Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

4

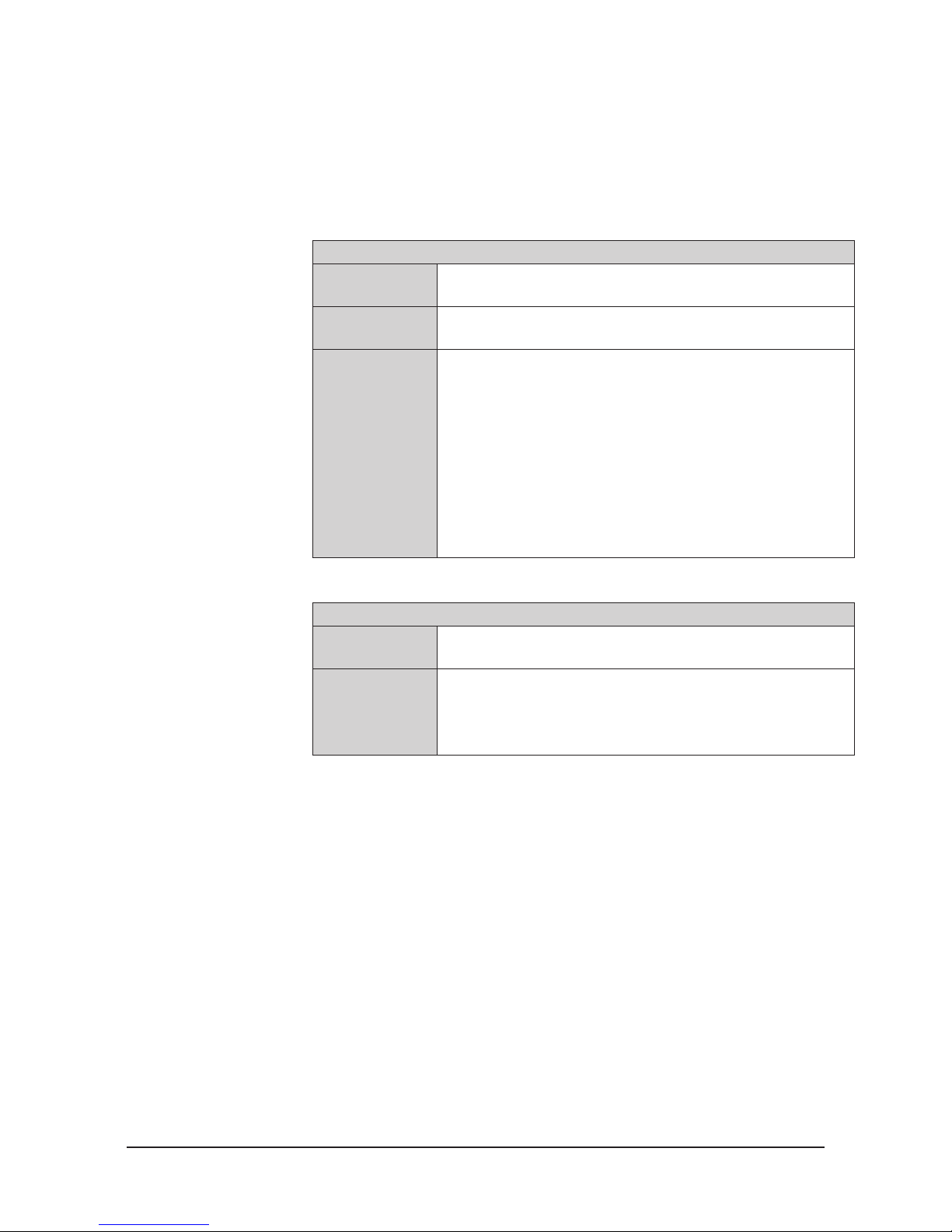

Table of Contents

Foreword .......................................................................................................................................... 2

Glossary ........................................................................................................................................... 3

1. Safety......................................................................................................................................... 6

1.1 ExplanationofNotications......................................................................................................... 6

1.2 General Safety Guidelines............................................................................................................ 6

1.3 Safety Precautions ........................................................................................................................ 7

2. Product Overview..................................................................................................................... 8

2.1 FeaturesandBenetsoftheVersaFinishDeburringTool ........................................................ 8

2.2 VersaFinish Part Numbering Legend .......................................................................................... 9

2.3 Technical Description ................................................................................................................ 10

2.3.1 Environmental Limitations ................................................................................................ 10

2.3.1.1 Operation .......................................................................................................... 10

2.3.1.2 Storage ............................................................................................................. 10

2.4 Compliance Unit Performance ................................................................................................... 11

3. Installation .............................................................................................................................. 13

3.1 Protection During Transportation.............................................................................................. 13

3.2 Inspection of Condition When Delivered .................................................................................. 13

3.3 Unpacking and Handling ............................................................................................................ 13

3.4 Storage and Preventive Maintenance During Storage............................................................. 13

3.5 Side Mounting Installation ......................................................................................................... 14

3.6 Pneumatic Connections ............................................................................................................. 15

4. Operation ................................................................................................................................ 17

4.1 Safety Precautions ...................................................................................................................... 17

4.2 Normal Operation ........................................................................................................................ 18

4.2.1 Air Quality......................................................................................................................... 18

4.2.2 Lubrication........................................................................................................................ 18

4.2.3 Media Selection................................................................................................................ 18

4.2.4 Deburring Tool Approach Path Should Be Slow and At an Angle..................................... 19

4.2.5 No Radial Loads............................................................................................................... 19

4.2.6 Program the Robot to Incorporate 50% Compliance Travel of the Tool ........................... 19

4.3 VersaFinish Working Environment............................................................................................ 19

4.4 Sensor Connections ................................................................................................................... 20

4.5 Tool Position and Programming ................................................................................................ 21