Installation

AW 4 | 5 | 7 OR-S – 6721866761 (2023/06)

10

charge pressure) of the expansion vessel is of highest importance.

Check the pre-charge pressure and function annually.

Furthermore, the function of automatic air vents should also be checked

during maintenance.

It is also important to check and document the top-up water quantities

via a water meter. Larger and regularly required water top-up quantities

indicate insufficient pressure maintenance, leaks or continuous oxygen

input.

Antifreeze

Unsuitable antifreeze can damage the heat exchanger or cause a fault in

the heat source or DHW supply.

Unsuitable antifreeze can damage the heat source and heating system.

Only use antifreeze as listed in the document 6720841872, which

contains antifreeze products approved by us.

▶ Only use antifreeze according to the specifications of the

manufacturer, e.g with regard to the minimum concentration.

▶ Follow the instructions of the manufacturer of the antifreeze about

regular checking of the concentration and corrective measures.

▶ The use of antifreeze reduces the efficiency.

Heating water additives

Unsuitable heating water additives can cause damage to the heat source

and heating system or cause a fault in the heat source or DHW supply.

The use of a heating water additive, e.g. corrosion inhibitor, is only

allowed, if the manufacturer of the heating water additive certifies its

suitability for all materials in the heating system.

▶ Only use heating water additives in accordance with the instructions

of its manufacturer about concentration, regular checking of the

concentration and corrective measures.

Sealants in the heating water can cause deposits in the heat generator,

therefore it is not advisable to use it.

Suitable water treatment products (inhibitors/cleaners) can be

obtained from the following manufacturers:

Follow the guidance of BS7593:20191) for treatment of water in

domestic hot water heating systems.

Table 6

3.5 Minimum volume and execution of the heating

system

To safeguard the heat pump function and avoid an excessive number of

start/stop cycles, incomplete defrosting and unnecessary alarms, it

must be possible to store a sufficient amount of energy in the system.

This energy is stored in the water volume of the heating system, and also

in the components of the system (radiators) and concrete floor

(underfloor heating system).

Check the Installer instructions for the respective Indoor unit (IDU) for

the conditions of the heating system.

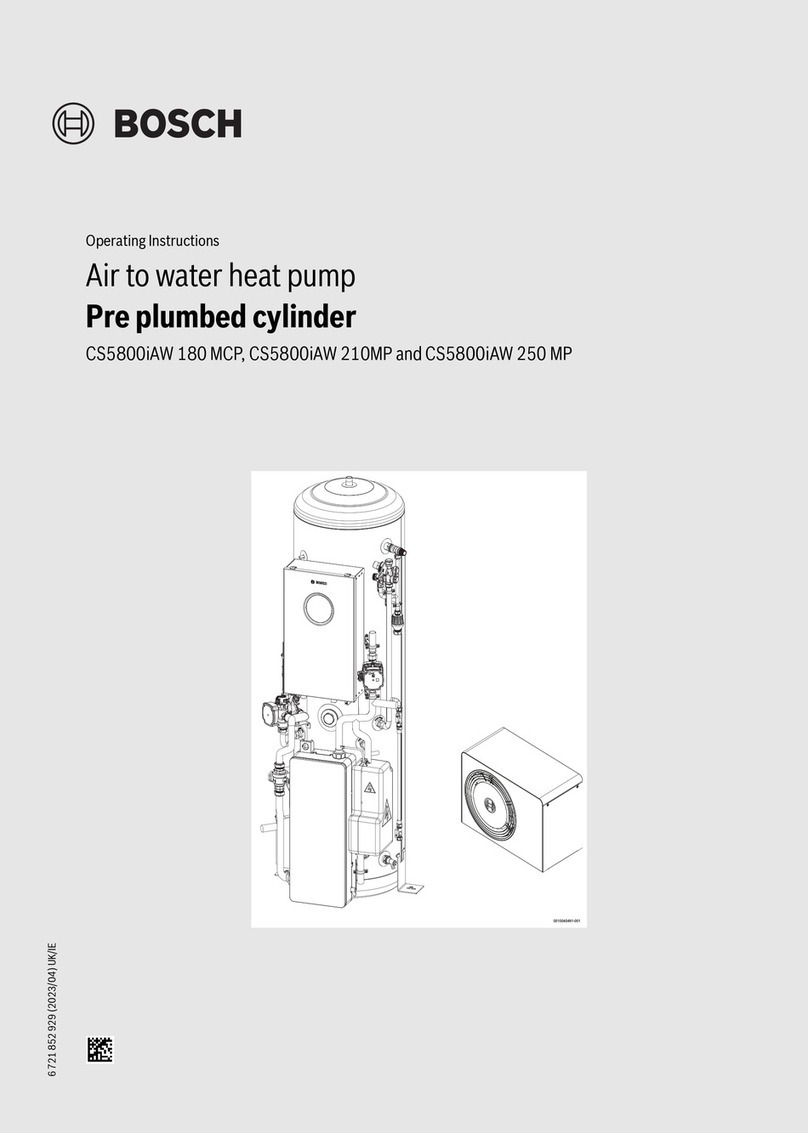

4 Installation

NOTICE

Damage to the heat pump due to water!

Electrical connections and electronics can be damaged if they are

exposed to water. The outer casing is a prerequisite for meeting the heat

pump's IP rating.

▶ The heat pump must not be placed outdoors without its back panel,

side panels, front plate and roof.

▶ Mount side panels without delay after the electric connections are

done.

▶ The heat pump may not be operated without the outer casing.

CAUTION

Risk of injury!

During transport and installation there isa risk of crushing injury. During

maintenance, internal parts of the appliance may become hot.

▶ The installer is obliged to wear gloves during transport, installation

and maintenance.

CAUTION

Risc of injury!

For installation it is not necessary to remove the front panel. Access to

the refrigerant circuit and electrical cabinet is possible from the side. In

case there is a need to remove the front panel, be aware of moving parts.

Serious injury to hand or fingers may occur.

▶ Keep hands away from moving parts.

▶ Disconnect power before servicing.

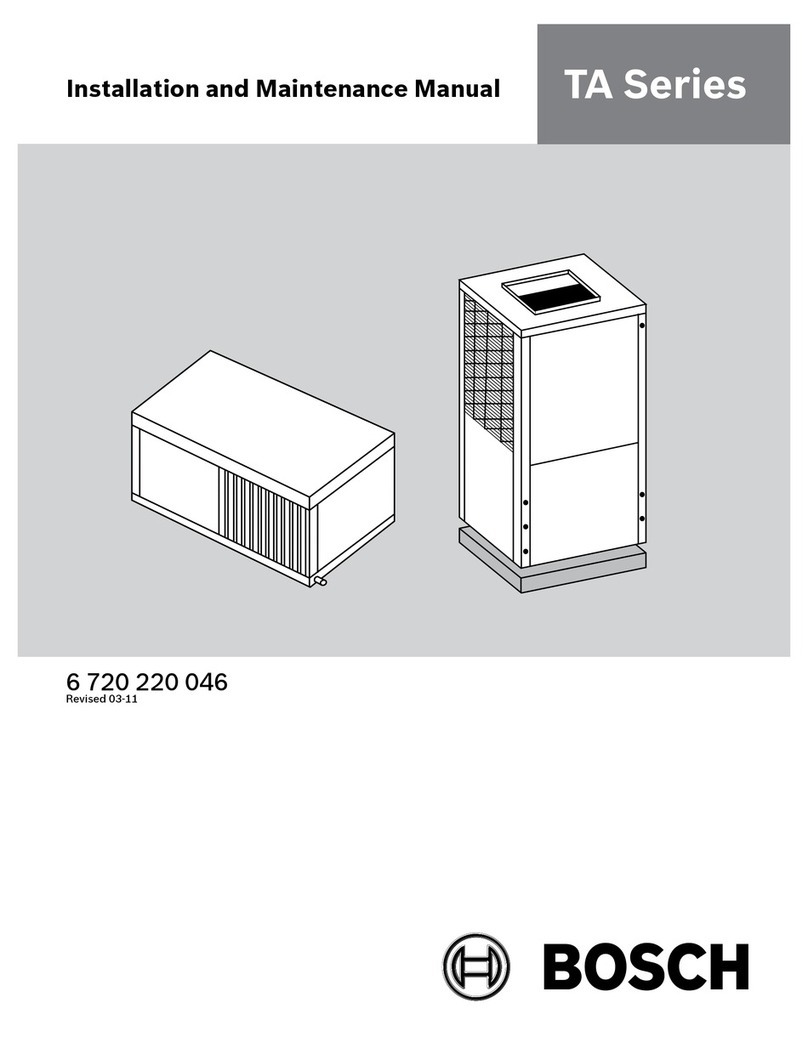

4.1 Checklist

Each installation is different. The checklist below provides a general

description of the installation process.

1. Install, level and fix the heat pump on a solid surface. The drill

template on the carton box can be used for this.

2. Remove the transport fitting (screw) for the compressor plate

(bild 31).

3. Pull out the loop of the drip tray heater and push it through the drain

connector (bild 25). Attach the drain connector to the heat pump.

4. Install a condensate tube from the heat pump and possibly a pipe

trace heater (accessory heating cable instructions).

5. Connect the pipes between the heat pump and the indoor unit.

6. Connect CAN-BUS cable to heat pump and indoor unit.

7. Connect power supply of the heat pump.

1) Only applicable in the United Kingdom

ADEY 01242 546700

www.adey.com

FERNOX 0330 100 7750

www.fernox.com

SENTINEL 01928 704330

www.sentinelprotects.com/uk