Manual 2100-586G

Page 7 of 25

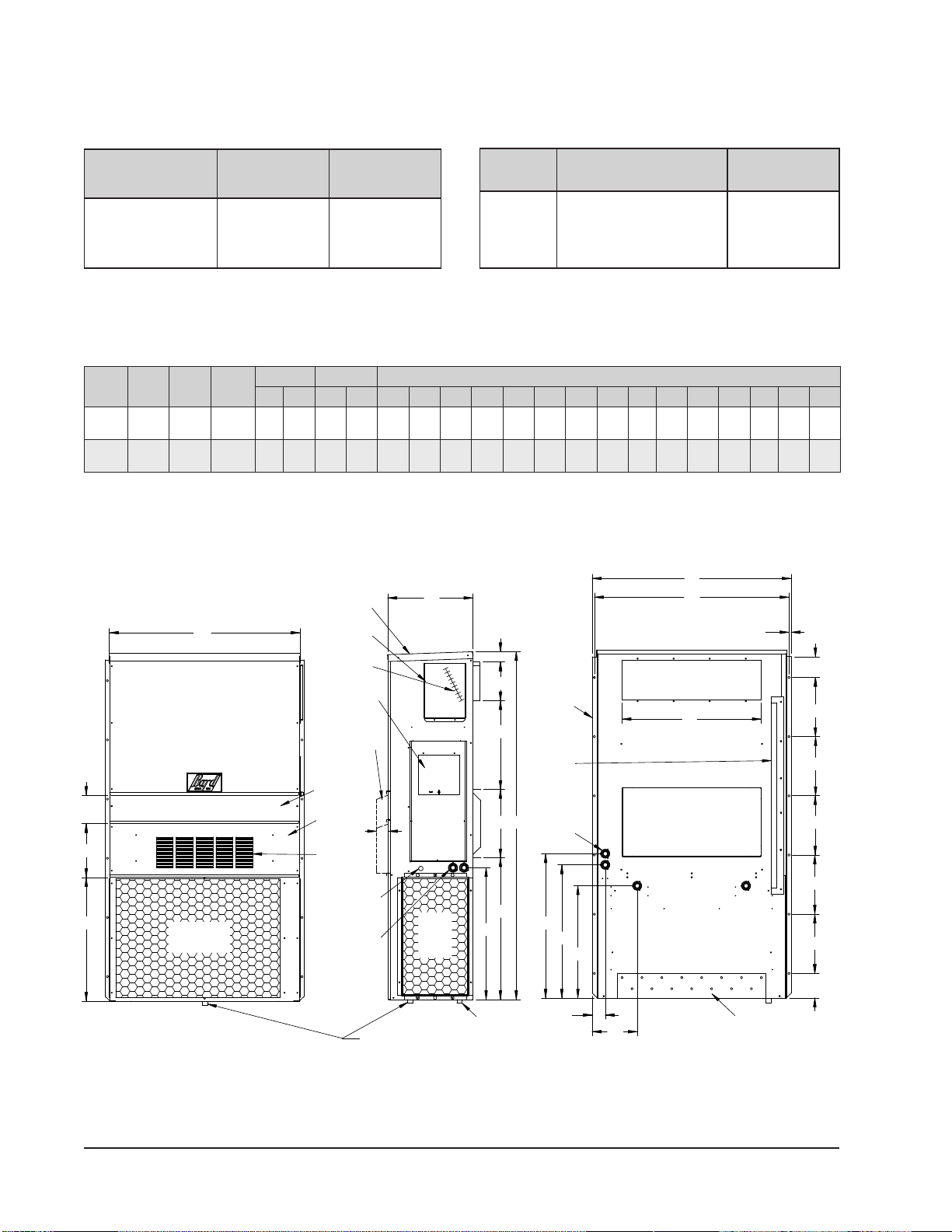

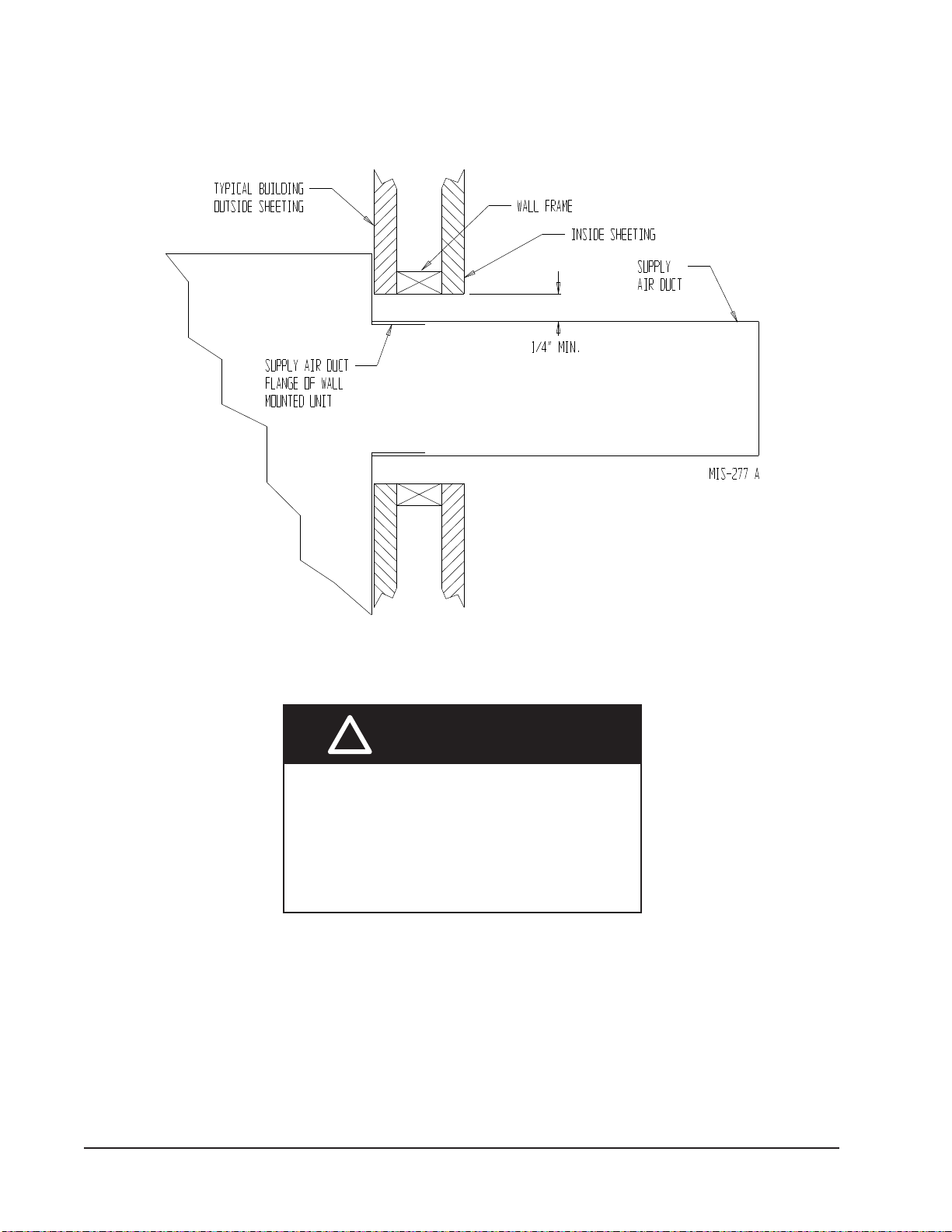

Wall Mounting Information

1. Two holes for the supply and return air openings

must be cut through the wall as shown in Figure 3.

2. On wood frame walls, the wall construction must

be strong and rigid enough to carry the weight of

the unit without transmitting any unit vibration.

3. Concrete block walls must be thoroughly inspected

to ensure that they are capable of carrying the

weight of the installed unit.

Mounting the Unit

1. These units are secured by wall mounting brackets

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket, attached

to skid for shipping, is provided for ease of

installation, but is not required.

2. The unit itself is suitable for 0" clearance, but the

supply air duct ange and the rst 3' of supply

air duct require a minimum of 1/4" clearance to

combustible material. However, it is generally

recommended that a 1" clearance is used for

ease of installation and maintaining the required

clearance to combustible material. See Figure 3

for details on opening sizes.

3. Locate and mark lag bolt locations and bottom

mounting bracket location (see Figure 3).

4. Mount bottom mounting bracket.

5. Hook top rain ashing, attached to front-right of

supply ange for shipping, under back bend of top.

6. Position unit in opening and secure with 5/16" lag

bolts; use 7/8" diameter at washers on the lag

bolts.

7. Secure rain ashing to wall and caulk across entire

length of top (see Figure 3).

8. For additional mounting rigidity, the return air

and supply air frames or collars can be drilled

and screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

Placement

1. On side-by-side installations, maintain a minimum

of 20" clearance on right side to allow access to

control panel and heat strips and to allow proper

airow to the outdoor coil. Additional clearance

may be required to meet local or national codes.

2. Care should be taken to ensure that the

recirculation and obstruction of condenser

discharge air does not occur. Recirculation of

condenser discharge air can be from either a

single unit or multiple units. Any object such

as shrubbery, a building or a large object can

cause obstructions to the condenser discharge

air. Recirculation or reduced airow caused by

obstructions will result in reduced capacity,

possible unit pressure safety lockouts and reduced

unit service life.

For units with a draw through condenser, such as

the C**H 11EER, it is recommended there be a

minimum distance of 15' between the front of the

unit and any barrier to airow.

Required Steps after Final Placement

(C48H & C60H Units Only)

The compressor is secured to the unit base for

shipping. Although unit will perform as designed

with the compressor secured in place, there may be

noticeable additional noise and vibration. To obtain

the lowest noise and vibration levels, remove the

compressor shipping brackets after the unit is in its

nal operating location.

Remove the side grille to gain access to the compressor

shipping brackets. The brackets are located on the

compressor double isolation base at the front and rear

of the compressor. The brackets are secured to the unit

base with two (2) screws and secured to the isolation

plate with a 1/4" nut. Remove and dispose of the two

(2) screws and brackets. Re-install the 1/4" nut once

bracket is removed.

INSTALLATION

Heavy item hazard.

Failure to bolt the unit to the wall could

result in the unit falling. Follow all mounting

instructions.

Failure to do so could result in damage, injury

or death.

!WARNING