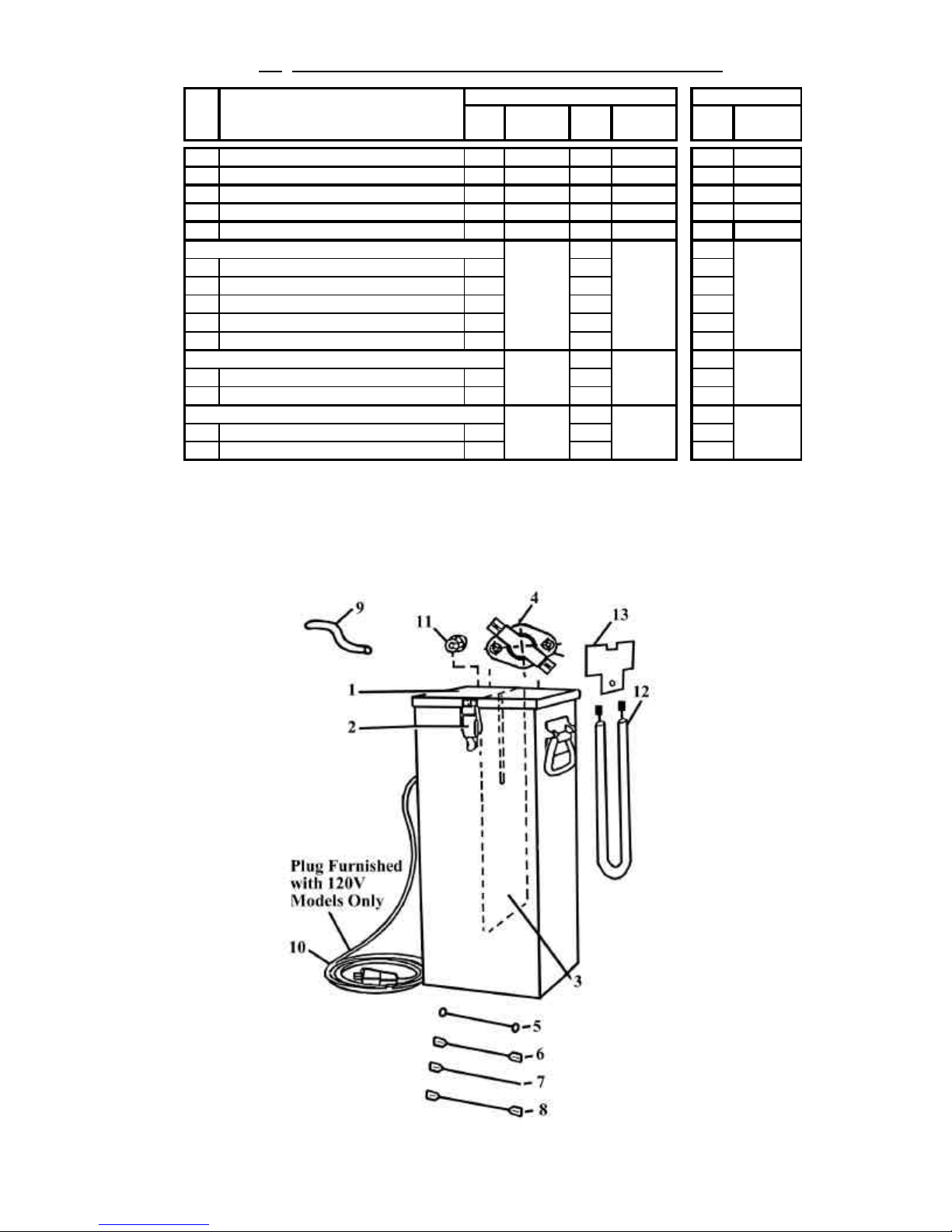

I. OPERATING INSTRUCTIONS FOR TYPE 50A SERIES

MODELS 7, 9, 10, 11, 14, 15, & 17 PORTABLE ELECTRODE STABILIZATION OVENS

*Caution* - To avoid oven damage, never place oven in contact with welding current.

**CAUTION**

All wiring should be done by licensed electricians in accordance with State & Local codes plus NEC (National Electric

Code) Standards. Improper installation or use may result in serious injury. Always remove oven from power source

before troubleshooting or repairing.

II. TROUBLESHOOTING - TYPE 50 OVENS

OVEN FAILS TO OPERATE - NO HEAT

1. If oven will not heat, check power supply.

2. Check plug at outer end of power cord. Check com-

plete power cord for continuity. If defective, replace cord

assembly.

3. Disconnect wires from heating element and check

heating element for continuity (access through top of

oven). If defective, replace elements.

4. On type 50A ovens check thermostat for continuity at

ambient temperature (access through top of oven). If

defective, replace thermostat.

OVEN OPERATES - OVERHEATS

1. Check thermostat operation as in number 5 (Oven

Fails To Operate - No Heat).

DryRod

Electrode Stabilizing

®

Type 50A Model, 9, 10, 11, 14, & 17 120V (AC/DC)

Plug power cord into suitable 120 Volt AC or DC power

source.

Type 50A Model 7 & 15, 240V (AC Only)

Plug power cord into suitable 240 Volt AC (Only) power

source.*

ELECTRODE HOLDING

1. Open lid of box and allow approximately 20 minutes

warm-up to drive out any retained moisture.

2. Place only dry electrodes within box. Keep lid closed

but unlatched while plugged into powered receptacle.

ELECTRODE STORAGE

3. When your job is done, the oven should remain con-

nected to its power source. If it becomes necessary to

disconnect from power, keep the lid closed and latched

to provide sealed storage of unused electrodes.

4. Your DryRod® oven has been preset at the factory for

optimum temperature control. The sealed thermostat is

not adjustable, but easily replaced if it fails. Average

stabilized temperature of the oven is 300°F with a full

load (average 250°F empty). A parts list and wiring dia-

grams are printed on the reverse side for your conven-

ience.

*Warranty is void if used with D.C. power source

TYPE 50A MODEL 15

Three Wire Grounded Circuit:

240 Volts AC (Only) *

Temperature: 300°F Average

(stabilized temperature)

Heating Element: Ring Type, 350 Watts, 240 Volts

TYPE 50A MODEL 14

Three Wire Grounded Circuit:

120 Volts AC/DC

Temperature: 300°F Average

(stabilized temperature)

Heating Element: Ring Type, 350 Watts, 120 Volts