5

I STALLATIO (CO TI UED)

•Running the unit on voltages which are not within ±10% of the

specified voltage may cause overheating and motor burn-out.

•Use the table to determine the minimum wire size (A.W. .)

extension cord.

•Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

•If the extension cord is worn, cut or damaged in any way,

replace it immediately.

EXTENSION CORD LEN TH (120V)

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.W. .

Up to 25 ft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

25 to 50 ft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

50 to 100 ft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

OTE: Using extension cords over 100 ft. long is not recommended.

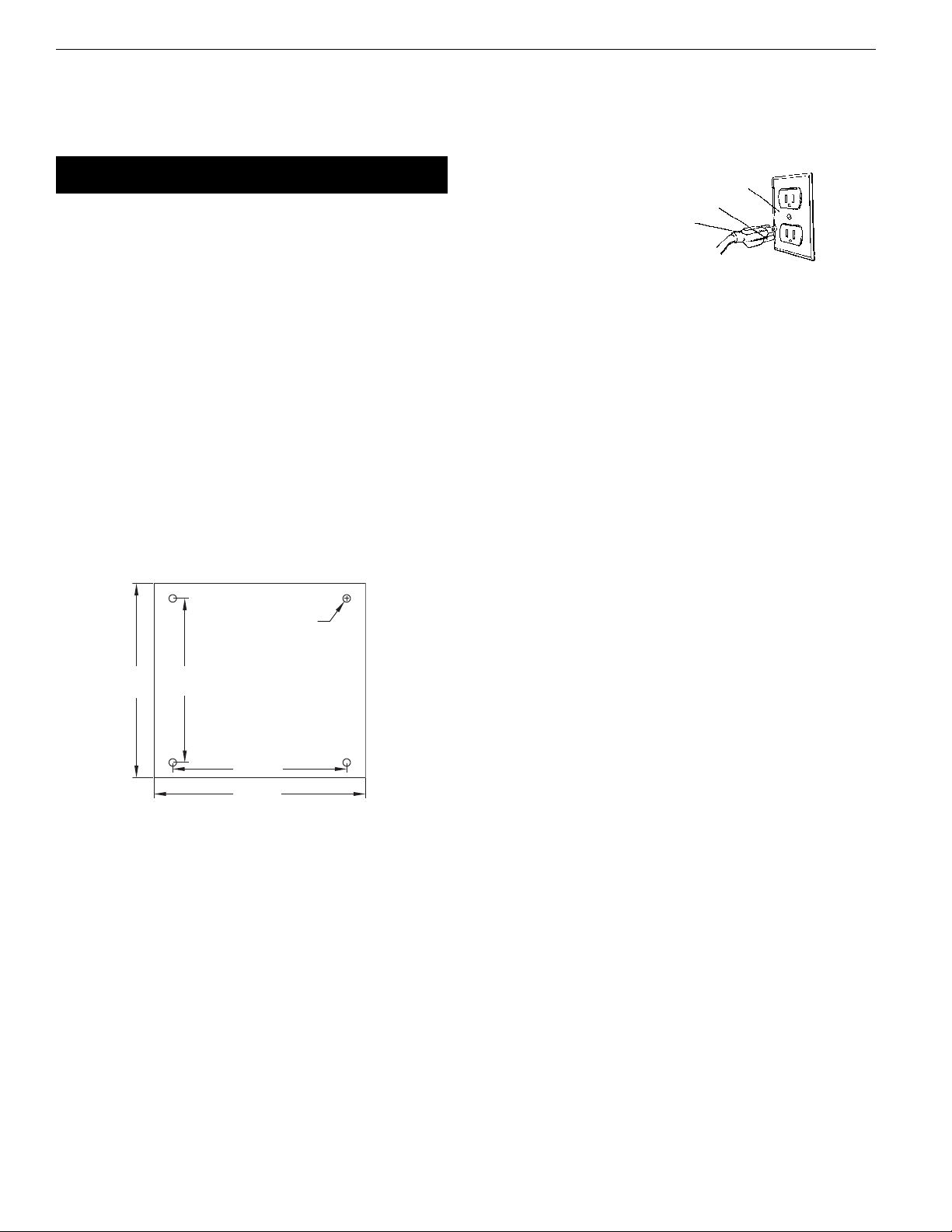

ELECTRICAL CO ECTIO S

WAR I G: All electrical connections must be performed by a

qualified electrician. Make sure tool is off and disconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

Motor and wires are installed as shown in wiring diagram (See

Figure 7). Motor is assembled with approved, 3-conductor cord to be

used at 120/240 volts. Motor is prewired at the factory for 120 volts.

To use the grinder with a 240V power supply, have a qualified elec-

trician rewire motor and attach a 240 volt, I5A three-prong plug

onto grinder line cord.

OPERATION

Refer to Figures 8 and 9.

WAR I G: Operation of any power tool can result in foreign

objects being thrown into eyes which can result in severe eye

damage. Always wear safety goggles complying with United States

ANSI Z87.1 before commencing power tool operation.

CAUTIO : Always observe the following safety precautions:

•Whenever adjusting or replacing any parts on the tool, turn

switch OFF and remove the plug from power source.

•Recheck table knobs and bolts. They must be tightened securely.

•Make sure all guards are properly attached and securely

fastened.

•Make sure all moving parts are free and clear of any interference.

•Make sure all fasteners are tight and have not vibrated loose.

•With power disconnected, test operation by hand to verify

clearance and adjust if necessary.

•Always wear eye protection or face shield.

•Make sure abrasive belt tracks properly. Correct tracking gives

optimum performance.

•After turning switch ON, always allow belt to come up to full

speed before sanding or grinding.

•Be sure motor runs clockwise on disc side. Abrasive belt must

travel down.

•Avoid kickback by sanding in accordance with the directional

arrows.

•Keep your hands clear of abrasive belt, disc and all moving parts.

•For optimum performance, do not stall motor or reduce speed.

Do not force the work into the abrasive.

•Support workpiece with belt table when sanding with belt.

•Never push a sharp corner of workpiece rapidly against belt or

disc. Abrasive backing may tear.

•Replace abrasives when they become loaded (glazed) or frayed.

•When grinding metal, move workpiece across abrasive to

prevent heat build-up.

•Never attempt wet sanding. If workpiece becomes too hot to

handle, cool it in water.

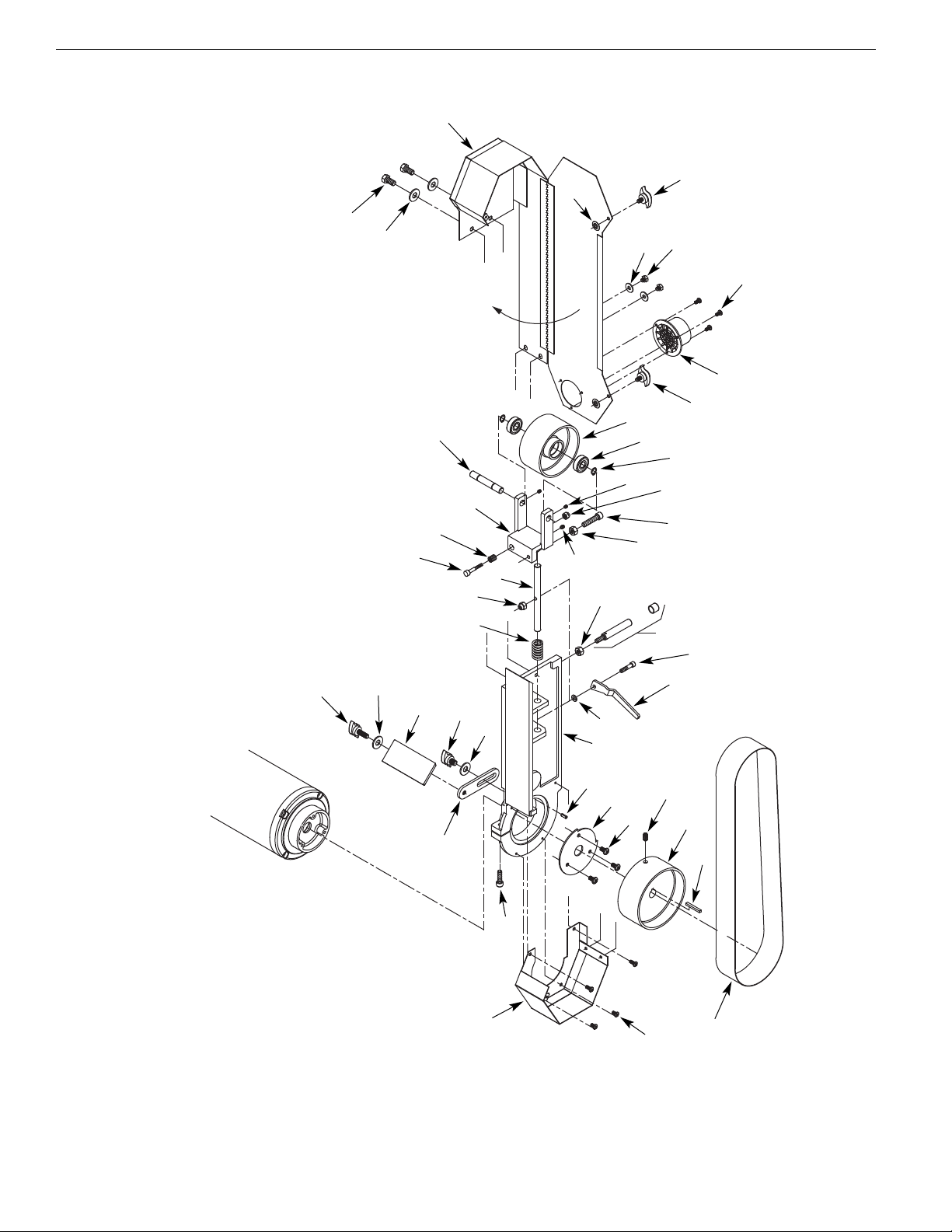

BELT I STALLATIO A D TRACKI G

Refer to Figure 8, page 8.

•Sanding belt should be replaced when worn, torn, or glazed.

Loosen belt cover knobs (Ref. No. 36) and open belt cover.

•Release belt tension by pulling up on tension handle Ref. No. 19).

Slide old belt off the drive and tracking wheels.

•Slide new belt over the drive and tracking wheels, center belt

on wheels, and pull down on tension handle to tension belt.

•Replace belt cover and tighten knobs.

•Rotate belt by hand to check tracking, belt should ride centered

on drive and tracking wheels. Adjust socket head bolt (Ref. No.

30) at top of tracking bracket to track belt properly. Be sure to

secure socket head bolts with hex nut (Ref. No. 22).

ADJUST BELT ASSEMBLY POSITIO

Refer to Figure 8, page 8.

The belt assembly can be adjusted from vertical to horizontal position.

•Loosen the belt housing bolt (Ref. No. 7) that clamps belt hous-

ing to motor

assembly.

•Tilt belt assembly to desired position (from vertical to horizontal).

Secure belt assembly position by tightening belt housing bolt.

ABRASIVE BELT FI ISHI G

•Finishing flat surfaces: Hold workpiece firmly with both hands,

keep fingers away from abrasive belt.

Use tool rest. Tool rest is used to position and stabilize work.

Keep end butted against tool rest and move work evenly across

abrasive belt. Use extra caution when finishing very thin pieces.

For finishing long pieces: remove tool rest. Apply only enough

pressure to allow abrasive belt to remove material.

•Finishing curved edges: Finish outside curves on flat portion of

abrasive belt.

ABRASIVE GRI DI G

•Keep a steady, moderate pressure on the work and keep it

moving at an even pace for smooth grinding.

•Pressing too hard overheats the motor and prematurely wears

down the grinding wheels.

Figure 7 – Wiring Diagram

3-Red 2- ray

4-Yellow

1-Black

120V

240V

3-Red

1-Black

2- ray

4-Yellow

Palmgren Operating Manual & Parts List 82088