Ausmig D260 User manual

M.I.G. Welder

TROUBLE SHOOTING

Symptom Possible Causes & Solution

User Guide

AUSMIG

REVERSE POLARITY

21

DANGER OF

ELECTROCUTION

BEWARE

OF SMOKE

AND STEAM

DO NOT USE NEAR FLAMMABLE

OR EXPLOSIVE MATERIAL

BEWARE OF

RAYS FROM

THE ARC

WARNING

WARNING:Protect yourself and others. Read and understand this manual.

ELECTRIC SHOCK: Can kill.

FUMES AND GASES: Can be dangerous to your health.

ARC RADIATION: Can injure eyes and burn skin.

* Read and understand your employer's safety practices.

* Keep your head out of fumes.

* Use enough natural ventilation, or both, at the

fume source to keep fumes and gases from the breathing zone and

the general area

* Wear correct eye, ear and body protection.

* Do not touch live electrical parts.

* Refer to AS 1674 and WTIA Technical Note 7 or the manufacturer's

recommendations for further information.

* Do not change voltage selection while the torch trigger is depressed.

* Wiring ! Select the correct primary power plug to suit the MIG

purchased.

* Disconnect MIG from power supply prior to servicing machine.

Rev:2.5

*IMPORTANT NOTICE*

AUSMIG MIG welders are covered by a Conditional Warranty.

Some Important Conditions of this Warranty are ;

* The Warranty Card Must Be Filled Out And Returned To The

Manufacturer. (If you do not have a warranty card please contact

your local Distributor.)

* Any UNAUTHORISED Tampering Or Repairs To This Machine Will

Void The Warranty. Repairs To Ausmig MIG Welders Are Only To Be

Performed By The Manufacturer Or Service Agent With Written

Authorisation.

1

CONTENTS

Bottle Mount page 3

Correct Gas

Regulator Assembly

Spool Assembly

Reverse Polarity

Wire Feed Rollers

Gun Assembly page 3

page 17

page 12

page 21

page 15

page 16

page 22

page 13

page 4

page 7

- Steel / Stainless Steel

- Aluminium & Non-Ferrous

Test of Operation

Wire Tension Test

Troubleshooting

BASIC COMPACT LAYOUTBASIC COMPACT LAYOUT

Typical Control Settings

Fuse 1 Amp Slow Blow

Power Switch

Wire Speed Control

OverHeat Indicator

Votlage Selection

Earth Lead Connection

Gas Regulator

Earth lead & Clamp

MIG Welding Torch

Euro Fitting Torch

Connection

Wire Drive

Compartment

Bottle Holder

Transformer

2

TIP ..

19

BASIC LAYOUT : TRAVELLERBASIC LAYOUT : TRAVELLER

Wire Drive

Compartment

Euro Fitting Torch

Connection

Wire Drive

Hanging Bracket

Wire Speed Control

Remote Wire

Drive

Door Latch

Removable

Mounting Post Bottle Holder

Digital Display

Volts & Amps

Power Source

Transformer

Positive

Connection

8 Metre

Power Cable

Remote Wire

Drive Socket

Power Switch

Overheat Indicator

Fuse 1 Amp

Slow Blow

Voltage Selection

Negative

Connection

Earth Lead

& Clamp

Gas Regulator

MIG Welding Torch

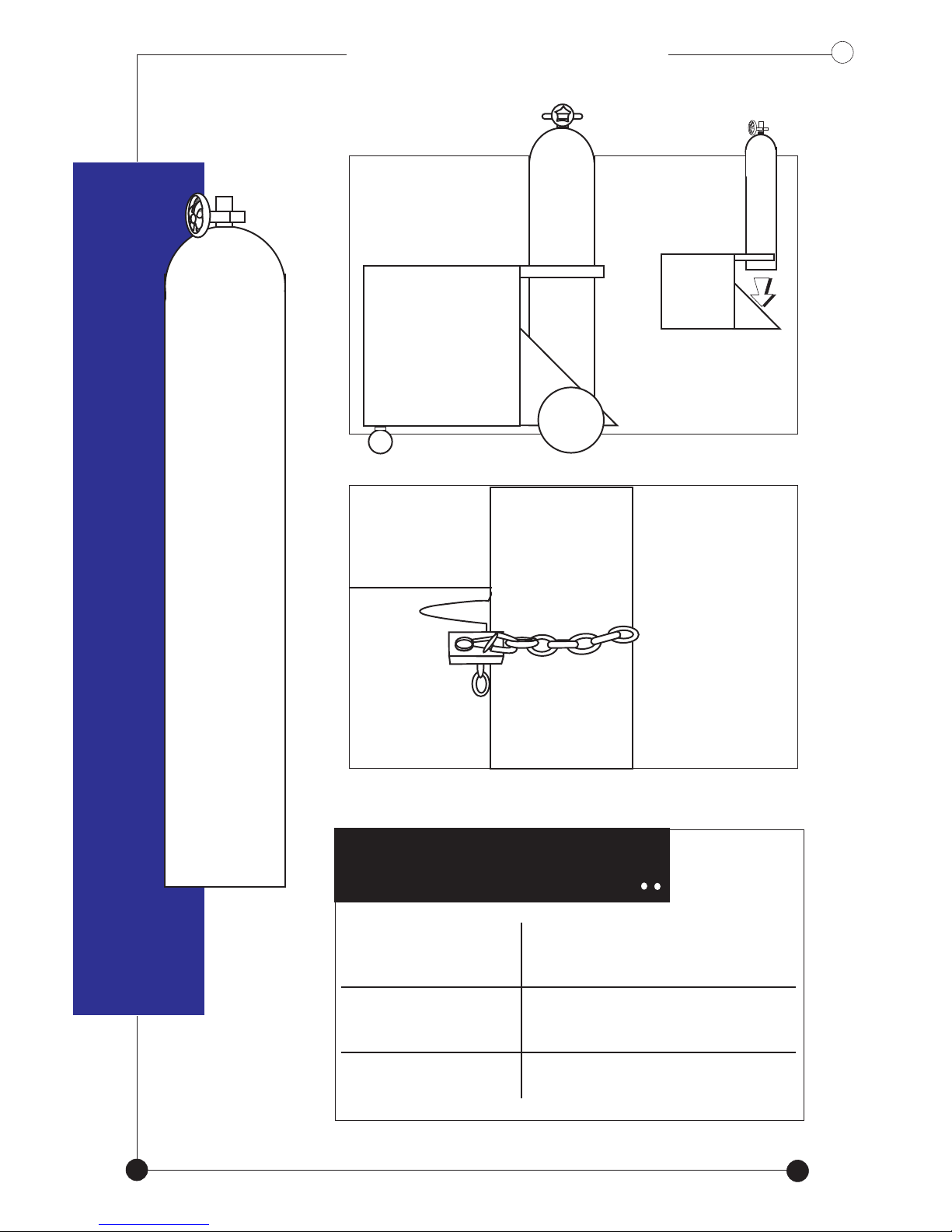

BOTTLE MOUNTBOTTLE MOUNT

Mount the bottle

on the holder

Secure

bottle with

the chain

CORRECT GAS

Stainless Steel

Steel

Aluminium

Argon Shield

Argon Shield

Pure Argon

(ARGON MIX)

(ARGON MIX)

Do not drop the bottle

onto the machine

3

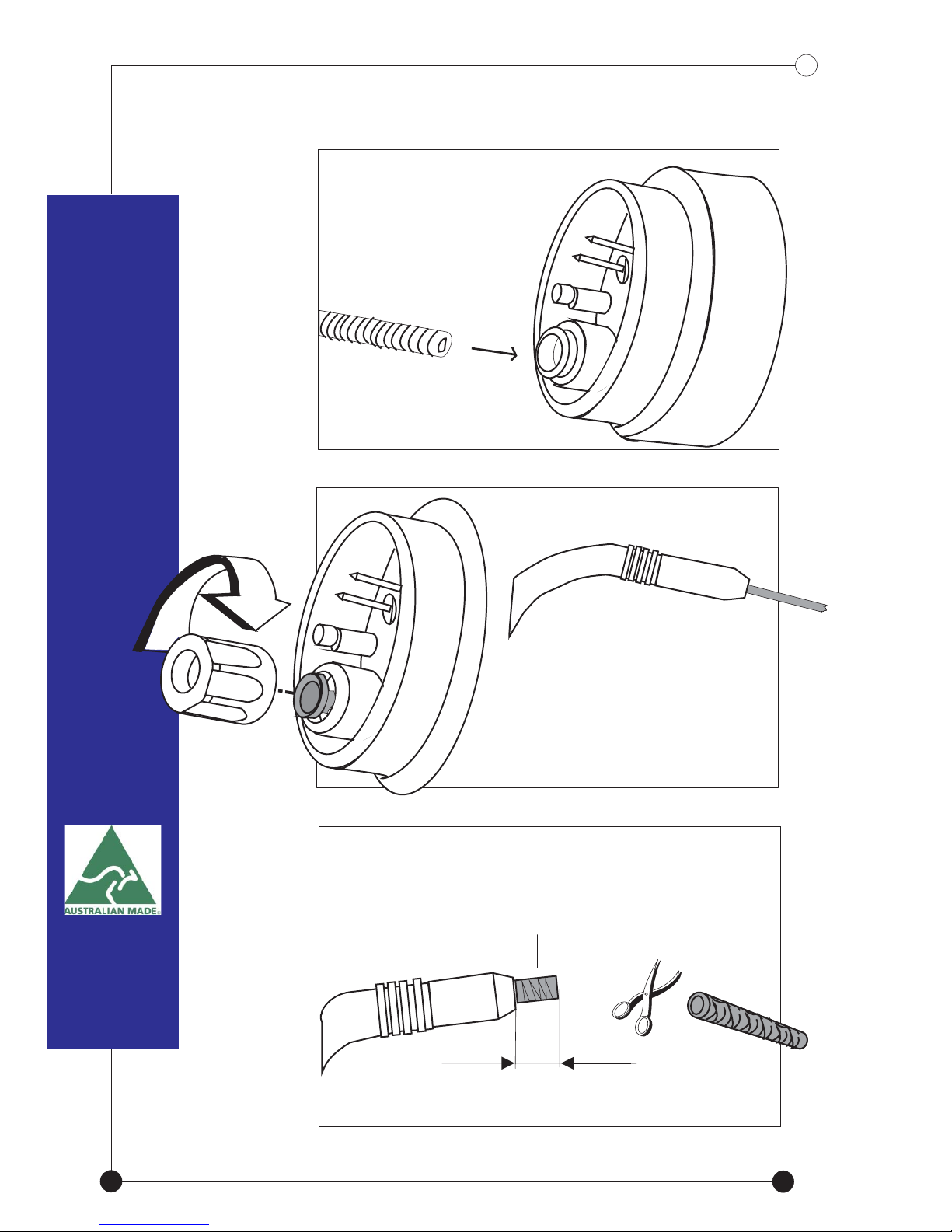

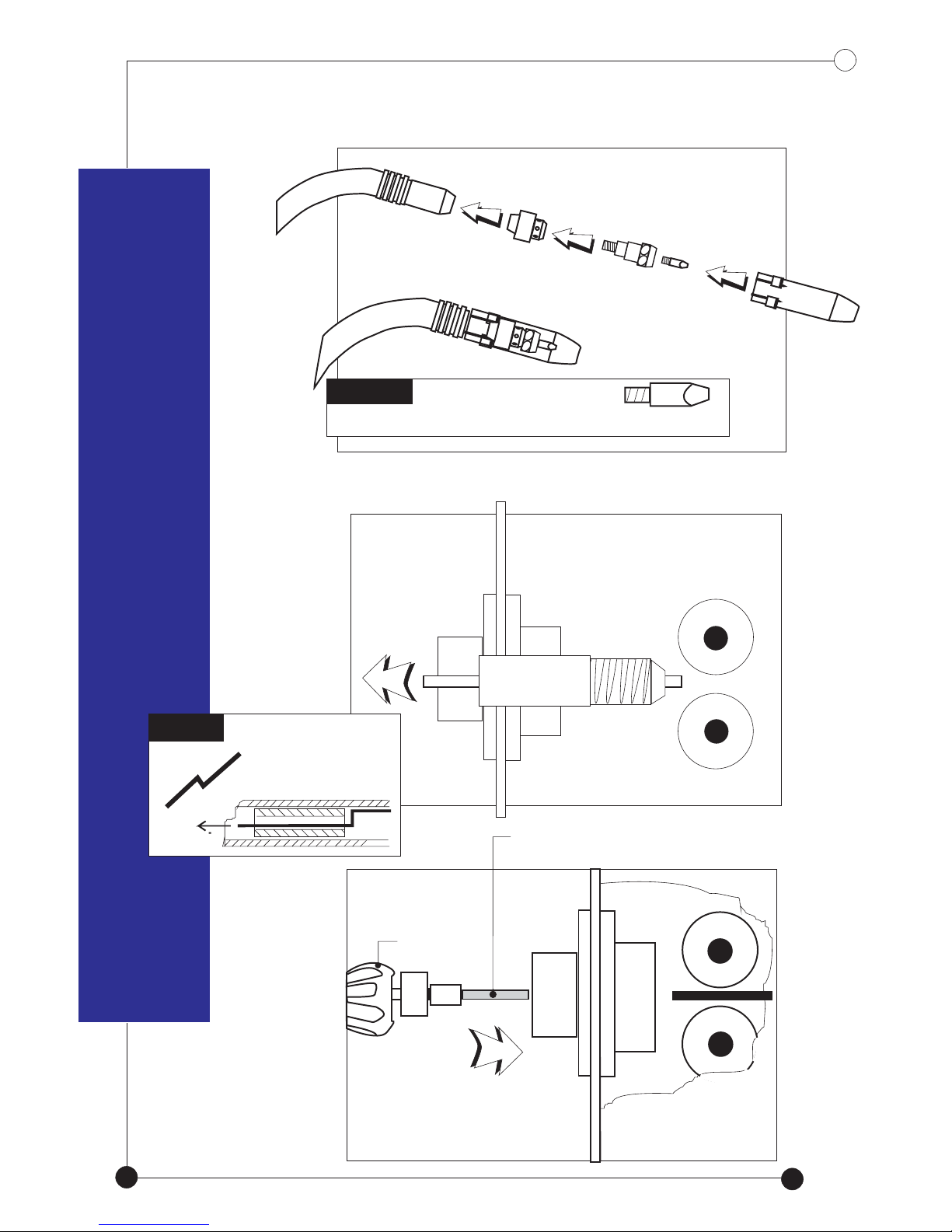

GUN ASSEMBLY

- For Steel / Stainless Steel

GUN ASSEMBLY

-For Steel / Stainless Steel

liner (A)

torch

Check

for

any

kinks

Remove liner

positioning

nut.. *A*

Lay gun and

liner straight

REGULATOR ASSEMBLY

4

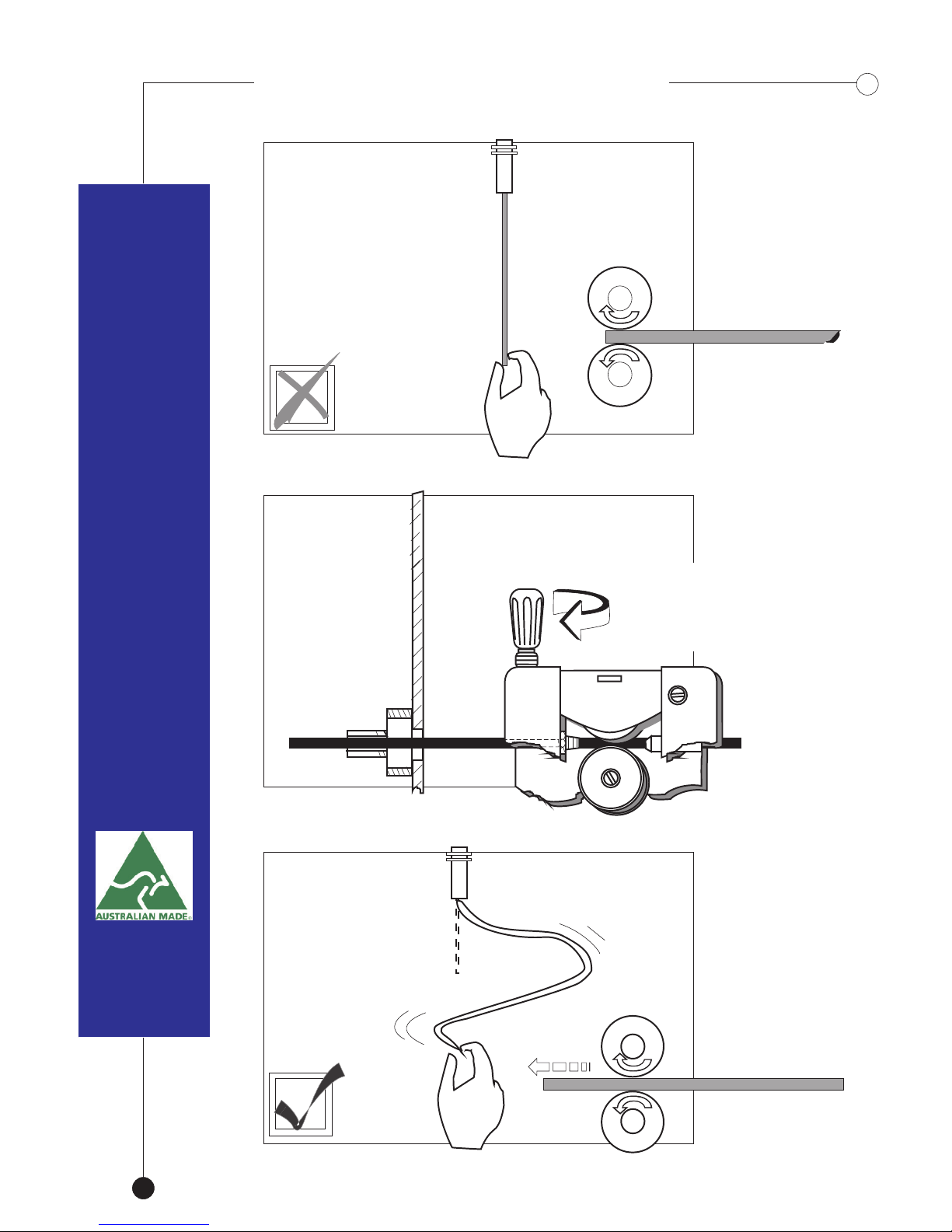

LINER

Ensure that the correct

tip is fitted for the

wire being used.

17

Disassemble

torch head..

Unscrew

Pull out

A

liner.

2mm

Cut excess liner leaving

2mm from the gun neck

Screw positioning

nut back tightly but

over tension.DO NOT

GENTLY feed

liner fully through

the euro fitting of

the torch

WIRE TENSION TEST

5

Re -assemble

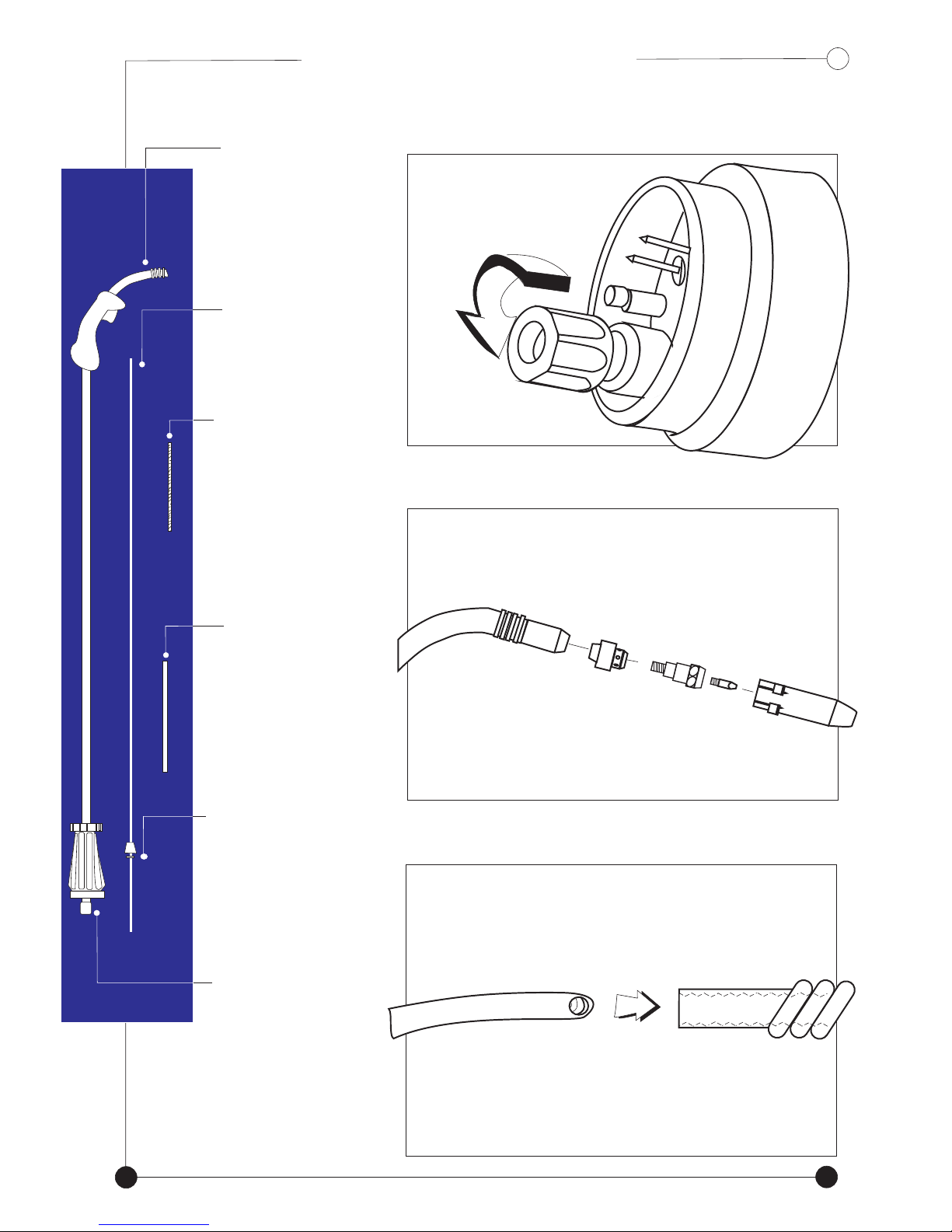

torch head

Slide nozzle on firmly

Euro fitting

*Slide Together*

Do not

allow the

guide tube

to touch

rollers.

Leave 2mm

gap between

the two.

6

Align the torch

and Euro Fitting.

Screw in the collar

until it “bottoms”.

Do not overtighten

Startup Procedure

15

TORCH

TEFLON

LINER (A)

BRASS

NECK

LINER

BRASS

TUBE

SECURING

COLLET

LINER

POSITIONING

NUT

A

Teflon

liner (A)

Screw liner into brass spring

neck tightly on the opposite

end from the securing collet

Unscrew liner

positioning

nut (E)

Disassemble

torch head

GUN ASSEMBLY

- For Aluminium & Non-Ferrous

GUN ASSEMBLY

- For Aluminium & Non-Ferrous

Brass spring

neck liner (B)

(B)

(C)

(D)

(E)

Lay gun and liner

out straight

Remove steel

liner if fitted

7

WIRE FEED ROLLERS

NOTE

GENTLY feed the

connected insert

fully through until

2mm is

protruding from

the gun head

Slide securing

collet & washer (D)

through to the end of the euro fitting

Screw back positioning

nut (E) through the liner

*Do Not Overtighten*

DO NOT CUT

EXCESS LINER YET!!

2mm

(B)

813

WIRE SPOOL ASSEMBLY Remove steel guide

tube from feed roller

TIP.. use a piece of mig

wire to hook and

remove steel guide

tube

TORCH

TEFLON

LINER (A)

Connect euro fitting

to mig machine

Re -assemble

torch head

NOTE

You MUST use aluminium contact tip

ALUM

9

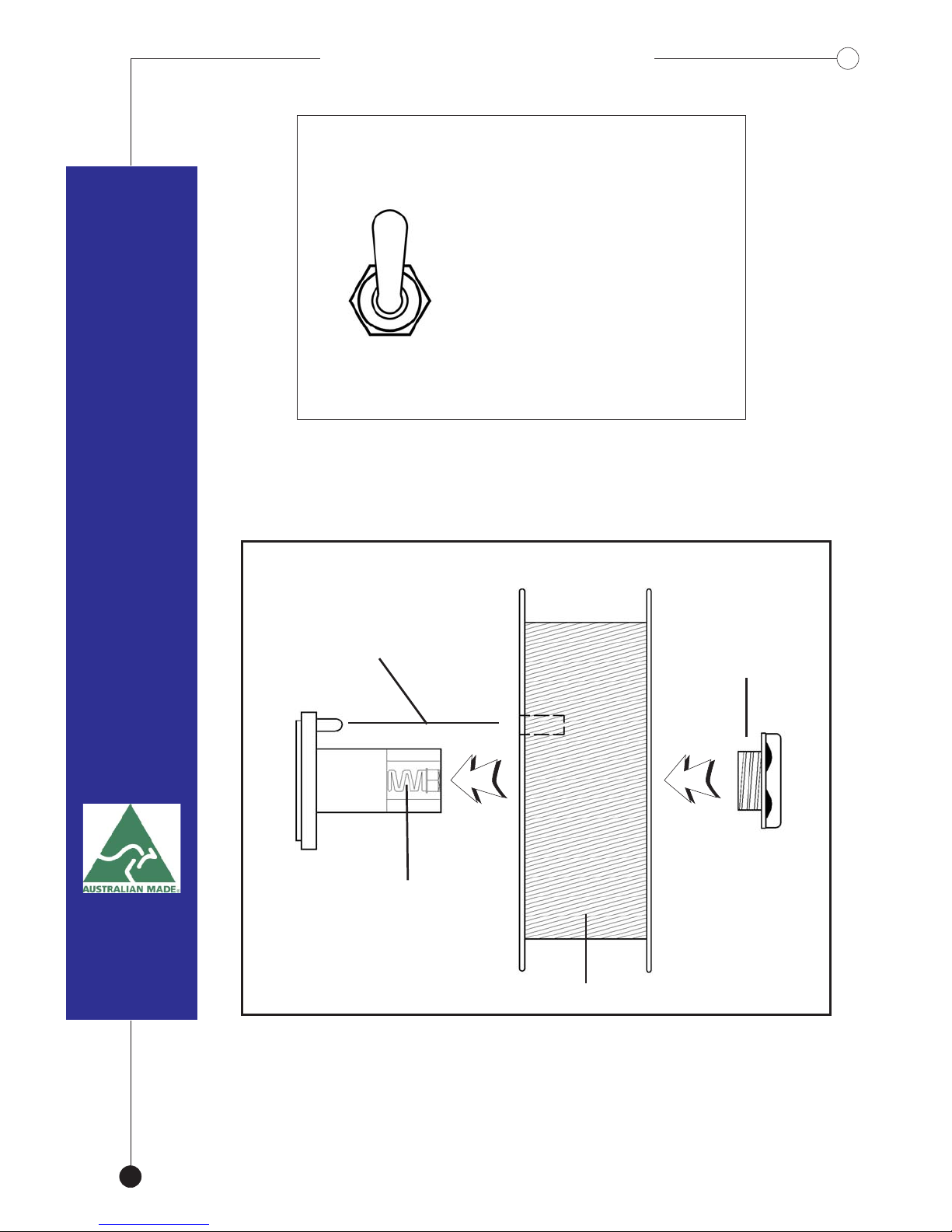

TOGGLE SWITCH

2mm

Cut excess liner ensuring a

2mm space is left

between roller and liner

Remove torch to align

brass tube

LINER

Using a hacksaw, cut brass

tube (C) to exactly the same length

as the protruding liner

10 11

Reconnect

euro fitting

to mig machine

Check that 2mm gap is between

the liner and the roller. DO NOT

let them touch.

2mm

Slide the brass tube over the

liner until 2 mm of the

liner protrudes from the neck

11

Ensure a “U”

Groove Roller

is fitted.

* Do not overtighten*

WIRE SPOOL ASSEMBLYWIRE SPOOL ASSEMBLY

TIP..

12

NOTE

9

TOGGLE SWITCHTOGGLE SWITCH

Steel

Alum

Select the appropriate

wire speed for your

application.

Slow speed for Steel.

Fast for Aluminium.

The Switch is located

on the back of the unit.

15 Kg Wire Spool

Spool hub

Adjustment

Locking Nut

Locating Pin

When fitting a spool of wire, ensure that the

locating lug is correctly aligned with the spool.

Do not overtighten the locking nut.

Release

Wire-Drive

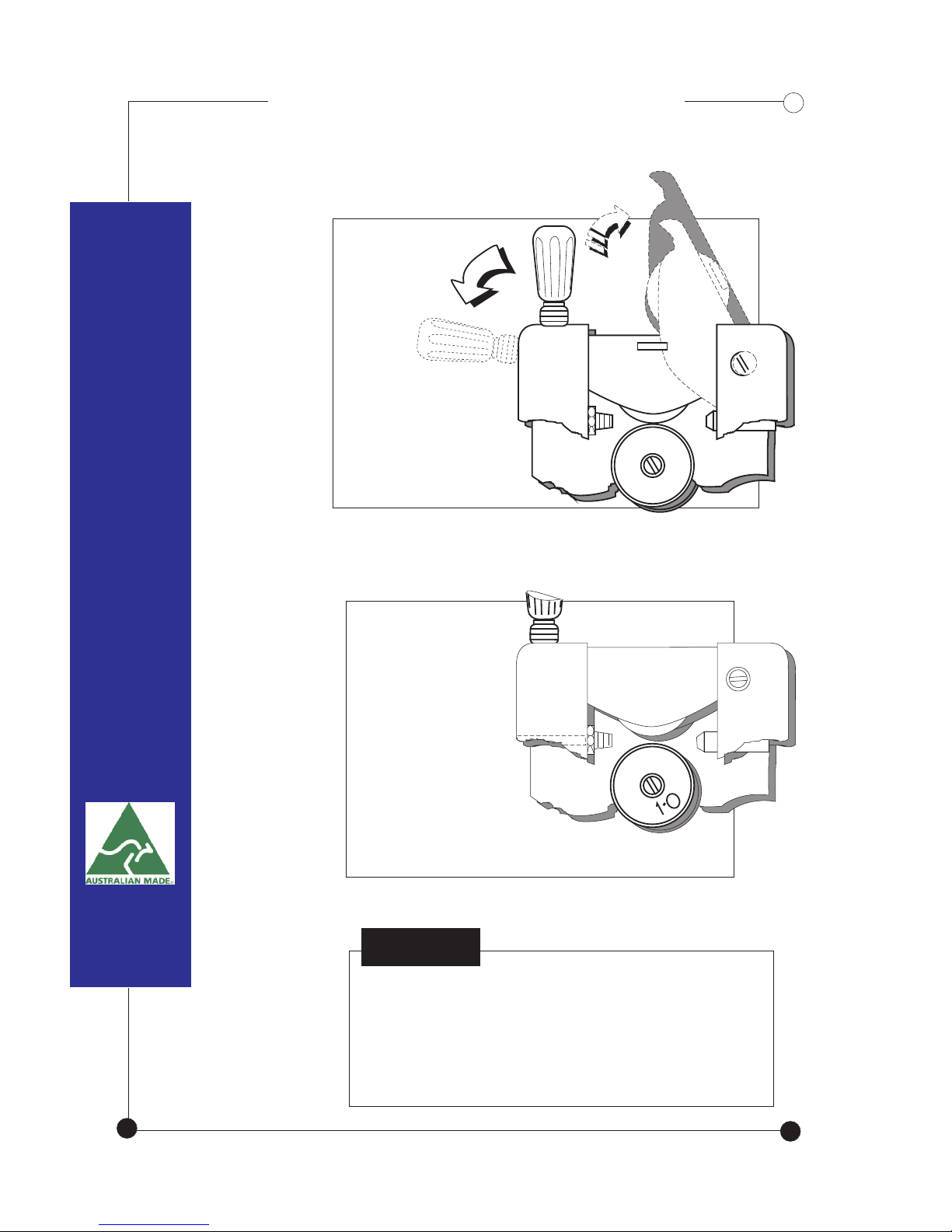

Tensioner

WIRE FEED ROLLERSWIRE FEED ROLLERS

NOTE

Liners should be blown through with

compressed air every time a roll of

wire is replaced .

Install the

appropriate

drive roller to

match the selected wire.

13

A

GUN ASSEMBLY

- For Aluminium & Non-Ferrous

Feed wire through

until it is 30mm

into the guide tube

8

14 7

Return roller 1

then tensioner 2

1

2

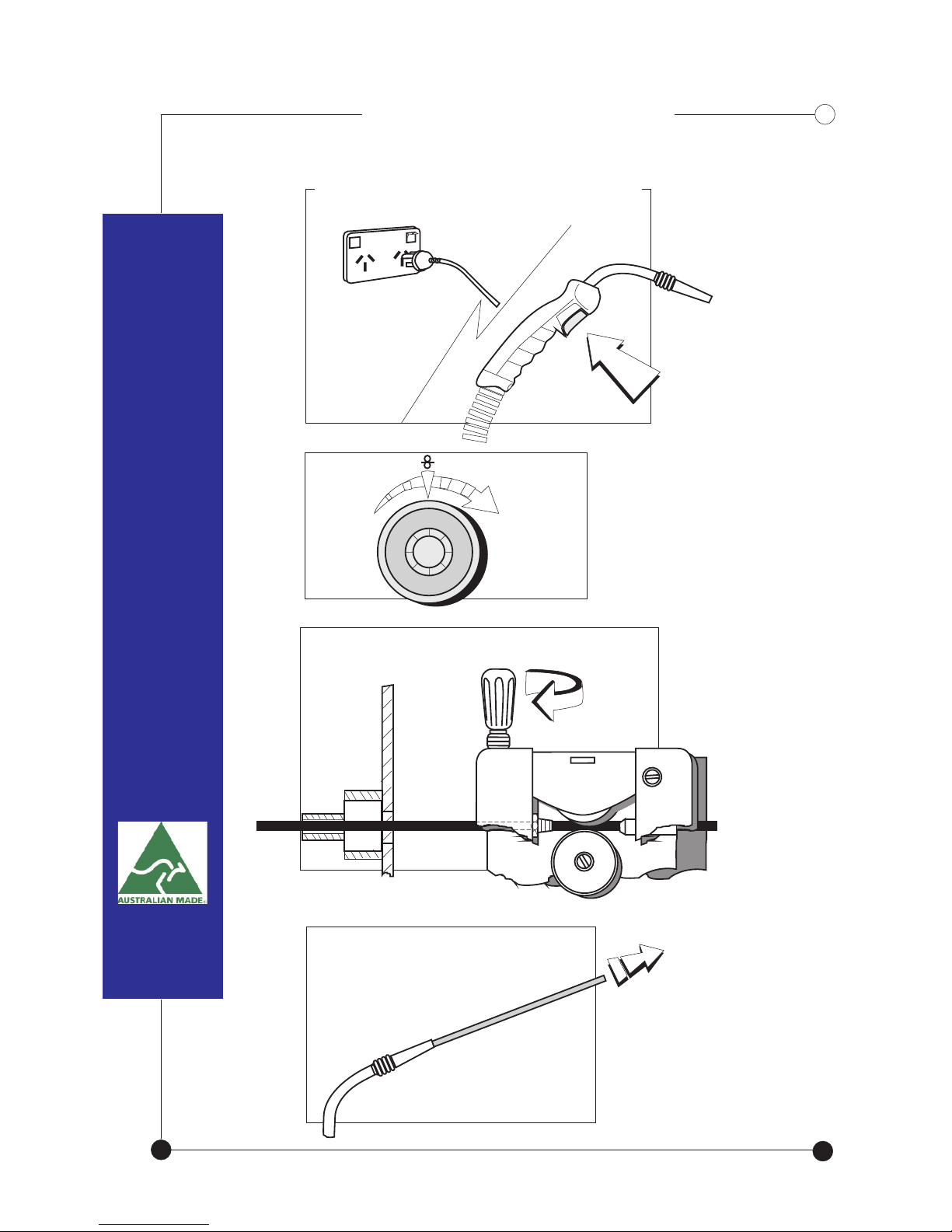

Startup ProcedureStartup Procedure

Keep trigger depressed

until wire protrudes out

from the gun head at

approximately 300mm

Twist tensioner until wire begins

to roll through

Plug into mains, switch machine on

Depress &hold trigger down

Adjust wire

speed control

knob to start

wire drive rollers

12

3

4

5

6

9

87

15

16

Twist tensioner

accordingly.

If wire slips

through the

rollers.. Not

enough tension

No wire

movement..

Gun head

Wire sways

and runs

through the

rollers without

slipping

Hold wire

WIRE TENSION TEST

Continuous

feed..

16

5

3 ~ 3.5 Maximum

Check setup if more

is required.

GUN ASSEMBLY

- For Steel / Stainless Steel

REGULATOR ASSEMBLY

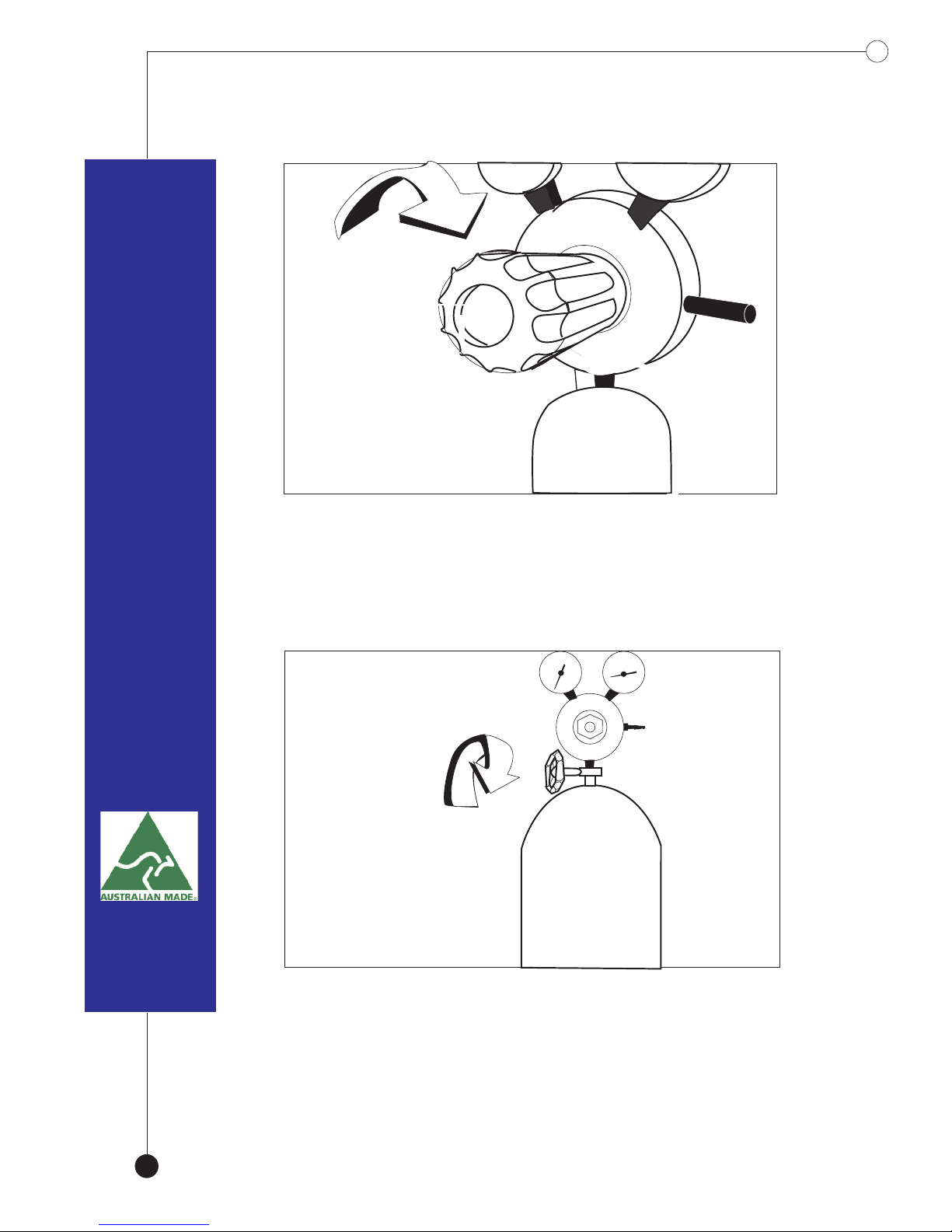

Screw regulator

onto gas bottle

17

Screw nut & tail

with gas hose connected

to the regulator.

Remaining gas

Flow rate.

Gas Outlet.

BOTTLE MOUNT

CORRECT GAS

Slowly open the gas bottle valve.

18 3

Screw in pressure adjustment knob

until slight resistance is felt.

This manual suits for next models

1

Table of contents

Popular Welding System manuals by other brands

EWM

EWM PICO 230 CEL operating instructions

Xcel-Arc

Xcel-Arc RAZORWELD MIG200 operating manual

Harbor Freight Tools

Harbor Freight Tools VULCAN MIG GUN LINER Owner's manual & safety instructions

DINSEO

DINSEO DIX GO 1206.M Operation manual

Lincoln Electric

Lincoln Electric Vernon Tool MasterPipe Compact Profiler Operator's guide

Lincoln Electric

Lincoln Electric STT-10 HEAD & CONTROLS BOOM MOUNT OR BENCH MODELS... Operator's manual