4

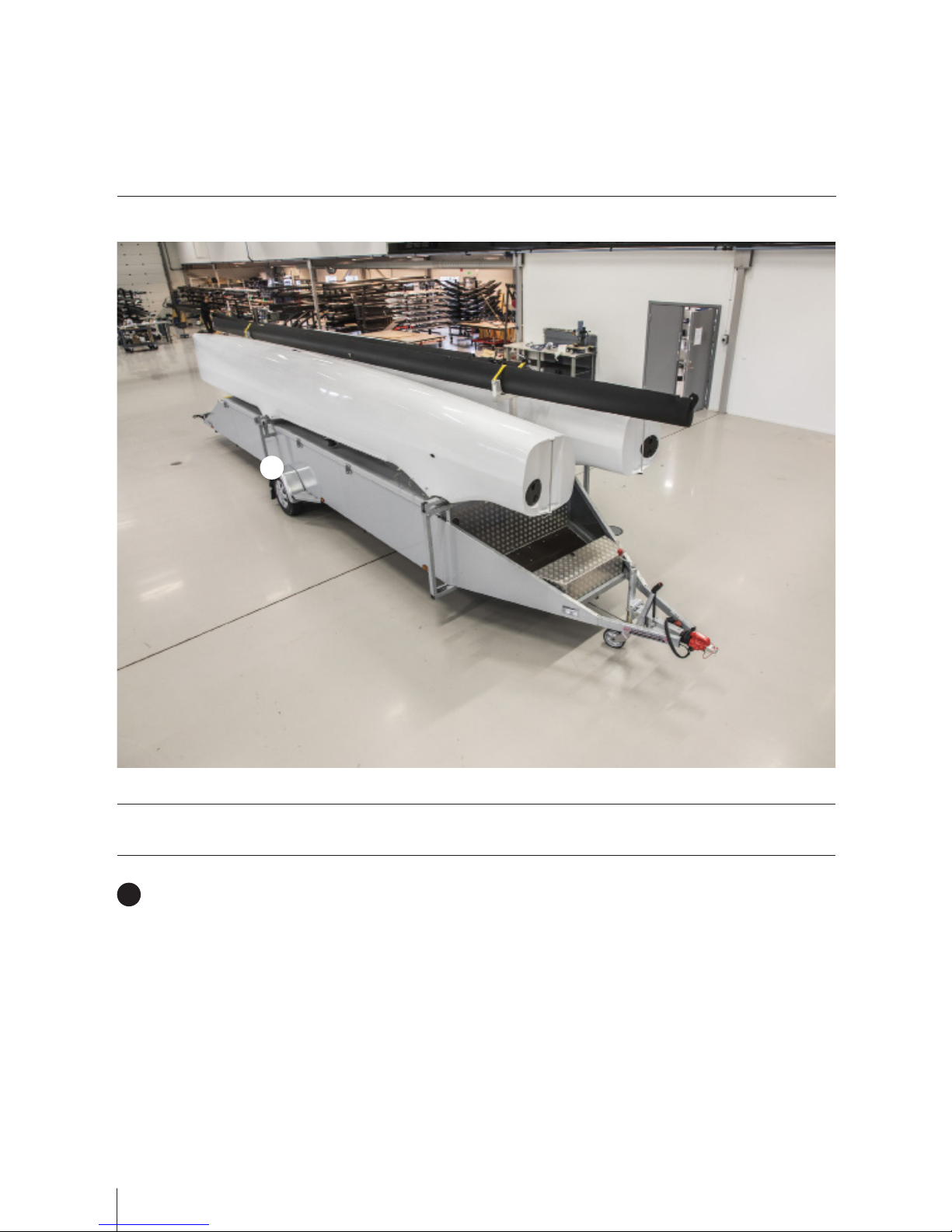

The instructions in this manual are made with the intention of making

owners safely put together, handle and use the boat for training and racing.

The M32 is a high performance racing boat designed and dimensioned for

inshore racing and should be used accordingly.

WE WANT TO STRESS THE IMPORTANCE OF FOLLOWING THIS MANUAL WHEN ASSEMBLING,

HANDLING AND SAILING THE M32. HAVING THE RIG ACCORDING TO THE RECOMMENDED

SETTINGS WITH THE SPREADER ANGLE, DIAMOND TENSION AND MAST RAKE BEING THE KEY

PARAMETERS.

RIG

•Mast rake should be 480mm +/- 5

mm.

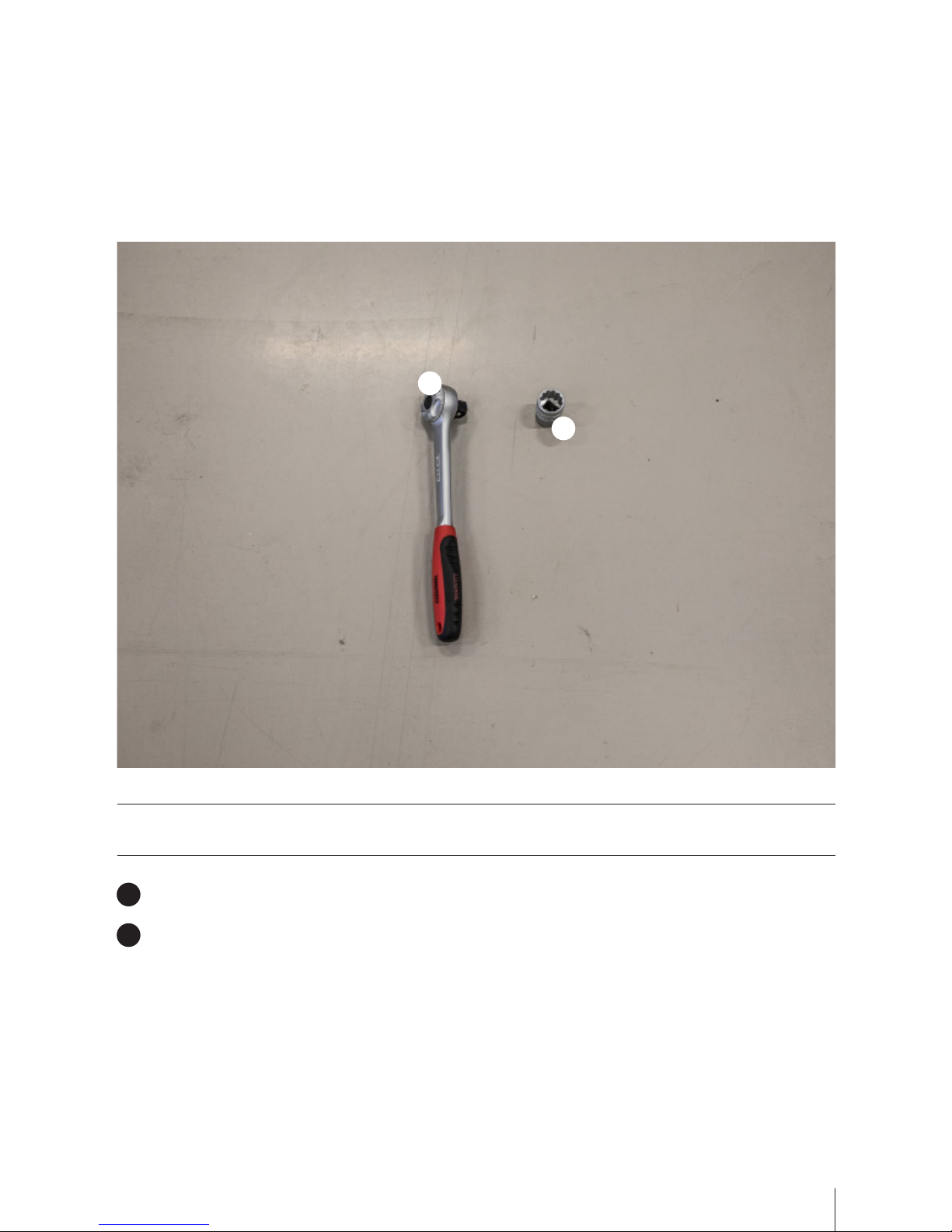

•The diamond tension using the Loos

& Co. gauge RT-10M (3,2-7,1mm) with

the base of the gauge in just above

the mast winch is recommended to be

in the interval 45-55.

•Spreader angle should be 190mm +/-

5mm.

•The soft rig setting is constantly

changing due to material properties.

It is important to always check the rig

settings before any sailing.

•We recommend Spinlock Rig Sense

RGS/0508 for measuring the aft stay

tension.

•Ensure that the cunningham line is

not resting on the diamond stay, a

dyneema can be put around the goo-

seneck to get a better angle for the

ring/block.

•The gennaker luff length should be

15,630 meter, measured bearing to

bearing, with a tension of 40 Kg on

the luff.

•In rig setting point 2 the measuring

point is defined as 70 mm above the

joint on the backside of the aft beam.

M32 CATAMARAN

TECHNICAL INFORMATION