Aumuller NT-S-2 KS2 Training manual

230

V

AC

Power suPPly NT-s-2 Ks2 / KsA - 230 V AC / 24 V DC

Assembly and Commissioning

Instructions

2

Power supply NT-S-2 KS2 / KSA

08

07

06

05

04

03

02

01

Abbreviations

Warning and Safety Symbols

Target Groups, Intended Use

Safety Instructions

Data sheet: 680029 - Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

Data sheet: 680027 - Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

Circuit Diagram: 680029 - Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

Circuit Diagram: 680027 - Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

Storage and Disposal

Warranty and After-Sales Service

Liability

CerticateandDeclaration

3 - 8

9

10 - 11

13

15

Contents

3

Power supply NT-S-2 KS2 / KSA

Abbreviations

Scale units

°C Degree Celsius

A Amperes

Ah Amp-hours

kg Kilogram

m Metres

min Minutes

mm Millimetres

N Newtons

s Seconds

Pcs. Pieces

V Volts

PU Packaging Units

Vpp Residual ripple (Voltage Peak-Peak)

W Watts

Ω / k Ω Ohm / Kilohms

Figures

AC Alternating current (50Hz / 60Hz)

DC Direct current

I Electric current

L Length

ME Module space unit (1 ME = 23 mm)

NC Contact „closed“ (normally closed)

NO Contact „opened“ (normally opened)

P Electric power

R Electrical resistance

U Electric voltage

Um Change over switch

Colour abbreviation according to IEC 60757

BK black GY grey VT violet

BN brown OG orange WH white

BU blue PK pink YE yellow

GN green RD red

Index of abbreviations

These abbreviations are used consistently throughout this instruction.

Unless stated differently, all dimensions indicated in this document are in mm.

General tolerances in accordance with DIN ISO 2768-m.

AP Surface mounting

WxHxD Width x Height x Depth

CAN CAN-BUS

CM Control-Module

COM Common connection

DIN German Institute for Standardisation

DM Drive-Module

EN European Standard

IN Input

LON Local Operating Network

OUT Output

PG Price group

PM Power-Module

PS Power supply

RAL Central European Colour Standard

RM6 Relay-Module

RWA Smoke and heat exhaust ventilation

SM Sensor-Module

UP Flash mounting

WM Weather-Module

WRG Wind direction sensor

Warning and safety symbols in these Instructions:

The symbols used in the instructions shall be strictly observed and have the following meaning:

Failure to comply with the warning notes results

in irreversible injuries or death.

Failure to comply with the warning notes can

result in irreversible injuries or death.

Failure to comply with the warning notes can

result in minor or moderate (reversible) injuries.

Failure to comply with the warning notes can lead

to damage to property.

wArNiNg

DANger

CAuTioN

NoTe

Useful note

for an optimum installation.

Note regarding the system conguration

using the free software of the Control Unit

manufacturer (USB connection).

USB

Caution / Warning

Danger due to electric current.

Attention / Warning

Risk of damage to / destruction of Control Unit, drives

and / or windows.

01

Preliminary remark

4

Power supply NT-S-2 KS2 / KSA

Preliminary remark

These instructions are intended for personnel trained in

electrical engineering and skilled operators of systems

for natural smoke ventilation (NRA / RWA) (natural smo-

ke exhaust system / smoke and heat exhaust system) and

natural ventilation via windows, who are knowledgeable

of operating modes and remaining risks of the system.

This device is not intended for use by per-

sons (including children) with physical,

sensory or mental limitations or lacking experience and / or

knowledge, unless they are supervised by a person who is

responsible for the safety or were instructed by him on the

usage of this equipment. Children should be supervised to

ensure that they are not playing with this device.

Cleaning and operator’s maintenance may not be per-

formed by children without supervision.

Target group

wArNiNg

By installing the drive to a movable ele-

ment of the window a so-called “pow-

er-operated window” is created which,

according to the Machinery Directive

2006/42/EG, represents a machine. The

control device is intended to control such

a window. Where it seems reasonable,

these installation instructions point out

sensibly predictable hazards and risks

resulting from a power operated window.

By connecting the window drives with

a control device and their operation the

builder of the complete system becomes

the manufacturer of the power-operated

window! If necessary, it is required to

perform a risk assessment of the comple-

te system in accordance with the Machi-

nery Directive 2006/42/EG when the uti-

lization or operation of the control device

or the connected window drives deviate

from their intended use!

Attention must be paid to possible

hazards when used with tilting or

rotating windows, whose secondary

closing edges are located at less than

2,5 m installation height above the oor,

under consideration of the Control Unit

and usage!

NoTe

NoTe

wArNiNg

Intended use

Area of application / Scope of application

This control device is intended for powering and cont-

rolling electromotive operated windows in facade and

roof areas. The prime task of this product, in combination

with the electric window, is to evacuate hot smoke and

combustion gases in case of re to save human lives

and protect property. Furthermore, the electric window

ensures fresh air supplied for natural ventilation of the

building.

Intended use according to the Declaration of Con-

formity

The control device is intended for stationary installation and

electrical connection as part of a building.

In accordance with the attached Declaration of Con-

formity the control device, in combination with

electromotive drives from Aumüller, is released

for its proper use at a power-operated window:

• Application for natural ventilation

with an installation height of the drive and

the bottom side of sash of at least 2,5 m above

the oor, or

with an opening width at the HSK of the driven

part of < 200 mm by a simultaneous speed of

< 15 mm/s at the HSK in closing direction.

• Application as NSHEV (natural smoke and heat

exhaust ventilator(s) for ventilation without dual

purpose for ventilation in accordance with EN12101-2.

We as manufacturers are well aware of our duties and

responsibilities regarding the development, manufactu-

ring and placing of safe window drives on the market and

consistently implement them. Ultimately, however, we have

no direct inuence on the usage of our drives. Therefore,

as a precaution, we point out the following:

• The builder or his agent (architect, specialist

planner) are obligated by law to evaluate the

hazards to persons, originating from the usage,

installation position, opening parametres as well as

the planned type of installation of the power

operated window and the external Control Unit,

already in the planning phase and to establish

necessary protective measures.

• The builder / manufacturer of the machine

“power-operated window” must implement the

planned protective measures at the installation site

or, if not yet established, determine them by theire

own responsibility and detect or minimise possible

remaining risks.

01

5

Power supply NT-S-2 KS2 / KSA

01

Preliminary remark

Risk analysis according to the

Machinery Directive required

The need for a risk assessment at the installation site due

to reasonably foreseeable misuse.

A risk assessment in accordance with the Machinery

Directive 2006 / 42 / EG by activation of the power-

operated window for natural ventilation is absolutely

necessary under the following conditions:

• the installation height of the drive and lower edge

of casement < 2,5 m above the oor

and one of the following conditions:

• the opening width at the HSK > 200 mm, or

• the closing speed at the HSK is > 15 mm/s, or

• the opening speed at the HSK is > 50 mm/s, or

• the closing force at the HSK is > 150 N

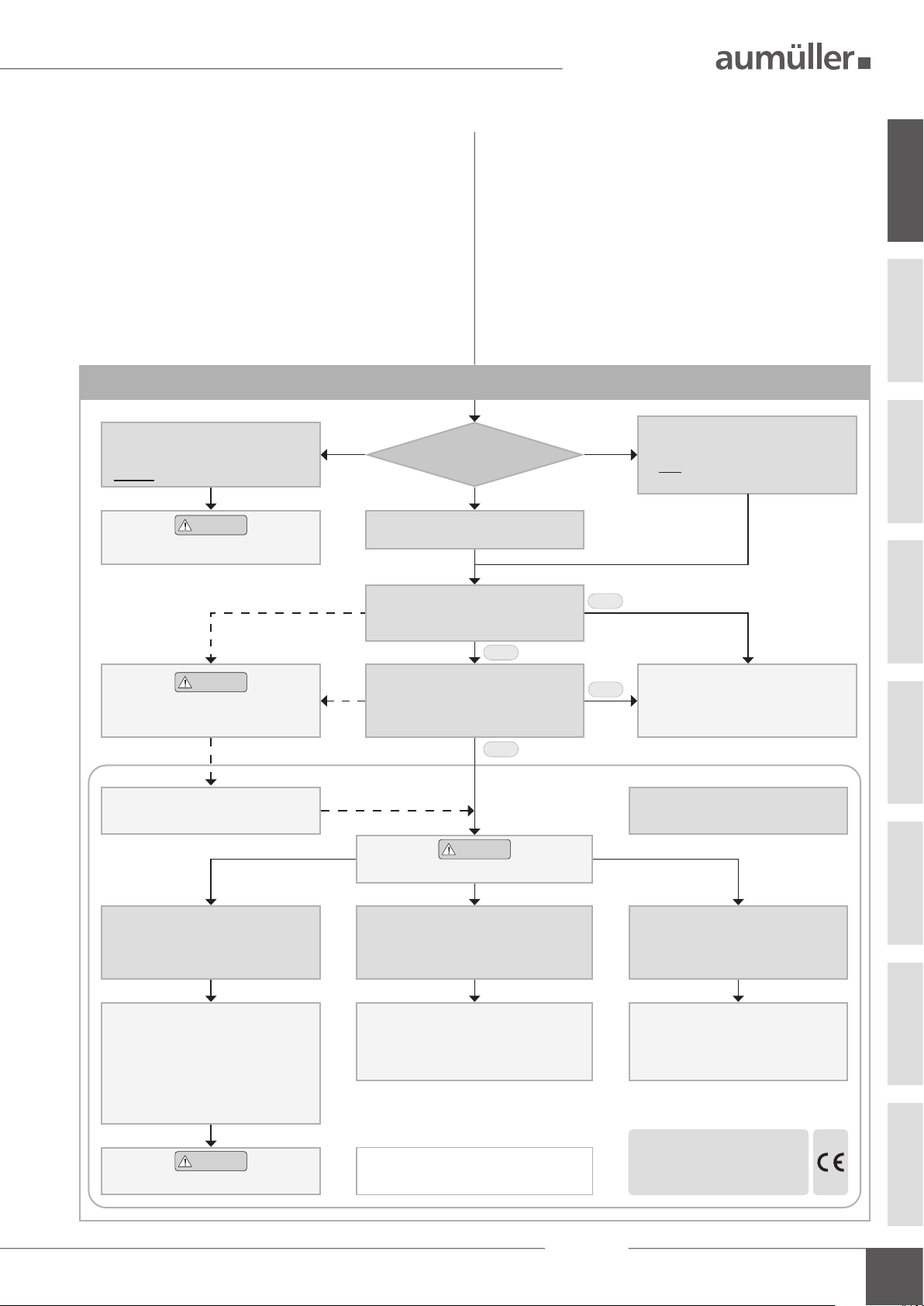

The following owchart can be applied, which also includes

the protective measures in accordance with EN 60335-2-

103/2016-05.

Hazard analysis according to DIN EN 60335-2-103

Contactless entrapment protection

(20.ZAA.8.1)

Passive infra-red and active light sensors

or

pressure mats

Contact-based entrapment protection

(20.ZAA.8.2)

Pressure-sensitive safety switch strips

or

Motor current monitoring systems

(internal and external)

Hold-to-run switch:

stops movement at HSK < 20 mm

at a closing force of > 150 N at HSK

(20.ZAA.5)

Operating element in

direct range of vision:

a.) Key switch or

b.) other switch,

then: installation > 1,5 m,

inaccessible for public

(7.12.1)

Keep people away during closing!

Caution

Protection devices

Caution

Using drives

NSHEV in accordance

with EN12101-2

without dual purpose for ventilation

NSHEV in accordance

with EN12101-2

with dual purpose for ventilation

(1.Z.109)

Natural ventilation

Installation height of drive and lower

edge of casement: > 2,5 m above oor

(ZAA.20.2)

Opening at HSK: < 200 mm and

Speed at HSK:

CLOSE <15 mm/s / OPEN < 50 mm/s

(20.ZAA.2)

Yes

Yes

No

No

No

risc assessment

required

Observe danger at NSK

< 2,5 m above oor!

Caution

Keep people away during closing!

Caution

In the environment with children /

people in need of protection

Information in parentheses refers

to the chapters of DIN EN 60335-2-103.

Declaration of Conformity

power operated window

+ CE label

6

Power supply NT-S-2 KS2 / KSA

01

Safety instructions

Crush and shear points

To avoid injuries, crushing and shear points between

casement and frame must be secured against entrapment

up to an installation height of 2,5 metres above the oor

with appropriate measures. This can be achieved e.g. by

using contact-based or contactless protective devices

against entrapment, which stop the motion through contact

or through interruption by a person. A warning symbol at

the opening element must indicate this clearly.

Routing cables and electrical connection

Electrical lines and connections may be routed or instal-

led only by approved specialist contractors. Never operate

drives, Control Units, operating elements and sensors at

operating voltages and connections contrary to the speci-

cations of the manufacturer.

wArNiNg

Area of application

The control device must be used only for its intended pur-

pose. For additional applications, consult the manufacturer

or its authorised dealer.

Installation

These instructions are intended for expert and safety-

conscious electricians and / or qualied personnel familiar

with the electrical and mechanical installation of drives and

control systems.

Mounting material

The required mounting material must be modied to t the

occurring load.

Safety instructions

It is important to follow these instruc-

tions for the safety of persons. These

instructions must be kept in a safe place

for the entire service life of the products.

Risk of crushing and entrapment!

Electric operated windows can close

automatically!

The compressive force is absolutely

sufcient to crush ngers in case of ca-

relessness.

The planning and calculation of the

wiring system is the responsibility of

the builder or its agent or the authori-

sed builder and must be performed

according to the statutory provisions.

NoTe

NoTe

All relevant instructions must be observed for the in-

stallation, specically:

• VDE 0100 Setting up high-voltage systems up to 1000 V

• VDE 0815 Wiring cables

• Specimen Guideline on Conduits German designation

(MLAR).

We recommend using exclusively sys-

tem components by Aumüller, because

their compatibility is carefully checked

in the factory. Aumüller shall not assume

liability for the system-compatible func-

tioning of third party components.

Applications and connections other than

explicitly described in these instructions

require the express written consent of

Aumüller. Utilization of applications and

components not expressly authorised by

Aumüller are considered as unintended

use even if their perfect functioning is

proven at commissioning (e.g. approval

under building law).

7

Power supply NT-S-2 KS2 / KSA

01

Safety instructions

The types of cable, cable lengths and cross-sections must

be selected in accordance with the manufacturer’s technical

data. If necessary, the cable types must be coordinated with

the competent local authorities and energy supply com-

panies. Low-voltage lines (24 V DC) must be routed

separate from the high-voltage lines. Flexible cables may

not be ush-mounted. Freely suspended cables must be

equipped with strain reliefs.

Clamping points must be checked for tightness of threa-

ded connections and cable ends. Access to junction boxes,

clamping points and external drive control systems must be

ensured for maintenance work.

Commissioning, operation and maintenance

After the installation and after each modication in the

set up all functions must be checked with a trial run.

After the installation of the system is completed the

end-user must be introduced to all important operating

steps. If necessary, he must be advised of all remaining risks /

dangers.

The end-user must be instructed in intended use of the

drives and, if necessary, the safety instructions.The end-user

must be specically instructed that no additional forces,

except for the pressure and tension in the opening and

closing direction of the casement, may be applied to the

spindle, chain or lever of the drive.

The power line on-site must be secured se-

parately and provided all poles separators.

After opening of the system housing voltage

carrying parts are exposed. The system must

be separated from the power supply and bat-

tery voltage before each intervention in the

Control Unit of the system.

Cables must be laid such way that they cannot

be sheared off, twisted or bent during operati-

on. It is recommended to perform an insulati-

on measurement of the system’s line network

and to document this.

wArNiNg

It is imperative that the information pro-

vided in the installation instructions of

the controlled window drives is observed

and obeyed!

NoTe Post warning signs!

During correct assembly of drives with mounting elements

at a window, and connection to an external Control Unit,

the interfaces resulting from the mechanical and electri-

cal performance characteristics of single elements must be

observed.

Other persons must be kept away from

the casement when a hold-to-run switch

(push button) is operated or when a

window, which has been opened by a

smoke and heat exhaust system, is clo-

sing!

The operating element of hold-to-run

switches must be installed within di-

rect view from the window, but isola-

ted from moving elements. If the switch

is not a key-operated switch it must be

installed at a minimum height of 1,5 m

and inaccessible to the public!

Do not allow children to play with

permanently mounted control devices

and keep remote controls out of reach of

children!

CAuTioN

CAuTioN

CAuTioN

Before working on the system, it must be com-

pletely disconnected from the power supply

and emergency power supply (e.g. batteries)

and secured against being switched on again

accidentally. While working in the Control

Unit the workplace must be secured to prevent

unauthorised access. You must ensure that

unauthorised personnel are unable to open

the Control Unit.

wArNiNg Check all functions of the system before

releasing it for operation.

The installation instructions of system components (smo-

ke detector, natural smoke and heat exhaust ventilators,

drives, etc.) are part of the documentation for the complete

system and must be kept accessible for authorised quali-

ed personnel, together with the installation and operating

instructions, for the entire service life of the system.

Replacement parts

System components are to be replaced only with spare

parts from the same manufacturer. Liability, warranty and

customer service are void if third-party parts are used. Only

original spare parts from the manufacturer are to be used

for expansions.

8

Power supply NT-S-2 KS2 / KSA

01

Safety instructions

Ambient conditions

The product may not be subjected to impacts or falls, or

to vibrations, moisture, aggressive vapours or other harmful

environments, unless the manufacturer has released it for

one or more of these environmental conditions.

• Operation:

Ambient temperature: -5 °C … +40°C

Relative humidity: < 90% up to 20°C;

< 50% up to 40°C;

no formation of condensation

• Transport / Storage:

Storage temperature: 0°C … +30°C

Relative humidity: < 60%

Accident prevention regulations and employer‘s

liability insurance guidelines

For work on or in a building or building part the provisi-

ons and instructions of the respective accident prevention

regulations (UVV and employer‘s liability insurance guide-

lines (BGR /ASR) must be observed and obeyed.

Declaration of Conformity

The control device is manufactured and inspected for

its intended use in accordance with the European guide-

lines. The relevant Declaration of Conformity is at hand.

If the use or operation of the control device or the con-

nected window drives deviate from this a risk assess-

ment must be performed for the complete powered

window system and a Declaration of Conformity according

to Machinery Directive 2006/42/EG issued as well as a

CE labeling obtained.

Guidelines and Standards

It is essential that the most recent versions of country-

specic laws, regulations, provisions and standards be ob-

served during installation and for electrical connections.

These are for instance:

State building code with special construction regulations

such as:

- Industrial construction guideline

- Venue regulations, etc.

MLAR - Sample Guideline on Conduits German desig-

nation

Provisions of the re protection authorities TAB

(technical connection conditions)

for Utility companies

German Regulations for Occupational Insurance Sche-

mes, such as:

- ASR A1.6 and 1.7(substitute for BGR 232)

Additional standards and guidelines, such as:

EN 60335-2-103 Safety of household and similar elec-

trical appliances

EN 60730-1 Automatic electrical controls

EN 12101-10 / prEN 12101-9 (ISO 21927-9/10)

Smoke and heat control systems

DIN 4102-12 Functional integrity of electric cable

systems

VDE 0100 Installation of high-voltage systems up

to 1000 V

VDE 0298 Use of cables

VDE 0815 Wiring cables (for telecommunication

and data processing systems)

VDE 0833 Alarm systems

VdS-Guidelines: 2593, 2581, 2580, 2592

Accident prevention regulations, in particular:

- VBG 1 „General rules“ and

- VBG 4 „Electrical systems and equipment“.

For placing on the market, installation and operation out-

side Germany, the relevant national laws, regulations,

standards and safety provisions apply.

The contractor is responsible for proper installation or

operation and the issue of a Declaration of Conformity

according to European guidelines.

9

Power supply NT-S-2 KS2 / KSA

Data sheet

02

2,0 A

Power supply NT-S-2 KSx

Power supply NT-S-2 KSx

Part.-No.: 680029

Operating voltage: 230 V AC (195 – 253 V AC, 50/60 Hz)

Rated power consumption: 30 W

Output voltage: 24 V DC (20 – 28 V DC / 2 Vpp)

Output current: 2,0 A

Outputs: 1x drive line

24 V DC / 2,0 A

Connections: 24 V DC drives, up to max. 2,0 A

Connection cable: non-halogen, grey 6 x 0,75 mm², length 3 meters

can be extended to a maximum of 25 meters

Housing: aluminum natural anodized, RAL9016

or optionally in other RAL colors

Dimensions (WxHxD): 41 x 26 x 215 mm

Connection terminals: screw terminals 1,0 mm² (rigid wire)

Protection rating: IP 32

Part.-No.: 680027

Operating voltage: 230 V AC (195 – 253 V AC, 50/60 Hz)

Rated power consumption: 30 W

Output voltage: 24 V DC (20 – 28 V DC / 2 Vpp)

Output current: 2,0 A

Outputs: 1x drive line

24 V DC / 2,0 A

1x continuous current

24 V DC / 0,2 A

Connections: 24 V DC drives, up to max. 2,0 A

24 V DC continuous current, up to max. 0,2 A

Connection cable: non-halogen, grey 6 x 0,75 mm², length 3 meters

can be extended to a maximum of 25 meters

Housing: aluminum natural anodized, RAL9016

or optionally in other RAL colors

Dimensions (WxHxD): 41 x 26 x 230 mm

Connection terminals: screw terminals 1,0 mm² (rigid wire)

Protection rating: IP 32

230 VAC

230

V

AC

Data sheet: Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

10

Power supply NT-S-2 KS2 / KSA

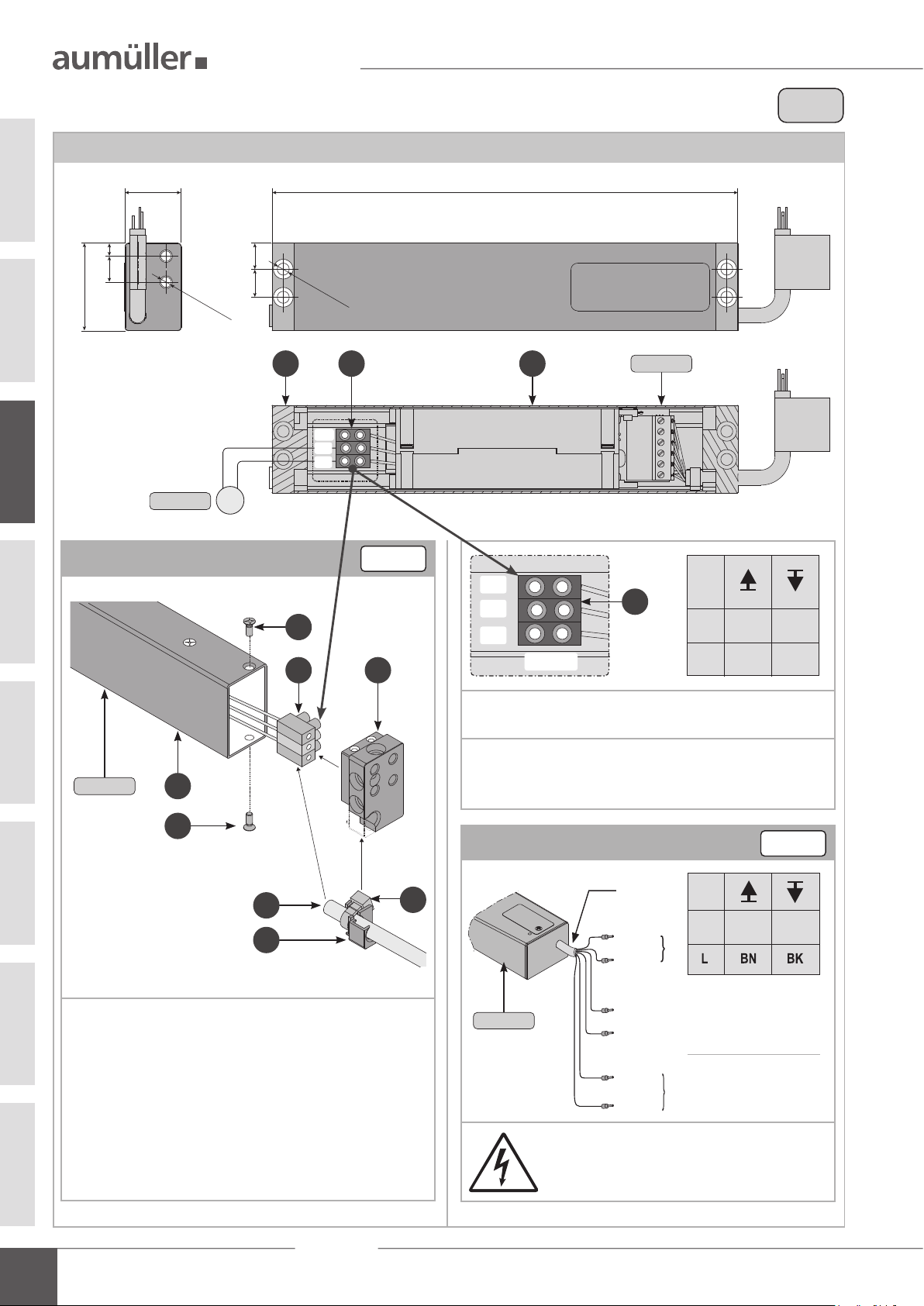

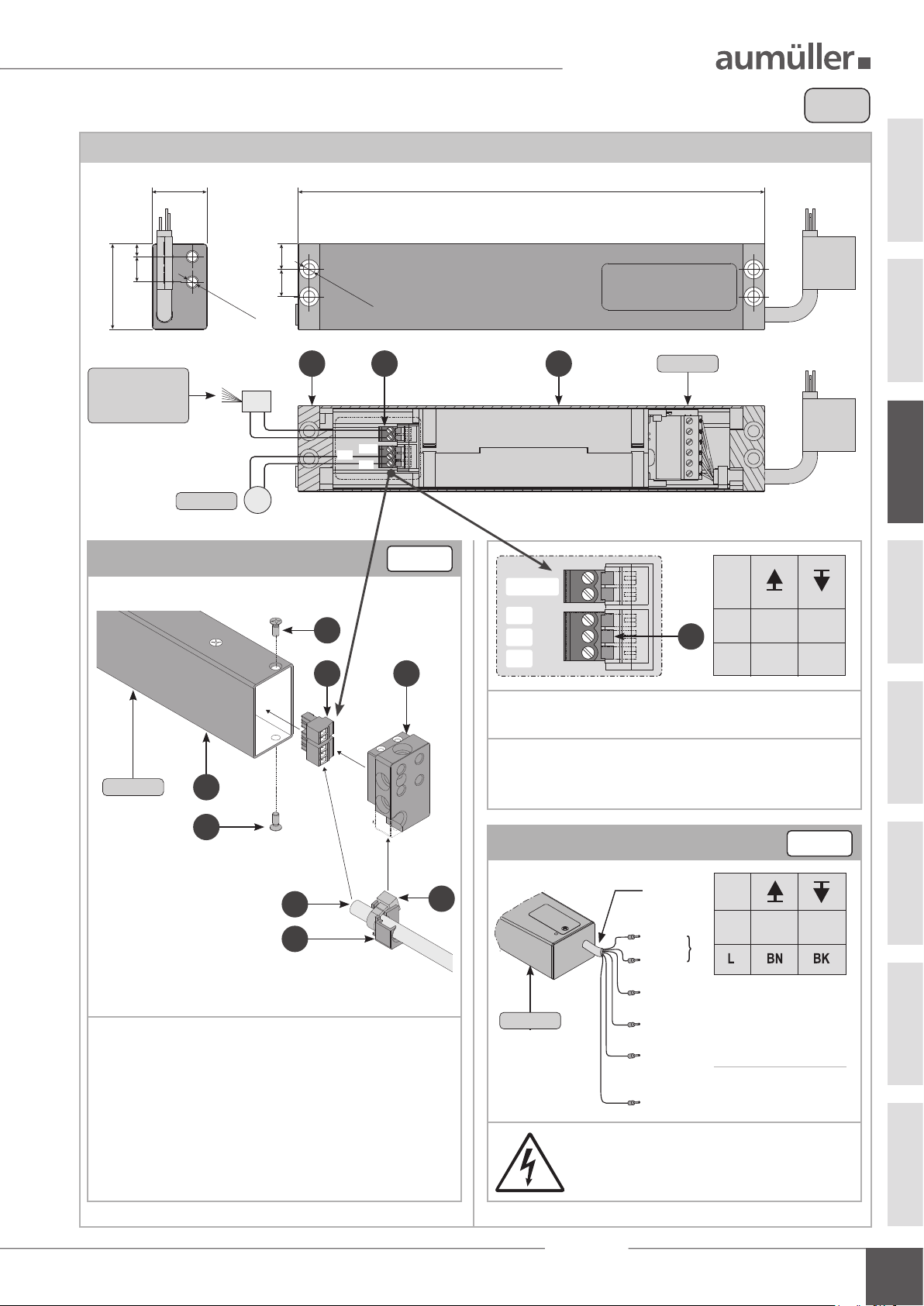

Power supply NT-S-2 KSx: 680029

Circuit Diagram

2,0 A

Circuit Diagram: Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

Connection assignment

Make sure when establishing the connection

that there is no voltage at the terminals!

Unused wires must be safely insulated!

M

215

WH

BN

BU

26

für M5

1213

6

41

12

für M6

230 V AC

230 V AC

AK

BK

WH

GN/YE = PE

GY

BN

BU = N

without function

(insulate cables safely)

for custom-made products

230V

680029

Connect the drive

Pull the terminal

out of the power supply housing

.

Connect the drive - using the connecting cable (not inclu-

ded in the scope of delivery) - to the terminal .

Mount connection cable in the cable entry - using cable

ties .

Plug in the terminal in the power supply .

Cable entry - with connection cable and cable ties -

push into the end cap .

Mount end cap with screws on the power supply

housing .

WH without function (insulate cables safely) for custom-

made products.

The running direction of the power supply may be changed

by interchanging (polarity reversal) the wires „BN - (brown)“

- „BU - (blue)“.

OPEN CLOSE

680029

680029

24V DC

BN +

+-

-

BU

4

5

5

7

2

3

1 6

7

24V

16

WH

BN

24V DC

BU

1

03

for M5

for M6

11

Power supply NT-S-2 KS2 / KSA

Power supply NT-S-2 KSx 680027

03

Circuit Diagram

2,0 A

Circuit Diagram: Power supply NT-S-2 KS2/KSA - 230 V AC / 24 V DC

Connection assignment

Make sure when establishing the connection

that there is no voltage at the terminals!

Unused wires must be safely insulated!

M

230

BU WH

BL

26

für M5

1213

6

41

12

für M6

230 V AC230 V AC

AK

BK

WH

GN/YE = PE

GY

BN

BU = N

= L

without function

(insulate cables safely)

for custom-made products

230V

680027

Connect the drive

Connect the drive - using the connecting cable (not inclu-

ded in the scope of delivery) - to the terminal .

Mount connection cable in the cable entry - using cable

ties .

Plug in the terminal in the power supply .

Cable entry - with connection cable and cable ties -

push into the end cap .

Mount end cap with screws on the power supply

housing .

WH without function (insulate cables safely) for custom-

made products.

The running direction of the power supply may be changed

by interchanging (polarity reversal) the wires „BN - (brown)“

- „BU - (blue)“.

OPEN CLOSE

680027

680027

24V DC

BN +

+-

-

BU

4

5

5

7

2

3

1 6

7

24V

16

WH

BU

24V DC

BL

1

continuous voltage

for at scan

(pinch protection)

for M5

for M6

12

Power supply NT-S-2 KS2 / KSA

04

13

Power supply NT-S-2 KS2 / KSA

04

Liability

We reserve the right to change or discontinue products at any time

without prior notice. Illustrations are subject to change.Although we take

every care to ensure accuracy, we cannot accept liability for the content

of this document.

Warranty and Customer serviceDemounting and dismantling

The Control Unit must be stored only in locations protected from mois-

ture, severe contamination and temperature uctuations (not above

30°C). The packaging must not be removed until the control system is to

be installed. Disconnect the batteries and store them separately after the

control device has already been in operation.

It is imperative that the following is observed for storage of the batte-

ries:

Before dismantling the Control Unit, isolate it comple-

tely from the mains!

If the Control Unit is permanently decommissioned the statutory provi-

sions for destruction, recycling and disposal must be observed. The con-

trol device contains plastic, metal, electrical components and batteries.

Replaced batteries contain highly toxic pollutants and may therefore only

be disposed of at collection points prescribed by the legislator.

Keep the storage time of lead-acid batteries short, be-

cause the batteries discharge as time passes. At the

latest after seven months in storage batteries must

be recharged. Use either a suitable battery charger or

connect the batteries to an EMB Control Unit and sup-

ply same with mains voltage. In both cases, charging

requires a minimum of 8 hours (depending on the

discharge state).

In principle, our:

„General Terms for the Supply of Products and Services of the Electri-

cal Industry (ZVEI)“.

„Terms for the used software“.

The warranty is compliant with legal provisions and applies to the

country in which the product has been acquired.

The warranty includes material and manufacturing defects incurred

during normal use.

The warranty period for delivered material is twelve months.

Warranty and liability claims for personal injuries or tangible damages

are excluded, if caused by one or more of the following:

• Improper use of the product.

• Improper installation, commissioning, operation, maintenance or

repair of the product.

• Operating the product, if installed defectively or incorrectly, or with

its safety and protection devices not working .

• Ignoring instructions and installation requirements in these in-

structions.

• Unauthorised constructional modications the product or accessories.

• Disaster situations due to the effects of foreign bodies and force

majeure.

• Wear and tear.

Point of contact for possible warranty claims or for repair parts or acces-

sories is the responsible branch ofce or the responsible person at

.

Contact data are available at our homepage

(www.aumueller-gmbh.de)

Disposal

The symbol of the „crossed-out dustbin“ means that you are legally

obliged to collect these appliances separately and recycle them in an

environmentally friendly manner. Do not throw old electrical appliances

into the household waste! Information on return options can be found at:

https://www.aumueller-gmbh.de/umweltschutz

Before disposing of old electronic devices, please delete all personal data

stored on them, if available. Remove any device batteries or rechargeable

batteries and put them in the old battery collection. Tape the poles be-

forehand to avoid a short circuit.

Dispose of the shipping and transport material, separated according to

material, in the appropriate recycling bin.

Disposal / Warranty

14

Power supply NT-S-2 KS2 / KSA

05

15

Power supply NT-S-2 KS2 / KSA

05

Translation of the original instructions (German)

Important note:

We are aware of our responsibility, which is why we present life-supporting and value-preserving products with greatest possible conscientiousness. Although we

make every effort to ensure that the data and information are as correct and up-to-date as possible, we still cannot guarantee that they are free from mistakes and

errors.

All information and data contained in this document are subject to alterations without prior notice. Distribution and reproduction of this document as well as the

use and disclosure of its content is not authorized unless expressly approved. Offenders will be held liable for the payment of damages. All rights reserved in the

case of a patent award or utility model registration.

Basically the General Terms and Conditions of

Aumüller

AuTOmATIC

GmbH apply to all offers, supplies and services.

The publication of these assembly and commissioning instructions supersedes all previous editions.

Certi cate and Declaration

of Conformity

We declare under our sole responsibility that the product

described under "Data sheet" is in conformity with the

following directives:

• 2014/30/EU

Directive relating to Electro-Magnetic Compatibility

• 2014/35/EU

Low voltage Directive

We further declare that the drive is an incomplete

machine within the meaning of the European Machinery

Directive (2006/45/EG).

Technical le and declaration at rm:

Aumüller

AumATIC

GmbH

Gemeindewald 11

D-86672 Thierhaupten

Ramona Meinzer

Managing Director (Chairman)

The proof of the application of a quality management

system is for company:

Aumüller

AumATIC

GmbH

according to the certication basis DIN EN 9001 as well

the "Declaration of Incorporation and Conformity" can

be accessed via the QR code or directly on our homepage:

(www.aumueller-gmbh.de)

Note:

Certikate and Declaration

9000021551_V2.0_KW 37.2023

This manual suits for next models

3

Table of contents