CONTROL PANEL

The refrigerator control panel is located between the

fresh food and freezer compartments of your refrigerator.

The refrigerator control requires +12 volts DC to operate.

There are three pushbuttons.

POWER ON –Pressing this pushbutton turns the

refrigerator on and off.

MODE –Pressing and holding this pushbutton cycles

the mode selections from AUTO, manual GAS, and

manual AC. Releasing the pushbutton selects the last

mode displayed. The selected mode will be displayed

for approx 5 seconds before all the mode indicators are

turned off. The active mode can be displayed at any

time by pressing and releasing the MODE pushbutton.

TEMP –Pressing and holding this pushbutton cycles the

temperature settings from 1 through 5 with 5 being the

maximum cool setting. Releasing the pushbutton

selects the last temperature setting displayed. The

selected temperature setting will be displayed for approx

5 seconds before all the temperature indicators are

turned off. The active temperature setting can be

displayed at any time by pressing and releasing the

TEMP pushbutton.

AUTO MODE

When the refrigerator is in the AUTO mode, the control

automatically selects the best energy source which is

available. When a more efficient energy source

becomes available, the refrigerator automatically

switches to the more efficient source. AC energy is

considered the more efficient energy source and is the

first choice selected by the control. Propane gas is the

second choice and is selected in the AUTO mode only

when AC energy is not available.

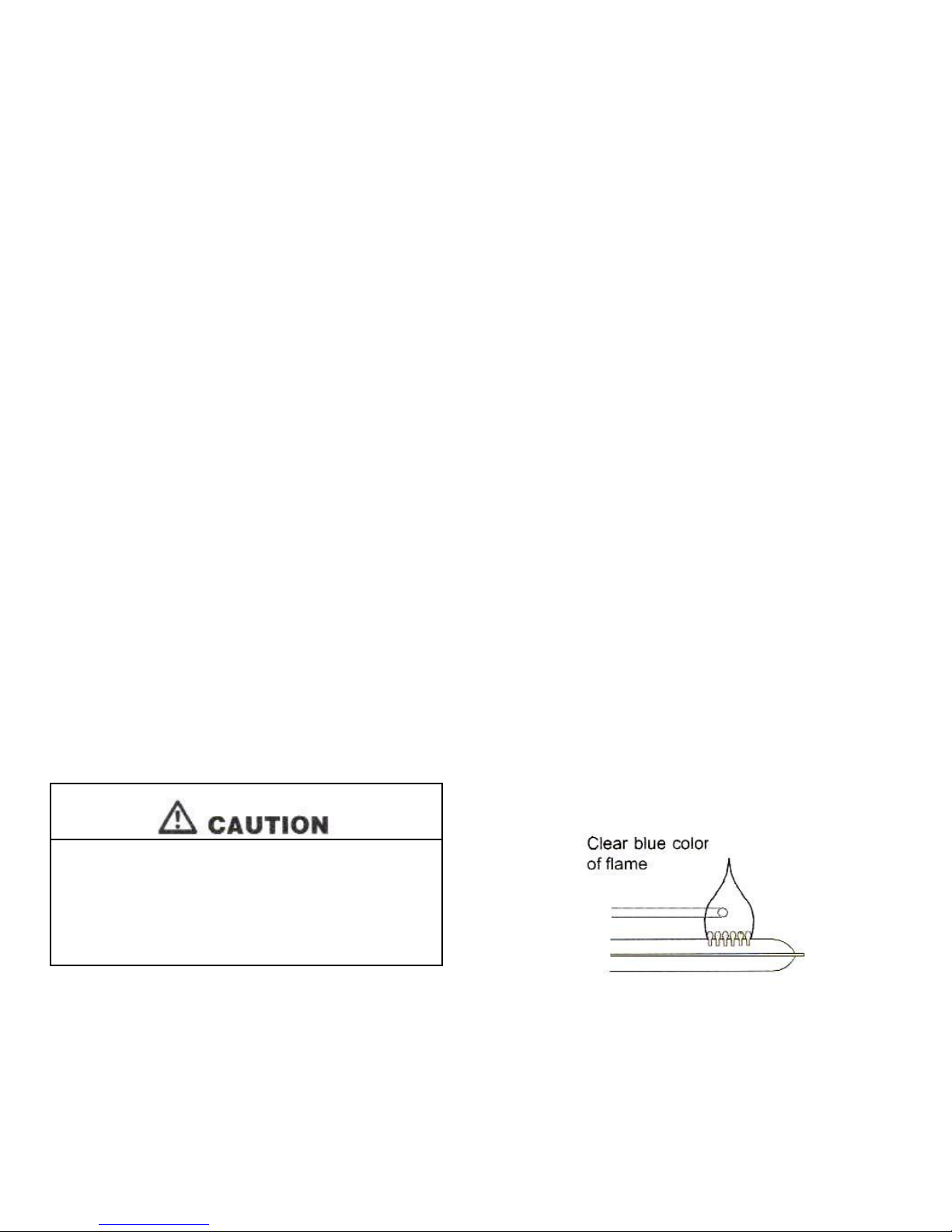

GAS MODE

The GAS mode can be selected either automatically or

manually. When switching to gas operation, the

refrigerator control begins a 40 second trial ignition

cycle. During this period, the control opens the gas

safety valve and begins sparking the burner. If after 40

seconds the control fails to detect the presence of a

flame, the control shuts off the gas safety valve and

stops sparking the burner. The CHECK indicator on the

control panel turns on indicating that the burner failed to

ignite. The CHECK indicator can be reset by turning the

refrigerator off and then back on again and a new 40

second trial ignition cycle begins. On initial start up or

after changing a propane tank, it is possible that air in

the gas supply lines will require 2 or 3 ignition trials

before successfully lighting the burner. If after repeated

attempts, the burner fails to ignite, stop and consult your

local dealer or an authorized Atwood Service Center.

MANUAL MODES

The manual modes allow for selection of either the AC or

GAS modes directly. If the selected mode’s energy

source is not available, the refrigerator is turned off, the

CHECK is turned on and the selected mode indicator flashes on

and off indicating which energy source is not available.

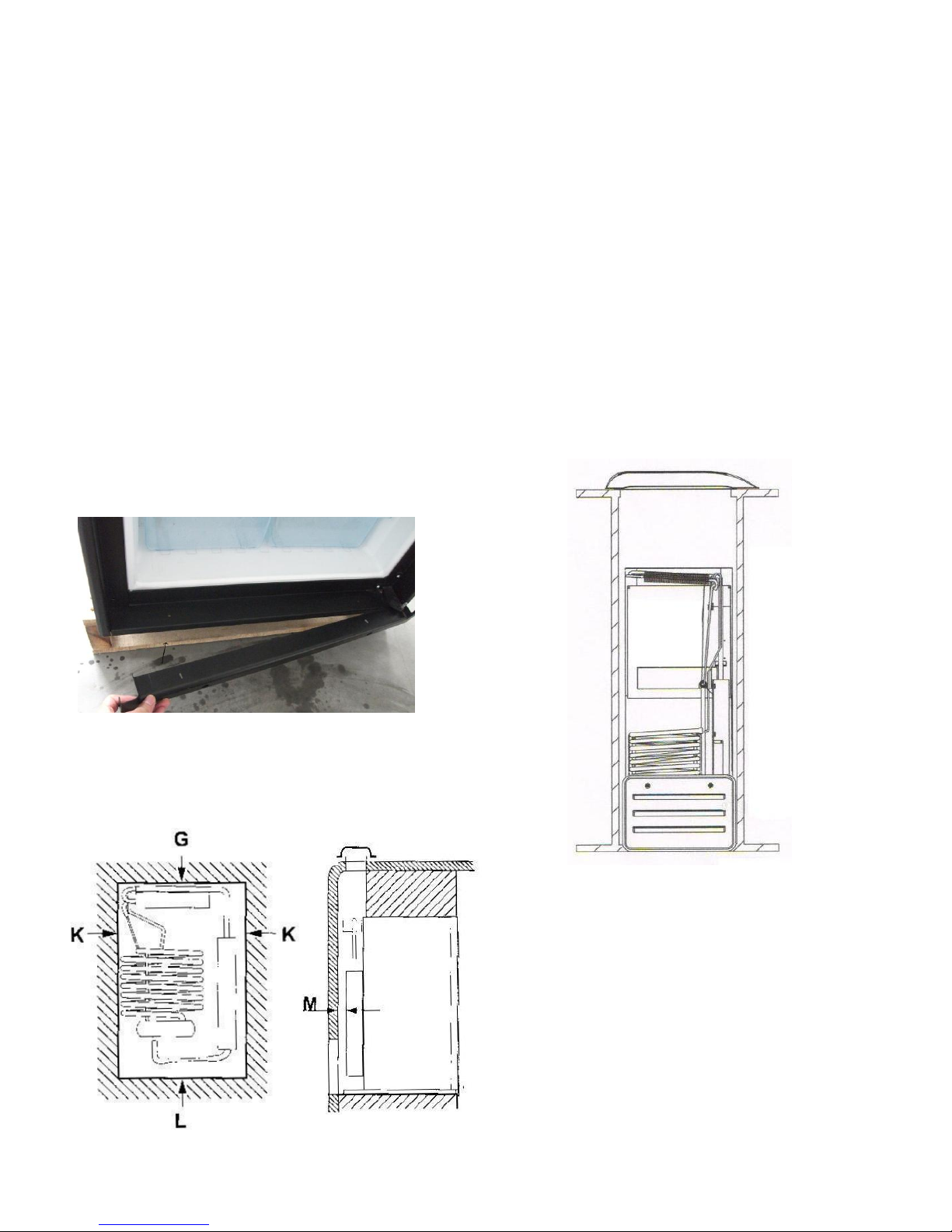

DOOR HANDLES

The door handles latch when closed to prevent the doors from

opening travel. When closing the doors, push each door into the

refrigerator cabinet until you hear a distinct “click” sound which

will indicate that the door is latched. To open a door, pull the

handle away from the refrigerator cabinet to unlatch the handle.

During off-season storage, the handle has a storage latch which

prevents the door from completely closing. Keeping the doors

partially opened during long term storage prevents odors from

building up in the cabinet. To engage the storage latch, open

each door about 1/2 inch, hold the door handle in the open

position, and push the storage latch into the cutout of the strike

plate. Never use the storage latch as a travel latch because the

doors will not be fully closed.

DOOR AJAR ALARM

This refrigerator has an alarm to alert you if the fresh food

compartment door is left not fully closed. If the door is left open

for more than 2 minutes, the CHECK light will be lit and a beeper

will sound a chirp approx every 5 seconds until the door is closed.

The refrigerator will continue to operate normally throughout the

door ajar alarm sequence.

MOISTURE DIVIDER HEATER

This refrigerator has a heater which is automatically controlled

and prevents moisture from forming on the center divider located

between the freezer and fresh food compartments.

BACKUP TEMPERATURE CONTROL SYSTEM

This refrigerator has a backup temperature control system which

allows the owner to have variable temperature control of the

refrigerator even if the temperature sensor should fail.

If the control cannot read the temperature sensor, the control

uses the selected temperature setting to control the refrigerator

cycle and adjust the temperature accordingly.

THERMAL SWITCH MONITOR

This refrigerator has a thermal switch which serves as an

overheating monitor.

TILT SENSOR TECHNOLOGY

This refrigerator control incorporates a patent pending tilt sensor

which enables the control to constantly monitor the angle at which

the refrigerator is operated. This feature is protects the user from

potential hazards attributed to prolonged operation at severe

angles of inclination. This monitoring function is completely

invisible to the user and only becomes apparent to the user in the

rare event that the refrigerator has been operated for prolonged

periods of time at severe tilt angles. Normal care in leveling of

your vehicle will prevent this feature from ever being noticed.