AUSTROFLAMM INDUSTRIES WEGA PELLET 1 User manual

a

TI\BLE OF CONTENTS

1 INFORMATION

2 ELECTRICAL COMPONENTS

3 OTHER COMPONENTS

4 FUNCTION OF THE STOVE

5INSTALIATION

6 TROUBLE SHOOTING

7 DIFFERENT READING

8 SCHEMATICS

1

2

3

10

11

15

23

26

2A

3/15i9

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 1

:&:::t:::!:i::\:::rtr:f :rt::t.tg:!::r:::::::!:::r:::::::1::1lr::r!:iliilririiiri:i.iiliiiiiliiiriiil:

Eitttt::itiiL2.:.1 :itlzit:ll:{it:::::::i::i:i::::::::::i':::i:i::::i:l,i:,:i:iji:i::::i::::i:,:l::ii:ii:i::,:::;:i:::,i:::

120 lb hopper

lnterchangeable side panels

Cast iron burn pot

25O F warming shelf

7,000 - 40,000 BTU output

Sealed ball bearings components

5 year limited warranty

Weight

Overall height

width

Depth

Flue size

Overall efficiency

Heating capacity

80 hrs continous single load operation

Available in various steel colors

or white ceramic tiles

For lower maintenance and ability

to use all pellet fuel grades

slow cooking and warming capability

Wide operational range

No lubrication necessarry

2 years on all electrical parts

350lbs

37 318"

2A 114"

25"

78o/o

25O0 sq. ft.

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 23/1 5/9s

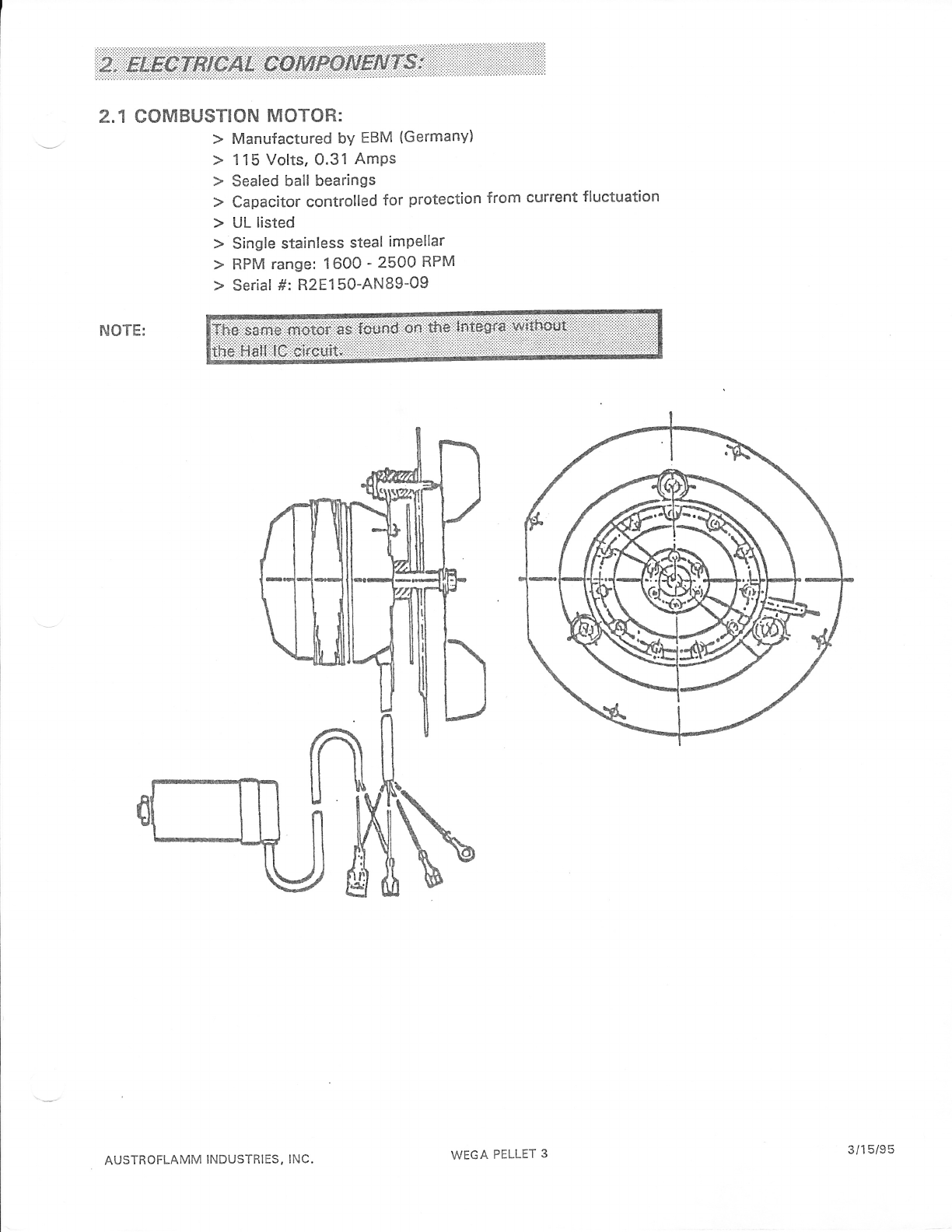

2.1 COMBUSTION MOTOR:

> Manufactured bY EBM {Germany)

> 115 Volts, 0.31 AmPs

> Sealed ball bearings

> Capacitor controlled for protection from current fluctuation

> UL listed

> Single stainless steal impellar

> RPM range: 1600 - 2500 RPM

) Serial #: R2E150-AN89-09

NOTE:

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 33/15i95

2.2 CONVECTION MOTOR:

> Manufactured bY EBM (GermanY)

> 12O Volts, 0.8 AmP, 60 Hz.

) Capacitor controlled for protection from fluctuation in current

> UL listed

> RPM range: 7OO - 1800 RPM

) Serial #: O2EO97-8D30-97

) cfm:194cuft/min

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 43/1 5i9s

2.3 AUGER MOTOR:

> Manufactured by Merkle Korff {USA)

> Used in many American pellet stoves

> 120 Volts, 0.55 Amps

> 1.1 RPM

) Same motor used in the lntegra series

> UL listed

) Ser. #: GF X4728 Rev. D

{A

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 53i 1 5/95

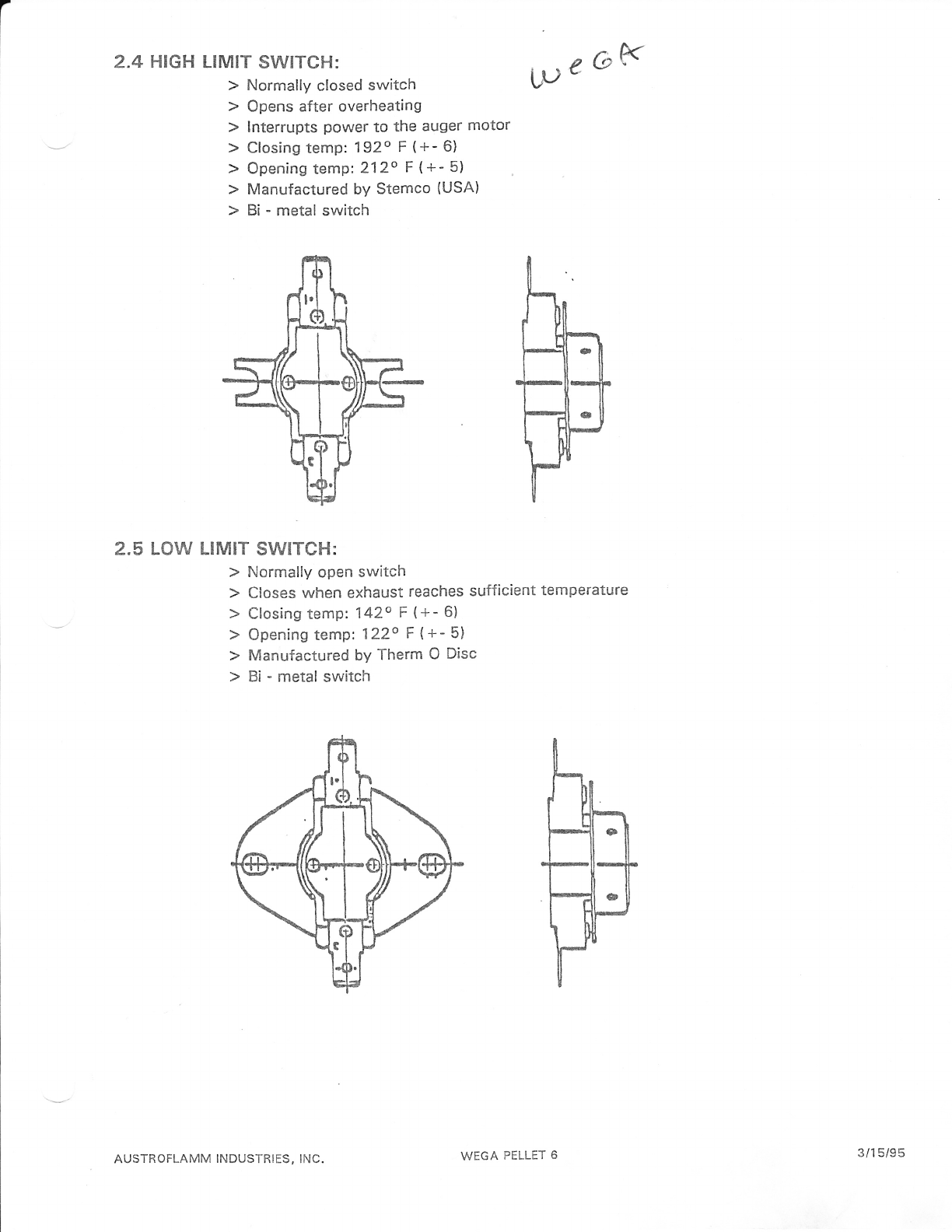

t' 2.4 HIGH LIMIT SWITCH:

> Normally closed switch

> Opens after overheating

) lnterrupts power to the auger motor

) Closing temp: 1920 F (+- 6)

) Opening temp: 2120 F (+- 5)

> Manufactured bY Stemco (USA)

> Bi - metal switch

2.5 LOW

we cK

LIMIT SWITCH:

> Normally open switch

) Closes when exhaust reaches sufficient temperature

) Closing temp: 1420 F 1+- 6)

) Opening temp: 1220 F {+- 5}

> Manufactured by Therm O Disc

> Bi - metal switch

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 63/1 5/9s

2.5 TERMINAL

brown wire

black wire

blue wire

BLOCK AND WIRING

Made with PVC

22 connection terminals

Same as on the lntegra

Wiring harness:

HARNESS:

w&64

" connection between circuit board

and termirialblock

* 7 wires connected to a

bigger cable

to room thermostat or

black wire from

black wire from comb. fan

.J Lblack wire from conv. fan

black wire from low limit sw.

blue wire to low limit-sw.

white wire from

black wire from

white wire to vacuum sw.

black wire to auqer

blue wire to conv. fan

blue wire to comb. fan

low wire to hiqh limit sw.

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 73/15i95

2.6 CIRCUIT BOARD + USER CONTROL BOARD:

) Combined circuit board and user control board

> TFK chips

> No changeable chiPs

> Manufactured bY Hieslmeyer

> new board equipped with a fuse: 250 Volt, 2 Amp ow blow fuse

> 4 potentiometers on the backside: 1 for convection fan

1 for auger feed

2 for combustion fan

NOTE:

) User side: * operating instructions

* auger light

* fuel on/off switch

t start switch

* Power knob

* air suPPlY adjustment

Auger motor don't turn don't turn

Convection motor

To increase the motor speed turn clockwise.

To decrease the motor speed turn counter-clockwise.

POl\'ER

("}

Uur- - IllI

ho:

&t senAv

TXn naTagcncraf

orr otr

r

fuet

r

TTA$T

ffi

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 817.O3.1995

2.7 VACUUM DIFFERENTIAL SWITCH:

> interupts power to the auger motor if vacuum in combustion

chamber is lost

> Closes: 0.33 w.c.

> Opens: 0.15 w.c.

) OPerating temp.: -40o F to +190o F

> Single pole, normally open contacts

NOTE:

Negative pressure connector

Normally open terminal

Common ter

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 93/1 5/95

3.1 BASIC FRAME (MADE OUT OF THE WEGA COOK STOVE)

3,2 DOOR (LEFT AND RIGHT) + DOORHANDLE + WINDOW

SINGLE DOOR ON NEW STOVE, SIMULAR TO INTEGRA STYLE

3.3 WARMING SHELF + TILES

3.4 SIX HEAT EXCHANGE TUBES + CLEANING ROD

3.5 FIREBRICKS

3.6 ASH PAN + BURN POT

3.7 HOPPER + HOPPERLID

3.8 BOfiOM REAR PANEL

3.9 SIDE PANELS IN A VARIETY OF COLORS AND MATERIAL

3.10 AUGER + SHAFT

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 1O 3/1 5/95

i*i**1r*9.

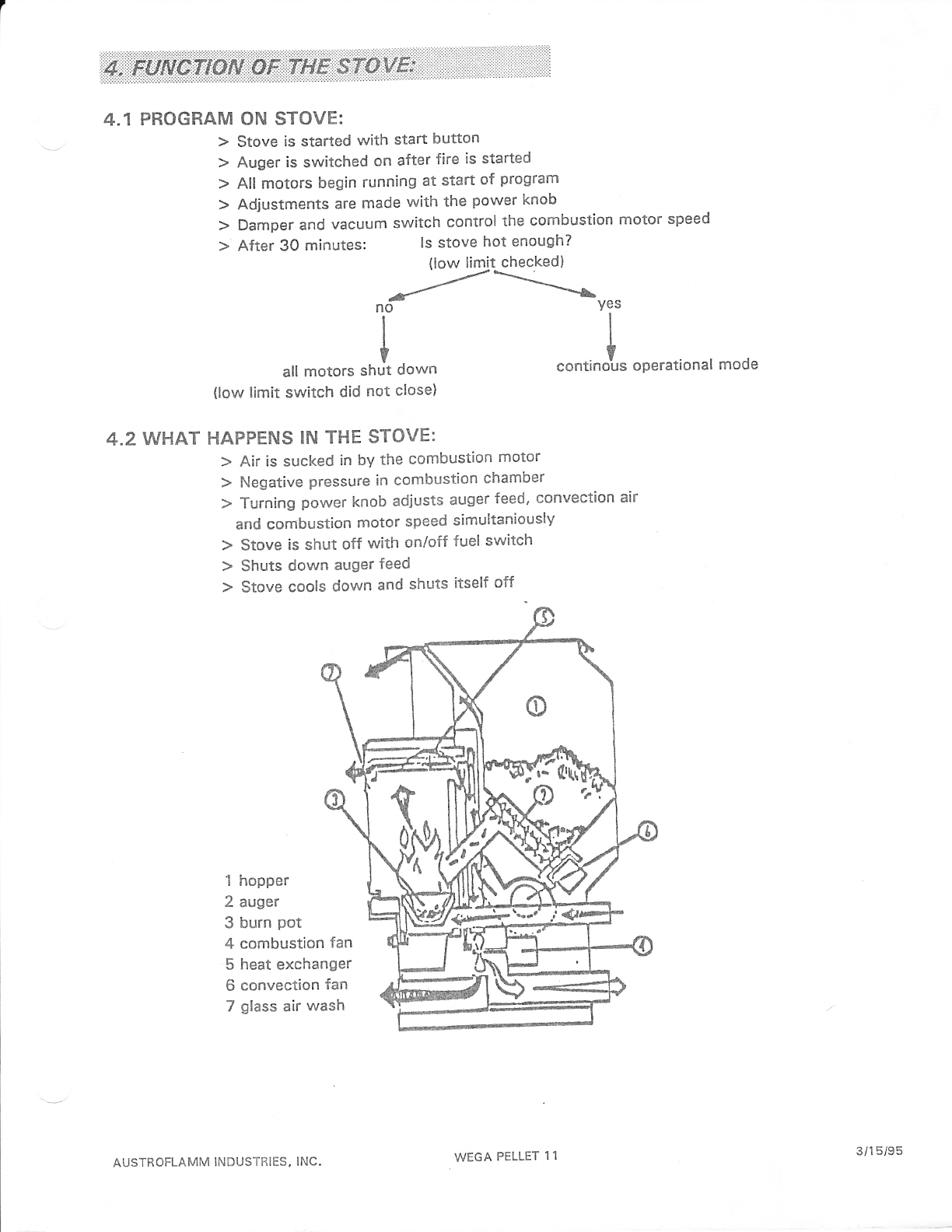

4.1 PROGRAM ON STOVE:

Stove is started with start button

Auger is switched on after fire is started

All motors begin running at start of program

Adiustments are made with the power knob

Damper and vacuum switCh control the combustion motor speed

After 30 minutes: ls stove hot enough?

{low limit checked)

/\

no Yes

I

I

all motors shut down

(low limit switch did not close)

4.2 WHAT HAPPENS IN THE STOVE:

I

"ontinJ" operational mode

> Air is sucked in by the combustion motor

> Negative pressure in combustion chamber

> Turning power knob adjusts auger feed, convection air

and combustion motor speed simultaniously

> Stove is shut off with on/off fuel switch

> Shuts down auger feed

> Stove cools down and shuts itself off

t hopper

2 auger

3 burn pot

4 combustion fan

5 heat exchanger

6 convection fan

7 glass air wash

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 11 3/1 s/95

4.3 THERMOSTAT OPTION:

> 1 15 Volts AC thermostat

> Connected in place of jumper wire on terminal block between 1st and Sth

terminal

> set thermostat on certain temperature

>Stoveoperatesatpowerknobsettinguntilreachingdesired

thermostat temperature. Once achieved stove then runs on 50% of

dial setting until room temperature falls below thermostat setting.

The stove then runs at dial setting again'

ca. 25000

max.

power knob on

control board

BTU

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 12 3/1 5/95

4.4 USER CONTROL BOARD:

> Powe!'knob:

> peltet consumption lbs/hr:

> auger light:

> on/off switch:

> {uel switch on/off:

* Adjustment of heat output

* lnfinitely variable

* Adjusts all'motors

*

+Flashes whenever power is sent to auger motor

4.5 sec. cycle

" Starts the stove

* All motors start at power knob setting

" Controls the auger feed

* on : auger cYcles

* off : auger stops

* Shuts down the stove bY depriving pellets to fire

* For nominal combustion air adjustment

" Adjustable from 1 to 5

* Factory setting at 3

* Owners fine tune adjustment

> air adiustment:

> auger Potentiometer on backside:

* To adjust nominal feed rate

* Turning clockwise : increases fuel feed

*Turningcounterclockwise:decreasesfuelfeed

) convection fan Potentiometer:

* On backside

* For nominal room air adjustment

* Turning clockwise : decreases fan speed

* Turning counter clockwise = increases fan speed

> combustion fan potentiometer on backside:

+ 2 Pots verY close together

* DO NOT ADJUST

* Use only adjustment on top to adjust combustion air

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 13 3/1 5/95

a

4.5 ROOM CONVECTION AIR:

) Convection motor draws in cold room air in

> Cold air passes through heat exchange area gathering heat from tubes

> Hot air is blown out through heat exchange tubes above the doors

4.6 AIR WASH:

> Gap between the glass and the cast iron'door

> located along the top edge of the glass

> Thickness of a credit card

> negative pressure in burn area draws room air in

> cold air is focused down inside glass face

>producesamovingairbarrierbetweenglassandmovingash

NOTE:

4.7 SAFETY FUNCTIONS:

> high limit switch:

NOTE:

) low limit switch:

> others:

* Normally closed switch

* Power runs through it

" lf stove temperature rises (over 2120 Fl , switch opens

and stops power from reaching auger motor

" Normally oPen

* Closes once exhaust temperature rises above 142o

" Reopens when exhaust cools below 1220 F

r Alerts circuit board to start shut down program

* Capacitors on convection and combustion motors

offers protection from power fluctuation

* Negative pressure prevent leaks into the room

* Vacuum switch opens auger circuit if a loss in

negative pressure is detected. This protection

stops auger feed if door is oPened

AUSTROFLAMM INDUSTRIES, INC, WEGA PELLET 14 3/1 s/95

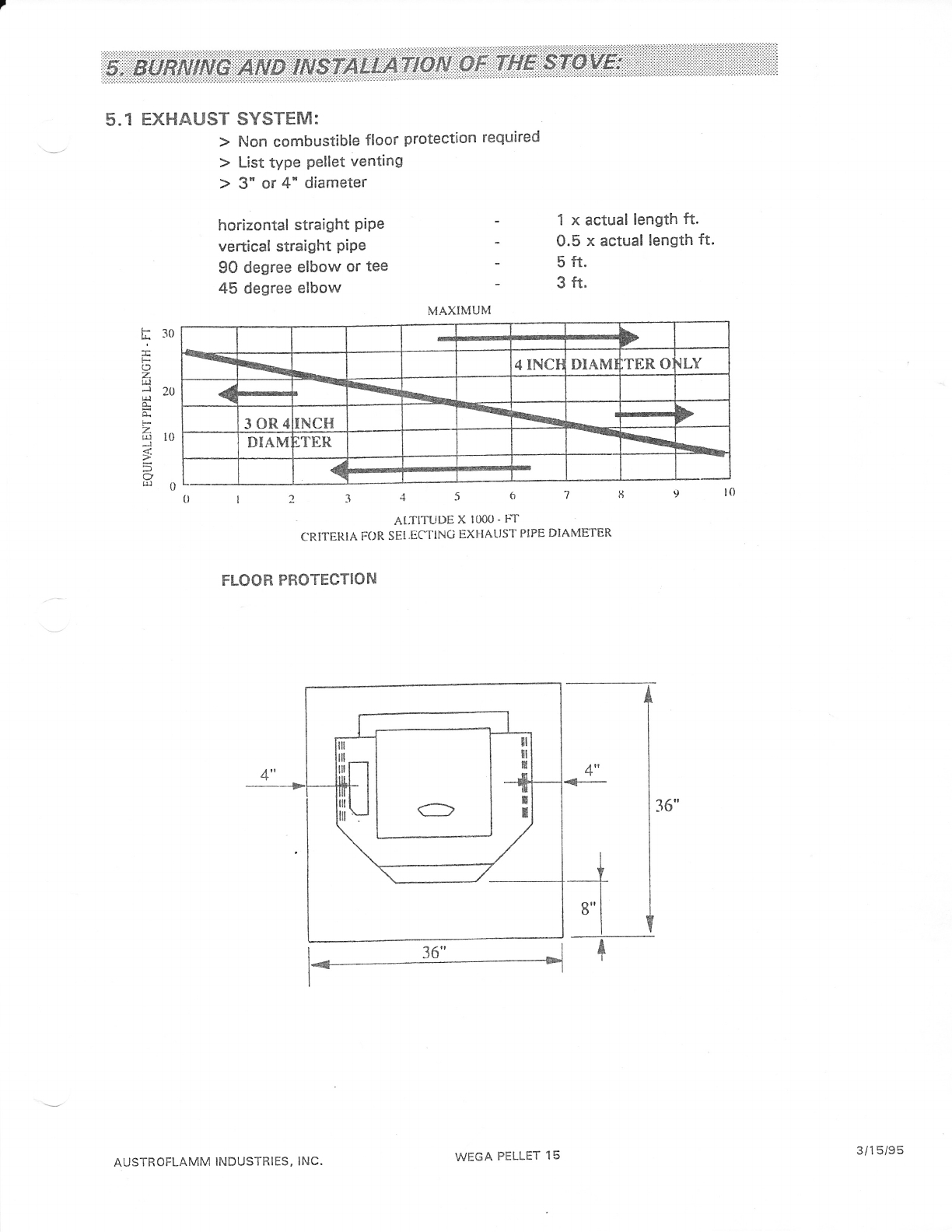

5.1 EXHAI.,IST SYSTEM:

> Non combustible floor protection required

> List type pellet venting

) 3" or 4" diameter

horizontal straight PiPe

vertical straight pipe

90 degree elbow or tee

45 degree elbow

- 1 x actual length ft.

- 0.5 x actual length ft'

- sft.

- 3ft.

MAXIMUM

q,o

I

F

o

z,

r20

q.l

E

F

frro

J

3

5

o

lrl O

AI:|ITUDE X IOOO- I.T

CRITERIA FOR SEI.ECTINC EXTIAI.JST PIPE DIAMETER

FLOOR PROTECTION

4"

36"

it

8"ll

ll

--T---

I

=- E- 4INCT DIAM TER OILY

Lb---

30R4 INCH =-

DIAM iTER =- b--

-

H

]

ti

fr

I

t

AUSTROFLAMM INDUSTRIES, INC. WEGA. PELLET 15 3/15/95

a

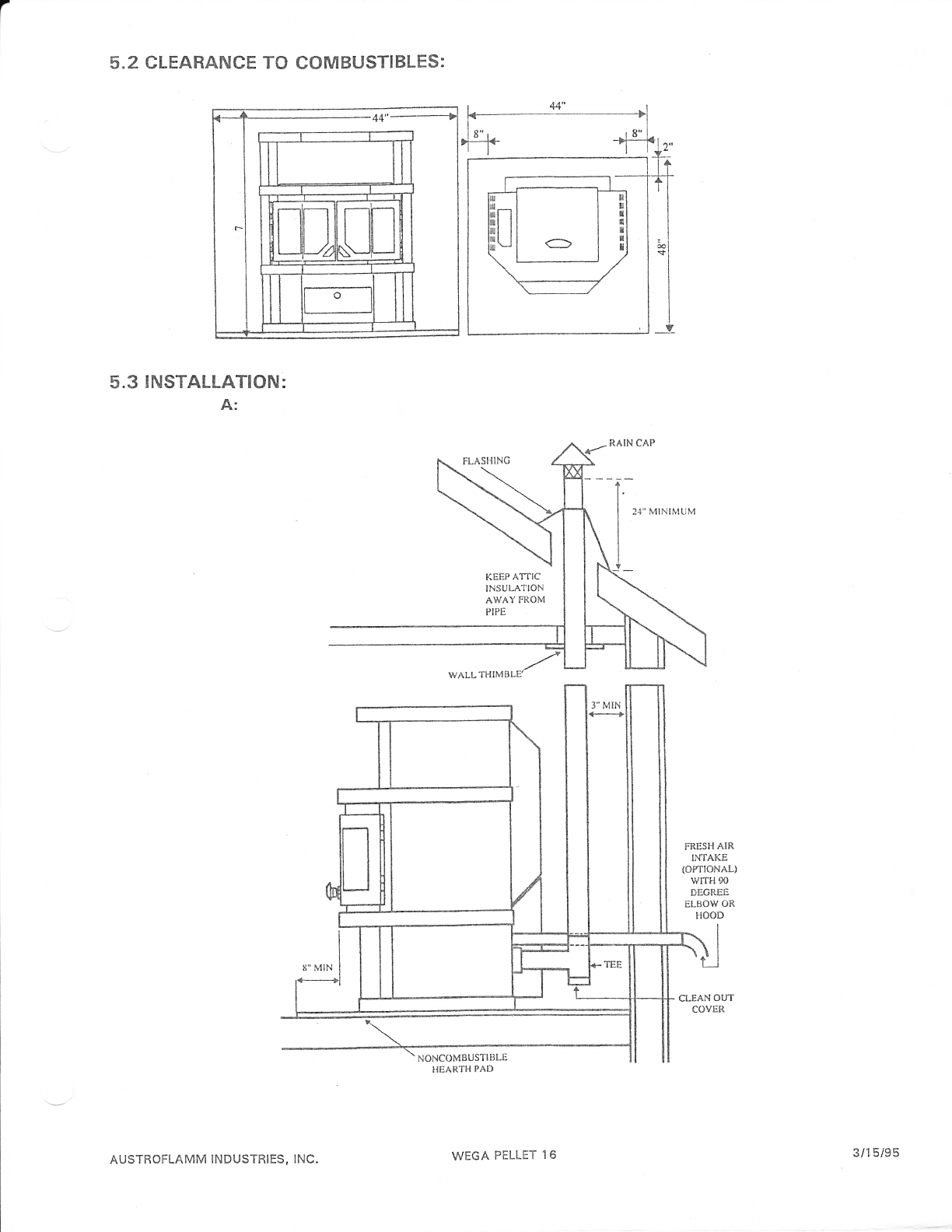

5.2 CLEARANCE TO COMBUSTIBLES:

5.3 INSTALLATION:

A:

FRESH AIR

INTAKE

(oFiloNAL)

wrrH 90

DEOREE

ELBOW OR

HOOD

\l

tt

CLEAN OUT

COVER

NONCOMBUSTITTLE

IiEARTH PAD

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 16 3/15/95

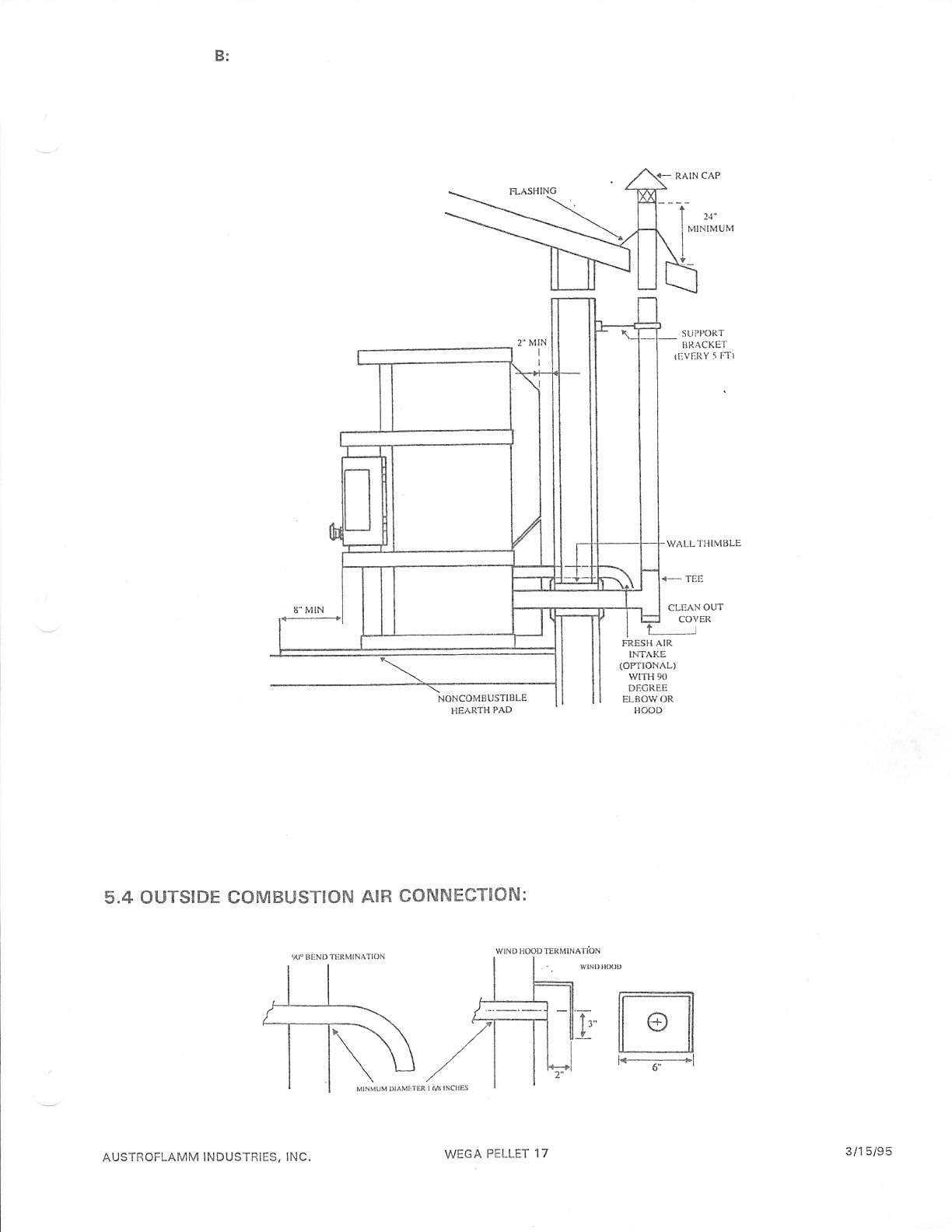

B:

5.4 OUTSIDE COMBUSTION AIR CONNEGTION:

WIND HOOD TERMINATION

AUSTROFLA,MM INDUSTRIES, INC. WEGA PELLET 17 3/1 5/95

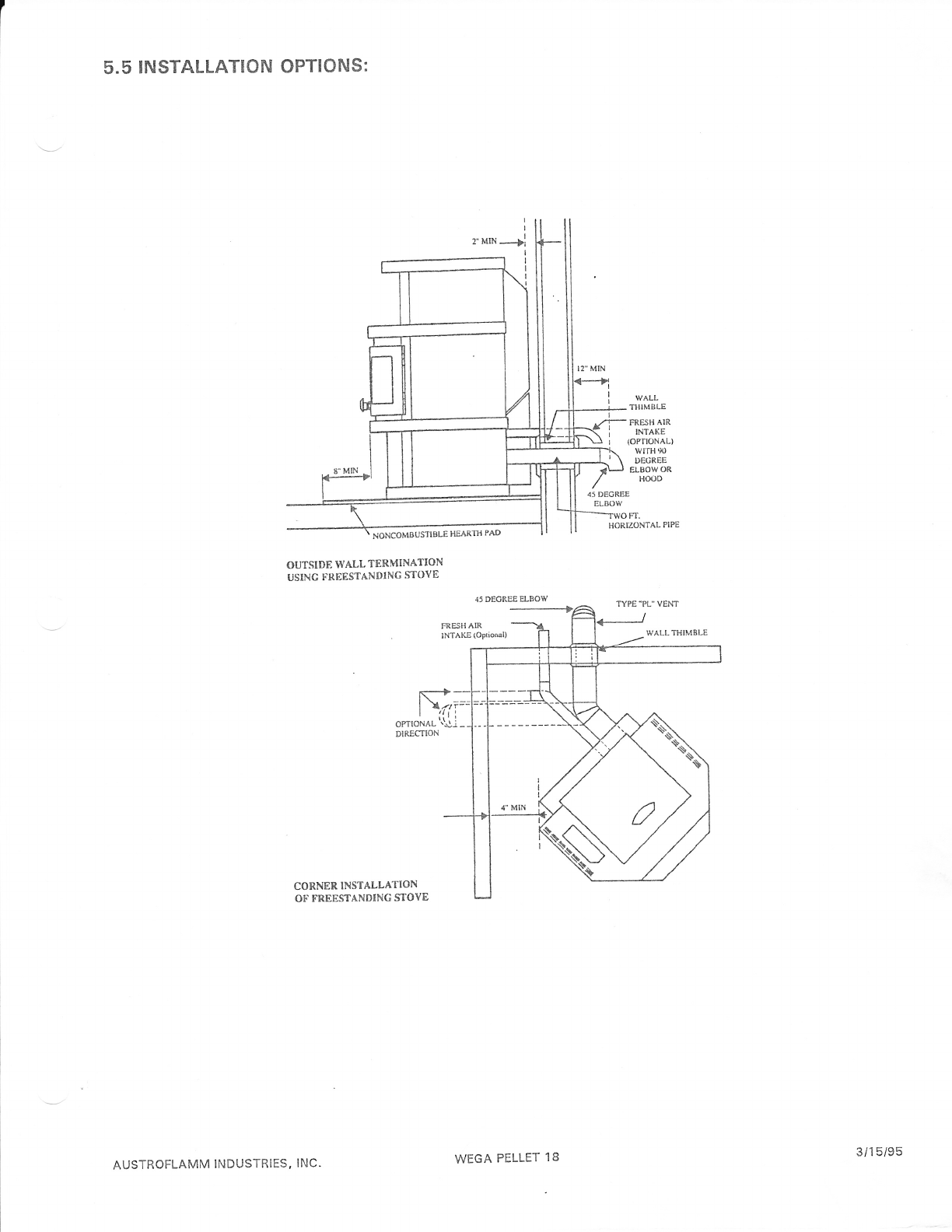

5. 5 INSTALLATION OPTIONS:

2'MIN I

--+lI

ki

i TNTAKE

| (OPnONAL)

WALL

THIMBLE

FRF.SH AIR

wfffi q)

DB:REE

€LBOW OR

HOC}D

45 DEGREE

€LAOW

HORTZONTAL PIPE

NONCOMBUSTIBLE HEARTH PAD

OUTSIDE WALL TERMINATION

USTNC T'REESTANDTNG STOVE

45 DEGREE ELBOW

FNESH AIR

T}{TAKE(Odidl)

CORNER INSTALLATION

OF FREESTANDING STOVE

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 18 3/',I 5/95

NOTE:

5.6 PREBURN PROCEDURES:

1 Check shipping carton for any sign of external damage caused by

shipping! lf container damage is present make thorough inspection

ofstovefordamagellfanydamageispresent,documentdamage

and file claim against shipper!

Check stove to make sure all components are present

check bottom of the hopper to make sure there is no foreign

material that could jam the auger

4 Connect power cord to 120Volts AC

SFillpelletsinhopperandstartthestovelettingitrunforone

cold cycle {30 minutes)' This will prime the auger'

6 After stove is off, put a small handful of petlets in the burn pot, use

a gel fire starter (stir around a little bit) and light it'

close the door and let the fire burn' Turn the fuel switch to the on

position as needed. set the power knob to desired operating position'

7 Let stove burn at least one hour, opening and closing doors

every 10 minutes to make sure the door gasket does not

stick to curing Paint.

I Turn fuel switch to off and let the stove cool down;

it will shut itself off.

9 You now have a product that you can install with confidence

that it will function correctly, provided you have properly instructed

the customer to the operational and maintenance procedures!

AUSTROFLAMM iNDUSTRIES. INC. WEGA PELLET 19 3/15/95

5.7 MAINTENANCE SCHEDULES:

Burn pot: clean as needed, 2 to 7 times weekly depending on

characteristics of pellet fuel used and operational

habits of stove owner

Ash pan: clean as needed, visually apparent

Doorglass:asneeded,usuallydaily,canbemoreorlessfrequent

depending on characteristics of pellet fuel used and

operational habits of stove owner

Heat exchange rods: once or twice a day, depending on characteristics of

pellet fuel used and operational habits of stove owner

Hopper: let hopper run almost empty and vacuum sawdust from

aroundauger.Dothismonthlyifdumpingpelletsdirectly

from the bag to hoPPer'

Annual service: remove combustion fan from cast aluminium housing,

clean impellar and housing area' clean out area in

combustion chamber (ash pan and burn pot), clean

heat exchange tubes, clean all the vent piping' remove

convection fan and clean impellar' clean hopper and

auger shaft, clean dirt and dust from all rear areas

ofthestove,particularlyaugermotorandareasclose

to circuittry!

AUSTROFLAMM INDUSTRIES, INC. WEGA PELLET 20 3/1 5i95

Table of contents