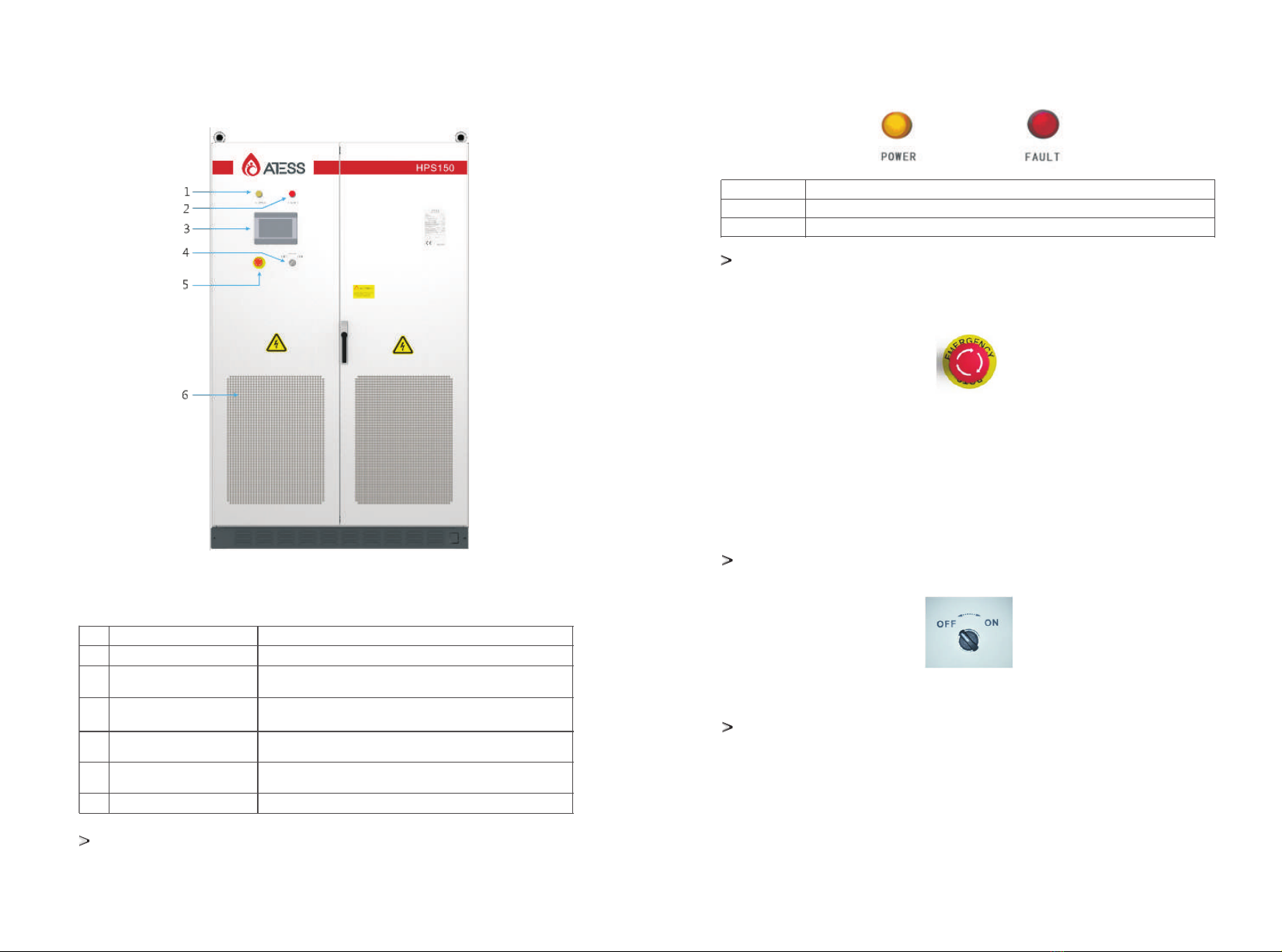

NO

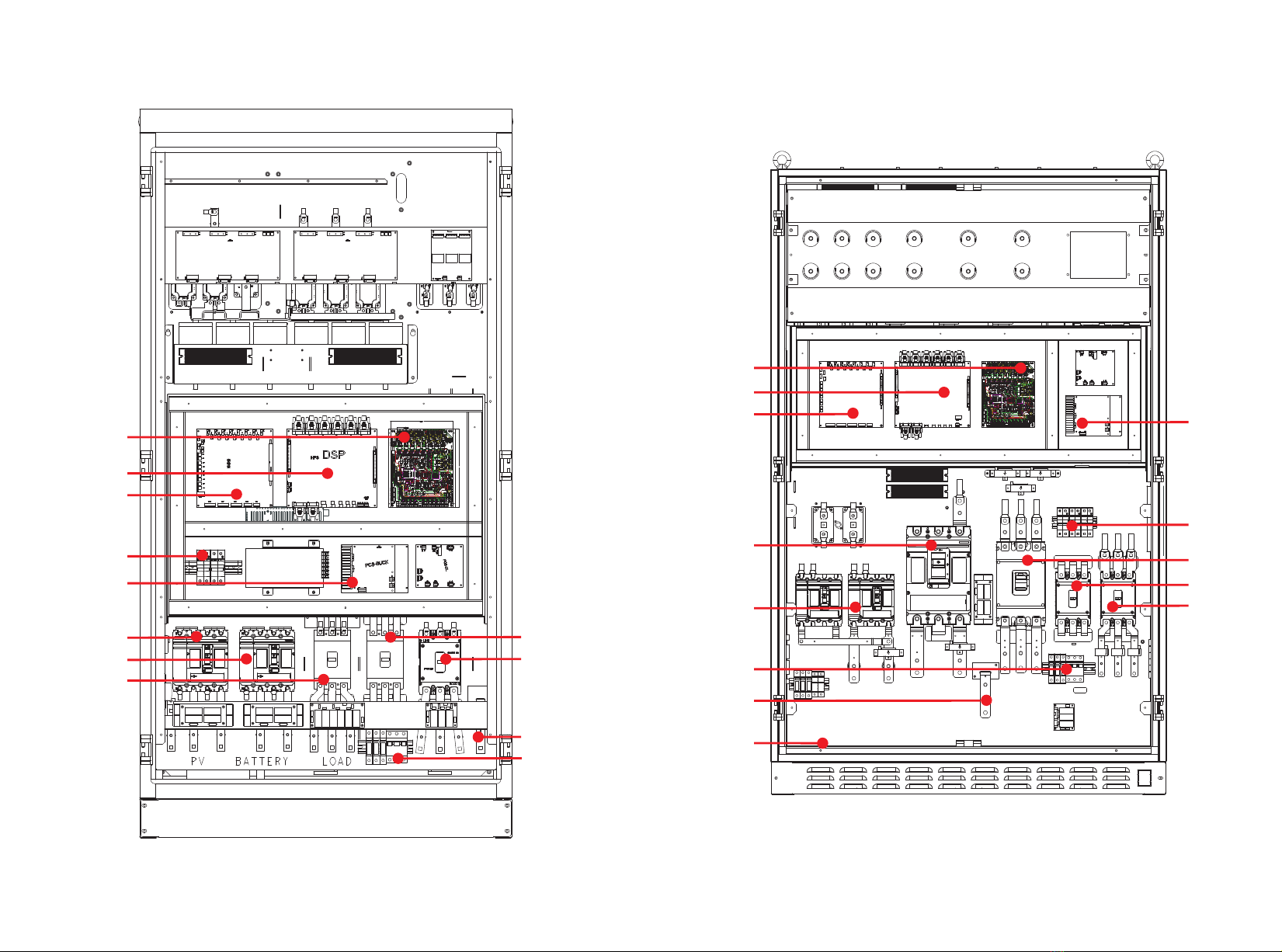

1

2

3

4

5

6

7

8

9

10

11

12

13

Name

PV input

Battery input

AC input

BYPASS

AC output

Power supply micro break*3

AC lightning protection switch

Interface board

Controal board

Sampling board

BUCK board

N terminals

Earth terminals

Description

Control the connection of battery and HPS

Control the connection of battery and HPS

Control the connection of grid and HPS

Maintenance switch, see 9.1.1 for details

Control the connection of load and HPS

power board, fan power switch

Switch for AC lightning protection

inverter power supply conversion PCB

inverter

interface

main control board, with communication

voltage current temperature sampling PCB

DC power supply PCB

Load and grid N terminals

Grounding bronze terminals

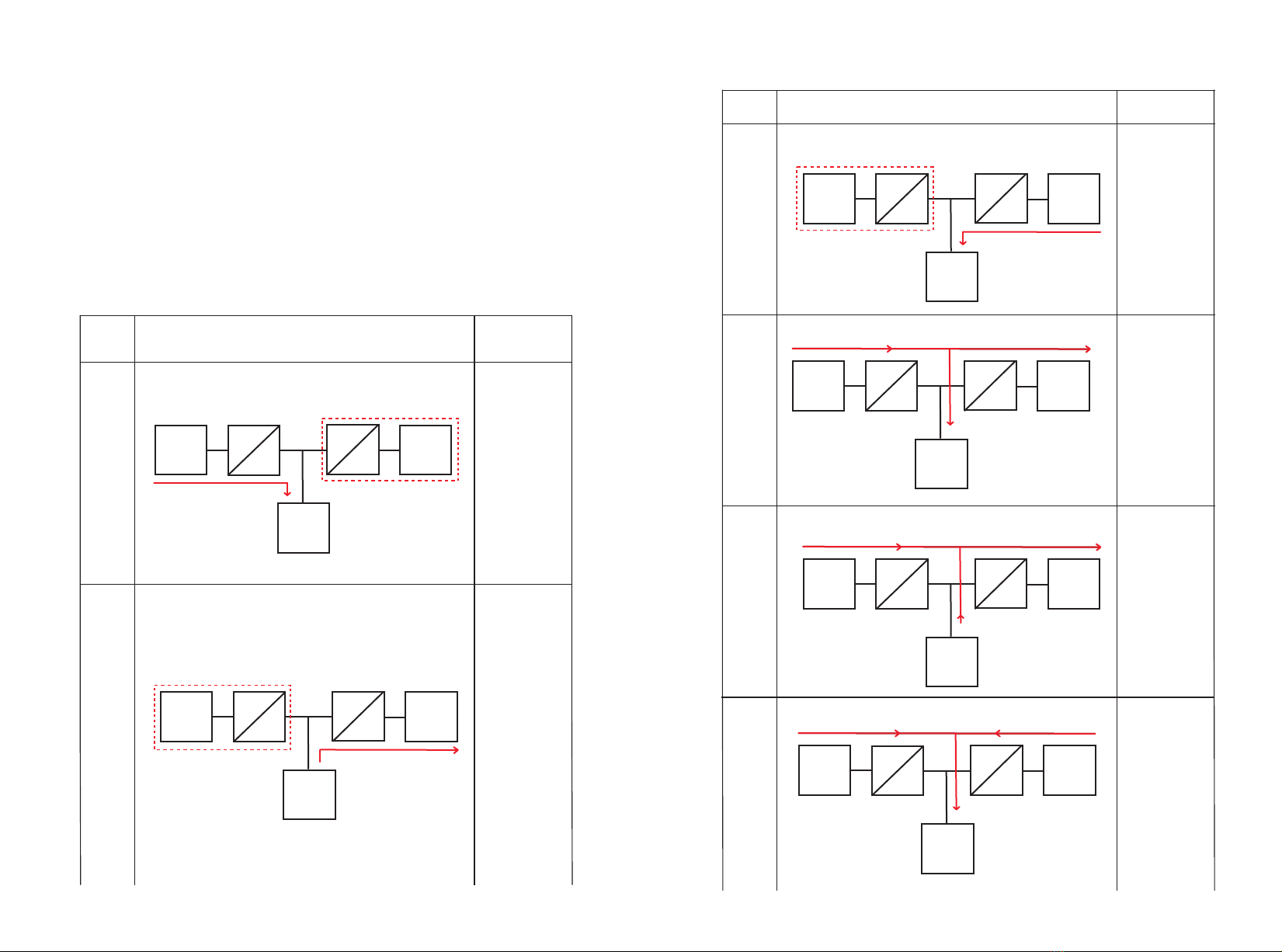

3.4 Operation mode and status

Please refer to Section for details on operation mode setup procedure.7.2.4

Caution!

Before the machine leaves the factory, the operation mode will be set according to the

technical agreement. ATESS will not be responsible for the consequences caused by

modifying the operation mode without the consent of ATESS. Please contact ATESS

personnel for modification if needed.

Anti-backflow

1.When anti-backflow enable is set to 1, feeding power to utility gird is restricted.

2.When anti-backflow enable is set to 0, HPS can feed power to utility grid.

enable

Optional functions in grid connection mode:

3.4.1 On grid mode

G charge together enable

1.When simultaneous charging function enable is set to 1, grid and PV can charge battery

simultaneously.

2.When simultaneous charging function enable is set to 0, grid and PV can not charge battery at

the same time.

Please refer to Section 7.2.4 for setup procedure.

rid&PV

3.4.1.1 Load first mode (anti-backflow function optional)

1. When PV energy is sufficient, PV supply priority to load, the remaining to battery.

2. When PV power is lower than load power, battery discharge automatically. if battery discharged cutoff

voltage or cut-off SOC (depending on battery type), it will stop discharging, PV and grid supply power to

the load together. The power supply can be restored when the battery is charged to the set value of

battery saturation.

See Chapter 7.2 for details of discharge cut-off voltage, SOC and BAT_charged_ saturation

3.4.1.2 Battery first mode (anti-backflow function optional)

1. When the PV energy is sufficient, PV supply priority to battery charge, the remaining to load;

2. When PV energy is insufficient, the PV charge the battery first. The power grid only supplies all loads

without charging the battery. It is optional to charge the battery at the same time (PV&grid charge

together enable, which is set to 1 by default when leaving factory);

3. If the grid connected backup mode is not discharged or switched to other modes, To maintain

electrochemical activity, the battery will enter the discharge state after one week of current limiting

charging, and the discharge power will be calculated according to battery specifications.

3.4.1.3 Time shifting mode(anti-backflow function optional)

The period of economic mode is divided into peak period, fair period and valley period. Please refer to

section 7.2.4 for the setting details.

1. Valley price: working logic is the same to the backup priority mode’s.

2. Fair price:

A. Battery can neither discharge nor be charged by grid.

B. PV power supply priority to load, the remaining to battery when PV power is higher than load.

C. When PV power is lower than load power, PV and grid supply load, PV doesn’t charge battery.

3. Peak price:

A. Grid will not charge battery.

B. When PV power is higher than load, PV supplies to load , the remaining to

battery.

C. When PV power is lower than load power, there are two conditions:

(1) When battery voltage is higher than the discharge cut-off voltage or the discharge cut-off SOC

(depending on the battery type), PV and battery supply the load.

(2) When battery voltage is less than or equal to the discharge cut-off voltage or the discharge cut-off

SOC (depending on the battery type), the battery does not discharge, and the PV and the grid jointly

supply the load and do not charge the battery.

3.4.1.4 Peak-shaving(Grid)

Note: in this mode, the upper limit power of power grid should be set. This value only limits the power

taken from grid, not the power fed to grid.

1. When PV power is greater than the load and charging power, do not take power from the grid, PV

supplies load and charge the battery;

2. (When PV power + upper limit power of grid) is greater than (load power + charging power), grid and

PV supply load and charge battery at the same time.

3. When (PV power + upper limit power of power grid) is greater than the load power, grid and PV supply

priority to the load and the remaining charge batteries.

4. When (PV power + grid upper limit power) is less than the load power, the grid, PV and battery supply

the load at the same time.

9 10