© 2008 RenewAire LLC Due to continuing product development, specifications are subject to change without notice.

For Technical Updates and other current info, visit www.breeze.renewaire.com

BR70_130_Manual_FEB08.doc. 140036_003 Revised 2/08 3

4510 Helgesen Drive, Madison, WI, 53718

608.221.4499, 800.627.4499, Fax: 608.221.2824

Mount the unit hanging bracket to the unit. Attach the

hanging bracket to the duct work. Make sure the unit

orientation provides for proper airflow direction in the return

duct. Refer to the air flow direction label on the unit. Using

the template provided cut a rectangular hole in the duct work.

To add rigidity to the duct, bend the edges of the hole into the

duct as flanges. Check the gasket on the back of the unit to

insure it is free of tears and rips. Add the long piece of gasket

provided in the hardware kit to the back of the unit to form a

rectangle with the other three pieces of gasket already applied.

Lift the unit and connect the hanging bracket on the unit into

the hanging bracket on the duct work. Use caution and an

assistant when installing the unit overhead. Swing the unit

into position and verify its fit. Attach the unit end flanges to

the duct work. Now fasten the crosswise bracket to the duct

work and then to the unit. The smaller crosswise bracket may

need to be installed after the lengthwise bracket if one of the

unit flanges cannot be attached to the return duct. Make sure

the screws used are properly selected for the loads and

substrate involve.

Note: All the provided brackets should be installed

surrounding the opening between the unit and return duct.

Exhaust & Outside Air Ducts

The Exhaust Air Duct and the Outside Air Duct connect the

unit to the outside. Flexible insulated duct is typically used.

For duct hung applications, the exhaust outlet and fresh air

inlet on the outside of the building should be at least ten feet

apart to avoid cross-contamination. Keep the length of the two

flexible ducts roughly equal and as short and straight as

possible. Normally, six inch insulated flexible duct is used.

Band or tape inner duct liner to inner flange of appropriate

collar. Drive a sheet metal screw through liner to secure duct

spiral wire to collar. Straighten insulation, and slide outer

duct jacket onto the outer flange of the duct collar. Secure

with band or tape.

If duct runs are exceedingly long (over 10 feet of flex duct for

130 CFM) or have excessive bends or elbows or if maximum

air flow rates are required, eight inch insulated flexible duct

should be used. The outer flange of the duct collar can be

used for both the inner and outer jacket of the flexible duct.

Care must be taken to insure that the duct is securely fastened

and sealed to the duct collar. Ducts connecting the unit to the

outside must be insulated with sealed vapor barrier on both

inside and outside of the insulation.

The inlets and outlets should be screened against insects and

vermin and shielded from the weather to prevent the entry of

rain or snow. The exhaust outlet should not dump air into an

enclosed space or into any other structure.

Mounting the Unit Thru-Wall

As another installation option the Breeze unit may be mounted

directly to the inside of an exterior wall. The Thru-Wall kit

must be used for this application. Refer to Thru-Wall

instructions packed with the TW kit.

Mounting the Thru-Wall Kit

The Thru-Wall Kit, or TW, consists of two hoods, insulated

metal ducts, an interior mounting plate, and small air seal

gasket. See Figure 5. The interior plate is attached to the

interior of the wall. Using the holes in the plate as a reference

CAUTION

INSTALL FRESH AIR INLET AWAY FROM SOURCES OF

CONTAMINANTS.

♦Do not locate the fresh air inlet where vehicles may be

serviced or left idling.

♦The fresh air inlet should be at least ten feet away from

any exhaust such as dryer vents, chimneys, furnace, and

water heater exhausts or other sources of contamination or

carbon monoxide.

♦Never locate the fresh air inlet inside a structure.

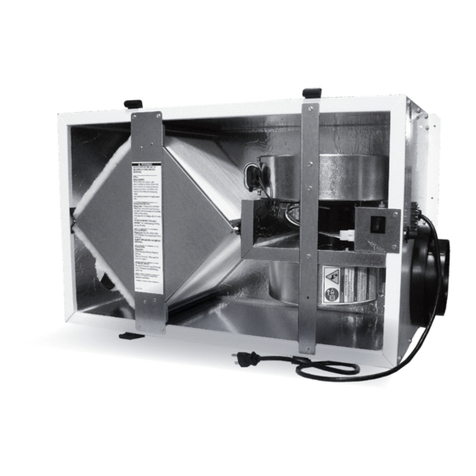

Figure 3. Side-Hung

Figure 4. Return Drop Hung