American Stainless Pumps

Stainless Steel Pumps for the Commercial Marketplace

www.aspumps.com 14032 S. Avalon Blvd. Los Angeles, CA 90061

Phone: (310) 630-8089 Fax: (310) 630-8095 Page 4

Disassembly continued...

8. Remove the rotating element of the mechanical shaft seal (item 300). This element is held in place by the

impeller only. If the rotating element does not come off easily, it is stuck to the shaft. Pry up the seal plate

(Item 400) with screwdrivers or pry bars. The seal plate should compress the seal spring and force the seal

off the shaft. If seal is stuck, and you must pry with force, do not pry towards your face or body. The seal

and seal plate can come free unexpectedly and injure you.

9. If the seal plate (item 400) did not come off with the seal, remove it now. If you plan to replace the stationary

seat, you will need to press it out from the back. Do not push with your finger, as you will probably cut it on

the edges of the seal plate when the seal pushes out.

10. If you plan to replace the motor, remove the four motor adapter bolts (Item7MB)witha 7/32” allen wrench and

removethe motor adapter plate (Item 600). If youarenot replacing the motor,leave the adapter plate in

place.

11. If the motor comes with a deflector, the deflector should go outside of the motor adapter plate and must be

removedif the adapterplateis to be removed.

12. Check the suction o-ring (item 510) in the case suction nozzle. It may be difficult to remove. Use a sharp

pointedawl or similar device to pry the o-ring from the groove. Replace ifdamaged,swollen,fretted, or just

wornout.

Assembly or Reassembly: SSP & SSPC

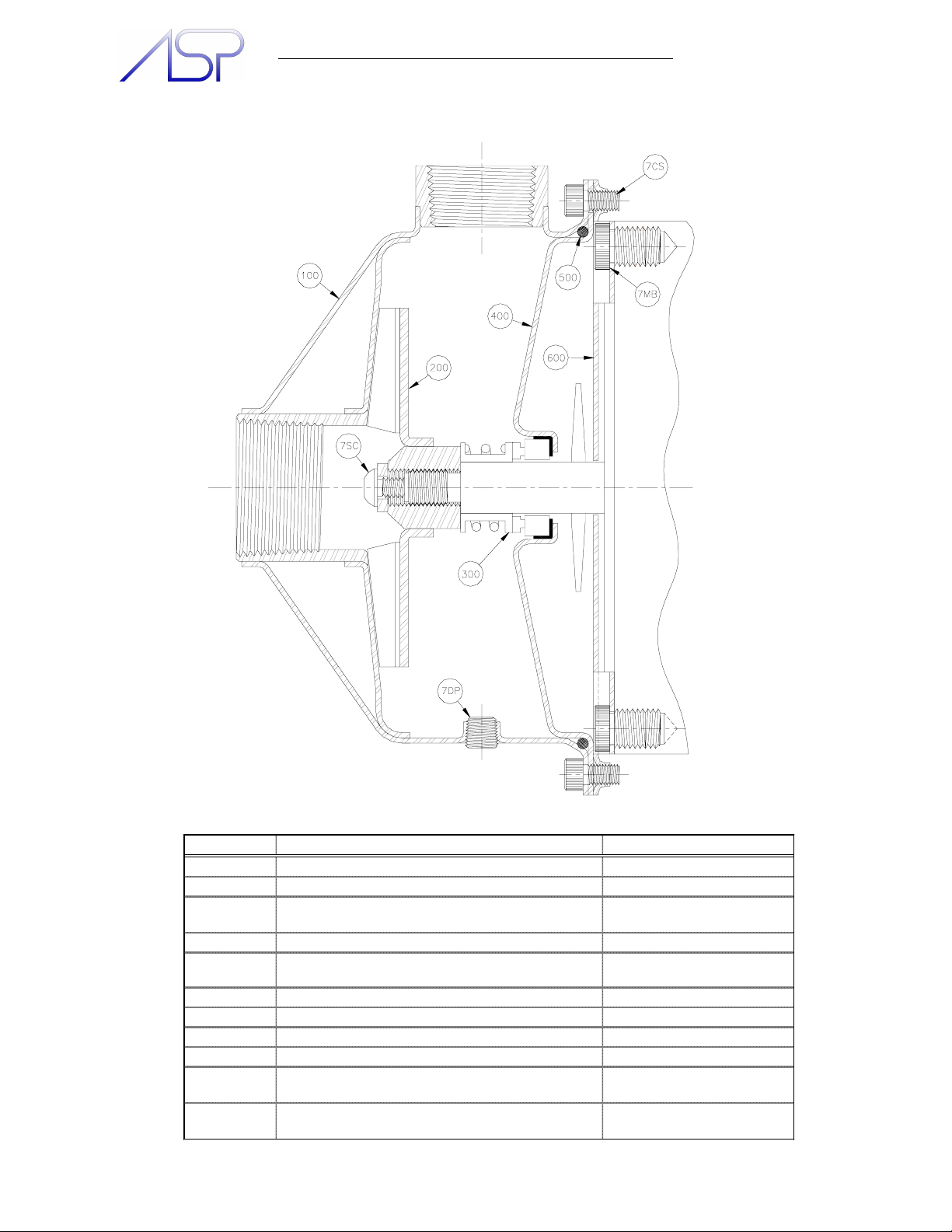

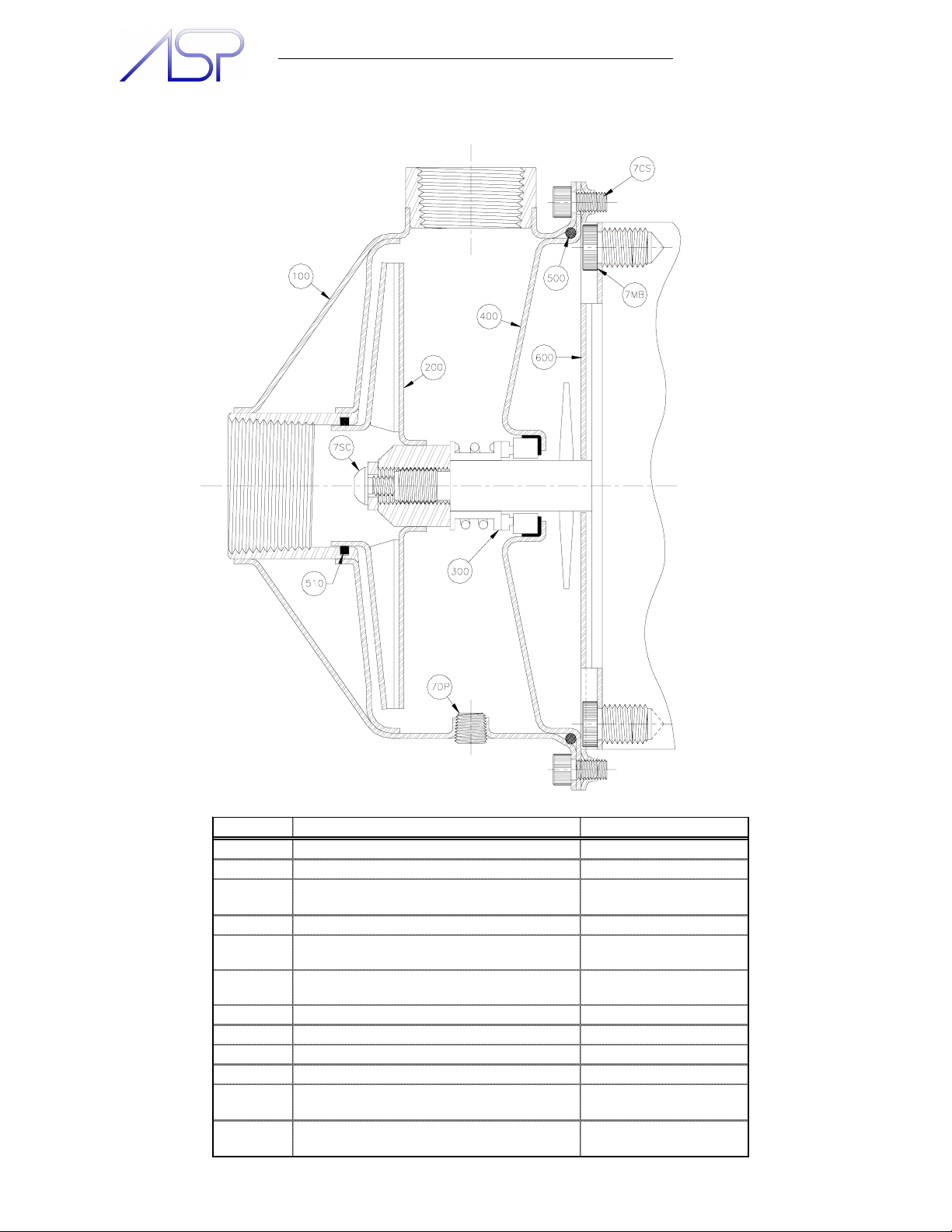

)See page xxx for model SSP, and page xxx for model SSPC cross sectional drawings.

)Assembly of the pump and motor is easier when the motor is standing face up so that parts do not fall off,

although access to the motor shaft at the rear of the motor will require a horizontal position.

)Itis considered good practice to replace the mechanical seal whenever you have todisassemblethe pump.

1. If replacingthemotor, remove the deflector from the motorshaft. Theremay not be enough room behind the

motoradapter plate for the deflector to spin freely.

2. Install the motor adapter plate (Item 600) with the four motor bolts (Item 7MB) using a 7/32” allen wrench. You

must use the low profile button head socket screws that came with the pump or other low profile head bolts.

There is not enough room for a standard cap head screw/bolt. Tighten the bolts. Install the deflector now.

3. Install the mechanical seal stationary seat into the Seal Plate (Item 400) by putting a suitable lubricant on the

cup seat and gently pressing into the seal plate bore. Do not get any lubricant on the seal faces. Use

the foam sheet from the seal box to protect the seal face from dirt and scratches while pressing into the

seal plate. Place the seal plate onto the motor adapter plate.

4. Lubricate the sealing elastomers on the rotating assembly of the mechanical seal and press gently onto the

shaft. You may have to hold the seal in place until the impeller is installed.

5. Model SSP Only: Place the necessary number and thickness of impeller spacer/washers onto the threaded

portion of the shaft. If you are not changing the impeller or the motor, use the same batch of spacer/

washersyou removed. See the section on

Setting Impeller Clearance

for procedures if you havechanged

the impeller to case setting.

6. (If motoristhree-phase, read section 7 below for Loctite instructions, thencontinuereading here) Thread the

impeller onto the pump shaft. Be sure the impeller hub is tight against the spacer/washers that are tight

against the shoulder of the motor shaft. If you leave the impeller loose, when the motor starts up, the

impeller will tighten up on the shaft so tightly that you may not be able to remove it later. You will need to

holdthe motor shaft from the rear ofthemotor with a large screwdriver, wrench or vise grips while tightening

theimpeller.

7. If motoris three-phase,and wiringhas beenreconnected, rotationmayhavechanged. Toprotectagainstrotation

inthe wrongdirection atstart up,reinstallthe lefthand threadedimpellerlocking screwand washer(item 7SC),

or for motor horsepowers less than 1 HP, install the impeller with a locking compound such as Loctite.

8. Install the case o-ring (item 500). Replace if brittle, damaged or misshapen.

9. Model SSPC Only: Install the suction o-ring (item 510). Replace if brittle, damaged or misshapen.

10. Model SSPC Only: Join up the back pull out assembly with the case. Do not force the pump into the case.

The suction O-ring (item 510) can be pinched when installing. You may have to back out the pump from the

case, center up the O-ring with your finger and slip in the pump assembly again. Before installing the case

bolts, check to be sure the impeller is spinning freely.

11. Model SSP Only: Join up the back pull out assembly with the case. Install the (8) case bolts (item 7CS),

leaving the bottom two bolts loose for attaching the base (not necessary with footed motors). Slip the

baseplate under the bottom two bolts. Tighten the case bolts while holding the baseplate in place.

12. Model SSP Only: Check the impeller to case clearance per the following instructions and adjust as needed.

13. Install and tighten the motor base hold down bolts.