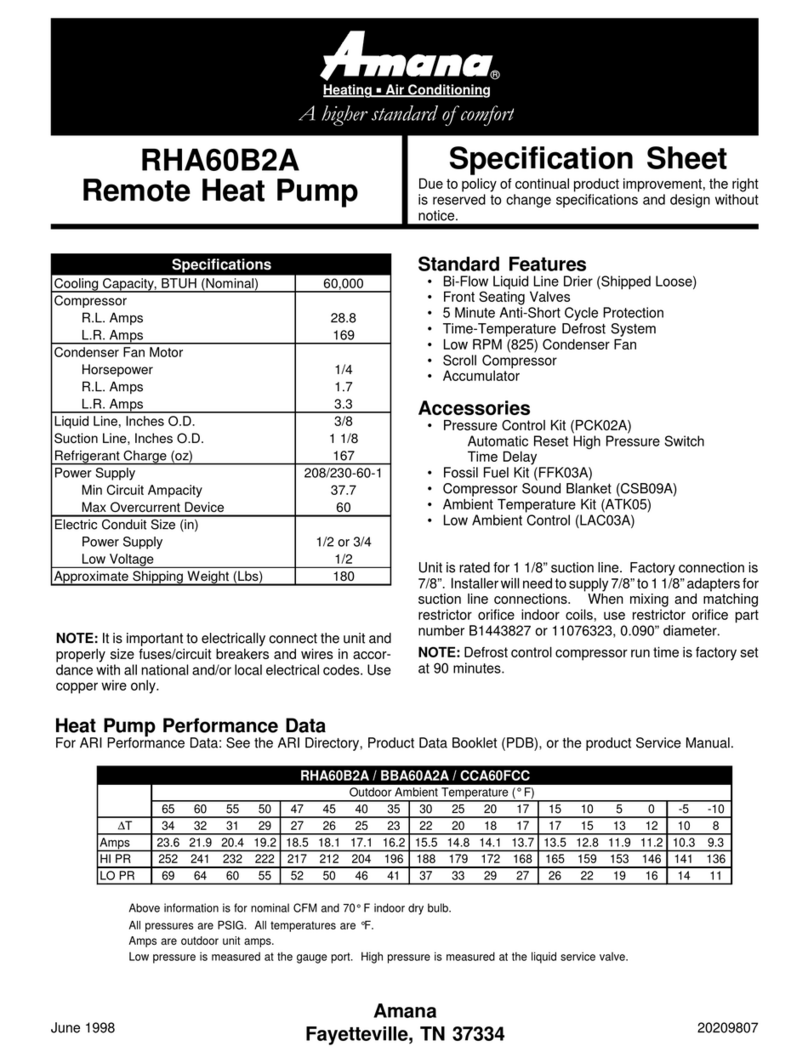

6. SPECIFICATIONS

Series Comfort High Power

Type Mini

5

Mini

8

Mini

11

Mini

14

Mini

16

Mini

11 HP

Mini

14 HP

Mini

16 HP

5 8 11,1 14 16 11,2 14 16

1,22 1,9 2,67 3,5 4,05 2,55 3,22 3,72

4,1 4,2 4,15 4 3,95 4,4 4,35 4,3

4,06 8 10 13 14 11,2 14 15,1

1,23 2,5 3,13 3,94 4,38 3,45 4,4 4,87

3,3 3,2 3,2 3,3 3,2 3,25 3,18 3,1

3,46 7,9 8,63 11 11,5 11,2 14 15

1,31 3,12 3,6 4,4 4,79 3,92 5,15 5,56

2,65 2,53 2,4 2,5 2,4 2,86 2,72 2,7

5,67 8 9,5 13,2 14,4 10,5 13,1 15,1

1,7 2,47 2,97 4,13 4,57 2,9 3,7 4,42

3,33 3,24 3,2 3,2 3,15 3,62 3,54 3,42

3,15 7 7,4 9,5 10 10,5 13,1 14,5

1,56 3,41 3,61 4,5 4,85 4,16 5,39 6,39

2,02 2,05 2,05 2,11 2,06 2,52 2,43 2,27

kW

kW

kW

kW

kW

1ø 230V, 50Hz 3ø 400V, 50Hz

A

42 dB/1m

cm 65,5 × 40,5 × 28,6

plate stainless soldered

DC-variable speeds

12,5 17,5 18,5 20 25,9 8,5 9,5 10,5

Max.

H×W×D

58×79×30

83×90×33 129×90×33 129×90×33

39,0 39,0 40,0 41,0 41,0 41,0 41,0 41,0

dB(A)

cm

(netto) kg

H×W×D

44 62 62 98 105 109 109 109

R410A

kg 1,35 1,7 1,7 3,35 3,35 2,5

DC-inverter (variable-speed)

electronic expansion valve

105 hPa

18 m

0,18 MPa / 0,55 MPa

Al-Cu vertical

hot gas through reverse valve

G1"

15-95%

600 - 2 500 1 000 - 5 500 1 000 - 7 500

Max. m 15 15 20 20 20 15

Max. m 15 15 20 20 20 15

°C -15 ~ 24 -20 ~ 35

Liquid mm ø 6,35 ø 9,52 ø 9,52 ø 9,52 ø 9,52 ø 9,52

Gas mm ø 12,70 ø 15,88 ø 15,88 ø 15,88 ø 15,88 ø 15,88

Min. / Max. m 5/15 5/20 5/20 5/20 5/20 5/20

3

m /h

+7°C / +35°C floor heating

Heating capacity

Input power

COP

+2°C / +35°C floor heating

-7°C / +35°C floor heating

+7°C / +45°C radiators

-7°C / +45°C radiators

Power source

Current

Noise level (indoor unit)

Dimensions (indoor unit)

Heat exchanger

Fan motor

Noise level (Sound pressure)

Dimensions (outdoor unit)

Weight (outdoor unit)

Refrigerant

Refrigerant amount

Connection

pipes

Diameter

Length

Length (chargeless)

Height difference

Diameter

Operation range

Compressor

Regulation of refrigerant circuit

Pressure loss of hot water (indoor unit)

Max. height of water column

Max. operation overpressure / HDW

Evaporator

Air flow

Defrosting

Heating circuit connection

Relative humidity limits

Heating capacity

Input power

COP

Heating capacity

Input power

COP

Heating capacity

Input power

COP

Heating capacity

Input power

COP

Notes:

The values of heating capacity/power input/COP are based on measurement of EN14511 standard.

Sound pressure level measured at distance of 5m from the device, 1.5m from the ground.

5