SERVICE MANUAL U AC Power PlusSERVICE MANUAL U AC Power Plus

10.8 10.8 MagnMagnetic switch for the reach stopetic switch for the reach stop ............................................................................................................................................ 10.210.211

10.8.1 10.8.1 Reach stop ..........................Reach stop ....................................................................................................................................................................................................10.2110.21

10.8.2 10.8.2 Reach stop Reach stop damping (2damping (2005w04÷)005w04÷)

(trucks with S3) (trucks with S3) .................................................................................................................................................................................................................................... 10.2210.22

10.9 10.9 FusesFuses.............................................................................................................................................................................................................................................. 10.2410.24

10.9.1 10.9.1 Standard .....................................Standard ...............................................................................................................................................................................................10.2410.24

10.9.2 10.9.2 Extra accessories ....................Extra accessories ......................................................................................................................................................................................10.2410.24

10.10 10.10 HornHorn .............................................................................................................................................................................................................................................. 10.2610.26

10.10.1 10.10.1 Connection .......................Connection .................................................................................................................................................................................................10.2610.26

10.11 At10.11 Atlet's let's truck truck computer computer ATCATC.................................................................................................................................................................. 10.2710.27

10.11.1 10.11.1 Component Component and interface and interface description description ......................................................................................................................................10.2710.27

10.11.2 Handling ...............................................................................................................10.2810.11.2 Handling ...............................................................................................................10.28

10.11.3 10.11.3 Service Service functions functions ....................................................................................................................................................................................................10.2910.29

10.11.4 10.11.4 Change Change passwords passwords ................................................................................................................................................................................................10.2910.29

10.11.5 10.11.5 Calibration and Calibration and control of control of the hydraulic the hydraulic levers levers ........................................................................................................ 10.3010.30

10.11.6 10.11.6 Running Running time functime functions tions ................................................................................................................................................................................ 10.3010.30

10.11.7 10.11.7 Printing of Printing of statistics statistics ............................................................................................................................................................................................ 10.3010.30

10.11.8 10.11.8 Collision Collision sensor sensor ........................................................................................................................................................................................................10.3010.30

10.11.9 ATC connector .....................................................................................................10.3010.11.9 ATC connector .....................................................................................................10.30

10.11.10 10.11.10 Checking the inputs aChecking the inputs and outputs .................nd outputs .................................................................................................................................10.3110.31

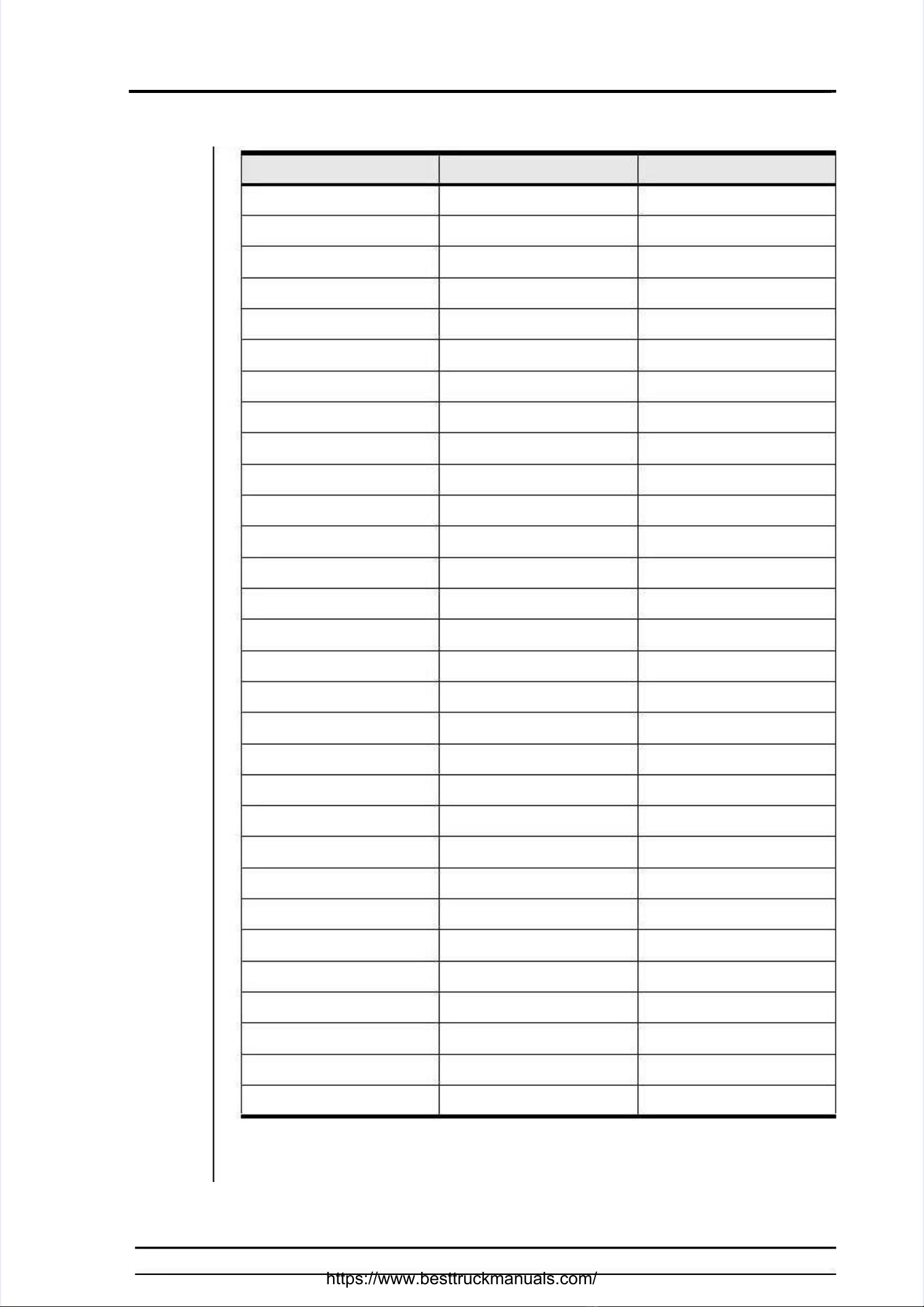

10.11.11 10.11.11 Digital inDigital inputs puts ............................................................................................................................................................................................................10.3110.31

10.11.12 10.11.12 Digital outDigital outputs “puts “XC1-XC11” XC1-XC11” ..........................................................................................................................................................10.3310.33

10.11.13 10.11.13 Digital outputs B+ suppDigital outputs B+ supply .....................................ly .........................................................................................................10.34........................10.34

10.11.14 10.11.14 Digital outputs 12 V supDigital outputs 12 V supply ..............................ply .................................................................................................................................. 10.3410.34

10.11.15 10.11.15 Digital outputs B+ suppDigital outputs B+ supply .....................................ly .........................................................................................................10.35........................10.35

10.11.16 10.11.16 Valve paValve parameters rameters ................................................................................................................................................................................................10.3510.35

10.11.17 10.11.17 Performance Performance parameters parameters ..........................................................................................................................................................................10.3610.36

10.12 10.12 Error Error codescodes...................................................................................................................................................................................................................... 10.410.411

10.12.1 10.12.1 General ...................General ................................................................................................................................................................................................................. 10.4110.41

10.12.2 10.12.2 Error cError code deode description scription .................................................................................................................................................................................... 10.4110.41

10.13 10.13 WarningsWarnings.............................................................................................................................................................................................................................. 10.5510.55

10.13.1 10.13.1 Description ...............Description ......................................................................................................................................................................................................... 10.5510.55

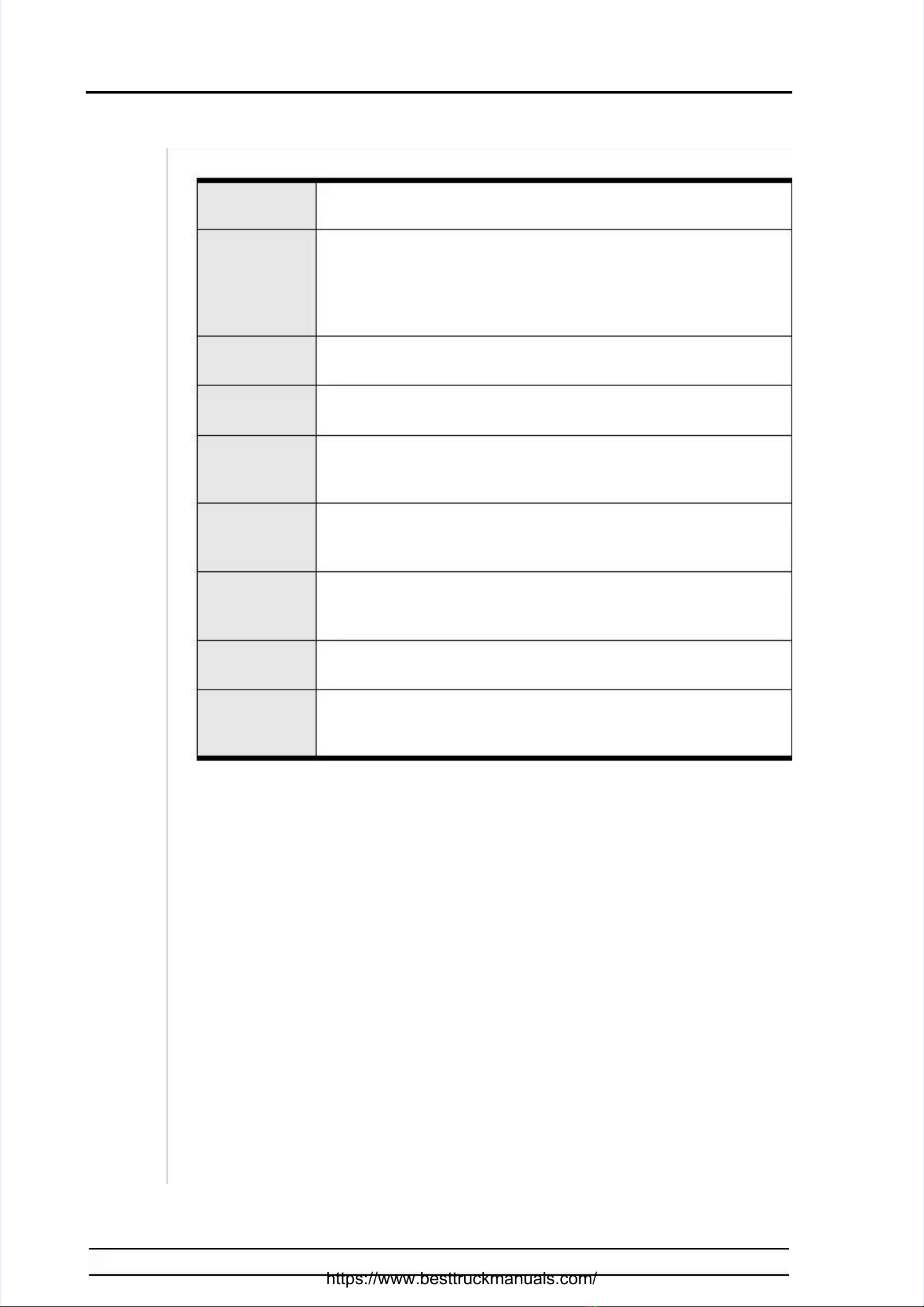

10.14 Menu 10.14 Menu tree tree ATCATC ............................................................................................................................................................................................................ 10.5610.56

10.14.1 10.14.1 Error log .......................Error log .........................................................................................................................................................................................................10.5610.56

10.14.2 10.14.2 Subinfo ...................Subinfo ................................................................................................................................................................................................................. 10.5610.56

10.14.3 10.14.3 General instructions with General instructions with all types of faults on tall types of faults on trucks in combinationrucks in combination

with power outagewith power outage ......................................................................................................................................................................................................10.56........................10.56