Section 3 Identification code, label of model and engine N0.

Section 4 Points for attention in maintenance

der of disassembly, this in assembling, can

not only increase the assembling speed, but also

ensure the rightness of assembling.

2.Replace the components

When replacing the components, be sure to

use qualified products provided by use lubricants

and grease which brank is assigned by lubricate.

3.Oil seal, shim, o-ring clip split pin,

elastic washer.

3.1 When disassembling to maintain the

engine, in order to ensure that the reassembled

engine have good sealing and connecting part is

fixed and reliable, all the oil seal, shim, o-ring,

clip, split pin and elastic washer should be

replaced, be sure to keep lip of oil seal surface

of shim and o-ring in cleaning condition.

3.2 When reassembling, apply lubricants to

lubricate all the mated components and bearing,

apply grease for oil seal.

-4-

1.Preparation when disassembling

1.1 First clean the dirt, mud and attachment

on the vehicle befor removing or disassembling.

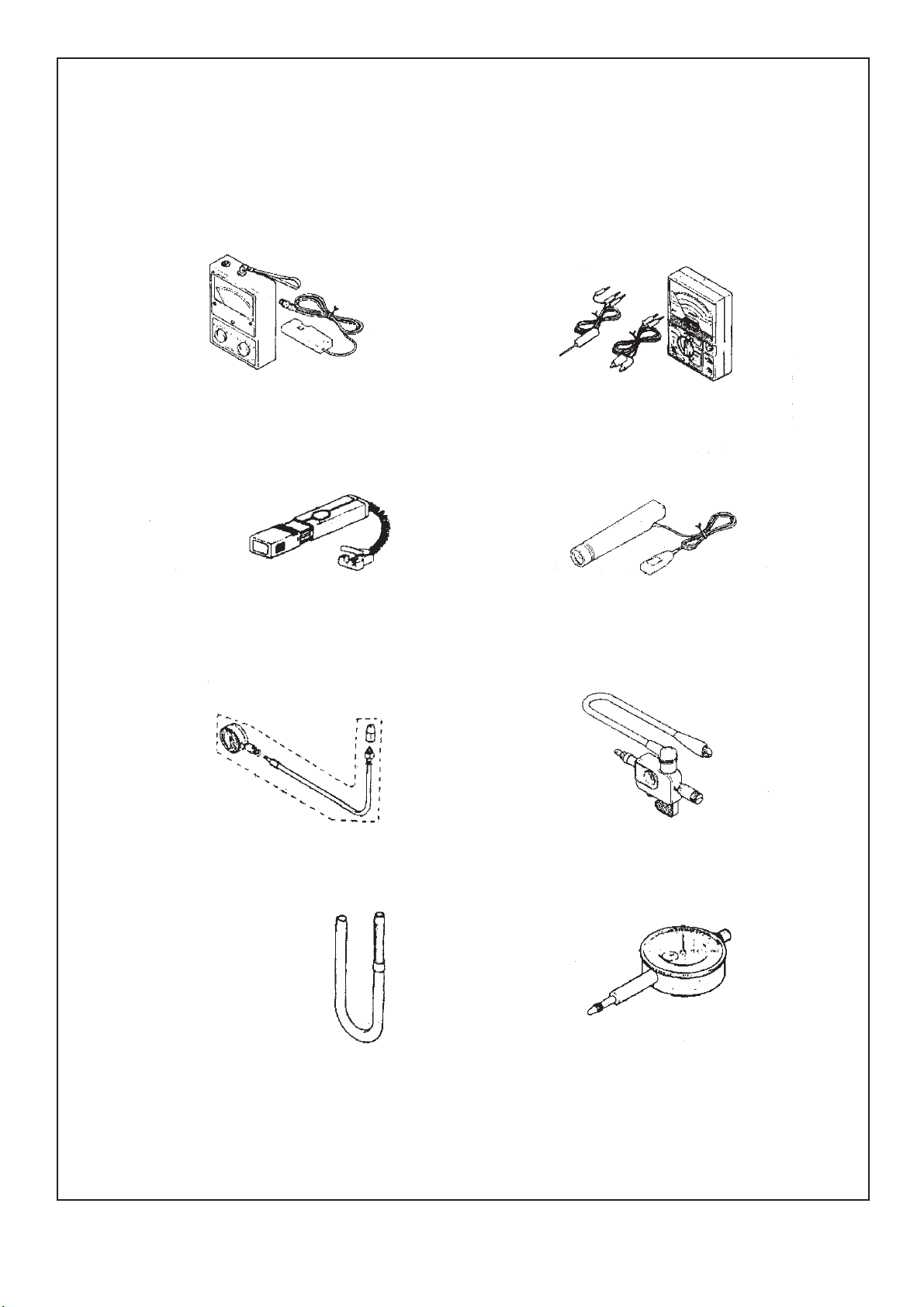

1.2 Use proper special too cleaning device

and means.

1.3 Keep all the components away from fire

source. Pay attention to the safety, Don’t be

burned by the high temperation portion of engine,

exhuaster and silencer etc. Be sure to take care

of each other when operation with other people.

1.4 When disassembling the ATV, put the

mated components, such as gear pairs, cylinder,

piston and other “mated” components by nor-

mal running in together, When assembling or

replacing these components, they should be in

pairs.

1.5 When disassembling the engine, clean

all the components and put in the tray in the or

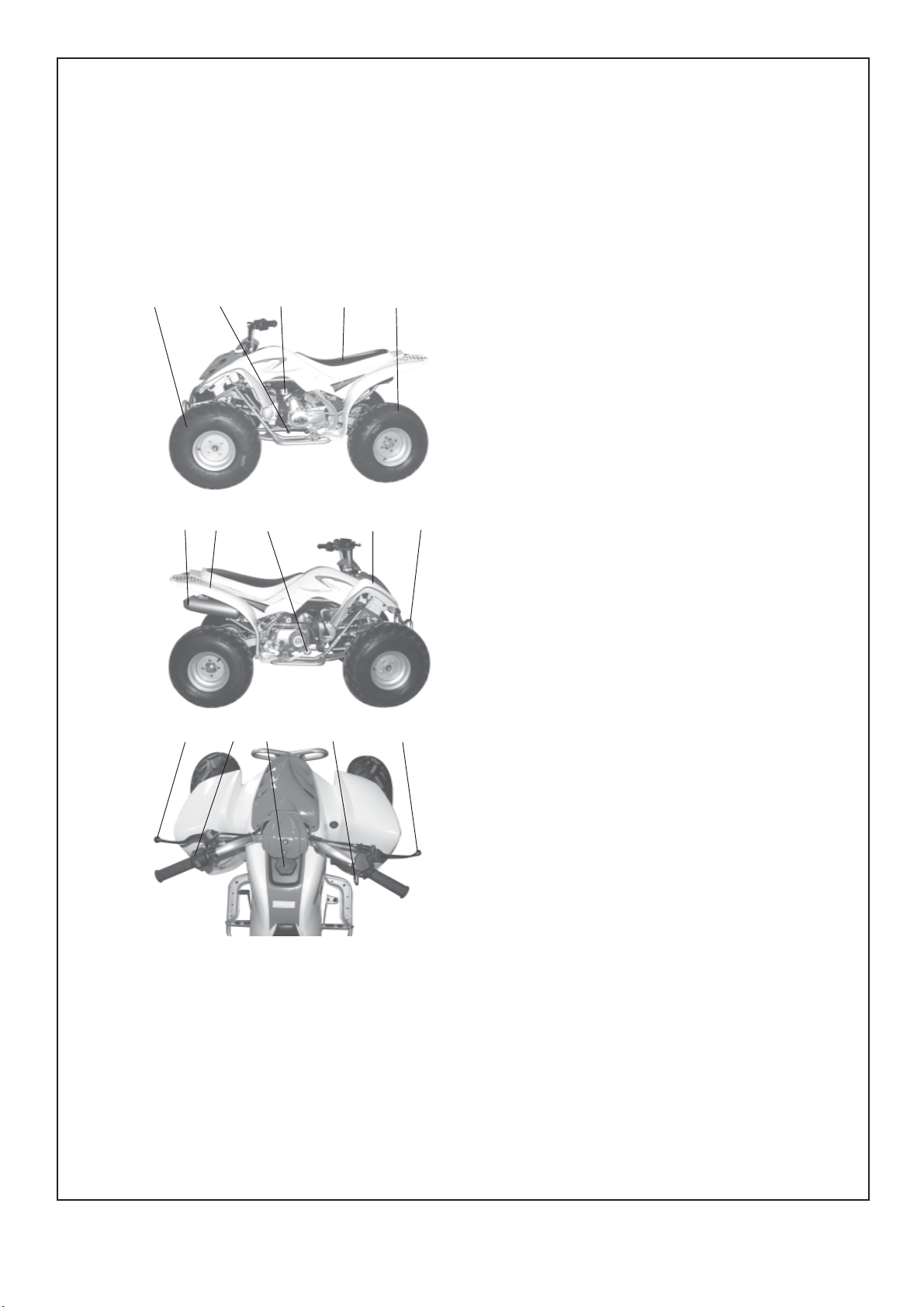

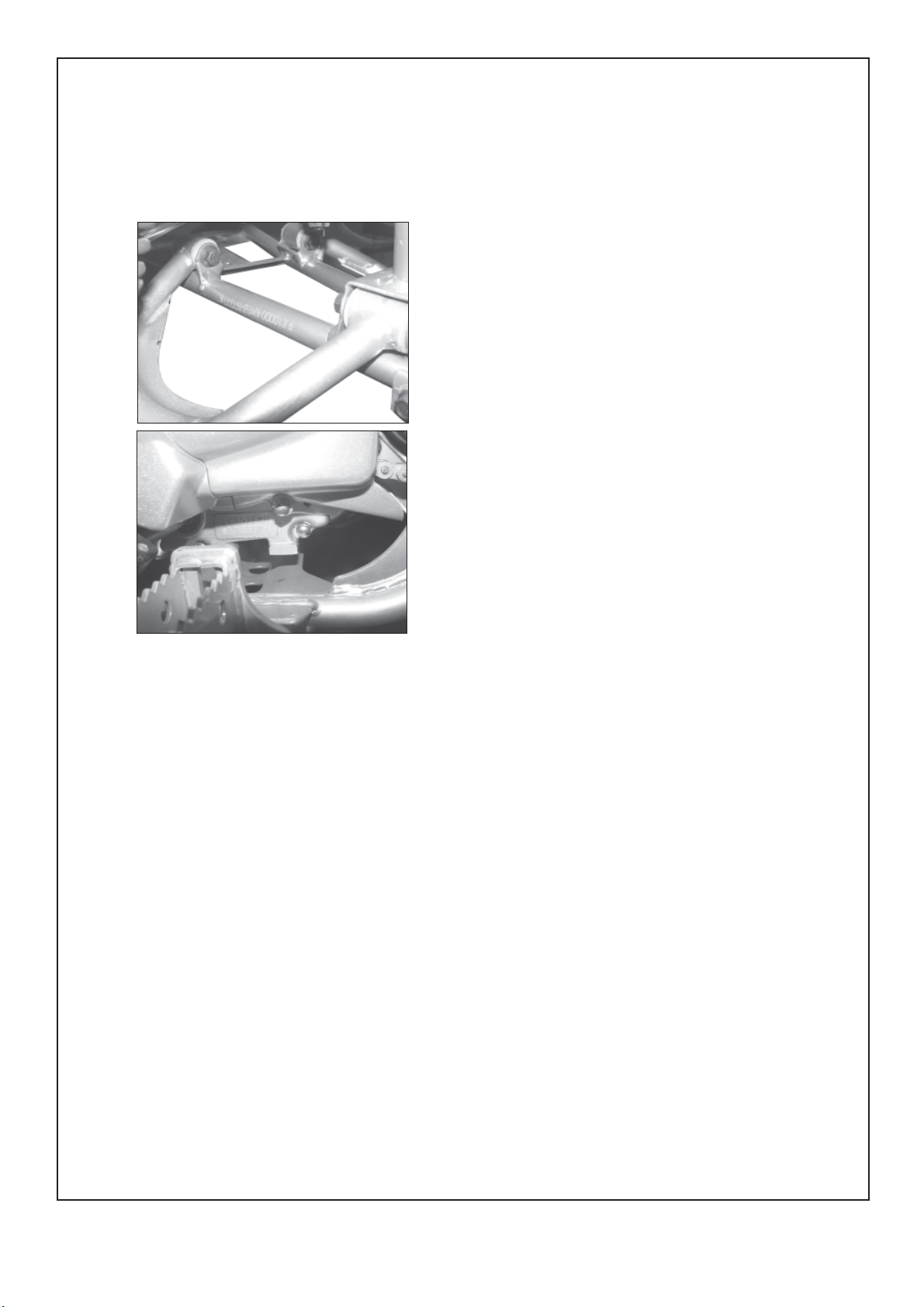

Identification code

It is engraved in the left or right side of front

supporting main take of engine of frame.

Engine N0.

The engine No. engrave onthe narrow point

position.