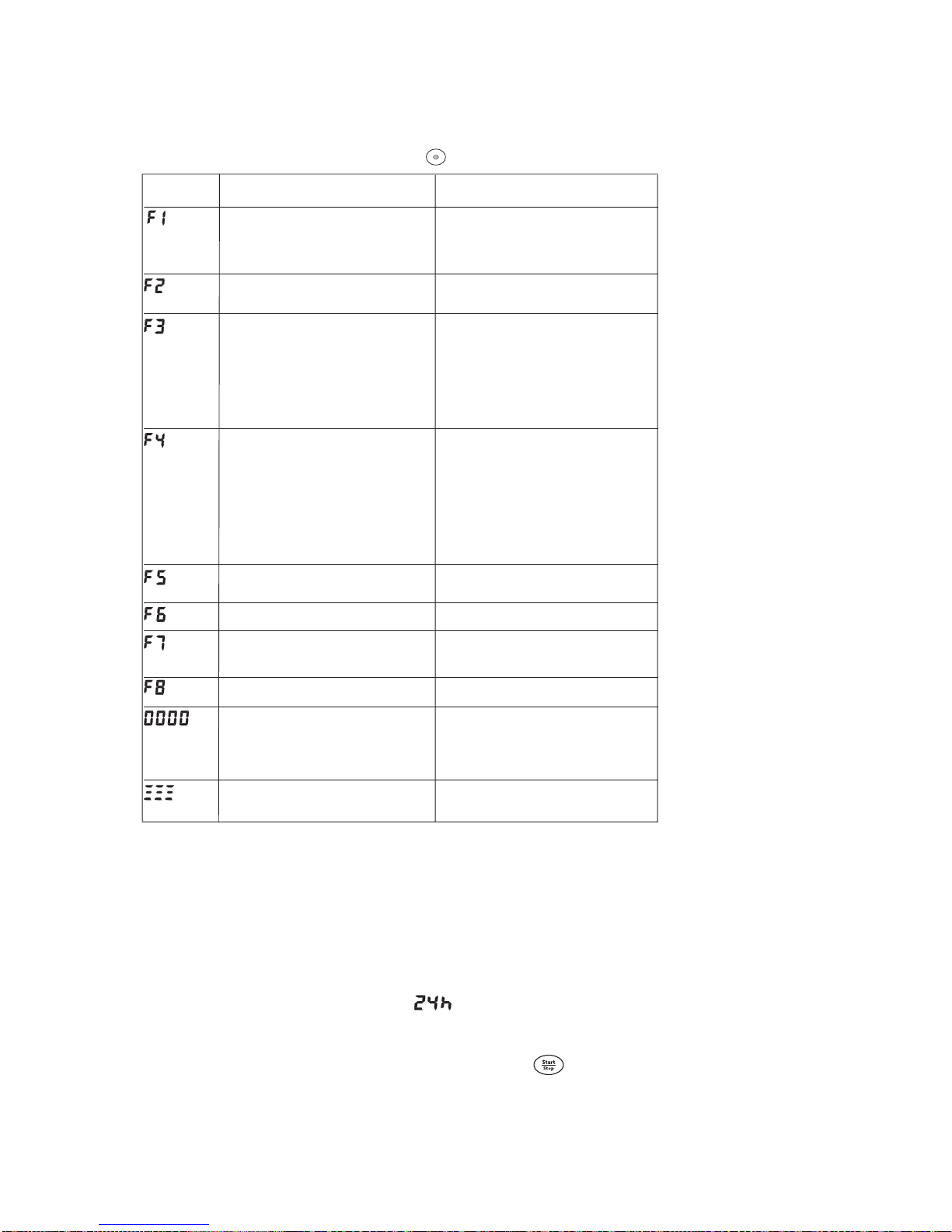

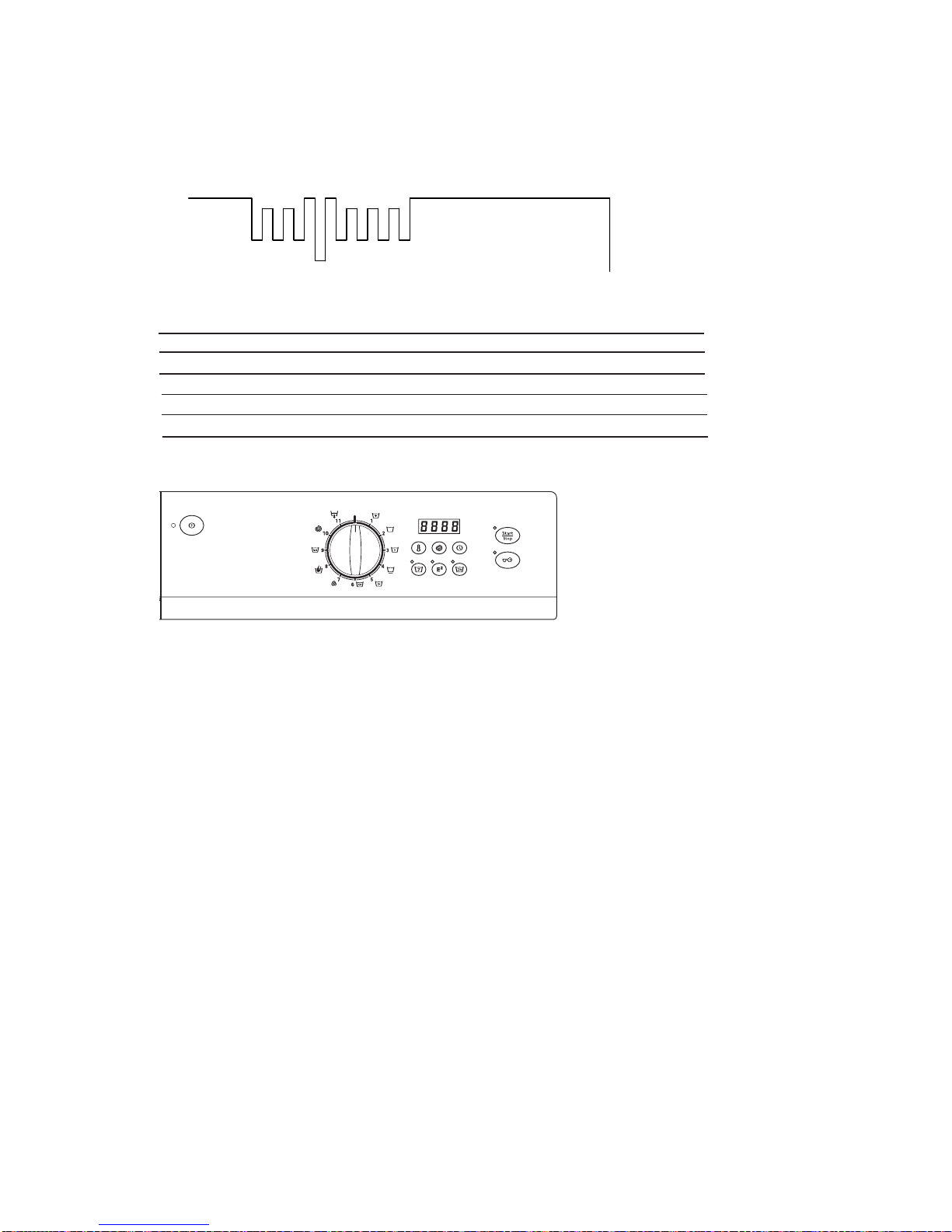

Flashing

Error messages

If an error or fault occurs in the course of the program this is indicated on the display.

N.B.

To reset the error message the main switch must be turned off.

Faultfinding

The machine does not start

1. Is the washing door properly closed?

2. Check that the Delayed start option has been switched on. The time remaining until start will then

appear in whole hours on the display, e.g. . To change: stop the program, change the setting and

restart.

3. Is there a break in the power supply? Check the house fuses (plugs).

4. Has the child lock been switched on? If so hold down the - button for three seconds.

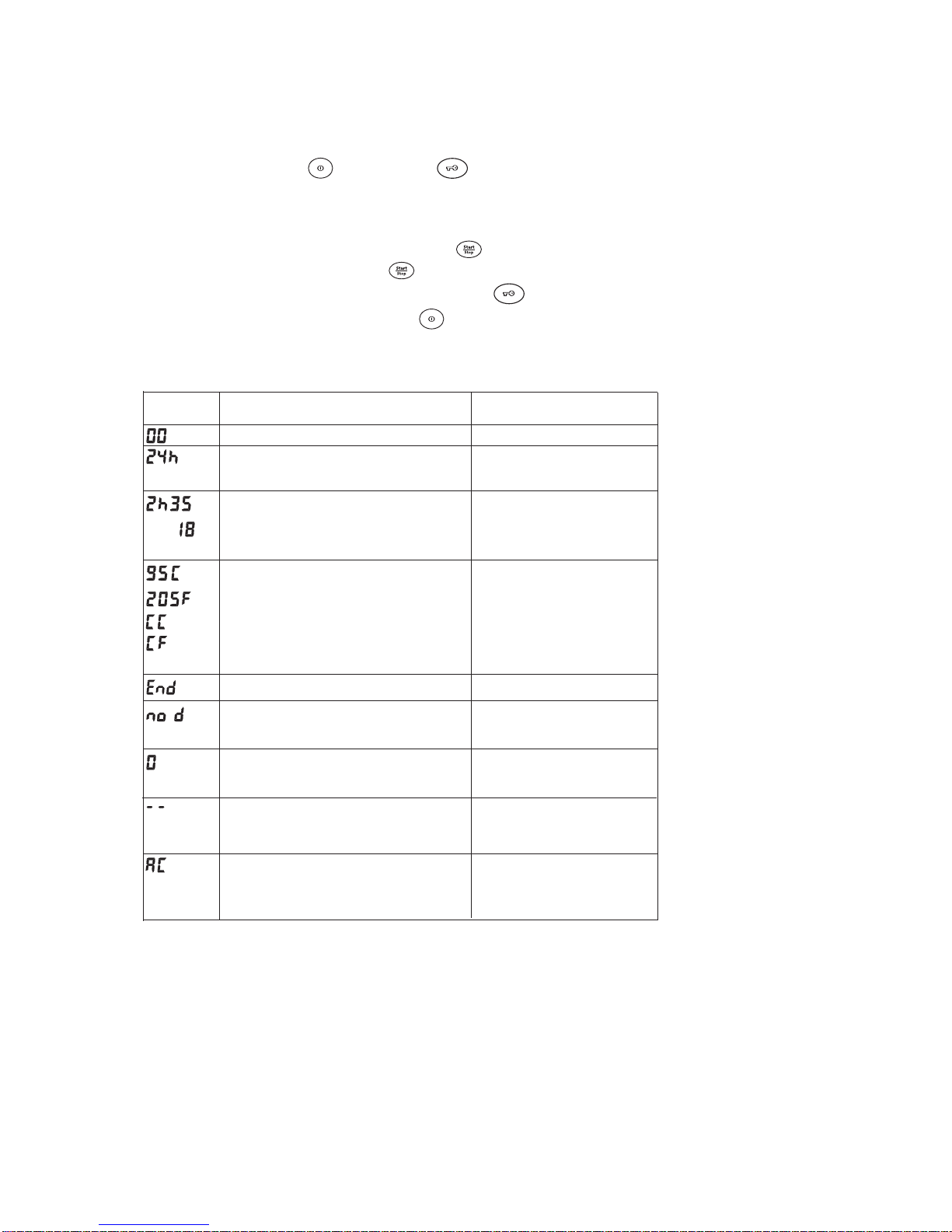

The display shows Description Explanation/proposed measure

Draining fault The machine indicates that it has not succeeded in

pumping out the water within 3 minutes.

Where there is a draining fault check:

- that no object has caught in the drain hose outlet

- that the drain pump is not blocked by foreign ob-

jects. Clean the pump, see Chapter 11, Maintenance

and cleaning, in the instructions for use.

- that there are no kinks in the drain hose.

After the fault has been remedied run the Drain pro-

gram. If this does not help, call service.

Water inlet fault The indicates that it does not reach the water level

within 5 minutes.

Where there is a fault in the water supply, check:

- that the cock on the water pipe is open.

- that the screen in the machine water intake is not

blocked.

1. Close the water cock.

2. Unscrew the hose.

3. Clean the screen in the inlet valve on the machine.

4. Retighten the hose.

5. Open the water cock.

6. Run the program again to check whether the fault

has been remedied.

Thermistor fault

Temperature stop fault

Foaming (this function is not provided on all machi-

nes).

The fault indication appears at the end of the pro-

gram, but foaming is checked after the main wash.

Run the rinse program once. Check the washing pow-

der doe. Use low lather washing powder.

Door opening fault

The machine has not spun. 1. The machine has a built-in imbalance sensor which

causes the speed to be reduced or the spin to be jum-

ped if there is major imbalance in the load. Turn off

the main switch and turn it on again. Open the door

and redistribute the wash.

2. After the fault is remedied run the Spin program.

You have tried to start a program with the door open. Close the door and try again.

Flashing

Over flow The sensor receives the first signal that Over flow has

taken place if, or example, an inlet valve has jammed or

if the machine has taken in water for a reason which the

sensor cannot control.

Machines with a float also receive the indication when

there is water at the bottom of the machine.

Wash motor fault Interruption in any cables to the motor gives rise to this

fault, which means that an interruption in the power to the

motor may also produce the fault. Locking of the motor

also results in an error indication.

The machine indicates whether there is an interrup-

tion or short-circuit in the thermistor.

Indicates whether the temperature is not reached

within 80 mins., 30 mins. For wool and hand wash.

A fault has occurred on the control card, which must

be replaced to ensure complete safety.