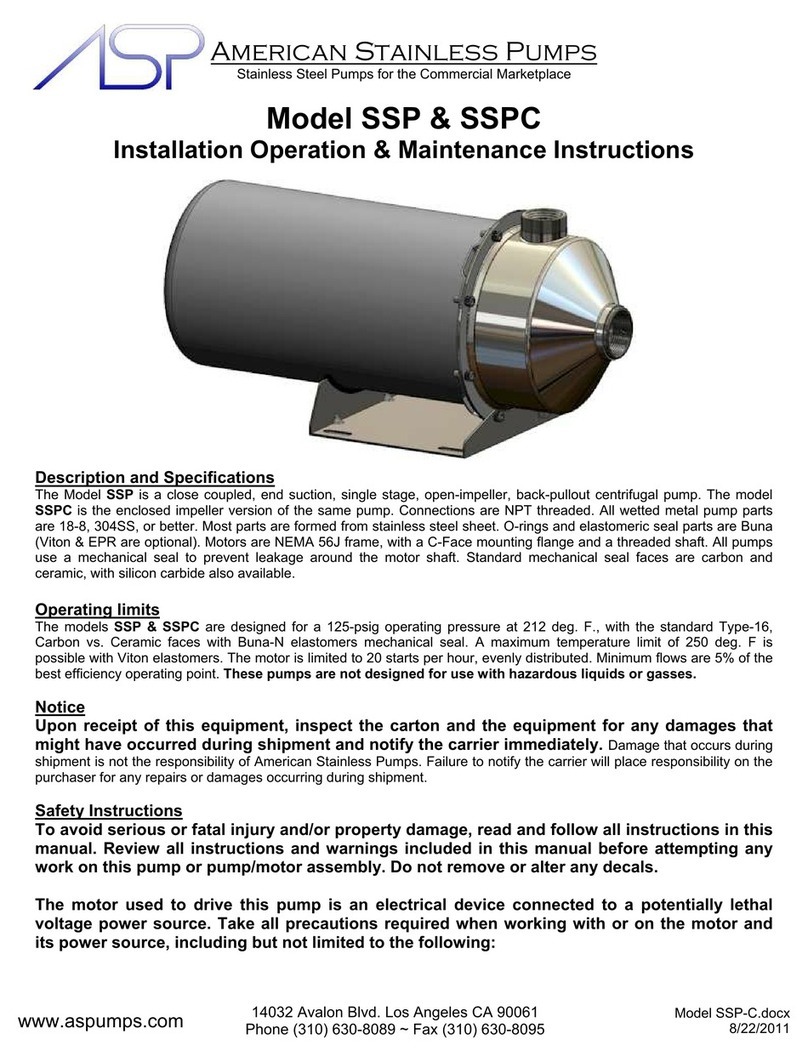

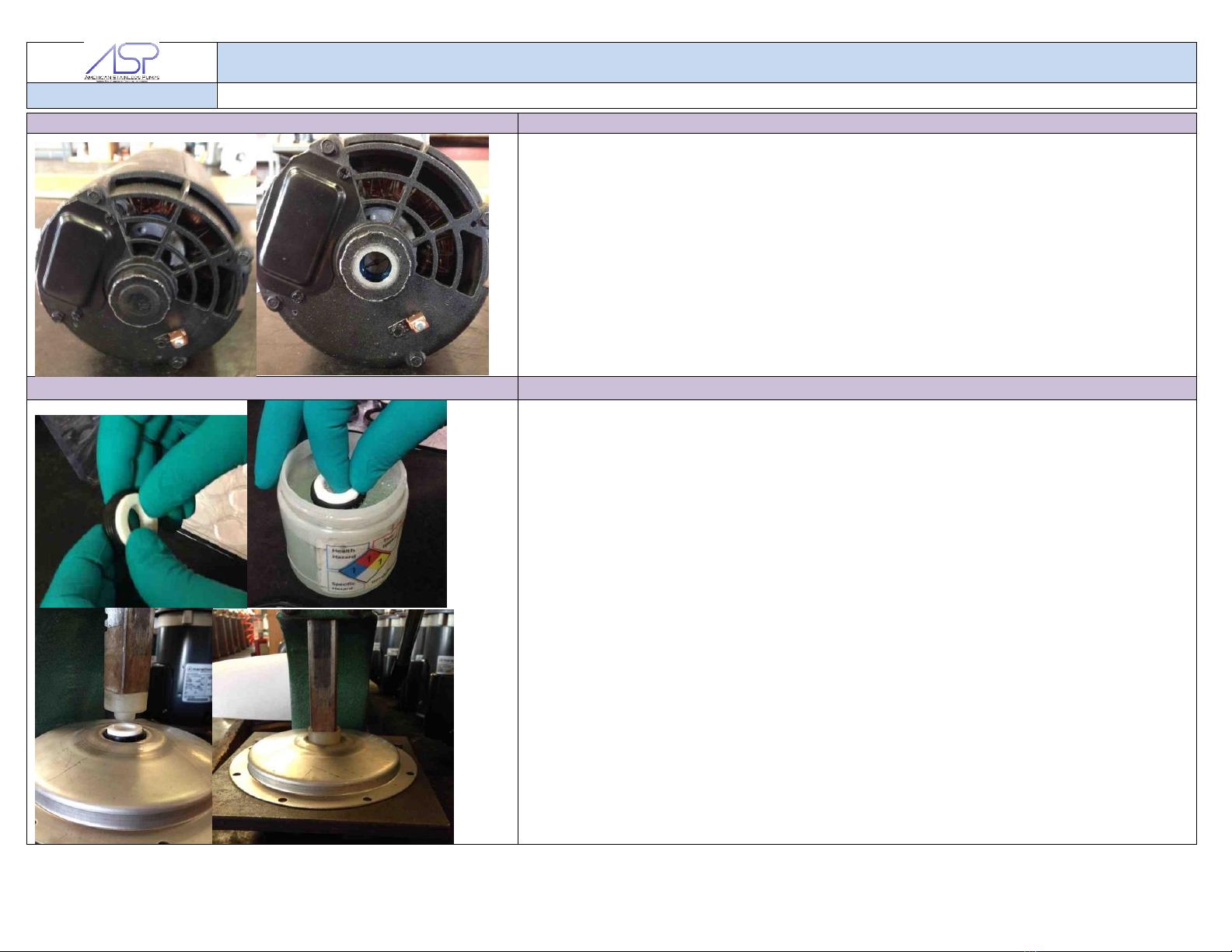

The motor manufacturer supplies a plug in the back of the motor. It can be seen in this

picture as a black plug at the center of the motor.

This plug must be removed in order to access the shaft during impeller installation.

The wire box cover shall also be removed in preparation for testing. (In the field, the

motor may be wired by accessing the wire port in the back/side of the motor and

installing an elbow.)

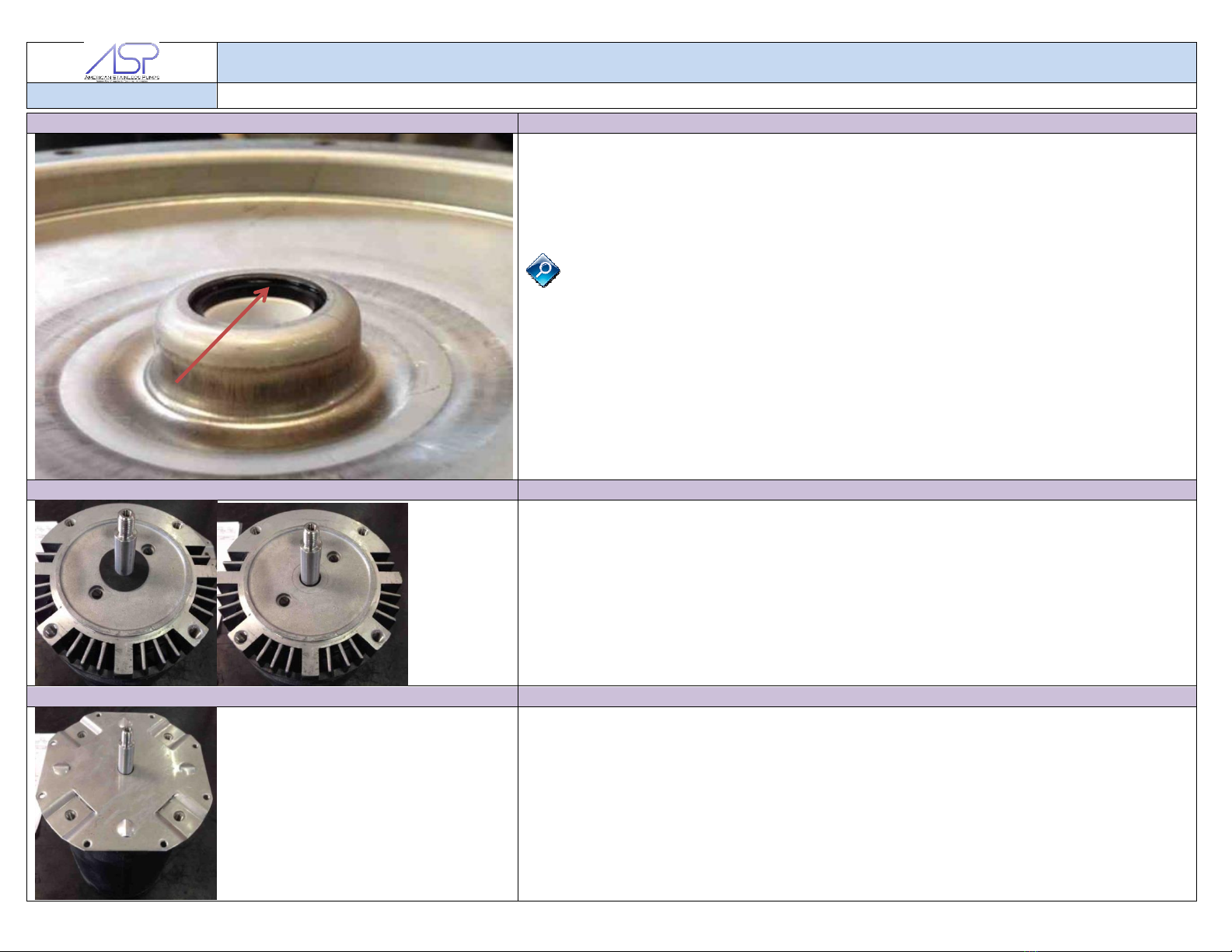

Using gloves to protect the seal faces from debris, dirt and fingerprints, massage the

seal into the seal seat (rubber). The seat needs to sit flat against the bottom of the seal

seat. Any tilt could lead to reduced seal life.

Dip the seal seat (rubber) into the pre-prepared lubricating solution (non-abrasive dish

soap/water combo). Be careful not to get solution on the face of the seal. Any solution

on the face of the seal may cause the stationary face to stick to the rotating face.

Place the stationary seal into the sealplate (as pictured).

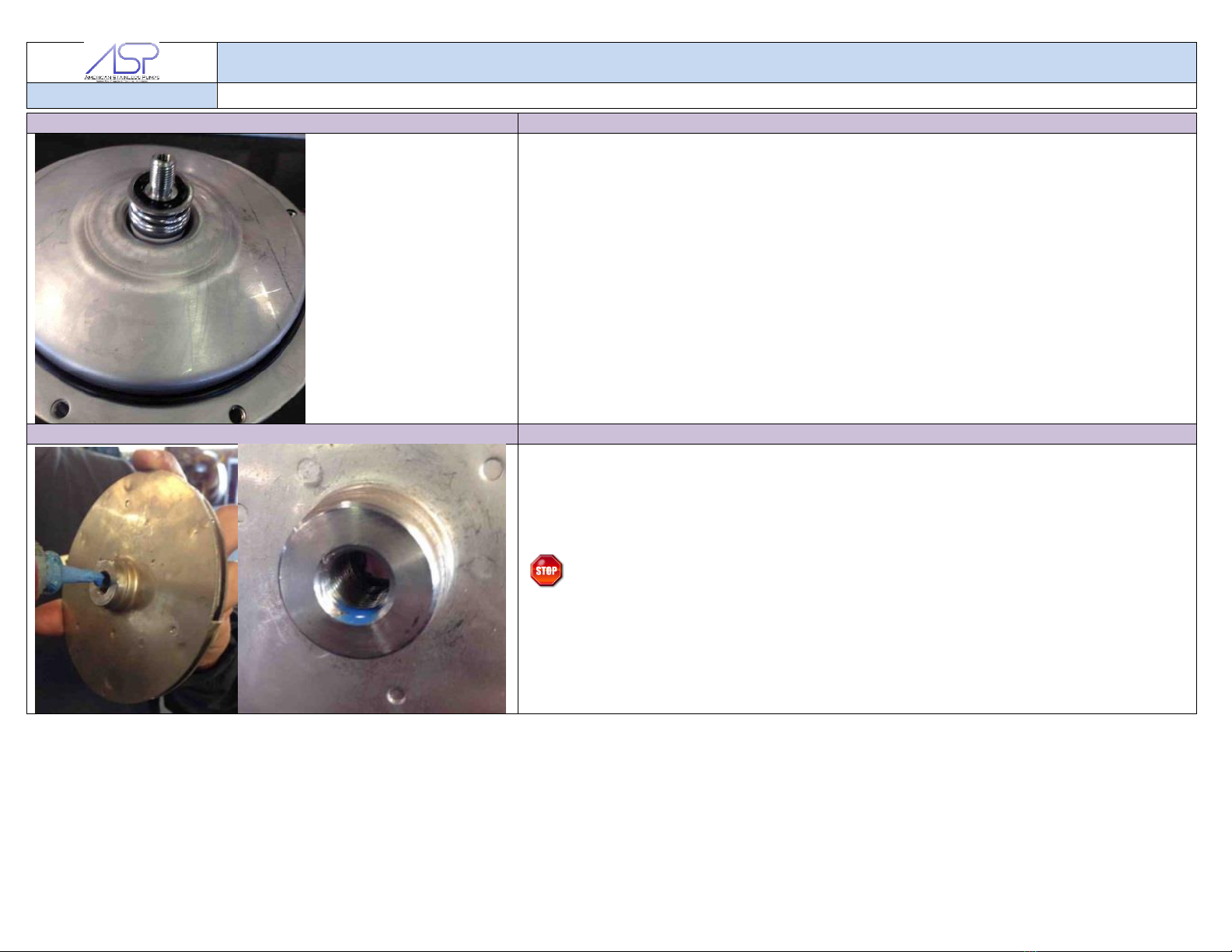

Using the arbor press, place the sealplate into the proper location on the arbor press

plate. The press and plastic tool should come down directly into the center of the seal

without touching the sides.

Pull down on the press handle and press the stationary half of the seal down until it is

stopped by the sealplates bore.

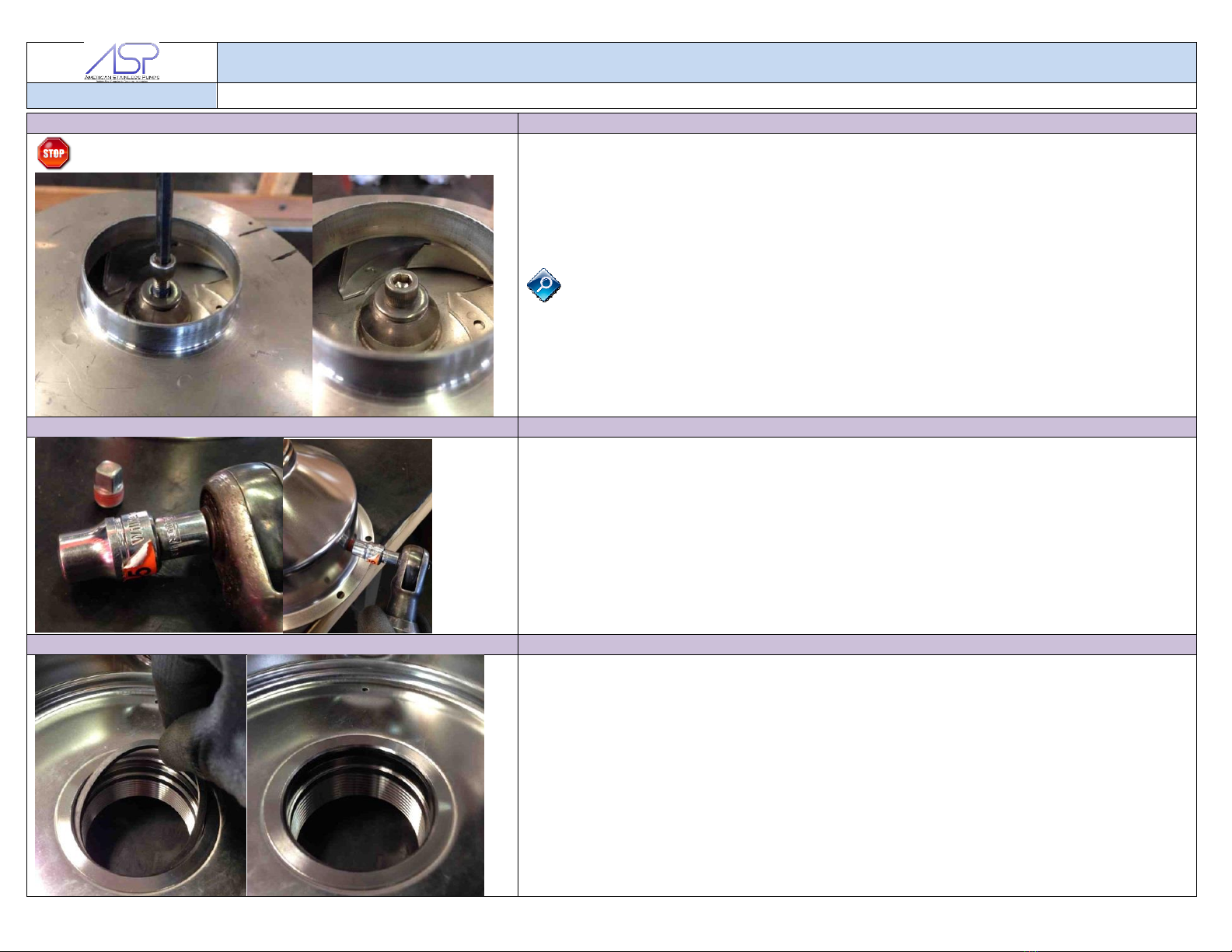

Rotate the sealplate 90 degrees and press, repeating 3 times until four sides of the seal

have been pressed down, ensuring the seal sits flat in the sealplate.