10

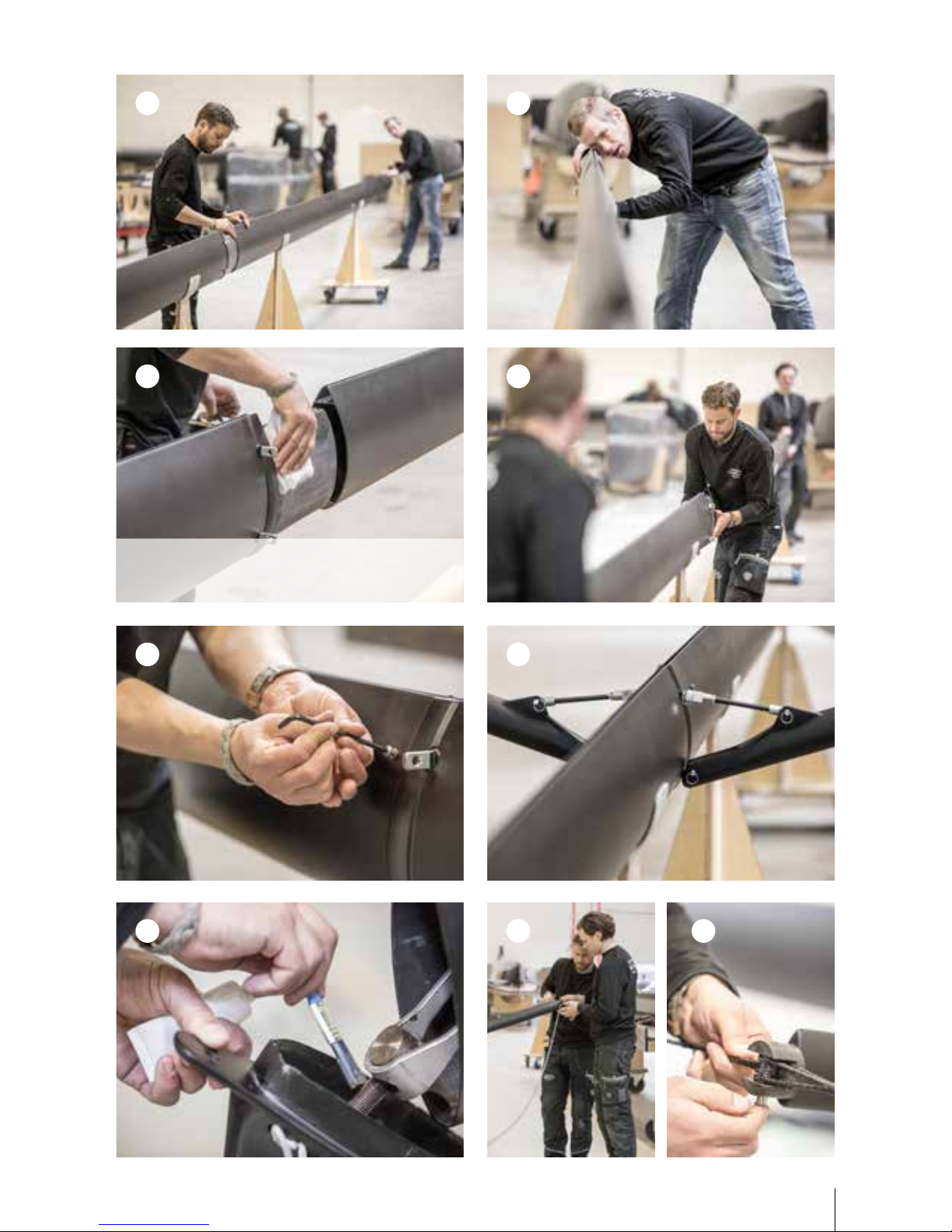

Tension the diamond turnbuckle until you

get your required prebend.

Prebend should be a minimum of 70mm

with full main and 80mm when sailing with

a reef.

Prebend is defined in this case as the

distance between the trailing edge at the

spreader and an artificial straight line

between the upper most point and lowest

point of the trailing edge of the luff track.

When measuring the prebend the mast

supports shall be placed 150cm above the

bottom end of the mast and one 20cm

above the upper diamond stay fitting.

8

9

It is VERY IMPORTANT that the clevis pin is orientated with the head facing towards the trailing

edge of the mast and the key ring is towards the leading edge of the mast. The shrouds can be

damaged and the mast can fall down if the clevis pin is orientated the wrong way.

The halyards need to have a diameter

of 8mm to prevent the halyards to

come out through the luff track. Do

not remove the cover or use lesser

diameters.

VERY IMPORTANT!

IMPORTANT!

Remove the top sheave to insert the Main

halyard. Use a small hook to pull the haly-

ards through the luff track. Tie the sail head

end of the halyards to the mast close to the

mast foot.

Let the Gennaker halyard at the bottom go

through the spinlock on port side of the

mast.

The diamond tension using the Loos & Co.

gauge RT-10M(3,2-7,1mm) with the base of

the gauge in just above the mast winch is

recommended to be in the interval 45-55.

If the required prebend is not reached at 55

on the gauge the spreader angle needs to

be adjusted.

Let the Main halyard at the bottom go

through the block on starboard side and up

to the winch.

10

12

13

11

How to check the spreader angle:

Pull a string tight between the center of the

spreader tips and measure the distance

between the string and the trailing edge of

the mast at the joint. Standard measure-

ment is 190mm, minimum is 180mm and

maximum is 200mm. Larger spreader angle

will give more mast prebend. The adjusted

length of the spreader turnbuckles must be

the same on both sides. A halft turn on turn-

buckles gives approximately a 5mm change

in spreader angle. As shown in picture 7a the

string should be pulled just above the end

fitting on top of the diamond stay.

7