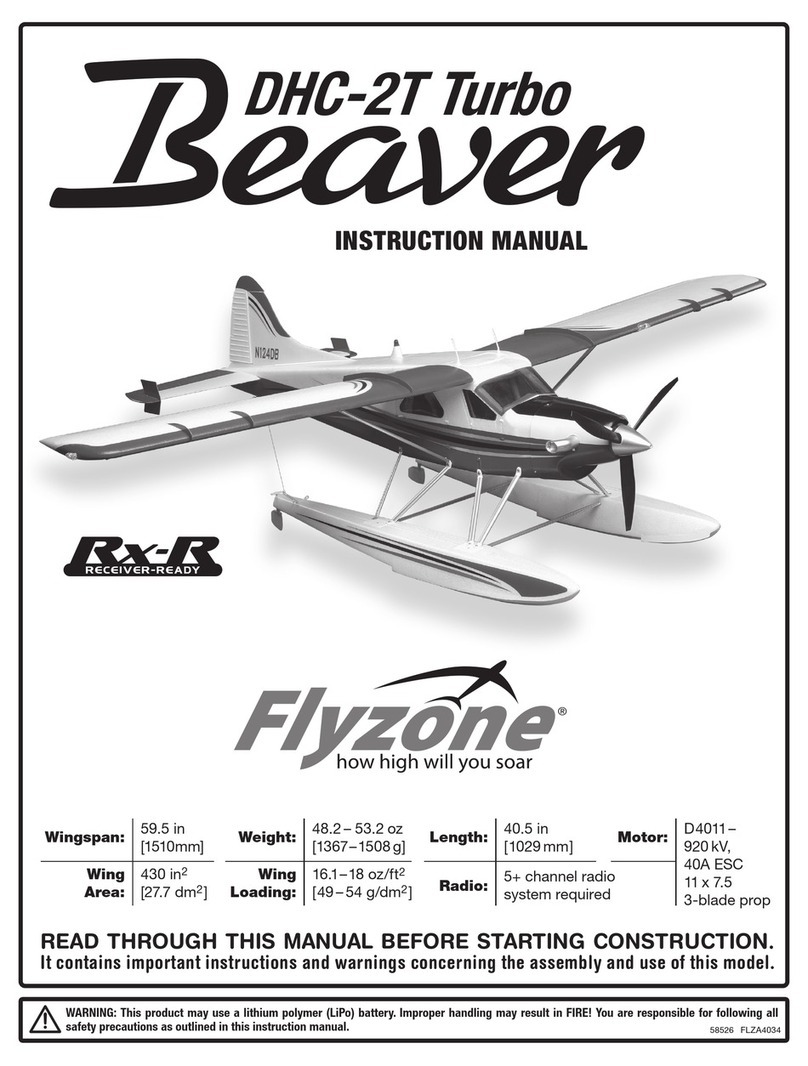

Distinguishing features of the gear rings (Item 2)

ITEM PIECES DENOMINATION

11 2Hub

2 1 Gear Ring

3 2 Set screw or

Cheese head screw

SHORE HARDNESS

(SHORE)

MARKING

(COLOUR)

80 SH A blue

92 Sh A white

95/98 Sh A red

64 Sh D green

Gewindestift oder

Zahnkranz

1

A- Nabe

3

2

B-Nabe

3

1

bei Klemmnabe Zylinderschraube

A-Hub B-HubGear Ring

Set Screw or

Cheese head screw in case of Clamping Hub

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

5.2 CHANGES OF COUPLING

DANGER!

A change at the coupling parts is only permitted

after having checked with the manufacturer.

For making the shaft bore by the user, please pay attenti-

on to the following items:

• The maximum admissible bore diameter d1 + d2 (see

Technical Data) must not be exceeded. In case of

disregard of these values, the coupling might break.

Flying fragments can cause serious personal injuries.

This concerns all materials.

• The predetermined planning and rotation accuracy of

the manufacturer must be adhered to.

• For making the finish bore, a careful alignment must be

made.

• For the axial safety device, please use a locking screw.

• If using a locking screw, following tightening torques

must be kept (see table):

5.3 MOUNTING

INDICATION!

Before mounting, we recommend to check the bores,

shaft, hub and feather key for accuracy.

A heating of the hubs to approx. 80°C eases the fitting

onto the shaft.

DANGER!

In order to avoid burnings by the contact with ted

hubs, please wear safety gloves.

CAUTION!

Please pay attention to the danger of ignition in

hazardous areas.

ATTENTION!

When mounting the coupling, please ensure that the

dimension E (see Technical Data) must absolutely be

kept, so that the gear ring is axially movable during

operation. Disregard might lead to damages.

• After mounting of the hubs to the shafts of the drive and

load side, the dimension “E” must be adjusted by relo-

cation of the aggregates or the hubs on the shafts.

• Shafts with inserted feather key and a smaller diameter

than the inner diameter of the gear ring dh may reach

into the gear ring. The distance between the shafts must

not be lower than 50% of the dimension “E”.

• For securing the hubs by relocation, please tighten the

locking screw with corresponding starting torque

(Table 5.3).

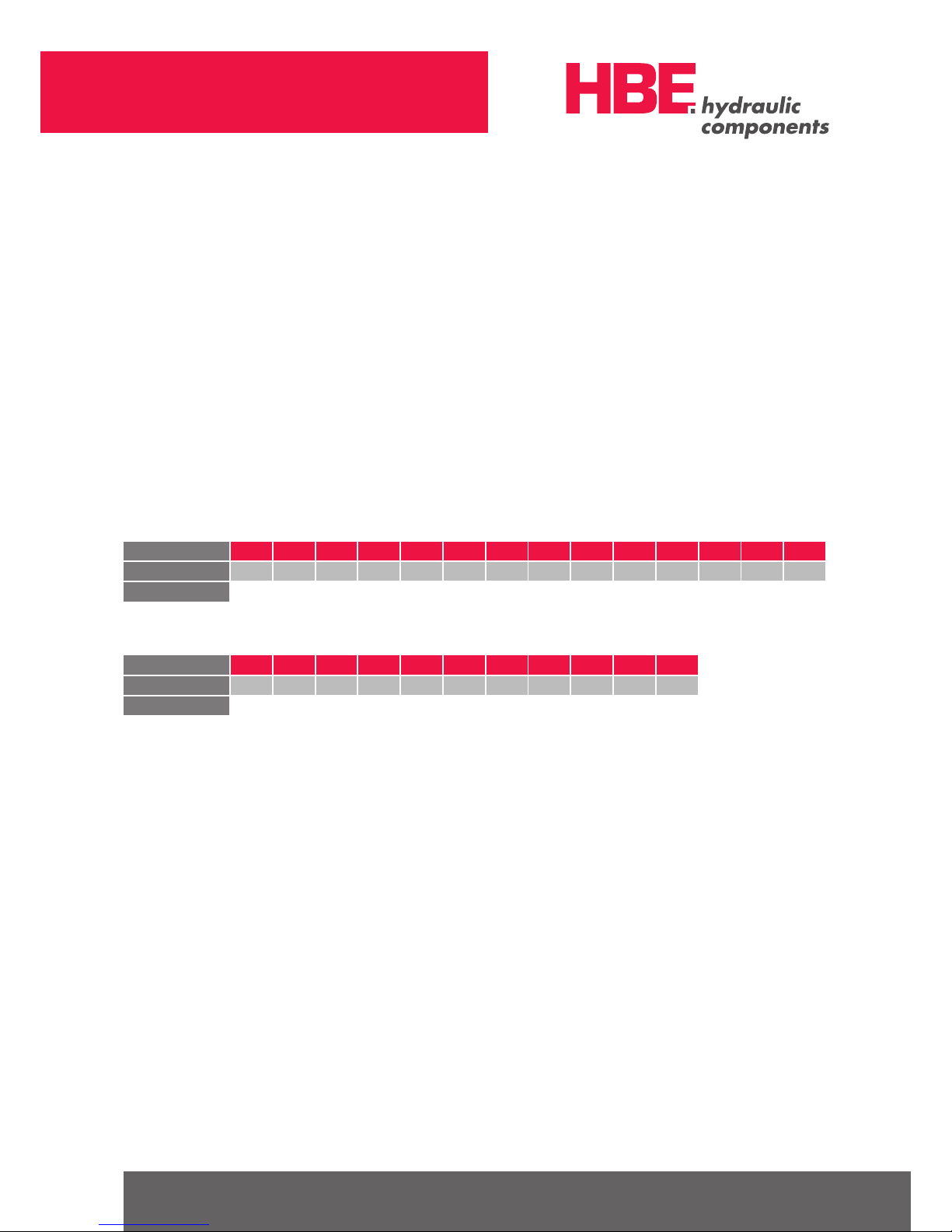

TYPE 14 19 24 28 38 42 48 55 65 75 90 100 110 125

THREAD M4 M5 M5 M6 M8 M8 M8 M10 M10 M10 M10 M12 M16 M16

TORQUE Nm 1.5 2 2 4,8 10 10 10 17 17 17 17 40 80 80

TYPE 14 19 24 28 38 42 48 55 65 75 90

THREAD M3 M6 M8 M8 M10 M10 M10 M12 M12 M16 M20

TORQUE Nm 1.34 10.5 25 25 60 60 60 100 100 250 490

Tightening torques of the locking screws

Tightening Torques of the locking screws for clamping hubs

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

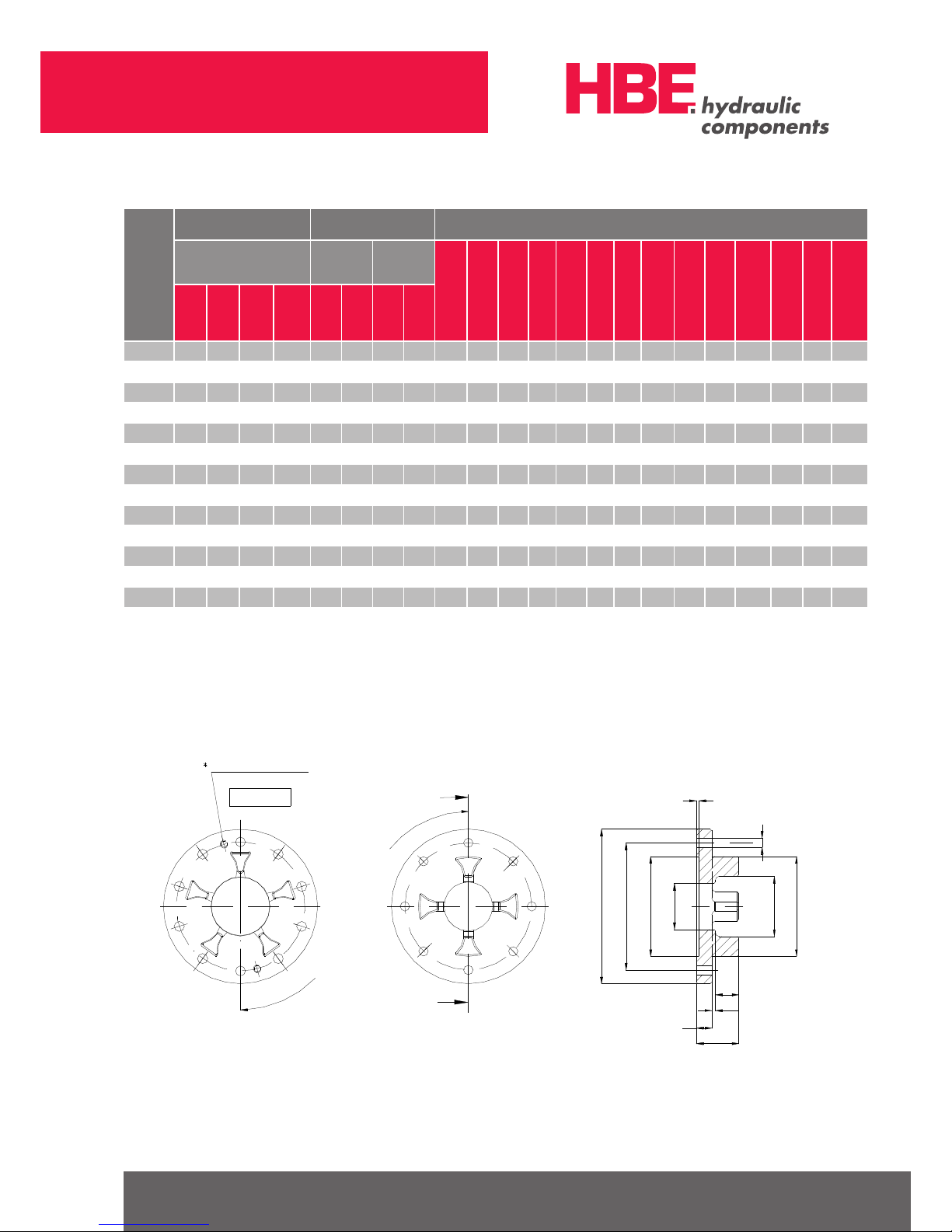

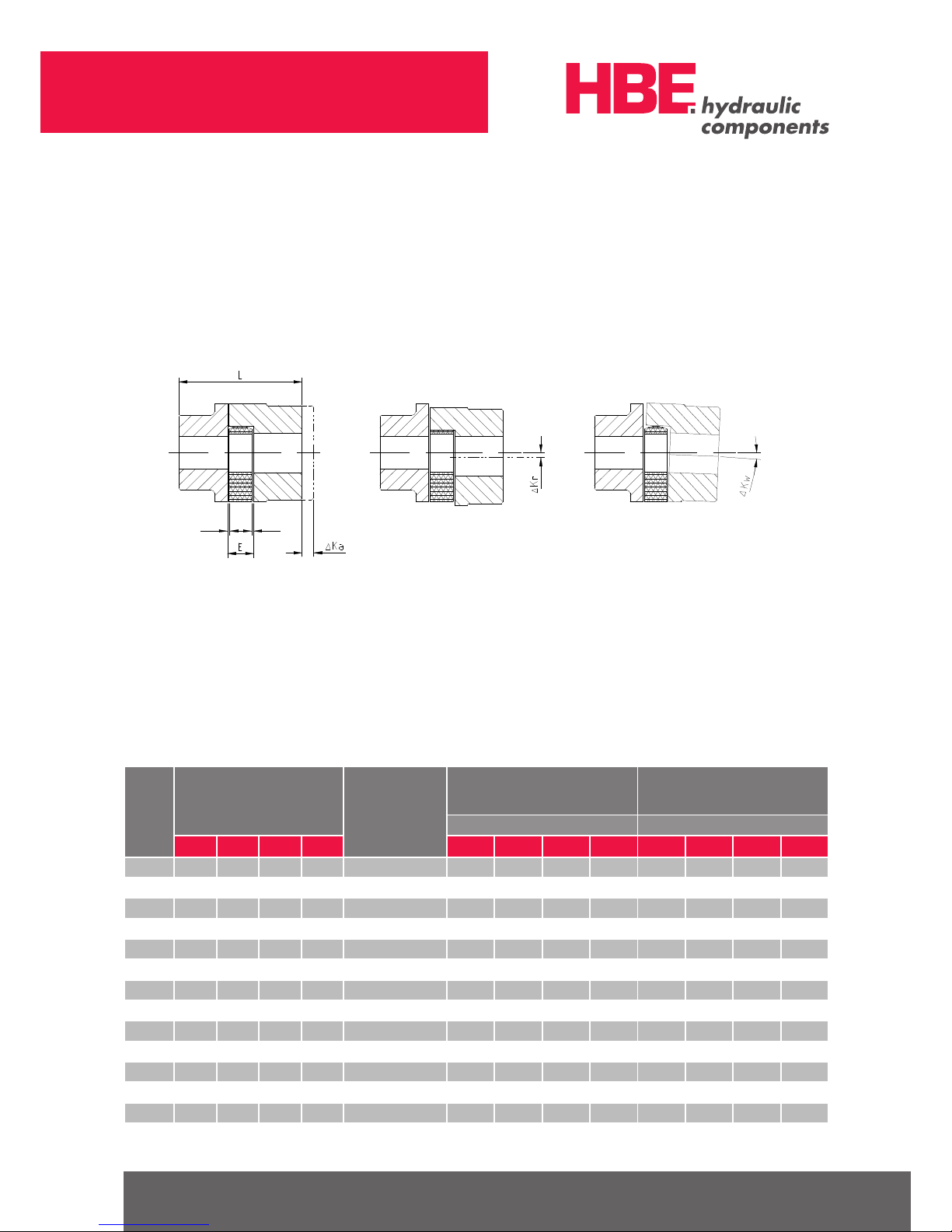

5.4 VALUES OF MISALIGNMENT

CAUTION!

During operation in hazardous areas, the ends of

the shaft must imperatively be aligned. Furthermore,

the durability of the coupling can be increased by

an exact alignment. Please keep the recommended

values of misalignment (see table).

Exceeding of the values will lead to damages on the

coupling. For operation in hazardous areas of ex-

plosion groups IIC (Designation II 2G c IIC T4), the

values must be reduced by 50%.

The values of the table are valid for an operating tempe-

rature T = +30°.

ATTENTION!

In case of an increase of the operating temperature,

the maximum permissible values of radial alignment

and misalignment of angle must be multiplied by the

temperature factor.

b

s s

Axial Misalignment Radial Misalignment Misalignment of Angle

TYPE DIMENSIONS

mm

AXIAL

MISALIGNMENT

∆KA

mm

RADIAL MISALIGNMENT ∆KR

mm

MISALIGNMENT OF ANGLE

∆KW

°

SPEED1 (1/MIN) SPEED1 N (1/MIN)

L E b s 750 1000 1500 3000 750 1000 1500 3000

14/16 35 13 10 1.5 1.0 0.22 0.20 0.16 0 .11 1.1 1.1 0.9 0.8

19/24 66 16 12 2.0 1.2 0.27 0.24 0.20 0.13 1.1 1.1 0.9 0.8

24/30 78 18 14 2.0 1.4 0.30 0.27 0.22 0.15 1.1 1.0 0.9 0.8

28 / 3 8 90 20 15 25 1.5 0.34 0.30 0.25 0.17 1.1 1.0 0.9 0.8

38 / 4 5 114 24 18 3.0 1.8 0.38 0.35 0.28 0.19 1.1 1.1 1.0 0.8

42 / 5 5 126 26 20 3.0 2.0 0.43 0.38 0.32 0.21 1.1 1.1 1.0 0.8

48 / 60 140 28 21 3.5 2.1 0.50 0.44 0.36 0.25 1.2 1.2 1.1 0.9

5 5 / 70 160 30 22 4.0 2.2 0.54 0.46 0.38 0.26 1.2 1.2 1.1 1.0

6 5 / 75 185 35 26 4.5 2.6 0.56 0.50 0.42 0.28 1.2 1.2 1.2 1.0

75/90 210 40 30 5.0 3.0 0.65 0.58 0.48 0.32 1.3 1.2 1.2 1.0

90/100 245 45 34 5.5 3.4 0.68 0.60 0.50 0.34 1.3 1.3 1.2 1.1

100/110 270 50 38 6.0 3.8 0.71 0.64 0.52 0.36 1.3 1.3 1.2 1.1

110/125 295 55 42 6.5 4.2 0.75 0.67 0.55 0.38 1.3 1.3 1.3 1.1

125/145 340 60 46 7. 0 4.6 0.80 0.70 0.60 -1.3 1.3 1.3 -

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

TEMPERATURE -25°C < +30°C +40°C +60°C +80°C

FACTOR ST 1.0 0.8 0.7 0.6

EXPLOSION GROUP CONTROLLING INTERVALS

II 2G C IIB T4 X

II 2D C T 110°C X

I M2 C X

After an operating time of 3000 h, 6 months after initial operation of the coupling at the latest, the elastic gear ring

must be put to test (visual check, torsion test).

In case of an unessential or no wear of the gear ring during first check, the check cycles can be set to an operating time

of 6000 h or 18 months at the same operating conditions.

In case of an increased wear at first check, we recommend to proceed as followed:

• Exchange of the gear ring

• Determination of cause

• Adjustment of the check cycles to the operating conditions

II 2G C IIC T4 X

After an operating time of 2000 h, 3 months after initial operation of the coupling at the latest, the elastic gear ring

must be put to test (visual check, torsion test).

In case of an unessential or no wear of the gear ring during first check, the check cycles can be set to an operating time

of 4000 h or 12 months at the same operating conditions.

In case of an increased wear at first check, we recommend to proceed as followed:

• Exchange of the gear ring

• Determination of cause

• Adjustment of the check cycles to the operating conditions

5.4 VALUES OF MISALIGNMENT

The maximum admissible values of misalignment men-

tioned in the table must only be used proportionally in

case of parallel radial alignment and alignment of angle.

Example 1: Example 2:

∆KR = 20 % ∆KR = 60 %

∆KW = 80 % ∆KW = 40 %

∆Ktotally = ∆KR + ∆KW ≤ 100 %

6. USE IN HAZARDOUS LOCATIONS

6.1 INDICATIONS

CAUTION!

Concerning the explosion groups IIB and IIC, follow-

ing materials are used by HBE:

Cast Iron (GG25, GG20) Stainless Steel (VA)

Spheroidal Cast Iron (GGG40) Sinter Steel (S)

Steel (St)

HBE does not use aluminium as material for the

couplings applied in hazardous areas.

6.2 CONTROLLING INTERVALS

90%80% 100%

30%

0

20%

10%

80%

50%

40%

70%

60%

100%

90%

70%

50% 60%

Winkelversatz Kw

Radialversatz Kr

10% 20% 30% 40%

Misalignment of Angle ∆Kw

Radial Misalignment ∆Kr

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

6.3 WEAR RATINGS

The check of the wear limit shall be made by a guide

between tooth flank and coupling claw.

In case of a backlash > X mm, the gear ring must be

exchanged.

6.4 IDENTIFICTION

Couplings for use in hazardous areas have to be marked

respectively for the permitted conditions of use.

Identification mark:

II 2G c IIB T4 X II 2G c IIC T4 X

II 2D c T 110°C X I M2 c X

The explosion groups IIB and IIA as well as the tempe-

rature ranges T3 – T1 are included in the identification

mark II 2G c IIC T4 X.

6.5 COMMISSIONING

Bevor commissioning of the coupling, following checks

and possible corrections must be made:

• Check of alignment

• Check of misalignment

• Check of distance dimension E

• Check of the tightness of the set screws in the hubs

• Check of the tightness of the fixing screws when using

flange hubs

CAUTION!

In hazardous areas, the set screws fixing the hubs

and the fixing screws of the flange hubs must be

secured against self-loosening, e.g. glue with Loctite

270.

TYPE WEAR LIMIT

X MAX.

mm

14/16 2

19/24 3

24/30 3

28 / 3 8 3

38 / 4 5 3

42 / 5 5 4

48 / 60 4

5 5 / 70 5

6 5 / 75 5

75/90 6

90/100 8

100/110 9

110/125 9

125/145 10

New condition

X = Wear

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

Afterwards, the user has to fit a coupling protection con-

sisting of a fixed cover. The cover is intended to protect

the coupling especially from falling items. The covers can

be provided with regular openings. Following dimensions

must not be exceeded.

The distance of the cover to rotating parts must be at

least 5 mm. The cover must be electrically conductive and

must be included in the potential equalisation. The cover

is only allowed to be taken off during a halt. Aluminium

bellhousings (also with damping flange) are permitted as

connecting element, if the content of magnesium is less

than 7.5 %.

CAUTION!

When mounting the coupling to machines of cate-

gory 2D, please ensure that there is no dust be-

tween cover and coupling. The couplings must not

operate in dust particles. When using the coupling

in machines of group I, category M2, the cover must

not consist of light metal (higher mechanical load).

During operation of the coupling please pay attention to:

• Changed operation noises

• Occurring vibrations

ATTENTION!

In case of changes or irregularities during the opera-

tion of the coupling, the power unit must be switched

off immediately. The cause of the disturbance must

be found out by the check list ”Trouble in service”

and be removed, if possible.

ROUND

OPENINGS

Ø

mm

RECTANGULAR

OPENINGS

SIDE LENGTH

mm

TOP OF COVER 4 4

SIDE OF COVER 8 8

6.6 TROUBLE IN SERVICE / CAUSES AND CLEARANCE

A disturbance by break of the fixing screws of the flange

couplings must be excluded under observance of the

selection criteria.

DISTURBANCES CAUSES INDICATIONS OF

RISKS FOR HAZARDOUS

AREAS

CLEARANCE

Changes of

running noises

Vibrations

Alignment fault

High temperatures

at the surface lead to

an ignition risk

• Stop the unit

• Check and remove changes in construction

• Check the drive unit for damages

• Check and correct, if necessary, alignment and dimension

E of the coupling

• Check the wear of the gear ring and exchange,

if necessary

Loose screws for axial

securing of the hub

Ignition risk by hot surface

and sparking

• Stop the unit

• Check and correct alignment and dimension E of the

coupling

• Check the wear of the gear ring and exchange,

if necessary

• Retighten the fixing screws by the starting torque and

protect it from self-loosening with Loctite

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

DISTURBANCES CAUSES INDICATIONS OF

RISKS FOR HAZARDOUS

AREAS

CLEARANCE

Changes of

running noises

Vibrations

Wear of gear ring

Short-term torque transfer

by metal contact

Ignition risk by sparking

• Stop the unit

• Dismount the coupling

• Remove the gear ring

• Check the parts of the coupling and exchange damaged

parts

• Renew the gear ring

• Check and, if necessary, correct the alignment

• Tighten the fixing screws with tightening torque and protect

it from self-loosening with Loctite

Break of

claw

Blockage and overload

rupture of claws by

operating errors

Ignition risk by sparking

due to metal contact of

the claws

• Stop the unit

• Dismount the coupling

• Check the shafts and feather keys for damages

• Check the drive unit for damages

• Mount the complete coupling

• Check the alignment

• Tighten the fixing screws with tightening torque and

protect it from self-loosening by Loctite

The parameters for the

determination of the

coupling do not correspond

to the actual operation

conditions. Dimensions of

coupling too small.

• Stop the unit

• Dismount the coupling

• Check the shafts and feather keys for damages

• Check the operating parameter and choose a harder gear

ring or bigger coupling

• Check the mounting space when deciding for a bigger

coupling

• Mount the complete coupling

• Check and correct, if necessary, alignment and dimension

E of the coupling

• Tighten the fixing screws with tightening torque and

protect it from self-loosening with Loctite

Increased wear of gear ring

Claws smash during torque

transfer

Premature wear

of gear ring

Error of alignment

Dimension E

was not kept

Ignition risk by high

temperatures at the

gear ring

• Stop the unit

• Check the mounting and remove errors of alignment

• Check the parts of the coupling and exchange damaged

parts

• Exchange the gear ring

• Check and correct, if necessary, alignment and dimension

E of the coupling

• Tighten the fixing screws with tightening torque and

protect it from self-loosening with Loctite

Torsional vibrations

destroy the charged teeth

inside

Ignition risk by sparking

during metal contact of the

claws

• Stop the unit

• Check the parts of the coupling and exchange damaged

parts

• Find out and remove cause of vibration

• Exchange the gear ring (eventually choose smaller or

higher shore hardness, please pay attention to the size of

the coupling)

• Check and correct, if necessary, alignment and dimension

E of the coupling

• Tighten the fixing screws with tightening torque and

protect it from self-loosening with Loctite

Solutions for Fluid Technology

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

DISTURBANCES CAUSES INDICATIONS OF

RISKS FOR HAZARDOUS

AREAS

CLEARANCE

Premature wear

of gear ring

Inadmissibly high

temperatures by contact

heating

Ignition risk by sparking

during metal contact of

the claws

• Stop the unit

• Check the parts of the coupling and exchange damaged

parts

• Find out and remove the source of heat

• Exchange the gear ring

• Check and correct, if necessary, alignment and dimension

E of the coupling

• Tighten the fixing screws with tightening torque and protect

it from self-loosening with Loctite

Aggressive environmental

conditions

(vapours, chemicals, etc.)

and/or liquids (bio oils)

• Stop the unit

• Check the parts of the coupling and exchange damaged

parts

• Check and correct the environmental conditions

• Check the operating medium and change, if possible

• Exchange the gear ring

• Check and correct, if necessary, alignment and dimension

E of the coupling

• Tighten the fixing screws with tightening torque and protect

it from self-loosening with Loctite

Solutions for Fluid Technology

H04 0 09 4a 09/17 www.plakart.de

www.e-holding.de

HBE GmbH

Hönnestraße 47 | 58809 Neuenrade | Germany

Phone +49 (0) 23 94 / 616-0

Fax +49 (0) 23 94 / 616-25

info@hbe-hydraulics.com

www.hbe-hydraulics.com

6.7 DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

According to the EG rules 94/9/EG dated 23 rd March, 1994 and the legal requirements

the manufacturer

HBE GmbH

Hönnestr. 47

58809 Neuenrade/Germany

hereby declares that the following products described in the operation and mounting instructions

Softex® – Elastic Couplings,

are non-electric devices acc. to the EG rules 94/9/EG and meet the security and healthy prescriptions for the conception and

the construction of the device concerning the intended use in hazardous locations as stated in subjoinder II of the guide. A

conformity to the norms EN 1127-1: 2011; EN 1127-2: 2002; EN 12463-1: 2009 and EN 13463-5: 2011 is given.

Following test certifi cate of type is existing for the Softex® – Elastic Couplings:

IBExU04ATEXB027 X

Acc. to RL 94/9/EG the technical documentation is deposited at the following place:

IBExU

Institut für Sicherheitstechnik GmbH

Fuchsmühlenweg 7

D-09599 Freiberg

Neuenrade, 14.11.14 i.V.

Date Detlef Lengelsen Holger Anton

Managing Director QS- Manager

Table of contents