Diffusion Dryer Model 250

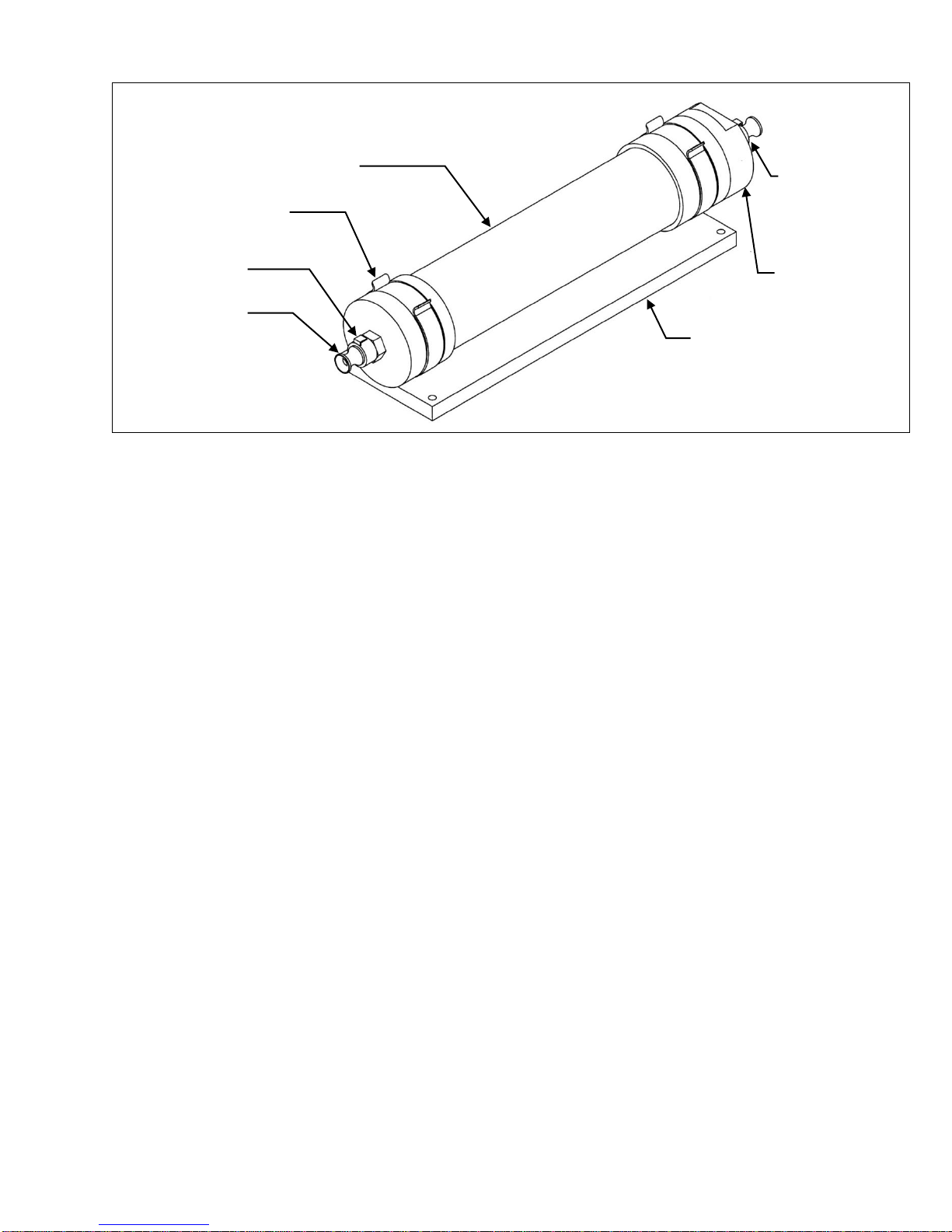

The Diffusion Dryer Components

Inlet and Outlet Connectors

The inlet and outlet connectors are CPCquick coupling

connectors with 1/8” nominal flow path. A matching set of quick

coupling insert is provided that connect to ¼” ID tubing. A set of

sealing plugs is also provided to prevent moisture from entering

the dryer while not in use.

Desiccant Dryer

The Diffusion Dryer is a general-purpose aerosol dryer consisting

of a Plexiglas cylinder terminated by two Delrin® end caps. The

inlet end cap has a removable cover allowing the desiccant

cartridge to be easily replaced.

The silica gel in the desiccant cartridge maintains a dry

atmosphere within the dryer. Passing the aerosol through this

tube dries the aerosol particles without substantial particle loss.

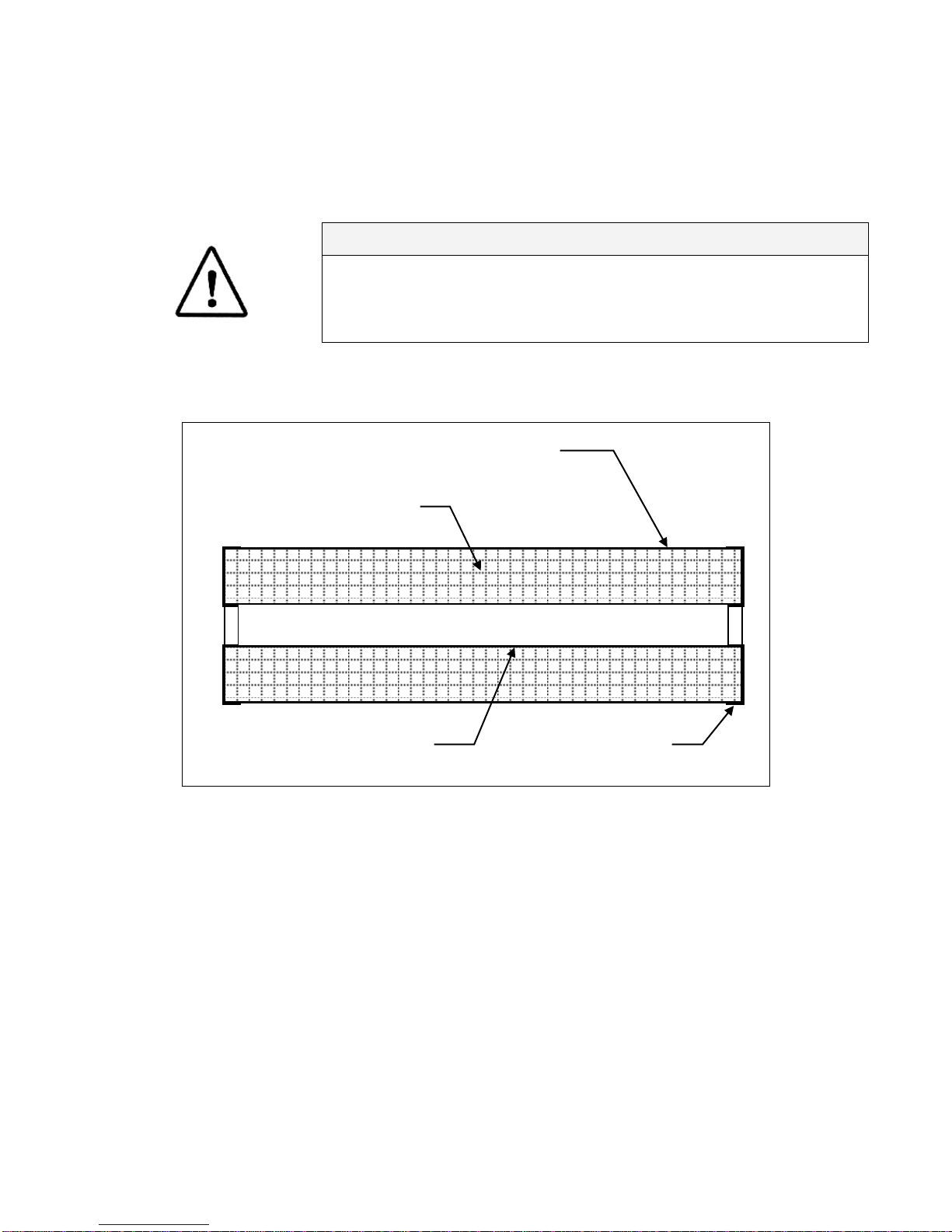

The silica gel cartridge

The desiccant cartridge is made of two perforated end caps

joined together by two wire mesh cylinders. The inner cylinder is

made of very fine wire mesh screen allowing moisture to diffuse in

the silica. The outer cylinder is made of a much larger wire mesh

screen allowing the user to view the silica gel while still retaining it

inside the cartridge. The annular space between the two wire

mesh and the end caps is filled with yellow silica gel. This silica

gel turns from a yellow color when dry to a dark green color when

fully saturated.

Why not use regular blue indicating silica gel?

ATI is taking the safety of its customer very seriously. Standard

blue indicating silica gel contains Cobalt Chloride in small

concentrations (0.5 to 1.0% by weight). As of July 1, 2000, British

Chemical Regulations have required that indicating silica gel be

labeled and disposed of as a hazardous material. While cobalt

chloride has not yet been listed on any U.S.-based hazardous

materials registries, its change in status suggests that this

material should be treated with the same level of protection as is

required elsewhere. Cobalt is a skin and respiratory system

sensitizer. The cancer status varies on Material Safety Data

Sheet (MSDS) reports provided by manufacturers and suppliers

from “no reports” to “Cobalt and its compounds have been shown

to cause cancer in laboratory animals.” The threshold limit value

(TLV) is 0.01 mg/m3