10

FAULT TRACING

The machine will not start.The machine will not start.

The machine will not start.The machine will not start.

The machine will not start.

1. Checkthehousebreakerswitch/fuses.

2. Checkthattheglass dooris closedsecurely.

3. Make sure the power switch is turned on and

theindicator lamp islit.

4. Ifthepowerswitchisonandtheindicatorlamp

is not lit, there is no power supply. Make sure

themachineisproperlypluggedintotheelectrical

outlet at the wall or on the back of the dryer.

5. If washer power cord is plugged into the back

ofthedryer,turnthepowertothedryeronand

see if the indicator light is lit. If it is not lit,

unplug the dryer power cord and replace it

firmlyinto thewall receptacle.

6. W620: Check that the Delay Start button is

notpressedin.

W640 and W660: Check that the Delay Start

symbol ( ) is not shown on the display.

The machine will not work.The machine will not work.

The machine will not work.The machine will not work.

The machine will not work.

1. Checkthe main powerswitch.

2. Checkthe door switch.

3. Measure the voltage between PF1 and PF3

(W600/W620) also between E1-1 and E1-2

(W640/W660).The value should be the same

asthemainpowersupplyvoltage(208–230V).

(Seepage 13 for values.)

4. Check the machine and house fuses. If it’s

necessary to change the fuses, investigate why

they have blown.

The washer door is difficult to close orThe washer door is difficult to close or

The washer door is difficult to close orThe washer door is difficult to close or

The washer door is difficult to close or

will not close.will not close.

will not close.will not close.

will not close.

1. Make sure nothing is caught in the door, such

asapronstrings,shoelaces,etc.

2. Make sure the power to the machine is on.

3. Checkthat the doorseal fits securely.

4. Checkthe door switch. (Seepage 14.)

The washer door leaks.The washer door leaks.

The washer door leaks.The washer door leaks.

The washer door leaks.

1. Check that the door seal is in good condition

andfitssecurely.

2. Make sure nothing is caught in the door, such

asapronstrings,shoelaces,etc.

The washer door will not open.The washer door will not open.

The washer door will not open.The washer door will not open.

The washer door will not open.

1. Make sure the power to the machine is on.

2. Be sure the washer is not still in a cycle.

3. W600/W620:MakesuretheProgramControl

knob is in the proper position (at a red mark).

4. MakesuretheDoorOpenbuttonwaspressed.

5. Checkthemachineandhousefuses.

6. Check the door lock. (See page 14.)

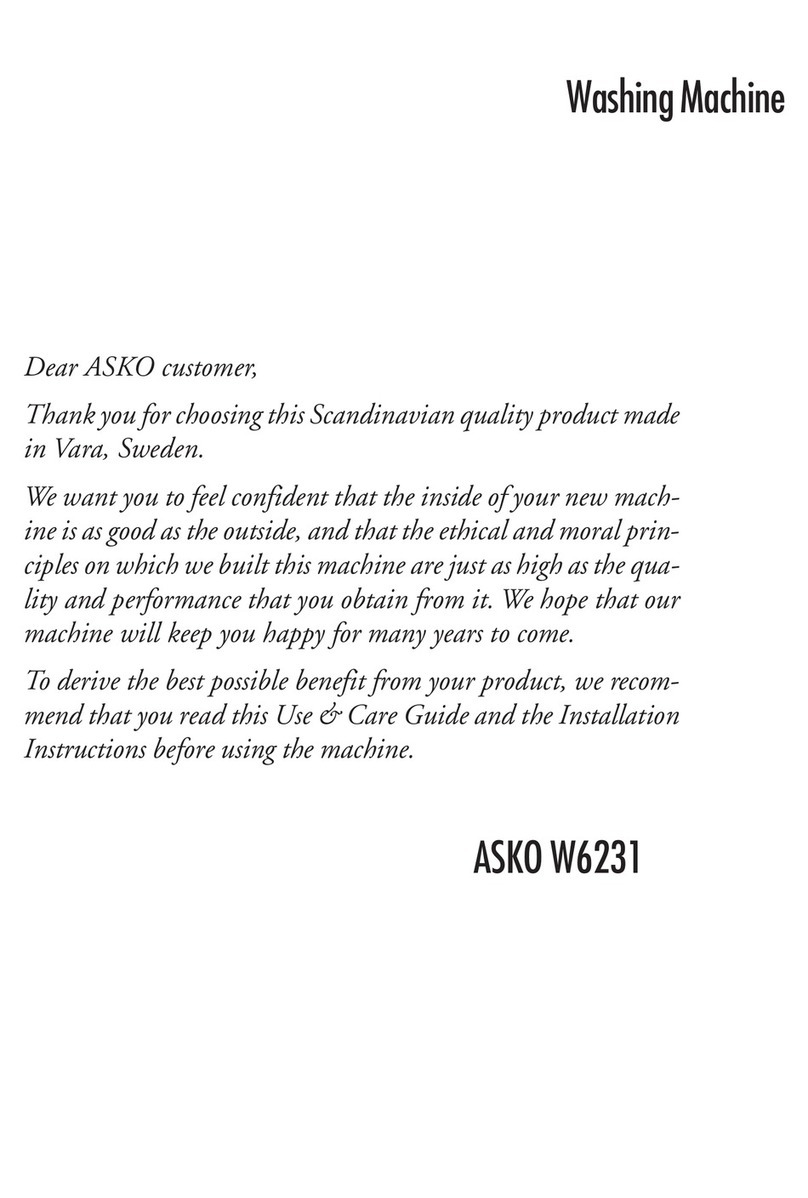

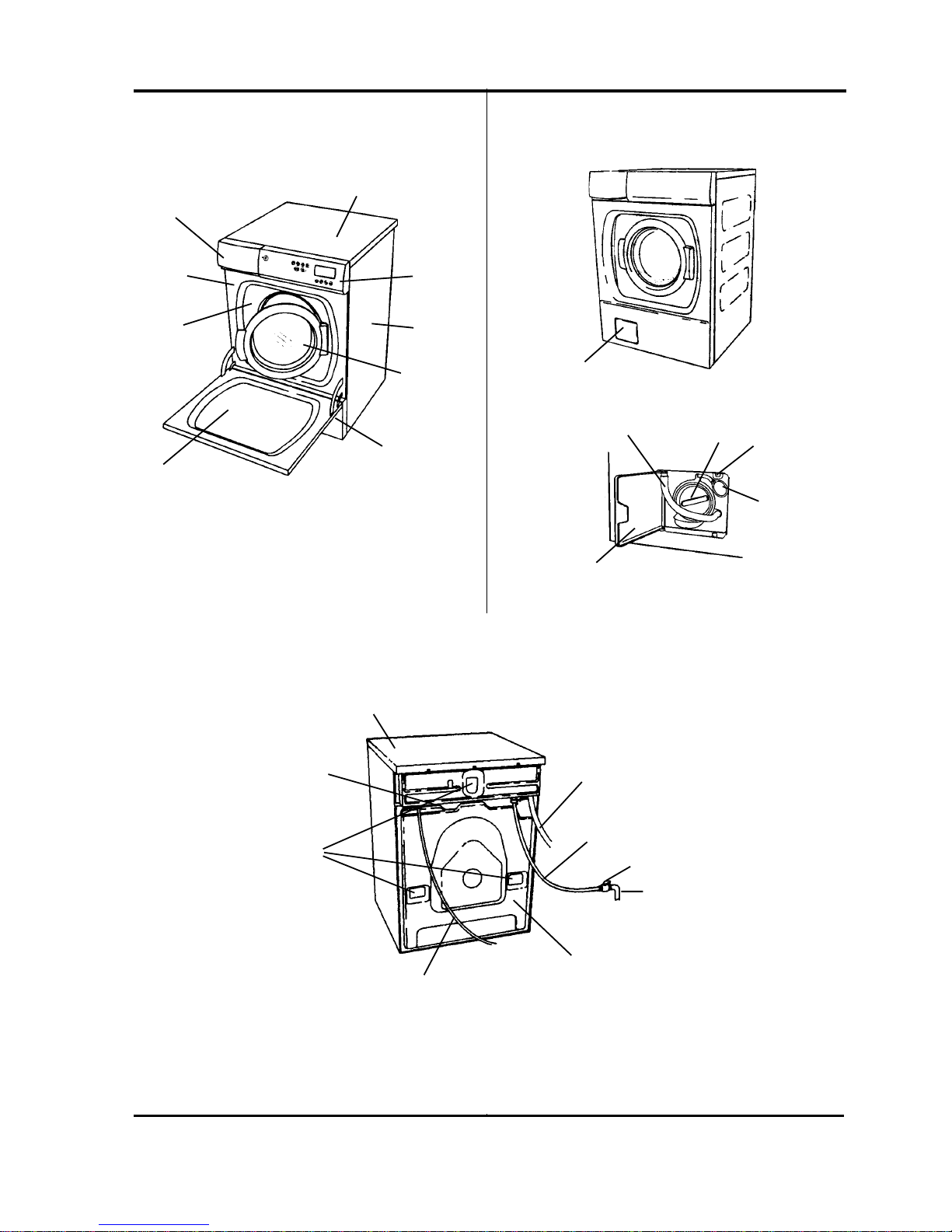

7. Ifthereisnowaterinthemachineandthedoor

won’t open in the normal manner, you should

be able to open it manually, as follows:

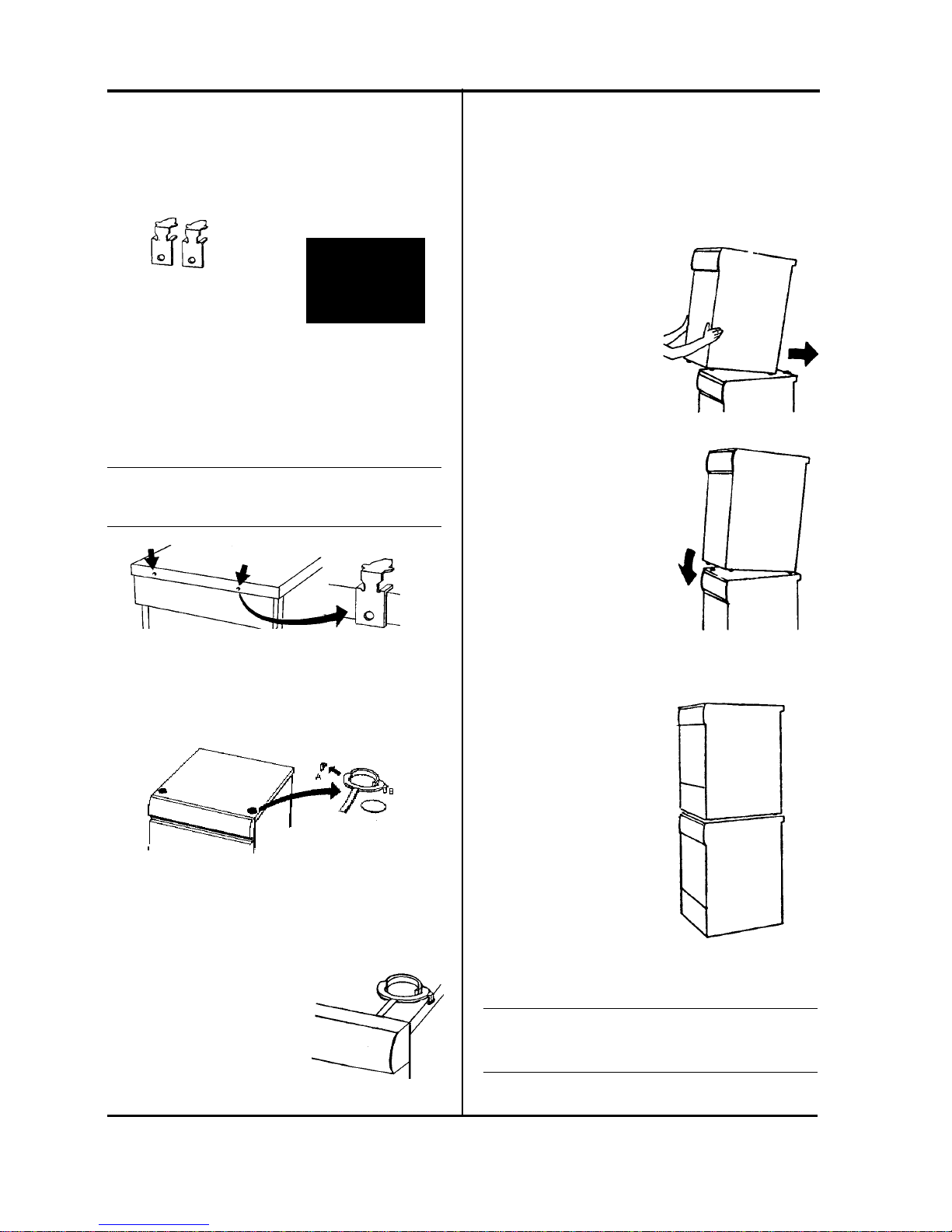

a. Make sure the power is turned off.

b. Usingaflatheadscrewdriver,gentlypryopen

thedrain pumpcover.

c. Empty out any water that may be in the

machine by disconnecting the drain hose

from the door pin (A).

IMPORTIMPORT

IMPORTIMPORT

IMPORTANTANT

ANTANT

ANT

If there is still water in the drum, make sure you

have a large container ready to catch the water.

d. Unscrew the emergency

door opener handle (B)

andpullitout(C)toopen

thedoor.

e. Replace the emergency

dooropenerhandle.

TT

TT

Temperature and speed cannot be select-emperature and speed cannot be select-

emperature and speed cannot be select-emperature and speed cannot be select-

emperature and speed cannot be select-

ed (W600 and W620).ed (W600 and W620).

ed (W600 and W620).ed (W600 and W620).

ed (W600 and W620).

1. Check the selector knobs. (See the schematic

diagramstofindthemeasuringpoints.)

The machine does not perform washingThe machine does not perform washing

The machine does not perform washingThe machine does not perform washing

The machine does not perform washing

rotation or does not reverse the direc-rotation or does not reverse the direc-

rotation or does not reverse the direc-rotation or does not reverse the direc-

rotation or does not reverse the direc-

tion of washing rotation.tion of washing rotation.

tion of washing rotation.tion of washing rotation.

tion of washing rotation.

1. Checkthat thedrivebelt issecure.

2. Check the programmer (W600/W620) or the

motor control board (W640/W660). (See the

schematicdiagramsformeasuringpoints.)

3. Check the motor. (See page 13.)

4. Checkthe levelswitch. (See page13.)

The washer doesn’t spin dry (W640/W660).The washer doesn’t spin dry (W640/W660).

The washer doesn’t spin dry (W640/W660).The washer doesn’t spin dry (W640/W660).

The washer doesn’t spin dry (W640/W660).

If “0000”is flashing in the top right corner of the

display,themachinedidnotspin.Themachinehas

abuilt-inout-of-balancesensorthatwillreducethe

spin drying speed or stop spin drying altogether if

theloadis toounbalanced.

1. Openthewasherandredistributethelaundry.

2. RunaSpinprogramtocheckthattheproblem

hasbeensolved.

A B

C