AUKS-FanCoil

6

2.1Feature

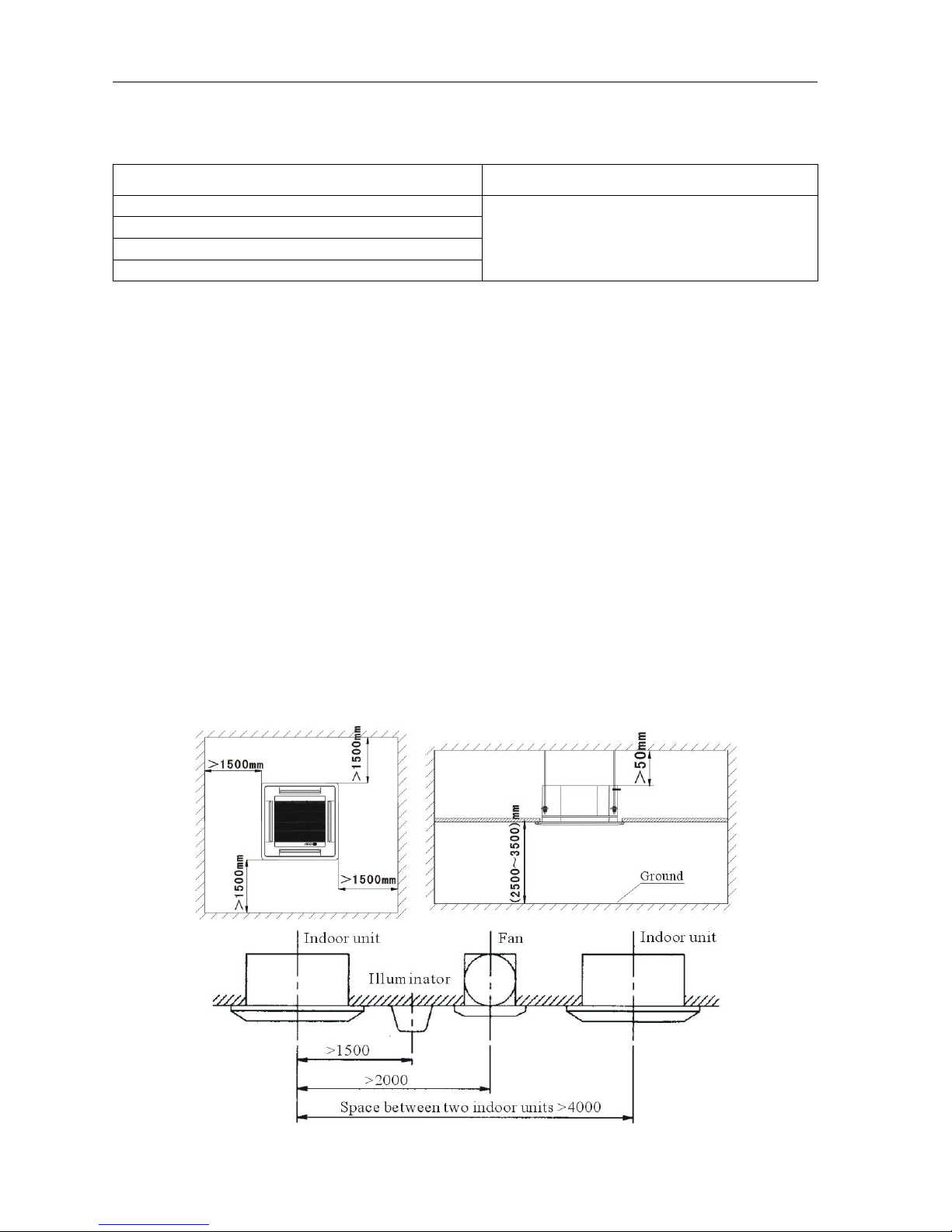

Four-way cassette fan coil unit is installed under the ceiling, compared with Floor &Standing type A/C, it

has following advantages: saving room space; Ceiling installation combining with the decoration,

makes the room more elegant; Flexible installation in anywhere in the ceiling and 4-direction blowing,

makes the indoor temperature is even and makes you feel more comfortable, so Cassette type A/C is a

perfect replacing Product of Floor &Standing type A/C.

Application occasions:

Small super market,restaurant, office, meeting room, villa,meeting room, livingroom a n d soo n , a n d i t

caneven b e u s e d a s t h e updating product formodern residential A/C.

Features:

◇Concealed design, ceiling installation, room space saving, i t i s v e r y suitable forfamily o r office

occasion;

◇WithSetting o r Auto t w o operation modes, four-way blowing, strongcirculating w i n d , multiw i n d speed,

t h e cooling o r heating capacity canreach t o e a c h corner o f t h e room;

◇One-step formed shell b y mold,appearance i s elegant;

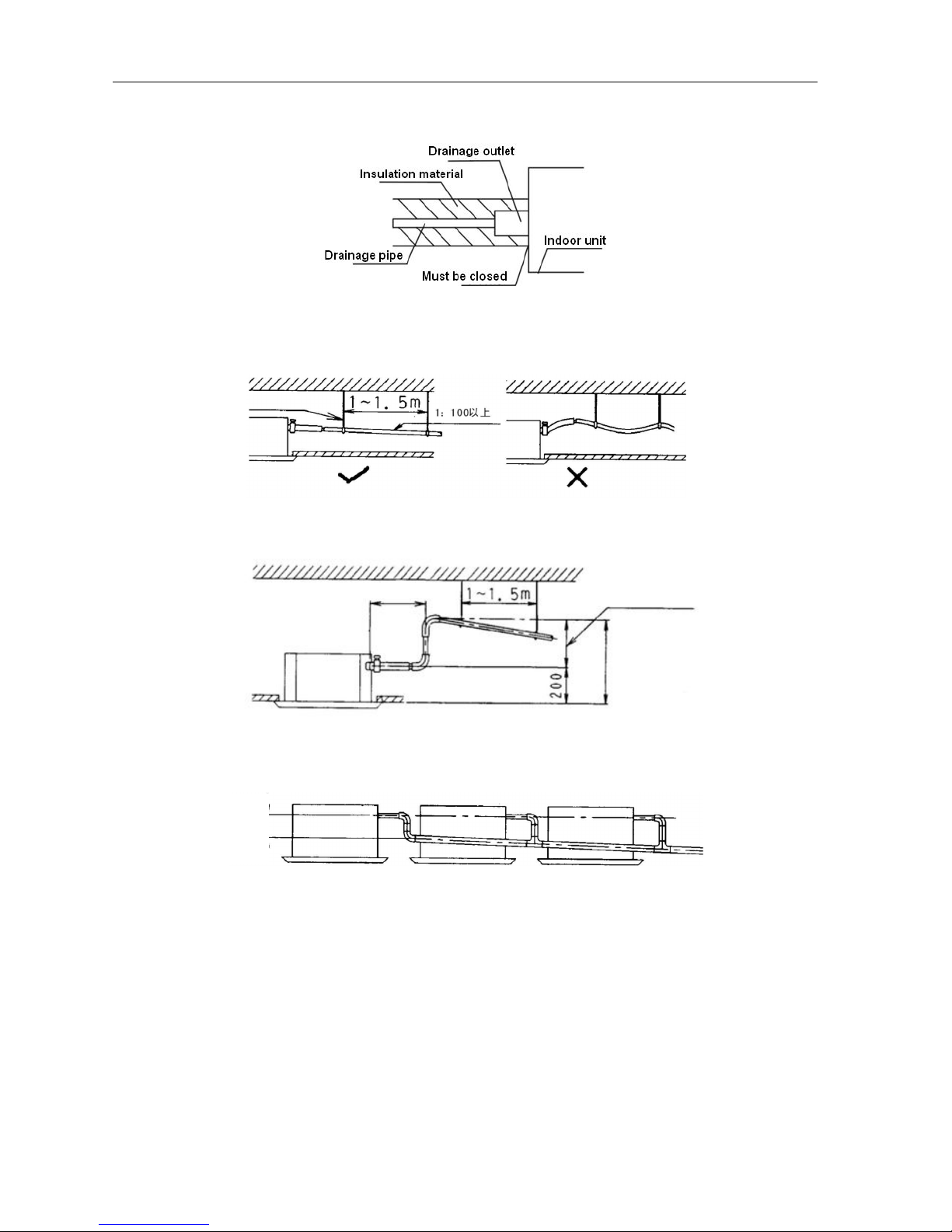

◇Special insulation design, achieves high heat insulation efficiency, a n d n o condensation o n shell;

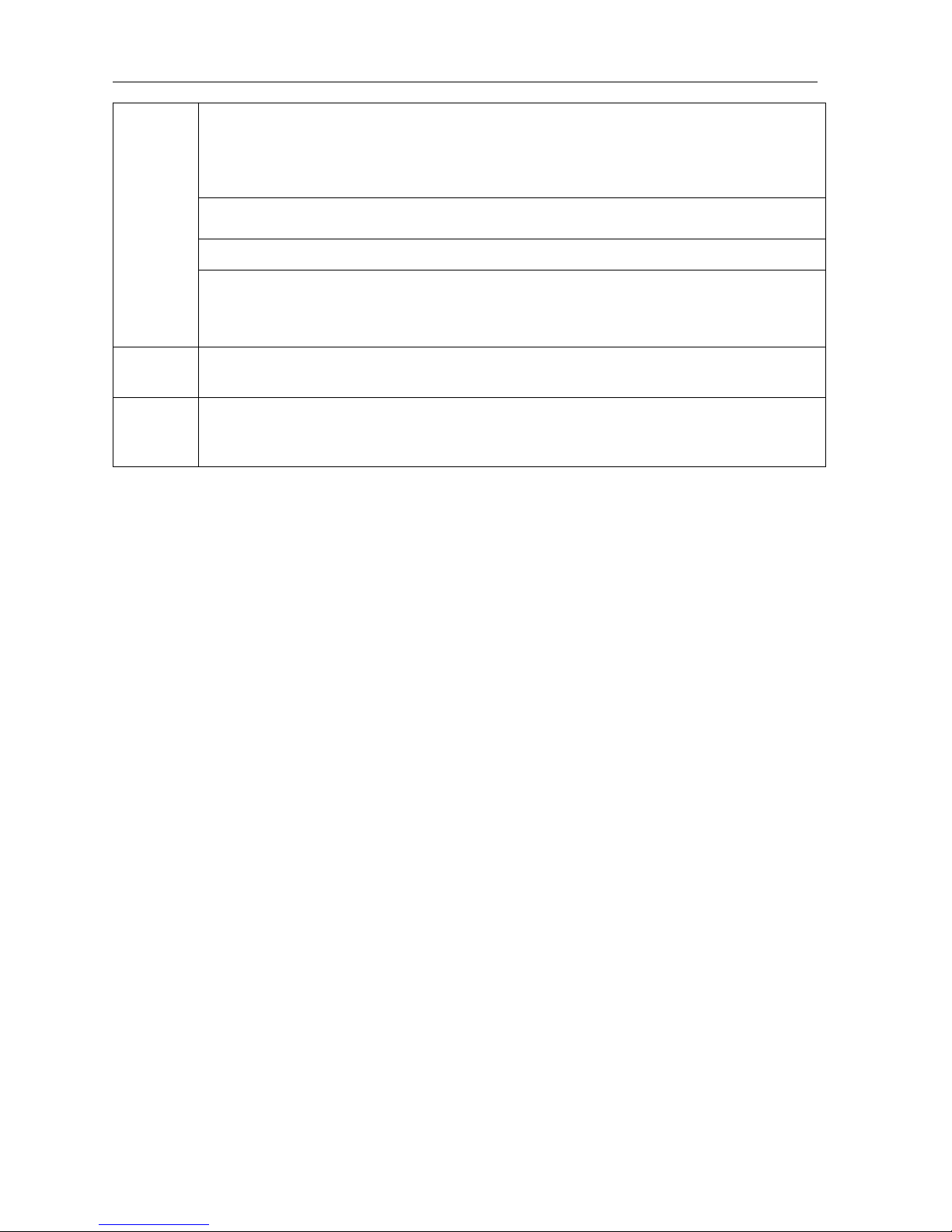

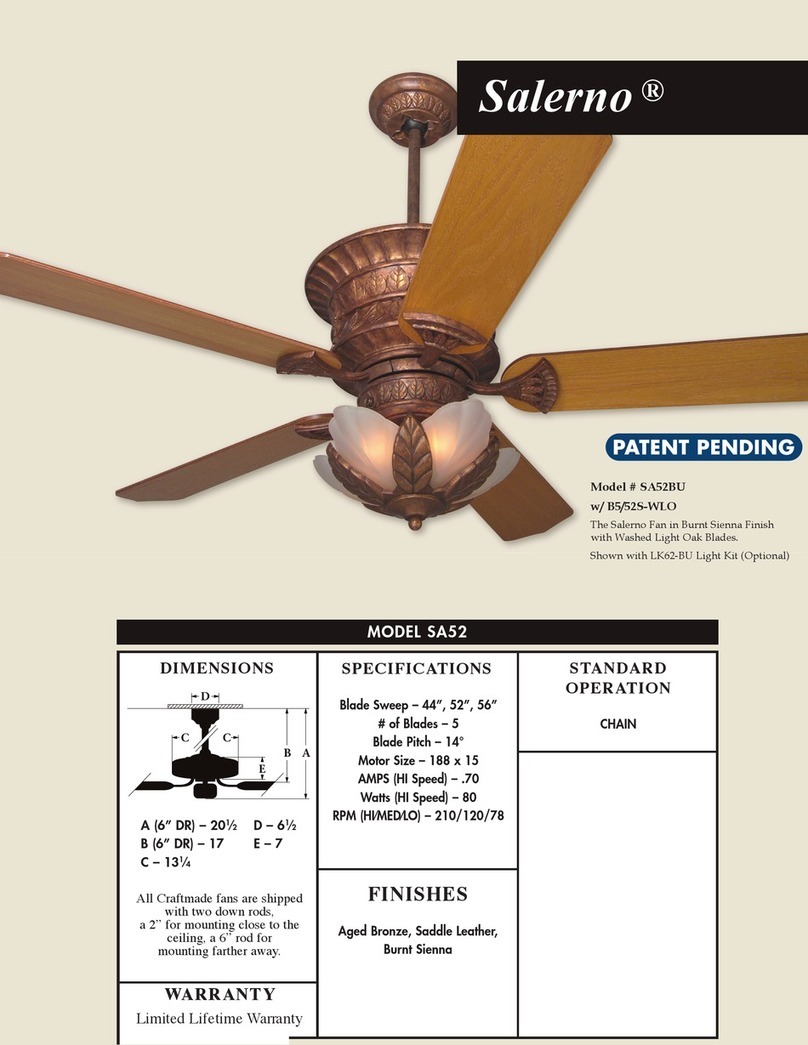

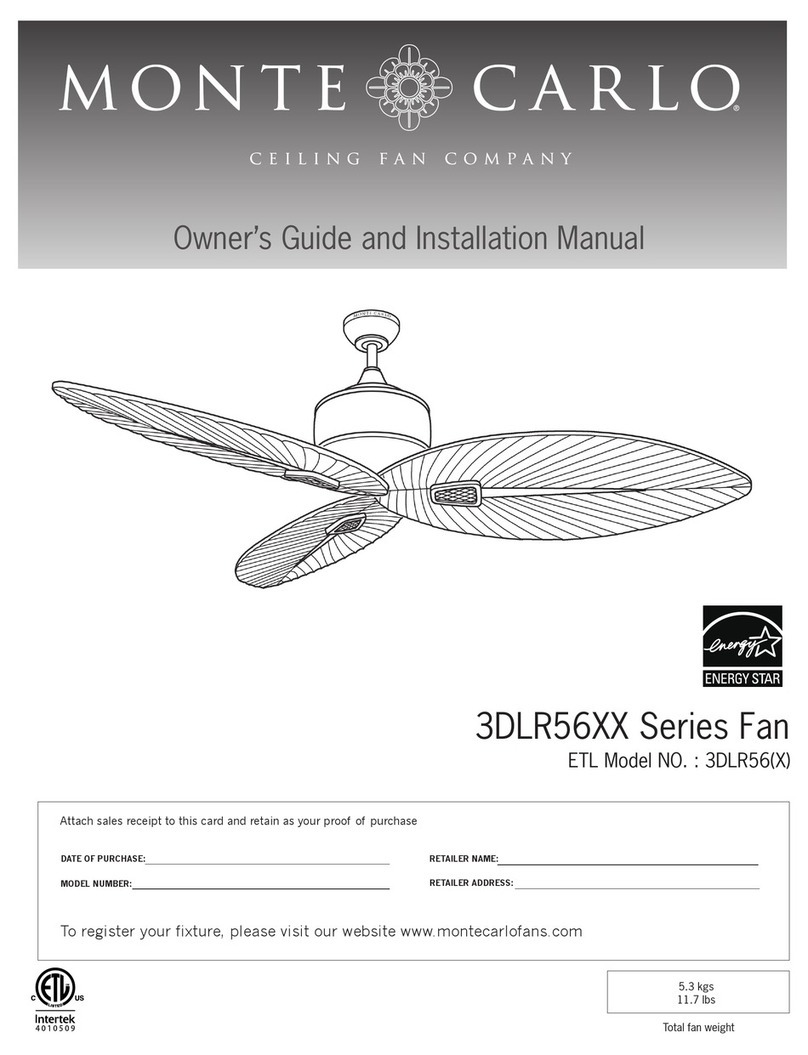

◇Built-in d r a i n pump, drain-head height i s u p t o 1.2meters, creating t h e ideal solution forperfect w a t e r

drainage, a l s o construction a n d installation i s mucheasier a n d convenient;

◇Long t e r m a i r filter, w a s h period i s t w o t i m e s longer t h a n normal filter, a n d maintenance i s free;

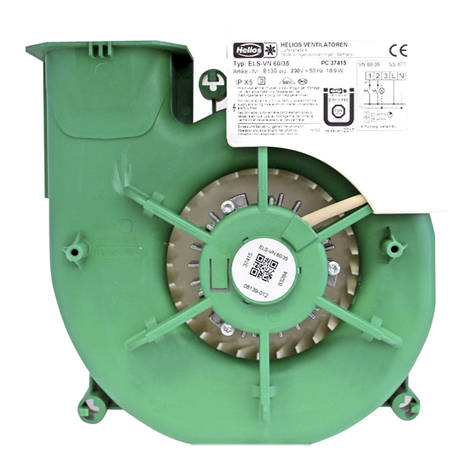

◇3 D helix a i r blade ensures t h e a i r flowsufficiently, reduces t h e u n i t thickness, a n d reduces t h e

operation n o i s e greatly;

◇Plastic d r i p t r a y adopts innovative foam-PS combined w i t h plastic technical, t h e thickness o f plastic

reaches 1 m m , a v o i d a n y leakage;

◇6segments heat exchanger, increase exchanging area, t h e efficiency o f heat exchanging increased

b y 10%~15%;

◇Ingenious hook design, t h e panel i s convenient t o install o r remove;

◇F r e s h a i r intake design, leading i n fresha i r t o improve indoor a i r quality anytime;

◇3-phase power supply t y p e u n i t s w i t h l o w ambient temperature cooling function, w h i c h makes t h e u n i t

canrun normally o n t h e condition t h a t t h e ambient temperature f a l l s down t o -15℃ ;

◇Auto-restart function;

◇Standard remote controller a n d optional w i r e d controller;

◇F a i l u r e automatic detection, i f t h e r e i s afailure, t h e indicator w i l l flasha n d t h e failure codewill display

o n t h e w i r e d controller, t h e failure cause i s easier t o b e found.