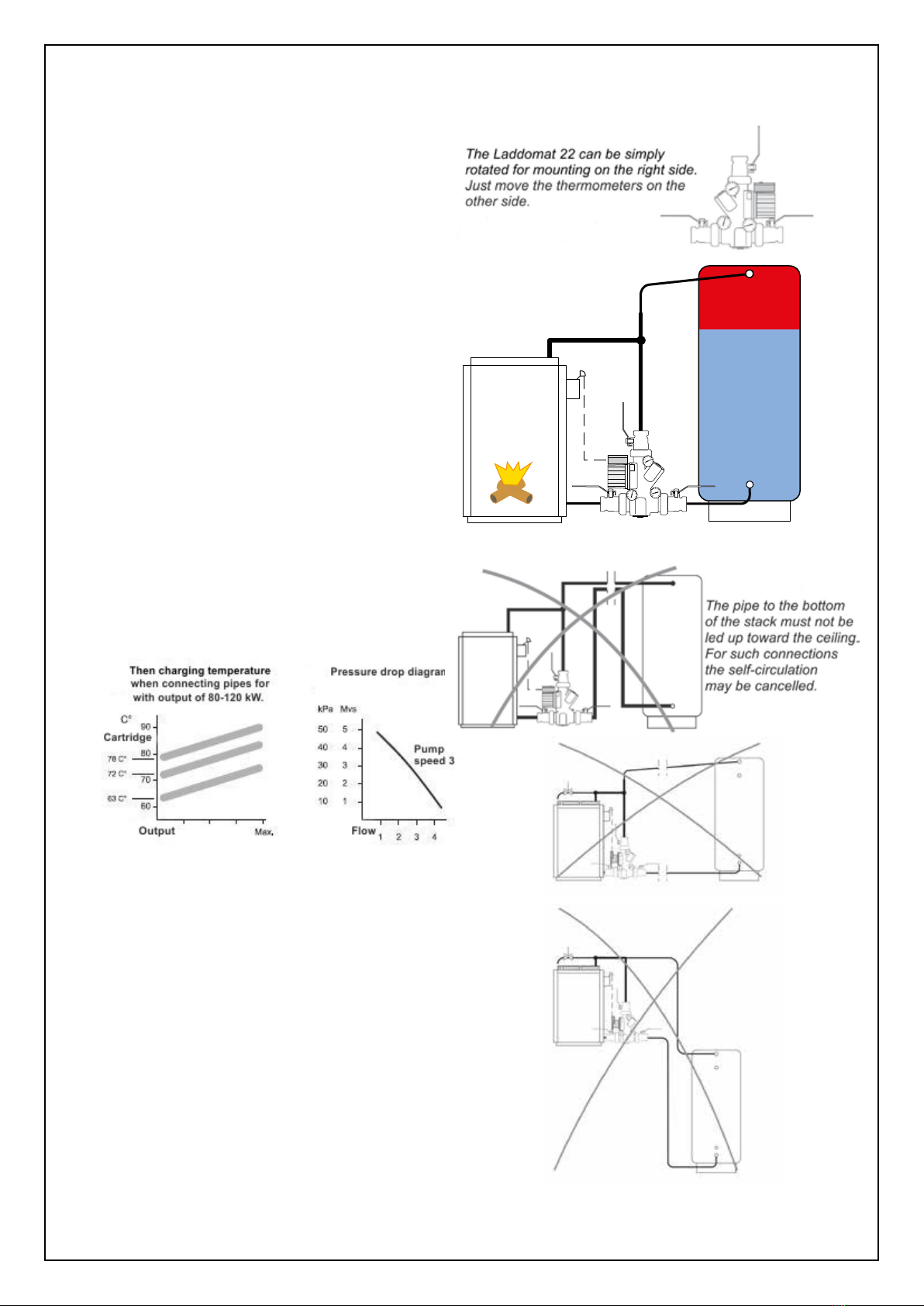

The Laddomat 22 is factory-fitted with a

thermostat No. 1456 which opens at 78 °C.

The thermostat No. 8719 opening at 72 °C is

included in the delivery (placed in the insulation of

the Laddomat 22).

For most installations, best the thermostat 78 °C is

proved. For boilers with a high output / low water

content as well as at systems with long pipe lines /

thin pipes, the thermostat opening at 72 °C may

be preferred. The thermostat cartridge with the

opening temperature of 72 °C should be used at

outputs above 35 kW.

The higher charging temperature gives more

accumulated heat. In addition, the losses in the

boiler after the fuel burns out in the boiler with the

thermostat having the opening temperature of 78

°C will be smaller, because the connection

between boiler and storage tank will be interrupted

sooner than with the use of thermostat having the

opening temperature of 72 °C.

Different amounts of air bubbles in the fresh

water are present in all new systems.

This air releases inside the boiler walls after

heating the water. The more the boiler heats up,

the more air bubbles are released. We therefore

recommend heating the boiler to the highest

temperature when starting it for the first time.

When the air released in such a way accumulates

in the circulation pump, it can cause cessation of

the circulation. At low temperatures the air releases

more slowly and manages to be discharged

through the expansion or venting.

When a lot of air releases in the system, remove

the thermostat cartridge for a short time.

In extreme cases it is appropriate to make some

firings without use of the thermostat cartridge until

the water is free of air. Remove the spring, plunger

and thermostat cartridge and warm up the heating

system with the upper shut-off valve closed.

After the water is repeatedly heated to 85-95 °C

and free of air, remount the thermostat cartridge

into place.

If, despite these measures, there will be faults in

the system operation, check whether lint or other

debris are not in the pump preventing the

circulation. Also check that the system is installed

correctly according to the documentation.

Important at the first start up

Check that the circulation pump is switched off.

Close the three shut-off valves.

Unscrew the cover opposite the pump.

Remove the cover with spring, plunger and

thermostat cartridge from the Laddomat 22 (Fig. 1).

The thermostat cartridge is held in place on the

plunger by an O-ring.

The thermostat cartridge can be easily removed

from the plunger using a screwdriver (see Fig. 2).

Push a new thermostat cartridge into the plunger.

Reinstall all parts into place and tighten.

Open the shut-off valves.

Wait a few minutes before starting the pump to

allow any air to rise and escape from the system.

The device is now ready for operation.

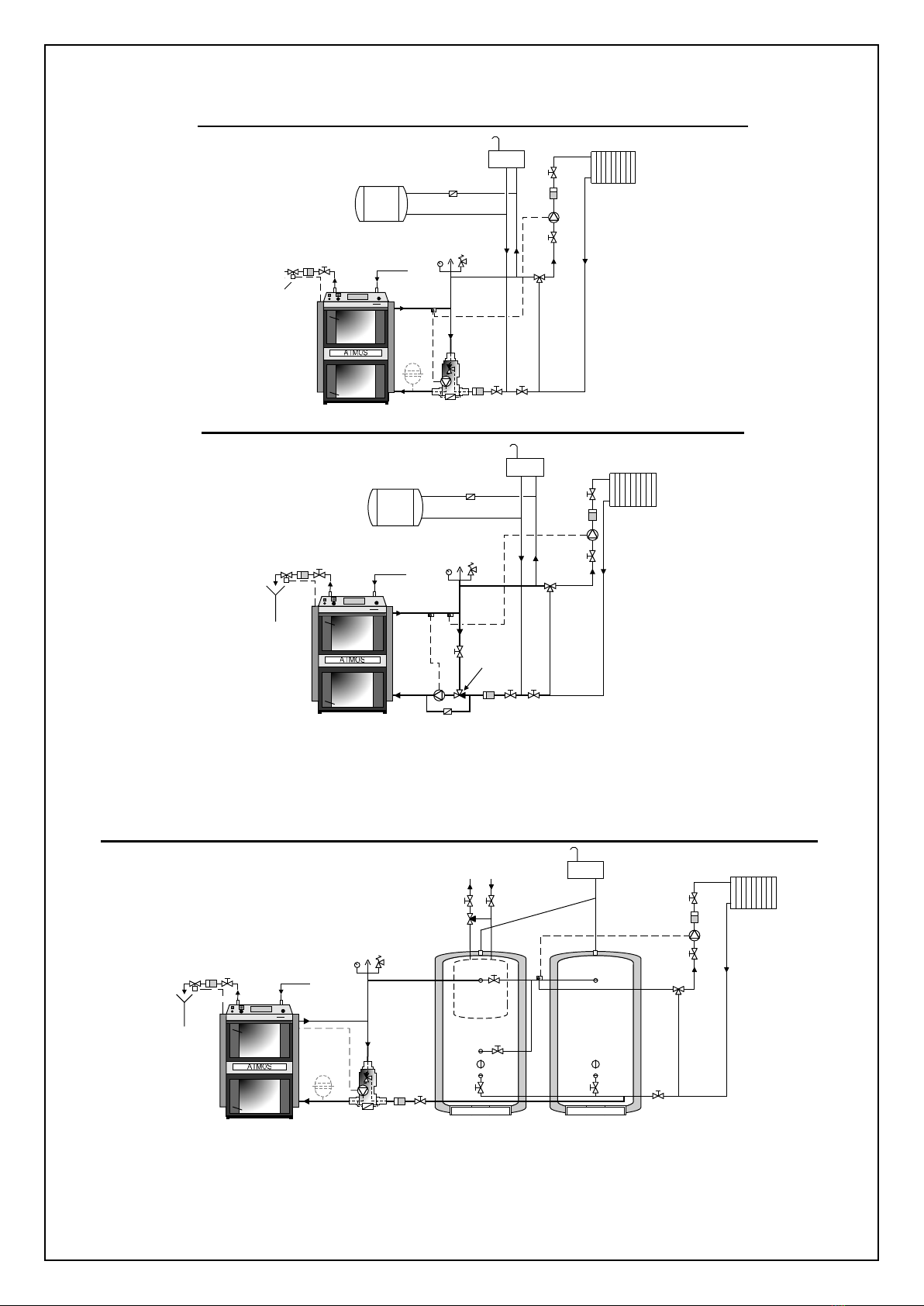

Blocking the check valve

If you, for some reason, need to completely

disconnect the self-circulation, the check valve

must be blocked. The check valve is blocked using

the blocking clip, which is located at the bottom

of the EPP-insulation (Fig. 3), which is fastened

around the check valve axis according to Fig. 4.

To reach the axis, the spring needs to be removed.

Instructions for replacing the

thermostat in the Laddomat 22

Fig. 3

Fig. 1

Fig. 4

Zde je umístěna náhradní

termopatrona a zajišťovací spona

Zajišťovací spona

(zpětná klapka zablokována)

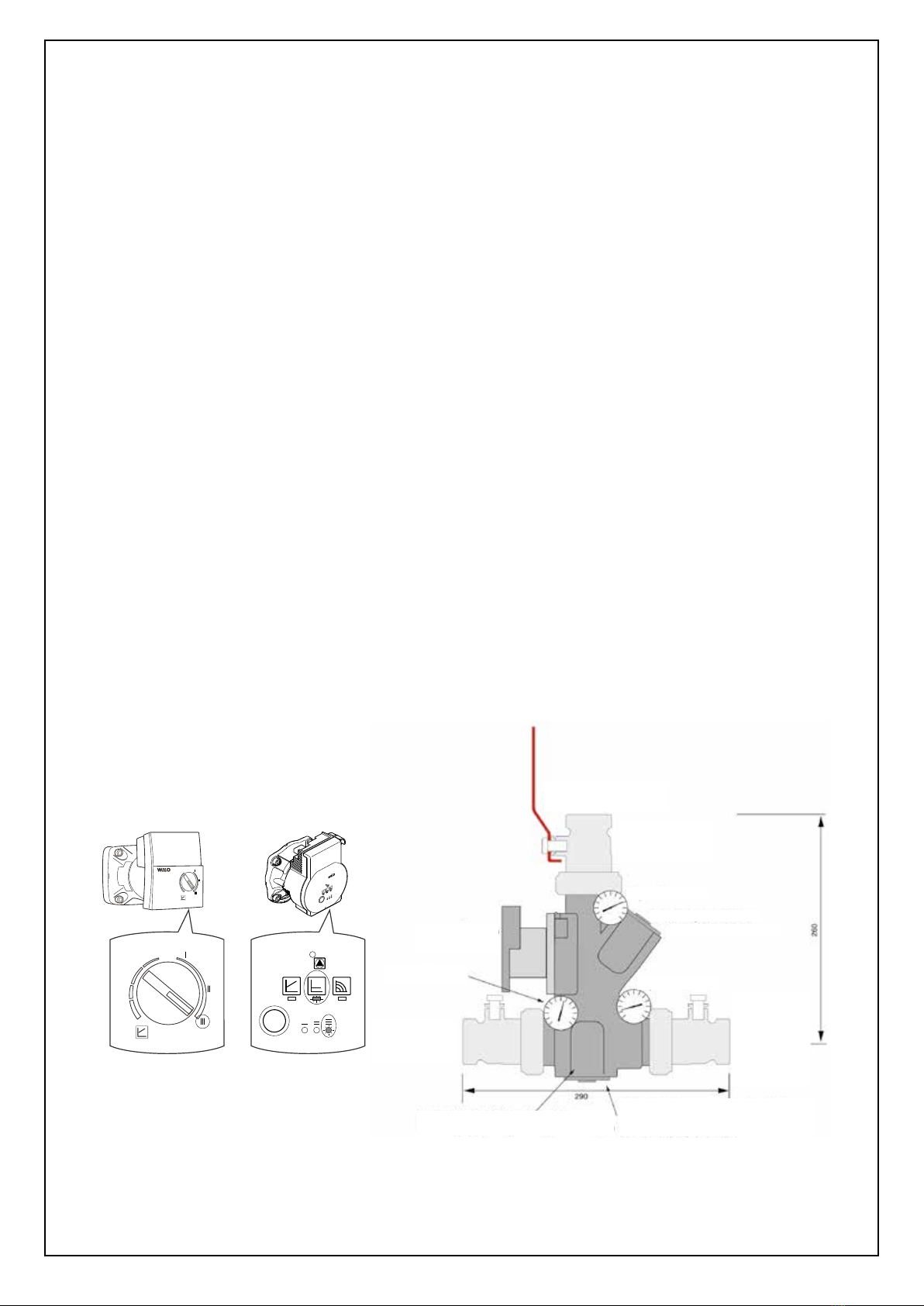

Changing regulation kit / Regelpaket wechseln

Thermostat not included / Thermoelement nicht enthalten

Old version / Alte Version, 212108:

New version / Neue Version, 212115:

22

Kryt - matice

Kryt - matice

Nová verze

Stará verze

Změna regulační sestavy

Neobsahuje termopatronu

Pružina

(prodloužená)

Termopatrona

(termostat)

O-kroužek

pístu

O-kroužek

pístu

Pružina škrtícího

ventilu

Škrtící ventil

Pouzdro ventilu

(plastová trojnožka)

O-kroužek

Pouzdro

ventilu

Fig. 2

Lock

O-ring

Spring

Vlave

housing

Piston

O-ring

Thermostat

cartridge

Here there is a spare thermostat

cartridge and blocking clip

Blocking clip

(check valve blocked)