ATECH CRATER-06 AP User manual

CRATER-06 AP

HEAVY DUTY 20” AUTOMATIC SLICING UPCUT SAW

1

CONTENTS

1. GENERAL INFORMATION

1. Introduction

2. Distributor

2. MACHINE’S DESCRIPTION AND PURPOSE OF USE

1. Machine’s Description

2. Technical Features

3. Cutting Diagram

4. Dimensions

5. Electric And Pneumatic Control Panel

6. Electric Circuit Inputs – Outputs

7. Electric Wiring Scheme

8. Pneumatic Wiring Scheme

3. SAFETY

1. Safety Information

2. Accident Prevention

3. General Safety Information

4. Safety Symbols And Meanings

4. TRANSPORT OF THE MACHINE

5. INSTALLATION OF THE MACHINE

1. Preparation

2. Instructions About Safe Connection Of The Machine To The Power Source

3. Air Pressure Setting

6. MACHINE SAFETY DATA

7. OPERATION

1. Presentation of the Panel and Program Input

2. Automatic Cutting

1. Recipe

2

2. Cutting List

3. Manual Cutting

4. Settings

1. Technician Settings

2. Input and Output Tests

8. SAFE INSTALLATION OF THE SAW BLADE

9. SAFE INSTALLATION OF THE BELT

10. MAINTENANCE

1. Routine Controls, Maintenance And Work Starting

2. Spray Mist System Maintenance

3. Work Day End Care

11. TROUBLESHOOTING GUIDE

12. COMPONENTS

1. Electric Components

2. Pneumatic Components

3

1. GENERAL INFORMATION

1.1. Introduction

The user’s manual given by the manufacturer contains information about the machine parts. Each machine operator

should read these instructions carefully, and the machine should be operated after fully understanding them.

Safe and efficient long-term use of the machine depends on understanding and following the instructions contained in

this manual. The technical drawings and details contained in this manual constitute a guide for the operator.

1.2. Distributor

ATECH MACHINE, INC.

www.ATechMachinery.com

Ph.: +1-240-505-1967

E-mail : info@ATechMachinery.com

*In case of any technical problem please contact your nearest ATECH dealer or ATECH head office through the above

mentioned phone or e-mail address.

*Technical labels with the model description of the machine are attached onto the front side of each machine.

*The machine serial number, motor values, air pressure, air consumption and production date are printed on the technical

label.

2. MACHINE’S DESCRIPTION AND TECHNICAL FEATURES

2.1. Machine’s Description

It is an automatic 20” straight upcut saw designed for serial cutting of (slicing) of aluminum profiles with a Ø500 mm (20”)

saw blade.

➢ The machine has been designed in compliance with UL & CSA Safety Directives.

➢ With the servo control system, time saving is achieved with profile feed speed and saw cutting height control.

➢ It is possible to precisely adjust the cutting speed infeed according to the type of material.

➢ During the cutting process, if the top safety guard is opened, the saw will not start cutting, and returns to start

position in case it is opened during the cutting process fopr safety reasons.

➢ In manual cutting mode, it cuts the desired size and automatically stops and waits in the ready position.

➢ In the automatic cutting process, after the number of cutting operations is completed, the machine stops

automatically and moves to the next memory and waits in the ready position.

STANDARD

ACCESSORIES

Ø500 mm (20”) Saw Blade

KN-M3 Conveyor

Screw Shaft Lubrication Unit

3 Qty. Vertical Pneumatic Clamps

3 Qty. Horizontal Pneumatic Clamps

Spary Mist Lubrication System

Air Gun

2 Qty. Chip Collector Manifolds

OPTIONAL

ACCESSORIES

Automatic Opening Top Guard

Industrial Type Chip Collector VCE 1570

4

Please stipulate the below mentioned data in all your correspondence regarding the machine with the manufacturer

and/or your ATECH dealer.

Machine model

Machine’s serial number

Voltage and frequency

Name of dealer where machine was purchased

Date of purchase

Description of the machine fault

Average daily operation period

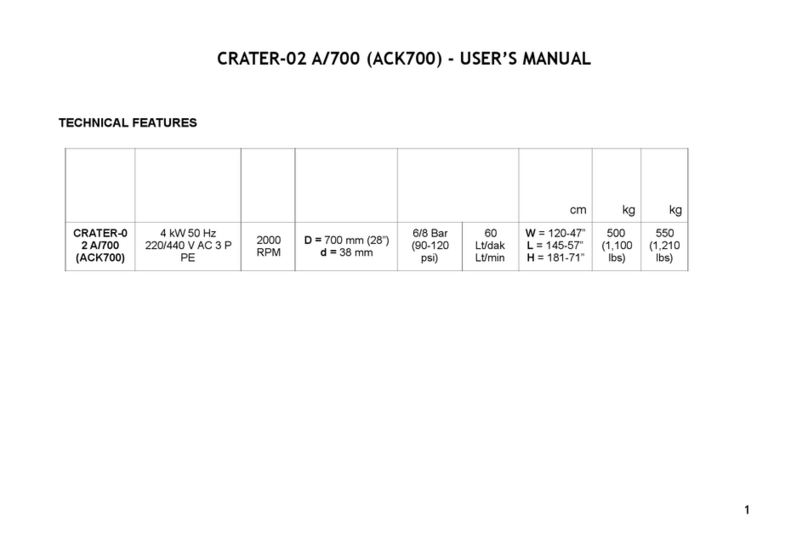

2.2. Technical Features

2.3. Cutting Diagram

5

2.4. Dimensions

2.5. Electric And Pneumatic Control Panel

There is an electrical panel at the top, the power supply must be turned off by the authorized electrician and should be

checked with the diagram on the cover in case of a problem.

In the lower part there is a pneumatic panel and the coolant receptacle. It must be opened by authorized

personnel and filled with suitable coolant. The coolant has to be water based.

The panel door must be closed and locked during operation. In the service work carried out for

maintenance and possible defects;

CLOSE ELECTRICAL AND PNEUMATIC POWER RESOURCES.

Set the air pressure between

6-8 bars. The manometer is

read as air pressure bar. If

the reading on the pressure gauge is less than or

equal to the desired pressure, turn the air pressure

adjustment switch to the right or left to adjust the

pressure to 6-8 bar.

The conditioner unit collects the water contained in the air system into the collection container so as not to damage the

pneumatic system components. Periodically (on the working day) drain the water by pressing or opening the button under

the conditioning cylinder deposit to drain the collected water.

2.6. Electric Circuit Inputs – Outputs

INPUTS

OUTPUTS

Start_Button

P00000

Servo_1_Pals_Infeed

P00040

Stop_Button

P00001

Servo_2_Pals_Saw

P00041

Emergency_Stop

P00002

Servo_1_Dir

P00042

Pressure

Adjustment

Knob

Manometer

Air Pressure and

Water Discharge

Oil Storage

Oil Additional

Stopper

6

Servo_1_Alarm

P00003

Servo_2_Dir

P00043

Servo_2_Alarm

P00004

Servo_1_Alarm_Reset

P00044

Empty

P00005

Servo_2_Alarm_Reset

P00045

Max_Limit_Switch

P00006

Servo_1_On

P00046

Top_Cover_Switch

P00007

Servo_2_On

P00047

Saw_Back_Cover_Switch

P00008

Saw_Motor

P00048

Saw_Front_Cover_Switch

P00009

Saw_Clamping_Piston_1

P00049

Empty

P0000A

Saw_Clamping_Piston_2

P0004A

Motor_Thermic

P0000B

Material_Infeed_Clamping_Piston

P0004B

Saw_Below

P0000C

Table_Piston

P0004C

Material_End_Sensor

P0000D

Conveyor_Piston

P0004D

Min_Limit_Switch_Home

P0000E

Coolant

P0004E

Empty

P0000F

Empty

P0004F

Empty

P00010

Empty

P00011

Empty

P00012

Empty

P00013

Empty

P00014

Empty

P00015

Empty

P00016

Empty

P00017

7

2.7. Electric Wiring Scheme

2.8. Pneumatic Wiring Scheme

8

3. SAFETY

3.1. Safety Information

The symbols shown hereunder are necessary to be read with special attention. Not reading or observing of them may

cause damage to the equipment or personal injury.

The IMPORTANT symbol above is one telling to apply special care and to be careful at carrying out the specified

operation.

The CAUTION! symbol above warns you against specific dangers and requires to read the text. Not observing may cause

damage to the equipment.

The above symbol DANGER WARNING, warns you against specific dangers and you have definitely to read them. Negligence

may cause damage to the equipment and bodily injury. Read the user’s manual carefully before using the machine or carrying

out maintenance works.

3.2. Accident Prevention

3.2.1. Our machines are manufactured in accordance with EN 60204–1 and EN 292–2 CE safety

directives, which cover national and international safety directives.

3.2.2. It is the task of the employer to warn his staff against risks, to train them on prevention of accident, to

provide for necessary safety equipment and devices for he operator’s safety.

3.2.3. Before starting to work with the machine, the operator should check the features of the machine, learn all details

of the machine’s operation.

3.2.4. Machine should be operated only by staff members, who have read and understood the contents of this manual.

3.2.5. All directives, recommendations and general safety rules contained in this manual have to be observed fully. The

machine cannot be operated in any way for purposes other than those described herein. Otherwise, the

manufacturer shall not be deemed responsible for any damages or injuries. And such circumstances would lead to

the termination of the warranty.

3.3. General Safety Information

1.

The

power

cable

should

be

led

in

such

a

way

that

nobody

can

step

on

it

or

nothing

can be placed on it. Special care be taken regarding the inlet and outlet sockets.

2. If the power cable should be damage during operation, don’t touch and unplug it.

Never use damaged power cables.

3. Don’t overload machines for drilling and cutting. Your machine will operate more

safely with power supply in accordance with UL & CSA stipulated values.

9

4. Don’t place your hands between parts in motion.

5. Use protective eye glasses and ear plugs. Don’t wear oversize clothes and jewels.

These can be caught by moving.

6. Keep your working place always clean, dry and tidy for accident prevention and safe

operation.

7. Use correct illumination for the safety of the operator. (ISO 8995-89 Standard The

Lighting of Indoor Work System)

8. Don’t leave anything on the machine.

9. Don’t use any materials other than those recommended by the manufacturer for

cutting operations on the machine.

10. Ensure that the work piece is clamped appropriately by the machine’s clamp or vice.

11. Ensure safe working position, always keep your balance.

12. Keep your machine always clean for safe operation. Follow the instructions at

maintenance and replacement of accessories. Check the plug and cable regularly. If

damaged, let it replace by a qualified electrician. Keep handles and grips free of any

oil and grease.

13. Unplug first, before conducting and maintenance works.

14. Ensure that any keys or adjustment tools have been removed before operating the

machine.

15. If you are required to operate the machine outside, use only appropriate extension

cables.

16. Repairs should be carried out by qualified technicians only. Otherwise, accidents amt

occur.

17. Before starting a new operation, check the appropriate function of protective devices

and tools, ensure that they work properly. All conditions have to be fulfilled in order

to ensure proper operation of your machine. Damaged protective parts and

equipment have to be replaced or repaired properly (by the manufacturer or dealer).

18. Don’t use machines with improper functioning buttons and switches.

19. Don’t keep flammable, combustive liquids and materials next to the machine and

electric connections.

3.4.

3.4. Safety Symbols And Meanings

Electric warnings.

Use protective goggles.

If main connection cable is damaged

during operation, do not touch it

and disconnect the main plug from

main socket.

Use protective earmuffs.

When machine is working, do not

make your hand close to saw blade.

Use protective gloves when

changing the saw.

Keep working environment clean,

dry and tidy.

Read operating instructions carefully

before using or maintaining the

machine.

3.5.

10

4. TRANSPORT OF THE MACHINE

* The transport should be done by qualified personnel only.

4.1.1. The machine should be transported by lifting with proper equipment (not touching the ground during the

transport).

4.1.2. Don’t lift the machine before ensuring that lifting devices or other equipment is placed properly under the machine.

4.1.3. For the weight and dimensions of the machine, 2.2. Technicial Features.

5. INSTALLATION OF YOUR MACHINE

The machine should be located at least 50 cm in front of the back wall. The machine is equipped with a burr collection bag

connector and power supply socket on the back side.

5.1. Preparation

5.1.1. The outer dimensions of the machine are stipulated in the dimensions page. The ground, where the machine will be

placed, should be even, solid enough to bear the weight of the machine.

5.1.2. At the double head automatic saw machine Crater all parts are delivered by the manufacturer ready for use.

5.1.3. Do not make electrical connections without removing the bolt and stop connections used for the detection of running

systems before the machine is started and without wiping the protective oil layer in working parts.

5.2. Instructions For Safe Connection Of The Machine To The Power Source

5.2.1. The three-phase electrical cable socket must have five inputs to the cable on the machine.

5.2.2. Use a connection cable sockets in accordance with the CE Safety Directives.

5.2.3. Check the inlet power supply before powering the machine.

The socket connections have to be made by a qualified electrician, the rotation direction of the saw blade has to be

observed by starting the machine. If the saw blade rotates in reverse direction, the socket connections have to be checked and

re-connected properly. If the direction of rotation of the saw blade is reversed, it is dangerous to Operator and equipment. It

causes the saw teeth to break and cracks.

Plug the machine's electrical power socket into the previously prepared 3-phase socket socket to follow the saw-turn

direction and follow the following procedures:

1. Turn on the switch and press the reset button on the screen. The machine will take its starting position.

2. Select manual operation on the screen and press the green button, the clamps will tighten.

3. Press the start button on the screen, then press the emergency stop.

4. Observe the direction of rotation of the saw blade.

5. The direction of rotation of the saw is available on the turn direction label on the table.

If the saw blade rotates in reverse direction: The electric socket connections have to be checked and corrected by a

qualified electrician. The direction of rotation of the saw blade must not be run without testing.

11

5.3. Air Pressure Setting

For the pneumatic system to operate properly, the air pressure must be 6-8 bars (90-120 psi). Do not operate at lower

pressures than 6 bars. Read the manometer on the conditioner to calibrate and check the air pressure.

Follow the steps below for air pressure settings.

5.3.1. Pull up the conditioner adjustment knob.

5.3.2. The pressure increases when the knob is turned clockwise, while the pressure decreases when it is turned counter-

clockwise.

5.3.3. When you read the 6-8 Bar pressure setting on the pressure gauge, lock the conditioner setting knob.

5.3.4. The conditioner unit accumulates the water contained in the air system into the collection container so as not to

damage the pneumatic system components. Automatically removes water collected when air is supplied to the

machine.

5.3.5. The oil recommended by the manufacturer in the conditioner is TELLUS C 10 / BP ENERGOL HLP 10 / MOBIL DTE

LIGHT / PETROL OFFICE SPINDURA 10.

6. MACHINE SAFETY DATA

6.1.1. It is not allowed to operate the machine with the protective cover and other protective

equipment removed.

6.1.2. Your machine must be operated with the voltage on the technical label. Let the electric

installation of your machine carry out by a qualified electrician only. Grounding must be

done. There will be irregularities in machine operation if grounding is not done properly.

6.1.3. Lifting, installation, electric, pneumatic maintenance of the machine should be carried out

by qualified personnel only.

6.1.4. Routine maintenance and scheduled maintenance should be carried out by qualified personnel after

unplugging the machine and disconnecting the air supply first.

6.1.5. Ensure that the machine has been cleaned, tested and maintenance before starting to operate.

6.1.6. Check the safety devices, power cable and moving parts regularly. Don’t operate the machine before having

replaced defective safety devices or faulty parts

6.1.7. Never replace the circular saw without disconnecting the air and the electrical and pneumatic power connection.

6.1.8. Keep foreign materials away from the working area of the machine, keep away from the machine’s moving

parts.

The saw blade continues its rotation for a while after switching off the motor.

Don’t use the machine for purposes other than it has been designed for (cutting of iron and other ferrous

materials).

The safety data have been defined above. In order to prevent physical damage or damage to the

equipment, please read the safety information carefully and keep the manual always in an easy accessible

place.

12

If the top guard is open, the motor will not start in terms of worker safety. However, you can tighten the

clamps with the top guard open so that you can place your profile and adjust and tighten it.

7. OPERATION

In the automatic cutting section, it provides automatic cutting in desired length, equal lengths and desired number from

the workpiece. Select how many seconds intervals the coolant will be activated from the settings page, it is between 0.5

seconds and 2 seconds depending on the material thickness. Then, by opening the Recipe page, write the desired length value

of the workpiece to be sliced in the “MEASURE TO CUT” section. Write the number of profiles to be processed (how many

profiles will be connected at the same time) in the "NUMBER OF PROFILES". For precise and clean cut, write the saw cutting

speed to “CUTTING SPEED” (meters / min). Write the total profile height in the "PROFILE HEIGHT" to adjust the saw output

height. How many cuts are written in the "CUTTING NUMBER" section. Bring the end of the profile to the middle of the saw

channel and fix the profile with clamps by pressing the green button. If the clamps do not tighten the profile, you can open it

by pressing the green button once more and adjust your vices according to the profile, do not forget to make the adjustment

both in the driver and machine part. If you are sure that you press the green button and tighten the profile, after you press the

"START" button on the screen, it will automatically start cutting. The cutting process will start with tip cleaning. In the

meantime, check the height and speed of sawing. In the opposite case, your hand will be on the emergency stop button. The

cutting process will continue until the specified number is completed or the profile ends until the cutting process starts. When

the work piece on the machine is finished, the machine will go to the stop position and wait for you to press the "START"

button. If it is desired to stop cutting or exit the page while slicing, press “STOP” button and wait for the machine to stop. When

the machine stops, the page can be exited and switched to another page, or the machine can continue slicing from where it

left off by pressing the "START" button.

7.1. Presentation of the Panel and Program Entry

CRATER AP500 Automatic cutting machines use of electronic positioning device;

Emergency Stop

Button

Clamp Button

Electronic LCD Control

Panel

13

OFF

ON

a. Turn the switch to the “1” position. Electronic positioning device is touch screen. Click on the language option that suits

you on the screen and pass the introductory page (ATECH).

b. Perform the position calibration of the material infeed system before starting the cutting process. To do this, press the

“RESET” button.

c. The home page is the display page with the operation selections. Operation is initiated by touching the desired operation

button. Also, press the page name to exit the page and return to the main page.

7.2. Automatic Cutting

When you want to process in automatic cutting, you can cut with the new cutting values that you will create from “RECIPE”

or by choosing the measurements you prepared previously from “CUT LIST”.

Cut List Line

Number

14

You can access the desired values by pressing the directional keys next to the cut list line number indicator to go to the

existing measurement values in the "CUTTING LIST". When you reach the desired value, press the "CLAMP" button and tighten

the clamps. You can then start the process by closing the top cover and pressing the "START" button.

NOTE : If the value written in the quantity section is completed, the machine will automatically switch to the next recipe in the

memory and wait for you to put the profile and press the “CLAMP” button.

7.2.1. Recipe

When you press the recipe button, you can create a new recipe, or you can access the values you prepared before and

make changes by cutting the values. Use the arrow keys next to the screen to access the existing values. To create a new recipe,

fill in the relevant places. Press “AUTOMATIC CUTTING” button to proceed and continue the steps as stated above. (7.2.

Automatic Cutting)

To make a recipe, you can also directly access this page by clicking the "RECIPE" button on the main page.

7.2.2. Cutting List

It is the section where the recipes of the created recipes are displayed. Select the operation to be performed in this section,

press the “AUTOMATIC CUTTING” button and continue the steps as stated above. (7.2. Automatic Cutting)

7.3. Manual Cutting

When you want to cut with “MANUAL CUTTING”, write the desired workpiece size in “CUTTING MEASURE” and “CUTTING

HEIGHT”. Then, enter the "CUTTING SPEED" value for the ideal cut. After entering the required values, first press the "CLAMP"

button and then the "START" button. After the cutting process, the vices will open automatically, you can get your profile.

7.4. Settings

Profile QTY

Cut Speed

Length

measure

to

be cut

Profile

Name

Cut QTY

Profile Height

15

As can be seen in the image above, "SAW THICKNESS" and "COOLING FLOW SPEED ADJUST" can be done in the settings

section. In case of unexpected problems, there are technician settings and components entrance and exit test section to be

used by the authorized staff.

7.4.1. Technician Settings

The machine is made ready for use by making the necessary settings by the manufacturer. In case of a

malfunction that causes the reference values to change, the authorized staff will log in to this page and

make necessary arrangements.

7.4.2. Input and Output Tests

It will be used by authorized personnel or trained personnel for the necessary procedures. Do not enter

this section unless necessary, since there is no section for cutting operations or settings.

8. SAFE INSTALLATION OF THE SAW BLADE

To remove the circular saw blade from the saw mile, apply the following sequence.

8.1.1. Cut off the machine's electrical and air connection. Open the front cover lock on the chassis. (Figure 1, 2)

8.1.2. Remove the saw casing cover sheet metal. (Figure 3)

8.1.3. Remove the M10 screw by turning with a 8 mm allen key (Hold the saw blade shaft at the opposite end with a other

8 mm allen key and prevent so that the shaft turns). (Figure 4, 5)

8.1.4. Remove the 30x8x7mm washer and Saw Flange parts regularly. (Figure 6)

8.1.5. Carefully remove the saw.

8.1.6. Fit the saw you want to change on the shaft, making sure the direction of rotation is correct.

8.1.7. When replacing the saw with the new one, use the portion of the saw blade that corresponds to the saw blade

diameter. The outer diameter of the saw ring is two parts according to 30 and 32mm.

8.1.8. Fit the other parts (Washer and Saw Flange) in order, following the reversal of the operations on the shaft.

8.1.9. Tighten the M10 screw by turning it clockwise with an 8 mm Allen key (Hold the saw blade shaft at the opposite end

with a other 8 mm allen key and prevent so that the shaft turns).

8.1.10. Install the saw cover. Close front cover.

NOTE : The saw you use must be sharpened / changed at certain intervals depending on the type of material being cut.

When the cut workpiece is burned at the end of cutting or when the cutting is forced, sharpening / changing

operation is performed.

16

Figure 1: Open The Front Cover.

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Saw Flange

Washer 30x8x7

Saw Washer

M10x20 Inbus

Screw

Ø500 mm Saw Blade

Coupling

17

9. SAFE INSTALLATION OF THE BELT

Follow the instructions below to safely replace the CRATER AP500 machine belt.

9.1.1. Remove the saw by performing saw changing operations.

9.1.2. Remove the saw casing sheet metal cover.

9.1.3. Remove the M6 screw by turning with a 5 mm allen key.

9.1.4. Remove the belt cover.

9.1.5. Loosen the M8 screws by turning them clockwise with a 6 mm Allen key.

9.1.6. Loosen the M10 key-head bolt with the 10 mm keys.

9.1.7. You can change the belt by loosening the motor block.

9.1.8. Once you have changed the belt, finish the process by following the procedures.

10. MAINTENANCE

1. Routine Controls, Maintenance And Work Starting

1.1. Make sure the table and all parts are clean and dry. Clean the table from the oil and dry it. Be especially sure of the

cleanliness and dryness of the handle.

1.2. Clean all surfaces of the machine from the sawdust, chips and foreign materials. Use glasses and glove to protect

yourself from harmful substances.

1.3. Check the saw blade against wear, bending, cracking and breakage before each use. Turn carefully to see each tooth

of the saw (after removing the saw protective housing). If the saw is damaged, change the saw.

1.4. Check the air pressure system pressure. If necessary, set the air pressure around 6-8 bar.

1.5. Check the air pressure filters and the oil level in the conditioner. If you do not have enough oil, complete it.

Loosen

with

10

mm

key

18

Disconnect the electrical power connection and air pressure connections before doing all this.

2. SPRAY MIST SYSTEM MAINTENANCE

10.2.1. Add the coolant prepared by opening the lid of the coolant into the container, provided that it is not filled completely.

(The coolant used should be close to water flow)

10.2.2. Note that the hose on the cover is fully inserted into the receptacle and above the filter.

10.2.3. Make sure that the cover is tightly closed and the hose does not break.

10.2.4. When you want to make lubrication, you can turn it on and off on the screen.

10.2.5. The lubrication action only happens when the saw goes up.

3. Work Day End Care

3.1. Disconnect the electrical and pneumatic power connections.

3.2. Clean all surfaces of the machine from the sawdust, chips and foreign materials. If cleaning of the protective housing

is necessary, remove the front cover and wear gloves to protect your hands from the cutting edges of the saw. Use

glasses to protect yourself from harmful substances.

3.3. If water and water based liquids are used during cutting operations, dry the machine with dry cloth at the end of the

work.

3.4. Apply a thin layer of oil to the plate to protect it from corrosion. If it is not to be used for a long time, lubricate with

a protective oil.

3.5. Avoid materials that damage the paintwork while cleaning the machine.

3.6. Lubricate both surfaces with machine oil or a protective oil to protect the saw from corrosion.

11. TROUBLESHOOTING GUIDE

Here are our suggestions to get rid of immediate problems. If the fault can not be rectified or if you encounter a fault other

than those listed below, please contact the technical service.

TROUBLES

CAUSES REMEDY

Low surface quality (at aluminum

and similar materials);

Rough surface,

Large chip,

Not homogenous surface,

Saw blade traces visible

Not cooling the saw blade surfaces.

Lubricating the saw blade cutting

surfaces,

Using of cooling liquid.

Using of damaged or blunt saw blade

or the saw rotating in reverse. Check the saw blade teeth. Replace if

necessary. Check the electricity.

Saw blade moves to quick. The cutting speed is too high fort he

material. Decrease the cutting speed.

Motor does not work (Start button is

pressed, not working) No power supply to the machine. Check the electric cable connections.

Check the electric power sockets.

Motor is working but the pneumatic

clamp piston do not work.

The air supply connections are

missing, or the air pressure is too

low.

Check the air compressor connections.

Adjust the air pressure between 6-8 Bar

on the conditioner.

The saw blade rotates in reverse

direction. The electric connection or the power

cable is wrong. Let the electric connections carry out by

a qualified electrician.

19

No lubrication. It may be related to the oil amount,

oil fluidity or valve.

Check the oil level.

Observe the oil hose in the oil.

Open the valve.

Be sure to use the appropriate oil.

Blow air into the end of the hose

inside the drum with an blow gun.

Lubrication is less. It may be related to the sprayer. Open the dimmer on the sprayer.

12. COMPONENTS

1. ELECTRIC COMPONENTS 2. HYDRAULIC-PNEUMATIC COMPONENTS

PART NAME QTY

ELECTRIC MOTOR 1

SERVO MOTOR 2

POWER CABLE 5x2,5 mm 3,5 m

PART NAME QTY

FRC 1/4 D MINI CONDITIONER 1

PNEUMATIC CLAMPS 6

KSØ50 x 5 PNEUMATIC CYLINDER 2

KSØ50 x 3 PNEUMATIC CYLINDER 2

KSØ63 x 5 PNEUMATIC CYLINDER 2

This manual suits for next models

1

Table of contents

Other ATECH Saw manuals