IMPORTANT SAFETY INFORMATION

Read all instructions before using the appliance and retain for future reference.

@This product should never be used/placed at high temperature, high humidity or in aflammable, explosive

and strong electromagnetic environment.

@When not in use for extended periods, switch the appliance off and disconnect from the mains.

@This product is high voltage inside. All repairs should only be carried out by aqualified engineer. Improper

repairs may place the user at risk ofharm.

@To avoid any damage, when the impeller rotates at high speed, do not touch it with hands or objects.

Caution

@The smog suction' seffect is affected by the distance between the smog suction hood and the point ofsmog

generated directly. Tests proved that the best distance is maintained at L0-15cm.

©if air flow speed surrounding the smog suction hood is fast, the smog suction effect will be worse. Need to

reduce the air flow.

@The longer length of smog suction pipes, the weaker effect of smog suction. The more smog suction pipe

bends, the worse effect ofsmogsuction.Recommendation: Minimize the pipe bends as much as possible.

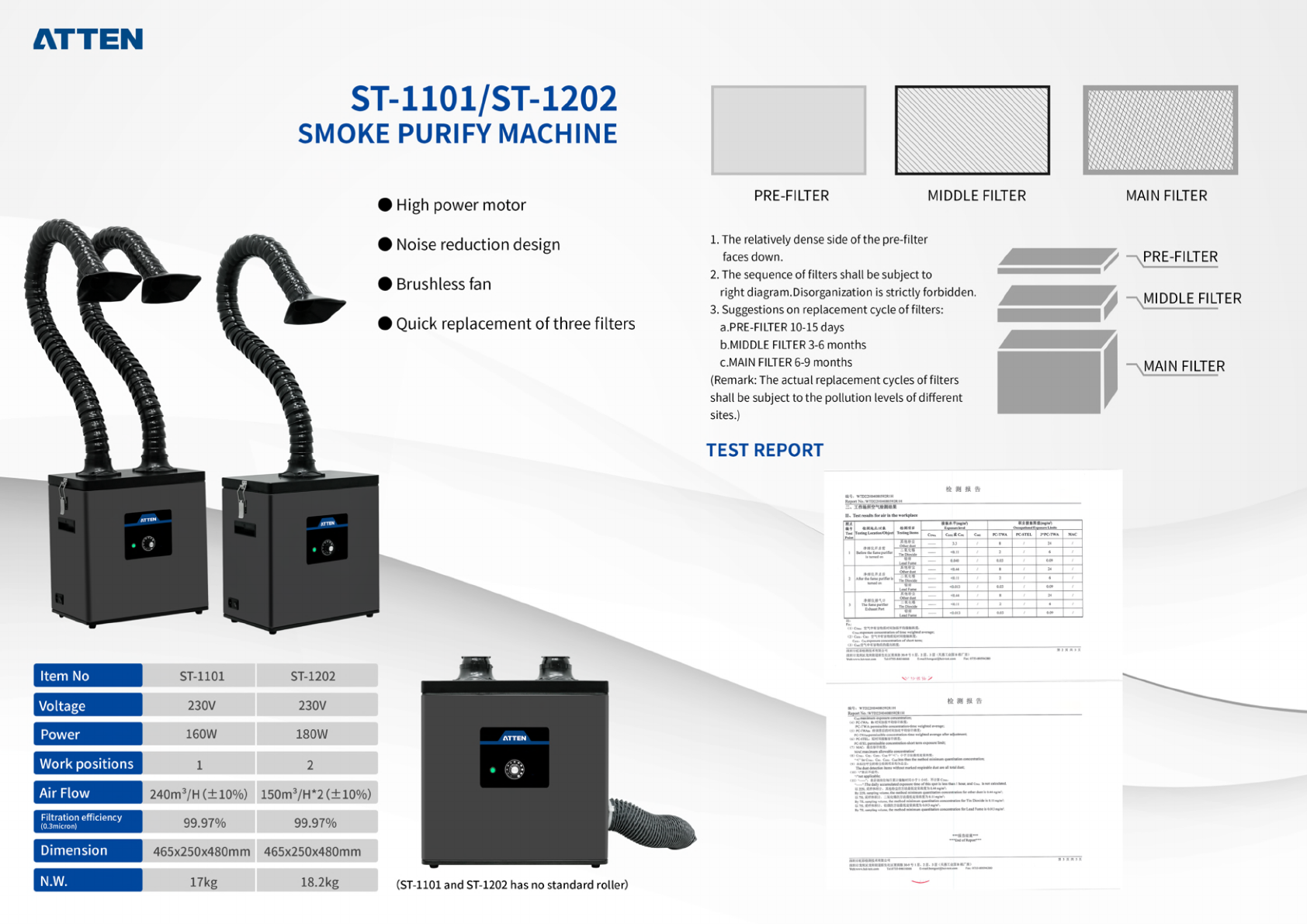

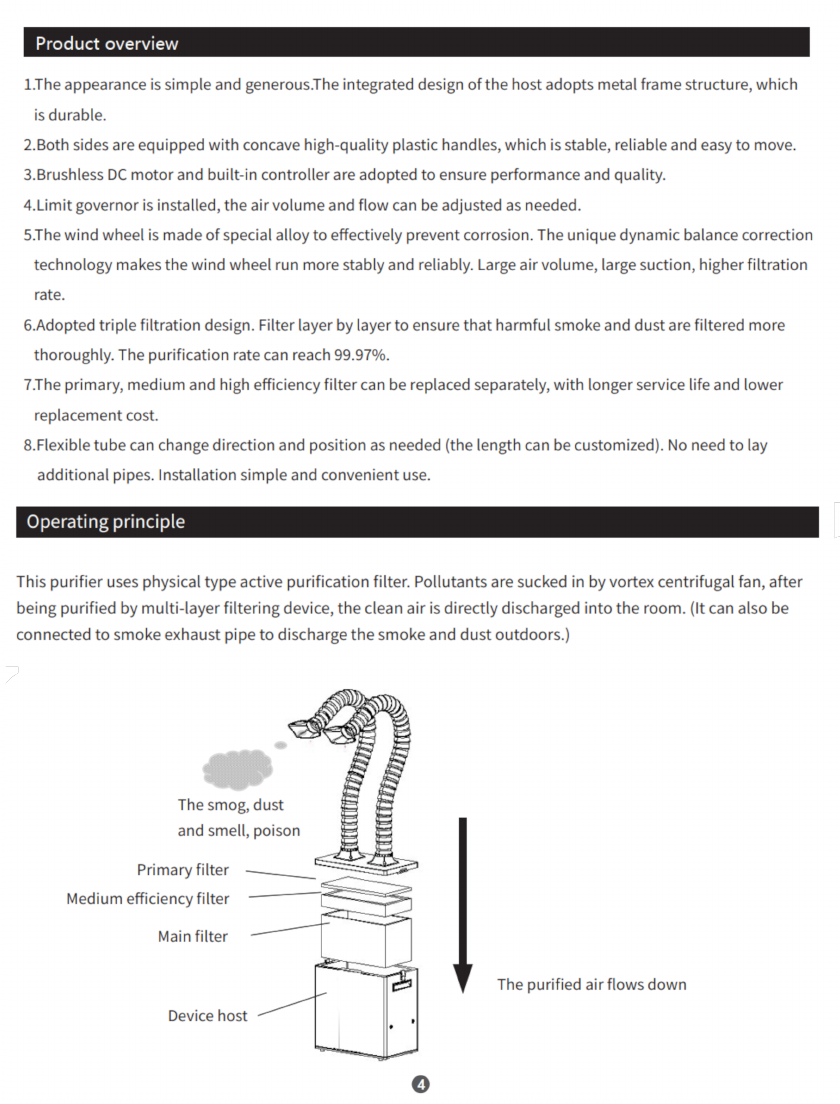

Filter Element Replacement

This product relies on avariety of filter cartridge parts to achieve filtering the smog, smell, toxic substances.

Therefore, the filter element parts as consumptive material, with the amount of saturation, should be replaced

on aregular basis.

Recommended replacement cycle:

Primary filter: 10-15 days

Medium efficiency filter: 3-6 months

Main filter: 6-9 months

The replacement period depends on the actual situation, i.e. different amounts of pollution generated in

different places. Please pay attention to the use and maintenance of the machine specified above, and

replace the filter element parts regularly;

Otherwise, it will lead to reduced suction, equipment damage, early scrapping of filters and environmental

pollution accidents and personal injury, which are not within the scope of our company's responsibility.

®