Manual BA 662

Page 2 of 10 Technical changes reserved. 09/2016

A.S.T. - Angewandte System Technik GmbH, Mess- und Regeltechnik

1. Safety precautions

In this operating manual, the installation, putting into operation and the operation itself of the

Strain Gauge Bridge Amplifier BA 662 is described. It is assumed that all measures are taken

by qualified staff only who have adequate knowledge in the fields of measuring and control

engineering.

ATTENTION! Any non-compliance with these safety precautions may result in

severe damage to property and health.

1.1. Field of application

The Strain Gauge Bridge Amplifier BA 662 has been designed to the purpose of amplifying the

output signals of sensors with metal-foil strain gauges, preferably force transducers and

transform them into standard signals. Any other application is regarded contrary to the

intended purpose. The manufacturer does not accept any liability for damages resulting from

such inappropriate usage. In this case it is the user alone who has to bear the risk.

Type BA 662 must not be used as the sole means to prevent dangerous conditions of

machines and plants. All machines and plants must be constructed in such a way (e.g. by

using mechanical stops, limit switches) that a condition of failure does not result in a situation

of severe danger.

It must be made sure that any erroneous setting or malfunction of the unit or its breakdown

cannot cause damage or be a risk to the operating staff or other persons.

1.2. Installation

The unit must be installed and connected in compliance with the current DIN- and VDE-

standards. Supply cables and signal lines shall be installed so that interference signals such as

electrical interference do not have any adverse effects on the function of the equipment.

1.3. Maintenance

The device does not contain any components that require maintenance. Repairs shall be

carried out by the manufacturer only.

2. Function

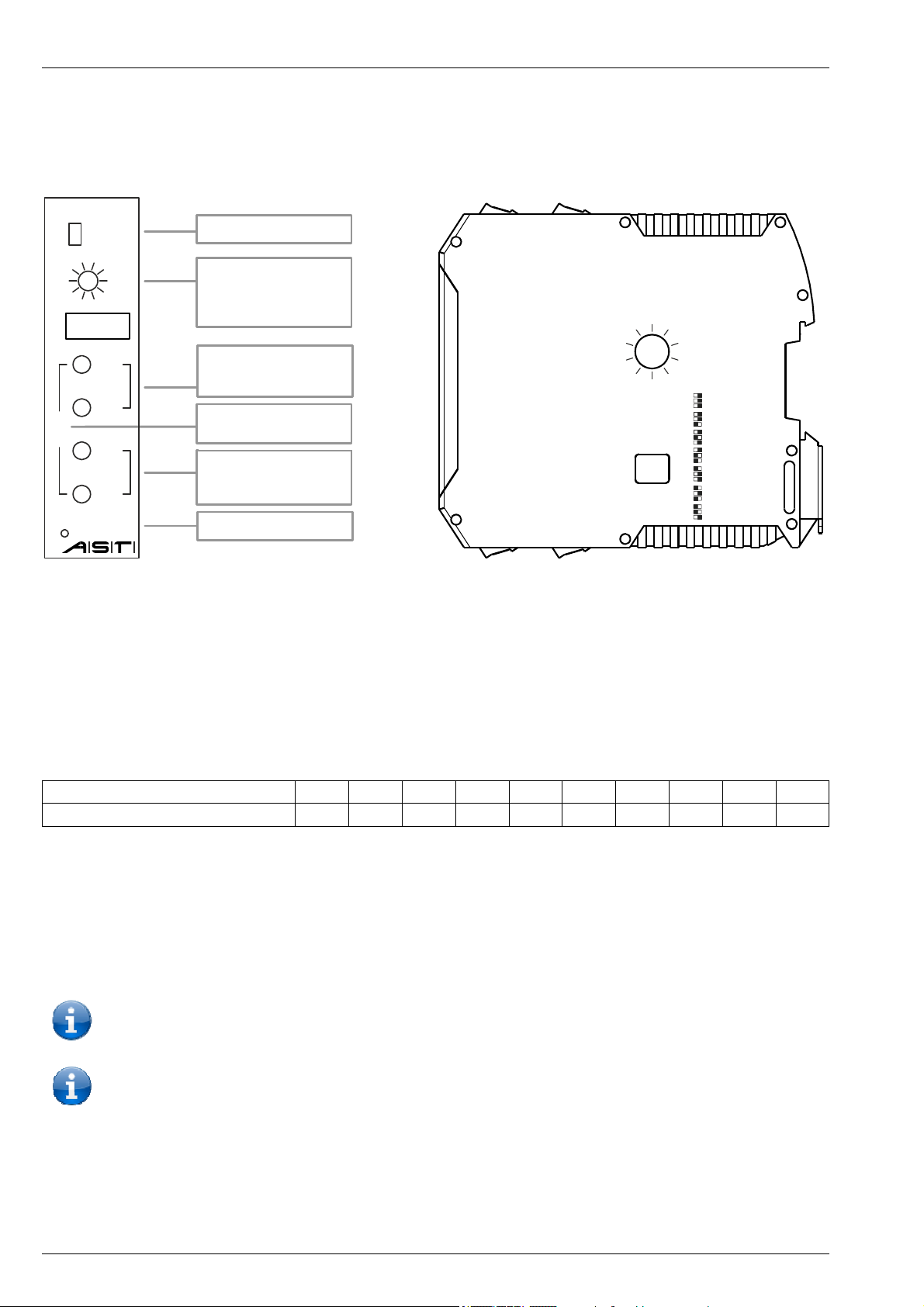

The Strain Gauge Bridge Amplifier BA 662 is a digital amplifier for the low-drift amplification of

the output signals of sensors with metal-foil strain gauges, preferably force transducers to

supply a standard signal of (-10/0...10) VDC or (0/4...20) mA.

An internal voltage source provides the stabilized feeding voltage for the sensor. The power is

supplied by an unstabilized source of (9...36) VDC. The Strain Gauge Bridge Amplifier is

delivered in a case for standard rails in accordance with DIN EN 50022-35.

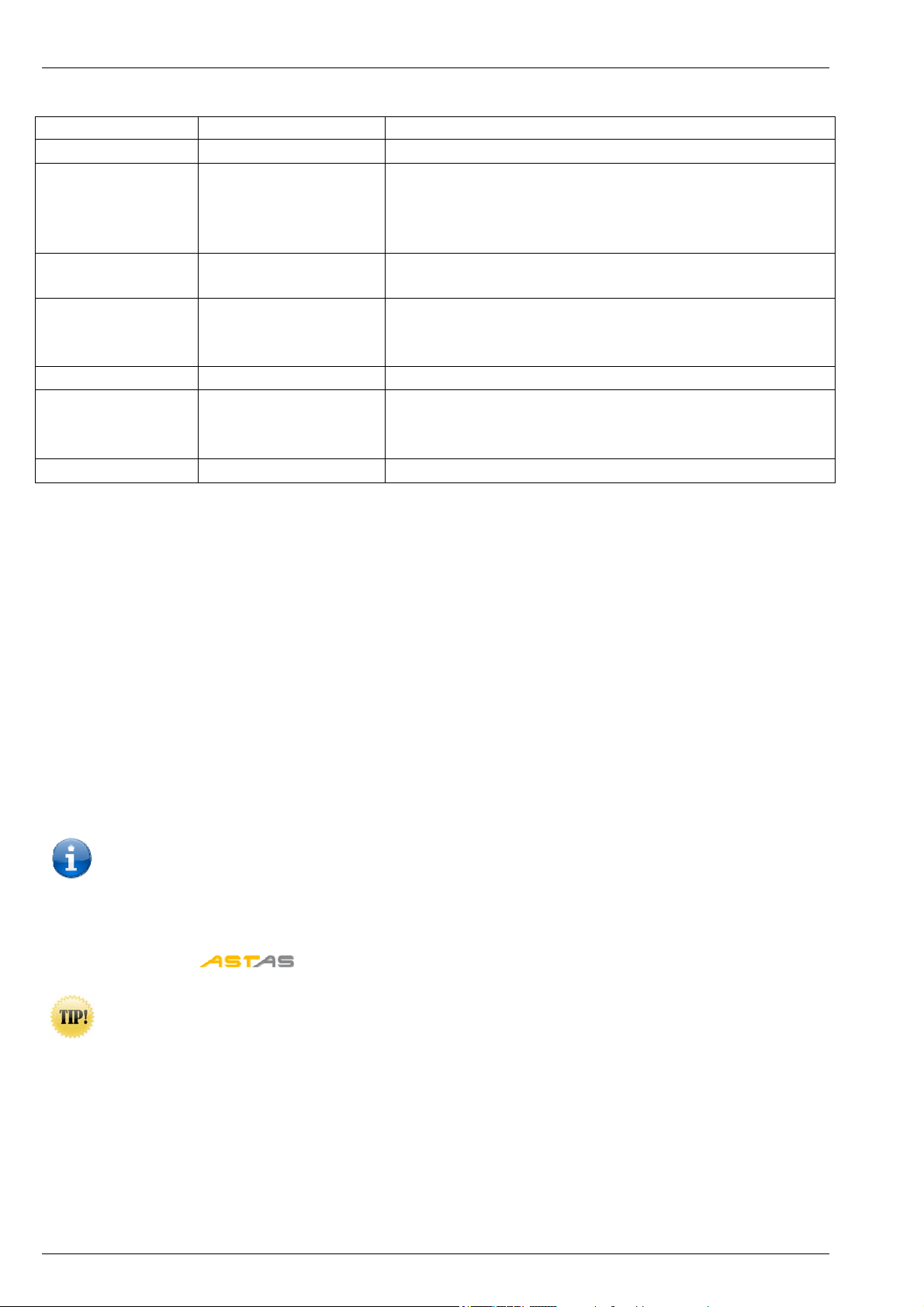

The BA 662 is delivered with a factory setting for an input signal of 2mV/V and a corresponding

output signal of ± 10V or 20mA. The other input signal ranges 0.1mV/V to 7mV/V can be

generated internally from the 2mV/V factory adjustments. The different settings of the factory

adjustments (zero point and gain) can be changed by the user through keys.

By an optically separated input, the zero-setting can be carried out by means of a superior

control and through the trigger input. The overload limit is not affected by such a zeroing, which

means that 100 % of the end-value adjustment of the sensor remains as end value. An existing

preload by a container can thus be set zero.