Autodesk HP xw9400 User manual

Autodesk®

Visual Eects and Finishing 2011 Edition

HP®xw Workstation

Hardware Setup Guide

©2009 Autodesk, Inc. All rights reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or

parts thereof, may not be reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Autodesk®Inferno®, Autodesk®Flame®, Autodesk®Flint®, Autodesk®Fire®, Autodesk®Smoke®, Autodesk®Backdraft®Conform software

Portions relating to MXF-SDK was developed by Media, Objects and Gadgets – Soluçoes de Software e Hardware, S.A.

(http://www.mog-solutions.com) in co-operation with Institut für Rundfunktechnik GmbH (http://www.irt.de).

Portions powered by Automatic Duck. ©2006 Automatic Duck, Inc. All rights reserved.

Portions relating to “dslib” C/C++ Copyright 1988-1989 Eugene Dronek and Rich Morin.

Autodesk®Flare™software

Portions relating to MXF-SDK was developed by Media, Objects and Gadgets – Soluçoes de Software e Hardware, S.A.

(http://www.mog-solutions.com) in co-operation with Institut für Rundfunktechnik GmbH (http://www.irt.de).

Portions powered by Automatic Duck. ©2006 Automatic Duck, Inc. All rights reserved.

Portions relating to “dslib” C/C++ Copyright 1988-1989 Eugene Dronek and Rich Morin.

Portions relating to MPEG Layer- 3; supply of this product does not convey a license under the relevant intellectual property of Thomson

multimedia and/or Fraunhofer Gesellschaft nor imply any right to use this product in any finished end user or ready-to-use final product. An

independent license for such use is required. For details, please visit http://www.mp3licensing.com.

Autodesk®SystemCentral™software

Adobe®Flash®Player. Copyright ©1996-2006 Adobe Systems Incorporated. All Rights Reserved.

Autodesk®Inferno®, Autodesk®Flame®, Autodesk®Flint®, Autodesk®Smoke®, Autodesk®Backdraft®Conform

Portions relating to MPEG Layer- 3; supply of this product does not convey a license under the relevant intellectual property of Thomson

multimedia and/or Fraunhofer Gesellschaft nor imply any right to use this product in any finished end user or ready-to-use final product. An

independent license for such use is required. For details, please visit http://www.mp3licensing.com.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December,

3December.com, 3ds Max, ADI, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo), ATC, AUGI, AutoCAD, AutoCAD

Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk, Autodesk Envision, Autodesk

Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap, AutoSketch,

AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil 3D, Cleaner,

Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer, Create>what’s>Next>

(design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer, DesignStudio,

Design|Studio (design/logo), Design Web Format, Discreet, DWF, DWG, DWG (logo), DWG Extreme, DWG TrueConvert, DWG TrueView, DXF,

Ecotect, Exposure, Extending the Design Team, Face Robot, FBX, Filmbox, Fire, Flame, Flint, FMDesktop, Freewheel, Frost, GDX Driver, Gmax,

Green Building Studio, Heads-up Design, Heidi, HumanIK, IDEA Server, i-drop, ImageModeler, iMOUT, Incinerator, Inferno, Inventor, Inventor

LT, Kaydara, Kaydara (design/logo), Kynapse, Kynogon, LandXplorer, LocationLogic, Lustre, Matchmover, Maya, Mechanical Desktop, Moonbox,

MotionBuilder, Movimento, Mudbox, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore, Opticore Opus, PolarSnap, PortfolioWall,

Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, RasterDWG, Reactor, RealDWG, Real-time Roto, REALVIZ,

Recognize, Render Queue, Retimer,Reveal, Revit, Showcase, ShowMotion, SketchBook, Smoke, Softimage, Softimage|XSI (design/logo),

SteeringWheels, Stitcher, Stone, StudioTools, Topobase, Toxik, TrustedDWG, ViewCube, Visual, Visual Construction, Visual Drainage, Visual

Landscape, Visual Survey, Visual Toolbox, Visual LISP, Voice Reality, Volo, Vtour, Wire, Wiretap, WiretapCentral, XSI, and XSI (design/logo).

The following are registered trademarks or trademarks of Autodesk Canada Co. in the USA and/or Canada and other countries: Backburner,

Multi-Master Editing, River, and Sparks.

The following are registered trademarks or trademarks of Moldflow Corp. in the USA and/or other countries: Moldflow MPA, MPA (design/logo),

Moldflow Plastics Advisers, MPI, MPI (design/logo), Moldflow Plastics Insight, MPX, MPX (design/logo), Moldflow Plastics Xpert.

Adobe and Flash are either trademarks or registered trademarks in the United States and/or countries. Automatic Duck and the duck logo are

trademarks of Automatic Duck, Inc. FFmpeg is a trademark of Fabrice Bellard, originator of the FFmpeg project. Python is a registered trademark

of Python Software Foundation. All other brand names, product names or trademarks belong to their respective holders.

THIS PUBLICATION AND THE INFORMATION CONTAINED HEREIN IS MADE AVAILABLE BY AUTODESK, INC. “AS IS.” AUTODESK, INC. DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS.

Published by: Autodesk, Inc.

111 Mclnnis Parkway

San Rafael, CA 94903, USA

Title: Autodesk Visual Effects and Finishing 2011Edition HP xw9400 Hardware Setup Guide

Document Version: 3

Date: April 16, 2009

Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Notation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Workflow for Hardware Setup and Application Installation . . . . . . . . . . . . . . . . . . . . . . . . 3

Hardware Configuration Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ensuring Proper Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power and Air Conditioning Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rack Mount Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Avoiding Damage from Static Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding Audio Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Receiving Your Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

BIOS and Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DVI-Ramp Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

AJA OEM-2K PCI-X Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3 Connecting Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Peripherals Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting the Keyboard, Mouse, and Tablet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting to Gigabit Ethernet (GigE) Networks . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting to the Infiniband (IB) Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 4 Setting Up Video Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Video I/O Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

v

Video I/O Setup for Workstations Using a DVI-Ramp2 . . . . . . . . . . . . . . . . . . . . . . . 18

Video I/O Setup for Workstations Using the NVIDIA Quadro SDI Board . . . . . . . . . . . . . . 20

Standard VTR Control Cable Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting Up VTR Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

VTR Emulation RS-422 Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 5 Setting Up Audio Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

About Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Audio Wiring Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Audio Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Understanding Remote vs. Local Control of the Lucid Converter . . . . . . . . . . . . . . . . . . . . 30

Audio Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuring the Lucid ADA 88192 Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adjusting Lucid ADA 88192 Converter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Lucid ADA 88192 Converter Settings for Remote Control . . . . . . . . . . . . . . . . . . . . . 32

Lucid ADA 88192 Converter Settings for Local Control . . . . . . . . . . . . . . . . . . . . . . 33

Audio Keywords in the Software Initialisation Configuration File . . . . . . . . . . . . . . . . . . . . 33

Chapter 6 Connecting Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting Media Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

About Autodesk Stone Direct Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting and Configuring the ATTO Fibre Channel Adapter . . . . . . . . . . . . . . . . . . 37

Connecting Storage Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

XR 6500 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

XR 6412 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

XR 5402 and XR 5412 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting Archiving Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Filesystem Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SCSI Tape Drive Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

vi | Contents

Introduction

Topics in this chapter:

■About This Guide on page 1

■Related Documentation on page 1

■Notation Conventions on page 2

■Contacting Customer Support on page 2

About This Guide

This guide describes how to set up the HP®xw9400 workstation for your Autodesk®Visual Effects and

Finishing application (Autodesk®Inferno®, Autodesk®Flame®, Autodesk®Flint®, Autodesk®Smoke®,

Autodesk®Backdraft®Conform).

If you already own an HP xw9400 workstation that shipped with a previous release of a Visual Effects and

Finishing application, you normally do not need to change its configuration. But you do need to verify its

BIOS and firmware settings. See BIOS and Firmware.

Use this guide in conjunction with the latest Autodesk Visual Effects and Finishing Installation and Configuration

Guide, to install and configure the hardware and software components of your Visual Effects and Finishing

system.

NOTE In most cases, both hardware setup and application installation is done on delivery by an authorized

technician, so you may not need to perform some of the procedures in these guides.

Related Documentation

This release has documentation that helps you install, configure, and use the software. This documentation

is available from the application DVD, on the Autodesk Web site, and is installed with the product (as PDF

files and as an HTML help system).

1

1

For a list of all the documentation available to you, visit http://www.autodesk.com/me-documentation. From

this page you can access the complete documentation library.

You should also refer to your product's release notes for all late-breaking release information.

Notation Conventions

A number of style conventions are used throughout your documentation. These conventions and examples

of their use are shown as follows.

ExampleConvention

install rpm -qa

Text that you enter in a command line or shell appears

in Courier bold. Press the Enter key after each com-

mand.

<filename>

Variable names appear in Courier, enclosed in angle

brackets.

limit coredumpsize

Feedback from the command line or shell appears in

Courier.

/usr/discreetDirectory names, filenames, URLs, and command line

utilities appear in italics.

Contacting Customer Support

For Autodesk Media and Entertainment Customer Support, visit http://www.autodesk.com/support.

Customer support is also available through your Autodesk reseller. To find a reseller near you, consult the

reseller look-up database at http://www.autodesk.com/resellers.

2| Chapter 1 Introduction

Getting Started

Topics in this chapter:

■Workflow for Hardware Setup and Application Installation on page 3

■Hardware Configuration Guidelines on page 4

■BIOS and Firmware on page 7

Workflow for Hardware Setup and Application Installation

The following procedure provides the general workflow for installing an Autodesk Visual Effects and Finishing

application on a workstation.

To install a Visual Effects and Finishing application on a workstation:

1Review the guidelines for working with hardware components. See Hardware Configuration Guidelines

on page 4.

2Connect all peripherals (mouse, keyboard, Wacom®tablet, graphics monitor) to the proper ports, and

connect your workstation to the Autodesk®Wire®network. See Peripherals Connection Diagrams on

page 13.

3Connect your workstation to the storage. See Connecting Storage on page 35.

4Connect a VTR and a broadcast monitor to your workstation. See Setting Up Video Hardware on page

17.

5Set up the audio hardware. See Setting Up Audio Hardware on page 29.

6Perform the procedures in the Red Hat Enterprise Linux Workstation 4, Update 3 Installation and Configuration

Guide to install your operating system and the Discreet®Kernel Utility (DKU).

7(Optional) If you need to reconfigure your media storage filesystem, see the Autodesk Visual Effects and

Finishing Installation and Configuration Guide for information on setting up a standard filesystem (such

2

3

as XFS), or the last version of the Autodesk Stone and Wire Filesystem and Networking Guide for information

on setting up the Stone®filesystem.

8Perform the procedures in the Autodesk Visual Effects and Finishing Installation and Configuration Guide

to install and license your Visual Effects and Finishing application.

Hardware Configuration Guidelines

In most cases, hardware integration and application installation are done on delivery by an authorized

technician, and some of the procedures in this guide may not be necessary. Still, it is a good idea to read

through all chapters to familiarize yourself with the configuration procedures for the following reasons:

■Many suspected problems with your system may be due to loosened connections or improperly configured

devices. This guide helps you troubleshoot problems by providing information about properly configured

systems.

■If you need to call Customer Support, familiarity with this guide allows you to help Customer Support

diagnose problems.

■If you want to move your system at any time, or upgrade certain hardware components, this guide

contains crucial information.

This guide, in conjunction with the Autodesk Stone Direct Configuration Guide, provides complete information

about the configuration of hardware components. However, hardware configuration should only be performed

by an experienced hardware integrator.

Your Autodesk system consists of high-performance hardware that must be configured in an environment

suited to its operational needs. The following sections discuss:

■Memory requirements

■Proper environmental conditions

■Power and air-conditioning

■Rack-mounting

■Static discharges

■Audio grounding

Memory Requirements

The HP xw9400 supports up to 16 GB of memory, and uses DDR2-667 ECC Registered / Unbuffered DIMMs.

The amount of memory required for your Autodesk Visual Effects and Finishing system depends on the

resolution of your projects, the type of work you perform and, in some cases, the platform on which you

are running the application. Refer to the Autodesk Visual Effects and Finishing Software Installation Guide to

determine the memory requirements for your Visual Effects and Finishing application.

Ensuring Proper Environmental Conditions

You should consider the following environmental guidelines for all hardware configuration:

■Place all components in an air-conditioned environment. All hardware components generate heat and

must be kept cool. See Power and Air Conditioning Requirements on page 5.

4| Chapter 2 Getting Started

■Make sure the rack on which hardware components are mounted is open or well ventilated. Follow the

ventilation specifications that apply to your system. See Rack Mount Requirements on page 5.

■Keep all hardware components in a clean, dust-free location.

■Minimize vibration and humidity.

■Do not block the vents on the component housing.

■Do not drape anything, such as a jacket or a blanket, over hardware components.

■Minimize electromagnetic noise by separating digital data and power cables from analog audio cables

and running them in different cable ducts.

Power and Air Conditioning Requirements

The values for power consumption and heat output were recorded on an Autodesk certified system with all

of the required peripherals and certified components.

NOTE These values can fluctuate if uncertified hardware components or third party applications are added to

your system. The use of uncertified hardware components or third party applications is not supported. Please

consult the manufacturer's documentation for standardized minimum and maximum values.

The following table summarizes the peak (at startup) power consumed by the HP xw9400 system and the

heat it generates under the maximum processing load produced by your Visual Effects and Finishing

application. For detailed specifications, including noise output, see the documentation provided by the

manufacturer.

Heat

(BTUs)

WattsMax. Amps (120V

/ 240V)

Startup Amps

(120V / 240V)

QuantityComponent

1228.683603.0 / 1.53.5 / 1.81HP xw9400

170.65500.5 / 0.30.5 / 0.31Miranda DVI-Ramp2

153.58450.5 / 0.30.5 / 0.31Lucid ADA 88192

NOTE Workstations equipped with the NVIDIA®Quadro®FX 5600 graphics board and the NVIDIA Quadro SDI

board do not use the Miranda DVI-Ramp2.

You must be able to meet the startup power requirement and have a climate control system with the capacity

to maintain the temperature of these components under the maximum processing load. Refer to the following

table for standard conversion benchmarks and an example of how they are used to establish climate control

requirements.

ExampleUnit Conversion

384 Watts = 1228.68 BTU1 Watt = 3.413 BTU

1228.68 BTU = 0.102 Ton of air conditioning12000 BTU = 1 Ton of air conditioning

Rack Mount Requirements

You can rack mount your Visual Effects and Finishing system. Plan for sufficient space in your rack mount

chassis to install the following components:

■An HP xw9400 system

Power and Air Conditioning Requirements | 5

■An AJA OEM-2K breakout box

■A Miranda DVI-Ramp2, if your workstation uses one

■A Stone®Direct storage chassis (XR model)

■Additional Stone Direct expansion chassis (XE model), as required

The form factor units of these components are provided in the following table.

Required Rack SpaceForm FactorQuantityComponent

5U5U1HP xw9400

1U1U1AJA OEM-2K breakout box

1U1U1Miranda DVI-Ramp2

2U2U1Stone Direct storage chassis (XR)

2U2U1Stone Direct expansion chassis (XE) (each)

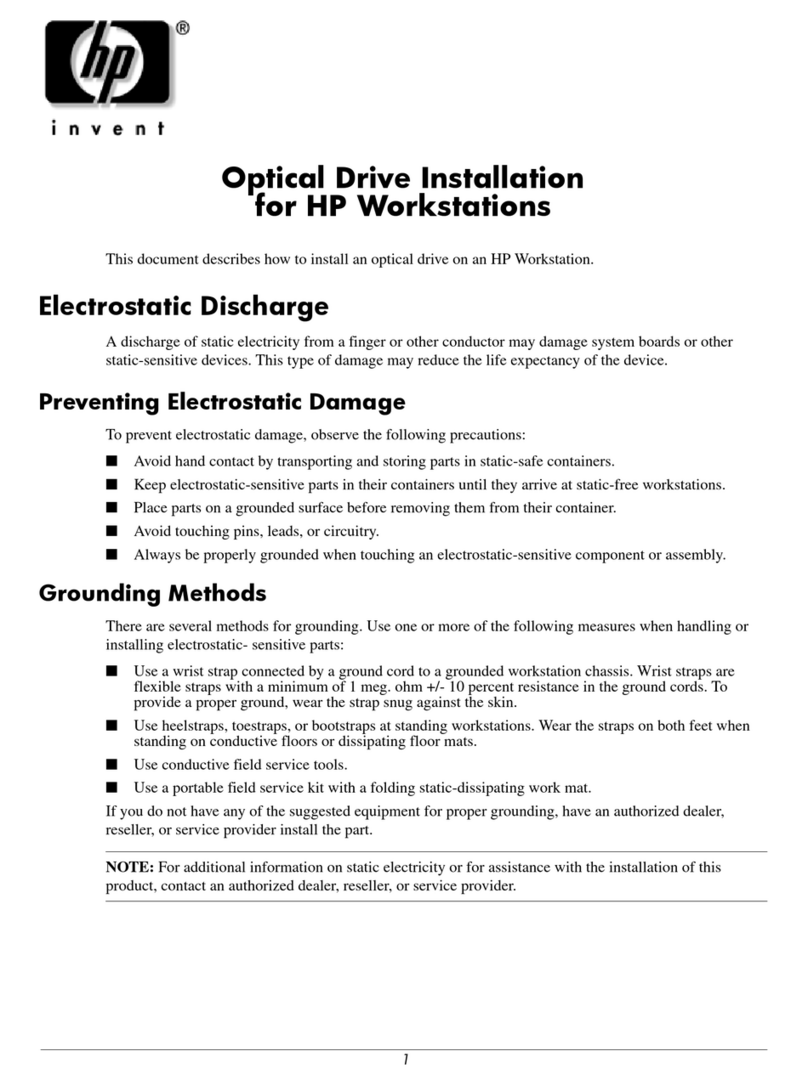

Avoiding Damage from Static Electricity

When installing any hardware equipment, take the following precautions to prevent damage to sensitive

components from static discharge:

■Make sure power is turned off on the component you are working on. It is a good idea to unplug

components until all other connections are configured.

■Always wear a grounded static wrist strap. Attach the strap's alligator clip to any grounded metal surface

on the component's chassis that you are working on. Place the wristband around your wrist.

■Do not handle any components unnecessarily, particularly boards and cards that slide in and out of PCI

slots on their parent hardware components.

Grounding Audio Hardware Components

It is important to properly ground your audio components. Otherwise, you may have ground loops, or

humming in the system. To ensure audio components are properly grounded, use the XLR-3 cables shipped

with your system. Using any other cables may cause humming in the system.

Receiving Your Shipment

When you receive your shipment, check all the boxes for dents or other markings that may indicate damage

during transport. If you suspect a component is damaged, carefully inspect it before setting up the system.

If you receive a damaged component, call Customer Support.

Use the enclosed packing checklist to ensure that you received all of the parts.

6| Chapter 2 Getting Started

BIOS and Firmware

In most cases, hardware integration and application installation are done on delivery by an authorized

technician, so you should not have to verify or upgrade the BIOS or the different firmwares. But, if you are

upgrading your Visual Effects and Finishing application yourself, perform the following procedures.

NOTE Refer to your product’s release notes for the latest system BIOS and firmware versions.

System BIOS

System configuration is done prior to delivery by an authorized technician. The procedures in this section

may not be necessary, and are provided here for informational purposes only.

Updating Your System BIOS

The BIOS version installed on your system appears on the screen while booting the workstation. The following

procedure describes how to update a workstation to the certified BIOS version required by your Autodesk

Visual Effects and Finishing application.

To update the BIOS on your workstation:

1Open a terminal, and log is as root.

2Insert the application DVD in the drive of the workstation and mount it.

3Go to the DKU_<version_number>/Utils/BIOS directory on the DVD,

where <version_number> represents the version of the DKU. For example:

cd /mnt/cdrom/DKU_4.0.0/Utils/BIOS

TIP If the DKU has already been installed on the workstation, you can access its contents in the

/usr/discreet/DKU directory, without having to use the application DVD.

Each platform supported by the version of your Visual Effects and Finishing application has its own

directory that contains an .iso file.

NOTE For more information about updating the BIOS on your workstation, refer to the README file also

located in the platform's directory.

4Type:

cd <platform>

5Burn the .iso file onto a CD and place it in the DVD-ROM drive of the workstation.

6Reboot the workstation and press F10 to enter BIOS.

7Optional: Press F8 to select a language.

8Select File | Flash®System ROM.

The Select a Drive dialog box appears.

9Select CD-ROM, and press F10 to confirm.

10 Select the .bin file.

The Flash System ROM confirmation dialog box appears.

11 Press F10 to confirm.

BIOS and Firmware | 7

12 Press any key.

A message stating that the system ROM flash was successful appears.

13 Verify system BIOS settings. See Checking Your System BIOS Settings on page 8.

14 Select File | Save Changes and Exit.

Checking Your System BIOS Settings

You do not normally need to adjust these settings. BIOS settings for the workstation are provided here for

informational purposes only.

To enter the system BIOS, you must press F10 while booting the workstation.

The following table lists the proper Autodesk certified BIOS settings. Items not listed are set to their default

factory settings.

ValueItemBIOS Menu

Optical DriveBoot OrderStorage

USB Device

Integrated SATABoot Order, Hard Drive

Integrated IDE

DisabledOS Power Management, ACPI S3 SupportAdvanced

EnabledChipset / Memory, ECC Support

EnableChipset / Memory, Memory Scrubbing

EnableChipset / Memory, Memory Node Interleave

EnableChipset / Memory, PCI Serr# Generation

EnableChipset / Memory, Net Watchdog Timer

DisabledChipset / Memory, ACPI Bus Segmentation

EnabledChipset / Memory, HPET

DisabledDevice Options, S5 Wake on LANI/O

WARNING Before installing Red Hat®Linux®, validate the BIOS Settings.

Restoring BIOS to Default Factory Settings

If there is any doubt about whether items contain factory default values, the following procedure restores

default factory settings.

To restore default factory BIOS settings:

1Press F10 while booting the workstation to enter the system BIOS.

2Select File | Default setup | Restore Factory Settings as Default.

3Press F10 to accept the changes.

4Select Apply Defaults and Exit, then press F10 to confirm.

8| Chapter 2 Getting Started

The factory system defaults are restored.

DVI-Ramp Firmware

NOTE Refer to this section only if your workstation uses a Miranda DVI-Ramp or Miranda DVI-Ramp2. If your

workstation is equipped with an NVIDIA Quadro FX 5600 graphics board and an NVIDIA Quadro SDI board, you

do not need a DVI-Ramp or DVI-Ramp2.

System configuration is done prior to delivery by an authorized technician. The following procedures may

not be necessary, and are provided here for informational purposes only.

Verifying DVI-Ramp and DVI-Ramp2Firmware

The firmware on your DVI-Ramp must correspond to the certified version required by your Visual Effects

and Finishing application version. Each firmware is itself associated to a DVI-Ramp version and a hardware

version. If the firmware on your DVI-Ramp does not match the hardware version listed in the table below,

you must update the firmware to the certified version.

Certified Firmware VersionHardware VersionVisual Effects and Finishing Application

Version

3.703.20DVI-Ramp2009 with

4.714.20DVI-Ramp

6.0506

6.0507

6.00DVI-Ramp2

6.0508

The DVI-Ramp firmware update utilities required to check your firmware version and perform the update

are included with the DKU version associated with the release of your Visual Effects and Finishing application.

The following procedure describes how to verify the firmware version of the DVI-Ramp.

To verify the firmware version of the DVI-Ramp:

1With the DVI-Ramp connected to your workstation and powered up, open a terminal, and log in as

root.

WARNING If your DVI-Ramp is connected to the HP workstation using a USB-to-Serial adapter, you must

remove the adapter from the USB port, and connect the serial cable of the DVI-Ramp to the serial port of the

workstation. This does not apply to DVI-Ramp2units.

2Insert the application DVD in the DVD-ROM drive of the workstation and mount it.

3Go to the DKU_<version_number>/Utils/DVI_firmwareUpdate directory on the DVD,

where <version_number> is the DKU version. For example:

cd /mnt/cdrom/DKU_3.0.0/Utils/DVI_firmwareUpdate

TIP If the DKU has already been installed on the workstation, you can access its contents in the

/usr/discreet/DKU directory, without having to use the application DVD.

4Run the info command to scan the DVI-Ramp's current firmware. Type:

./info

The output is similar to the following example:

DVI-Ramp Firmware | 9

Versions:

Hardware = <Hardware Version>

Micro = <Firmware version>

Genlock = 3.21

DVI = 4.01

FrameBuffer = 4.05

SDI = 4.10

Where <Hardware Version> is the current version of the DVI-Ramp hardware, and <Firmware

version> is the firmware currently loaded in the DVI ramp. If the firmware version does not match

the hardware version listed in the table that precedes this procedure, you must perform the firmware

update procedure.

Updating the DVI-Ramp Firmware

The firmware on your DVI-Ramp must correspond to the certified version required by your Visual Effects

and Finishing application version. If you verified the firmware on your DVI-Ramp and it did not match the

certified version, you must update it. The following procedure describes how to update the firmware version

of the DVI-Ramp.

To update the DVI-Ramp firmware:

1Open a terminal, log in as root, and go to the DKU_<version_number>/Utils/DVI_firmwareUpdate

directory of the application DVD, where <version_number> represents the version of the DKU. For

example:

cd /mnt/cdrom/DKU_3.0.0/Utils/DVI_firmwareUpdate/

TIP If the DKU has already been installed on the workstation, you can access its contents in the

/usr/discreet/DKU directory, without having to use the application DVD.

2From the DVI_firmwareUpdate directory, launch the DVI-Ramp upgrade utility by typing:

./updateDVI

The script checks the hardware version of the DVI-Ramp and then installs the firmware update. The

update should take between 5 and 10 minutes. You can monitor the progress of the firmware update

in the terminal.

The DVI-Ramp is rebooted several times during the firmware update. Any monitors connected directly

to the DVI-Ramp (such as the graphics monitor and/or a broadcast monitor) flash each time the

DVI-Ramp is rebooted. This is normal and indicates that the firmware is being updated.

3Once the firmware update is complete, updated hardware information for your DVI-Ramp appears in

the terminal.

4If you had to remove the USB-to-Serial adapter, reconnect the serial cable to the adapter, then put the

adapter back in the USB port. Restart the HP workstation.

AJA OEM-2K PCI-X Firmware

System configuration is done prior to delivery by an authorized technician. The following procedures may

not be necessary, and are provided here for informational purposes only.

10 | Chapter 2 Getting Started

Verifying the AJA OEM-2K PCI-X Firmware

The firmware on your AJA OEM-2K PCI-X (AJA PCI-X) must correspond to the certified version required by

your Visual Effects and Finishing application version. Refer to your product’s release notes for the latest AJA

OEM-2K PCI-X firmware versions.

The AJA PCI-X firmware update utilities required to check your firmware version are included with the DKU

version associated with the release of your Visual Effects and Finishing application. The following procedure

describes how to verify the firmware version of the AJA PCI-X.

To verify the AJA PCI-X firmware version:

➤ Open a terminal, and type:

cat /proc/driver/aja

An output similar to the following should appear:

AJA Driver Name: oem2k

Version: 4.1 Beta 11

Card #: 0

Board Version String: OEM 2K - Rev 0

PCI Version: 0x55

Board ID: 10196500

FPGA built on 2007/09/18 at 10:57:41

NOTE If there is no aja file in /proc/driver, you are using an outdated driver or the driver is not loaded and

you must install the latest DKU for your workstation. Refer to the Autodesk Visual Effects and Finishing Software

Installation Guide.

Updating the AJA PCI-X Firmware

The firmware on your AJA PCI-X must correspond to the certified version required by your Visual Effects

and Finishing application version. If you verified the firmware on your AJA PCI-X and it did not match the

certified version, you must update it. The following procedure describes how to update the firmware of the

AJA PCI-X to the certified version required by your Visual Effects and Finishing application.

To update AJA PCI-X firmware:

1Log in as root and open a terminal.

2Insert the application DVD in the DVD-ROM drive of the workstation, and mount it.

3Go to the DKU_<version_number>/Utils/AJA_firmwareUpdate directory of the DVD,

where <version_number> represents the version of the DKU. For example:

cd /mnt/cdrom/DKU_3.0.0/Utils/AJA_firmwareUpdate

TIP If the DKU has already been installed on the workstation, you can access its contents in the

/usr/discreet/DKU directory, without having to use the application DVD.

4Run the AJAfw_update utility to scan the AJA current firmware and, if required, update to the latest

firmware version. Type:

./AJAfw_update

The script checks the firmware of your AJA board, and one of the following events occurs:

■The script detects that the firmware and drivers need to be updated and prompts you to start the

update. In this case, continue to the next step of this procedure.

AJA OEM-2K PCI-X Firmware | 11

■The script indicates that the firmware is up-to-date and exits. In this case, you are finished; go to

step 6 of this procedure to eject the DVD.

NOTE For more details about the AJA firmware procedures, consult the README file located in the current

directory.

5Start the firmware update by typing Yand then pressing Enter.

While the AJA board's firmware and drivers are being updated, your workstation appears to be frozen

and your mouse and keyboard do not work. This is normal and indicates that the firmware is being

updated. Once the firmware update is complete, you are returned to the terminal.

6When you are returned to the terminal, return to the root directory and eject the DVD by typing:

cd /

eject /mnt/cdrom

7Shut down your workstation by typing:

shutdown -g0

If your workstation does not prompt you to power down, press the power button for 10 seconds to

force a power down.

8Disconnect the power cord.

9Wait 10 seconds, reconnect the power cord, then restart your workstation.

12 | Chapter 2 Getting Started

Connecting Peripherals

Topics in this chapter:

■Peripherals Connection Diagrams on page 13

■Connecting the Keyboard, Mouse, and Tablet on page 15

■Network Connections on page 16

Peripherals Connection Diagrams

Before you boot your workstation, connect all hardware peripheral devices as illustrated in this chapter. For

storage connection diagrams, see Connecting Storage on page 35.

The following two diagrams identify the ports to which the peripherals connect on the HP xw9400

workstation:

■The first diagram illustrates the peripherals setup for an HP xw9400 workstation equipped with a NVIDIA®

Quadro®FX 5500G graphics board and a DVI-Ramp.

■The second diagram illustrates the peripherals setup for an HP xw9400 workstation equipped with a

NVIDIA Quadro FX 5600 graphics board and an NVIDIA Quadro SDI board.

NOTE All the diagrams in this document illustrate a Gigabit Ethernet (GigE) adapter located in PCI slot four. Your

workstation may also be configured with an optional QuickSilver InfiniSERV 9000 PCIe-DDR adapter that replaces

the GigE adapter. On the HP xw9400 workstation, the PCI slots are numbered one to seven from top to bottom.

For detailed information on video connections, refer to Setting Up Video Hardware on page 17.

For detailed information on audio connections, refer to Setting Up Audio Hardware on page 29.

3

13

HP xw9400 Workstation with DVI-Ramp

Graphics monitor sync

reference output

AJA OEM-2K

To Wire network

(Infiniband option available)

To house network

NVIDIA graphics to

DVI-Ramp2

To DVI-Ramp2 control

To storage

To keyboard, mouse,

USB tablet

14 | Chapter 3 Connecting Peripherals

Table of contents

Other Autodesk Desktop manuals

Popular Desktop manuals by other brands

Fujitsu

Fujitsu CELSIUS M720 operating manual

Cincoze

Cincoze DC-1100 user manual

HP

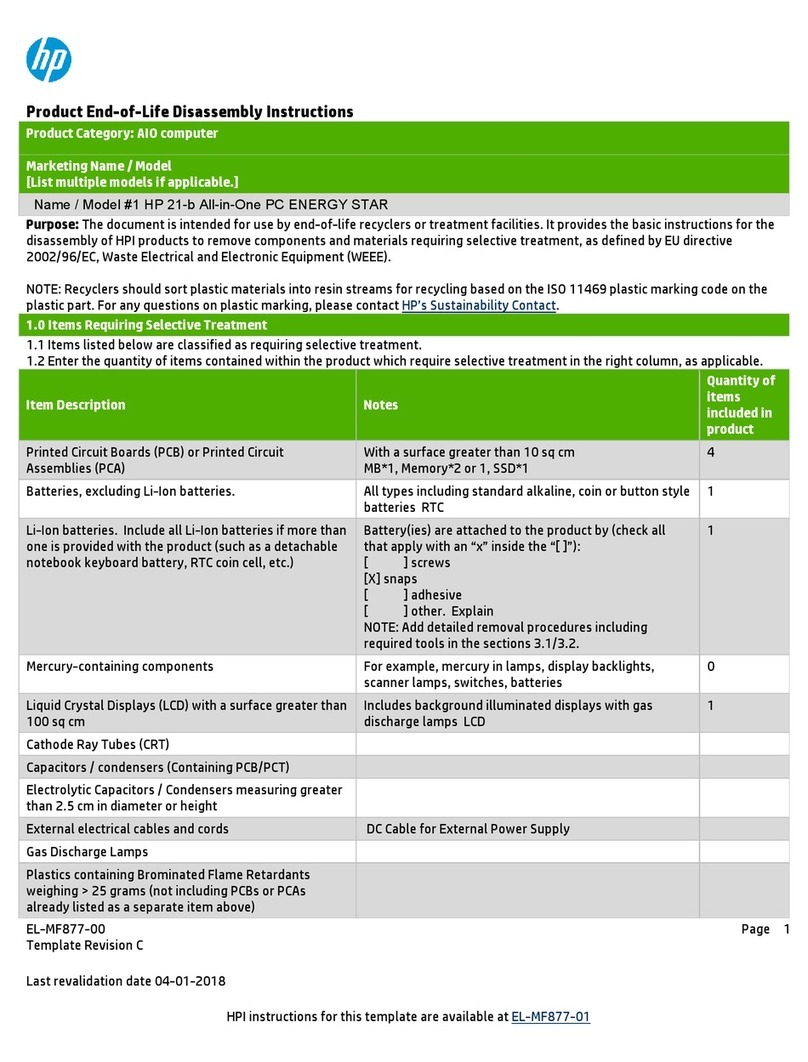

HP 21-b All-in-One ENERGY STAR Product End-of-Life Disassembly Instructions

Lenovo

Lenovo ThinkCentre Edge 62z user guide

Radio Shack

Radio Shack TRS-80 Model 4 Technical reference manual

HP

HP Workstation xw6000 installation guide