Speedheater 1100 S Instruction Manual

INSTRUCTION & SAFETY MANUAL

MAKE SURE YOU READ AND UNDERSTAND THE OWNERS MANUAL PRIOR TO USING

THIS TOOL. IMPROPER HANDLING CAN CAUSE PERSONAL INJURY AND MAY CAUSE FIRE.

To ensure the best possible use of your tool, we recommend you read the following

instructions carefully as well as the accompanying safety instructions.

DEAR CUSTOMER

Congratulations for choosing The Speedheater Infrared Paint Remover, model 1100 S.

1

ESTIMADO CLIENTE

Felicitaciones por elegir El Removedor de Pintura Infrarrojos Speedheater, modelo 1100 S.

Para asegurar la óptima utilización de la herramienta, se recomienda leer las siguientes

instrucciones cuidadosamente además de las instrucciones de seguridad incluidas.

MANUAL DE INSTRUCCIONES Y SEGURIDAD

MODE D'EMPLOI ET CONSIGNES DE SÉCURITÉ

LEA Y ENTIENDA EL MANUAL DEL USUARIO ANTES DE UTILIZAR ESTA HERRAMIENTA.

LA MANIPULACIÓN INCORRECTA PUEDE CAUSAR LESIONES PERSONALES E INCENDIOS.

Merci d'avoir choisi le Décapeur infrarouge Speedheater, modèle 1100 S.

Pour une utilisation optimale de votre appareil, nous vous recommandons de lire

attentivement les instructions et consignes de sécurité suivantes.

CHER CLIENT, CHÈRE CLIENTE,

ASSUREZ-VOUS DE LIRE ET DE BIEN COMPRENDRE LE MODE D'EMPLOI AVANT D'UTILISER

CET OUTIL. UNE MAUVAISE UTILISATION PEUT CAUSER DES BLESSURES OU UN INCENDIE.

English

Español

Fran aisç

2

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS

SAFETY PRECAUTIONS

INSTRUCTIONS FOR USE

TROUBLESHOOTING GUIDE

CLEANING AND MAINTENANCE, CHANGING IR TUBES

SPARE PARTS LIST

WARRANTY

3

Page

5

11 - 14

- 8

9

15

16 - 17

18

19 - 20

English

4

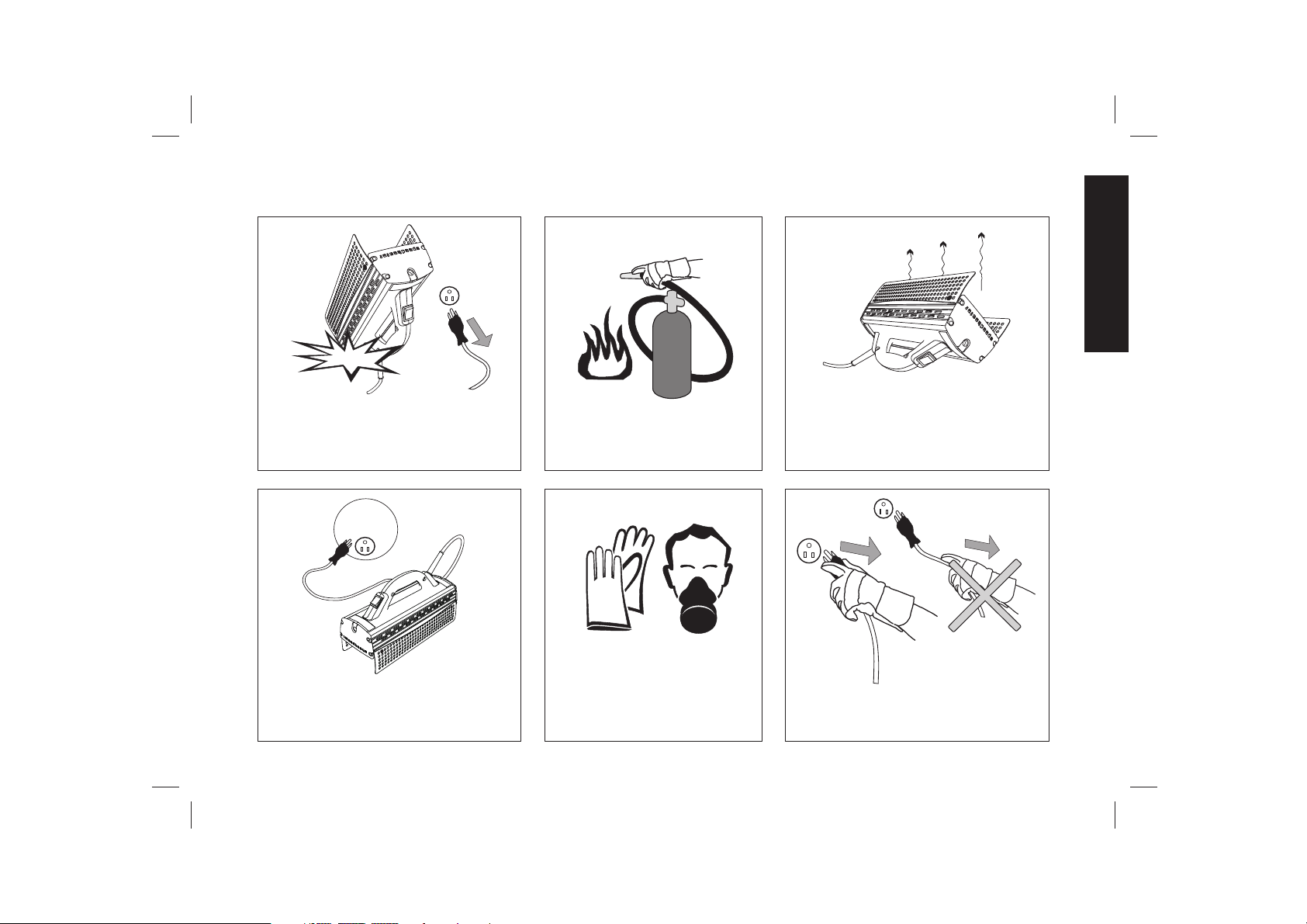

LIKE ANY POWER TOOL IT CAN BE DANGEROUS NOT USED PROPERLY.

READ THE FOLLOWING INSTRUCTIONS CAREFULLY AND FOLLOW

ALL SAFETY PRECAUTIONS.

IT IS THE RESPONSIBILITY OF THE OWNER TO USE THE SPEEDHEATER

INFRARED PAINT REMOVER, MODEL 1100 PROPERLY.

BASIC SAFETY INSTRUCTIONS SHOULD ALWAYS BE FOLLOWED WHEN USING

THIS ELECTRICAL TOOL IN ORDER TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK AND PERSONAL INJURY.

THIS INSTRUCTION & SAFETY MANUAL IS NOT INTENDED TO SERVE

AS WARRANTY, GUARANTEE OR REPRESENTATION CONCERNING THE

FUNCTION AND OPERATION OF THE SPEEDHEATER INFRARED PAINT

REMOVER, MODEL 1100 S.

THIS TOOL SOFTENS PAINT, VARNISH AND PUTTY, ENABLING IT TO BE

SCRAPED OFF EASILY. USE A HIGH QUALITY SCRAPER WITH THIS TOOL.

DO NOT LEAVE UNATTENDED.

5

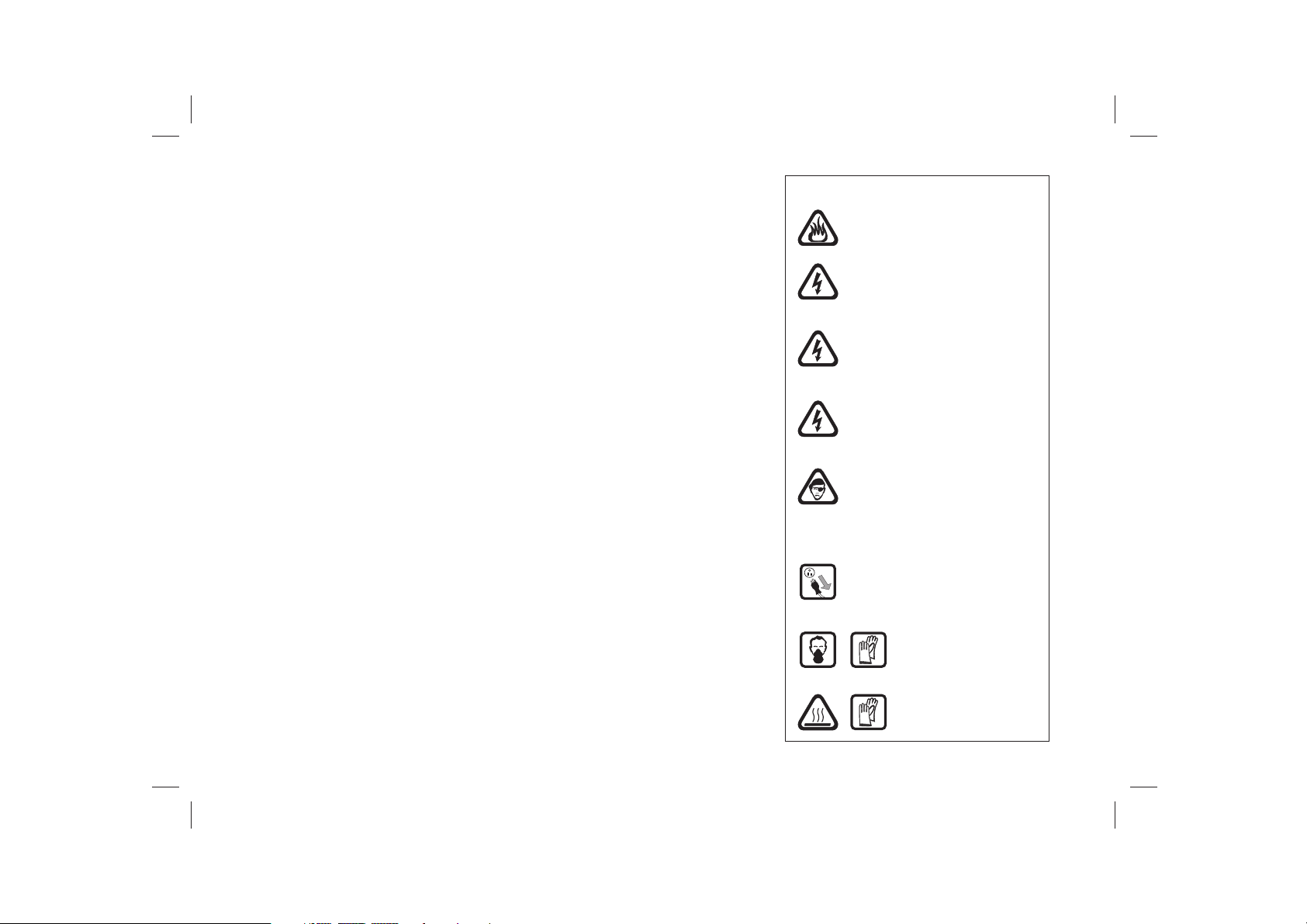

METAL SURFACES ARE HOT WHEN

IN USE. USE HEAT PROTECTIVE GLOVES.-

ALWAYS USE A RESPIRATORY MASK

AND/OR PROVIDE FOR GOOD

VENTILATION. FOLLOW LOCAL

LAWS AND REGULATIONS.

TURN OFF THE TOOL WHEN NOT IN USE .

DURING TEMPORARY WORK

BREAKS, ALWAYS TURN THE TOOL

UPWARDS FROM THE SURFACE AND NEVER

LEAVE IT UNSUPERVISED SINCE IT CONSTITUTES

A FIRE HAZARD

NEVER USE THE CORD TO

CARRY THE TOOL OR PULL THE PLUG

FROM AN OUTLET.

IF THE DEVICE IS EXPOSED TO A

THRUST OR OTHER DAMAGE, IMMIDIATELY

CUT THE POWER BY PULLING THE PLUG AND

CHECK THE DEVICE´S ELECTRICAL

COMPONENTS.

ALWAYS USE A POWER OUTLET

WITH A GFCI (GROUND FAULT CIRCUIT

INTERRUPTER) WHEN WORKING

WITH THIS POWER TOOL.

SAFETY PRECAUTIONS

IMPROPER HANDLING OF THIS

POWER TOOL MAY CAUSE FIRE: ALWAYS

KEEP A FIRE-EXTINGUISHER AT HAND

English

GFCI

PERSONAL SAFETY

Always ensure there is a fire extinguisher close at hand. In case of fire,

immediately switch the tool off and secure your safety.

Call an emergency number or a fire station immediately for assistance.

Always avoid any bodily contact with grounded surfaces such as pipes,

radiators, stoves or refrigerators. There is a risk of electric shock if your body is grounded.

An electric shock may cause severe personal injury or death.

. (Ground Fault Circuit Interrupter) when working with

this power tool. GFCI is designed to cut off the power when electricity is flowing through the ground wire.

This is an excellent protection against electric shock. If you are required to meet OSHA and NEC standards, you

must utilize a GFCI when working with any power equipment according to Federal United States law. If the tool

is not connected to a proper outlet, you may receive an electric shock which may lead to severe injury or death.

Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not

use any adapter plugs since this may cause fire or electrical shock that may cause injury or death. If the tool

should malfunction, the ground provides a low resistance path to carry electricity away from the user.

Grounded cords that comply with all codes and ordinances must be used.

The use of accessories or systems other than those

recommended in these instructions may cause personal injury, like as electric shock, fire or other. Use only

original spare parts and accessories from the manufacturer for this tool. Using parts other than those

specified in the spare parts list or otherwise approved by the manufacturer may cause personal injury and

render the warranty invalid. The same applies to using non-approved or unauthorized service centers.

The tool has been manufactured in accordance with prevailing regulations. Repairs should onlybe carried out

by a properly qualified electrician to avoid the risk of personal accidents or injury.

Disconnect the plug from the power source before making any

adjustments. Always disconnect the power cord when not in use or when the tool is being serviced.

Failing to do this may lead to electric shock. Someone may also turn on the machine involuntarily, which can

cause fire and or severe injury.

Ensure that a firm foothold can be obtained and that the work surface is stable.

Use the necessary safety equipment when working at heights. Firmly attach all anchoring points. If you intend

to utilize ladders and scaffolding, follow the safety instructions of that equipment carefully. Always use

appropriate safety equipment such as heat-protective gloves, a respiratory mask, eye protection, nonskid safety

shoes and a hard hat, where appropriate in order to avoid damage. Follow local laws and regulations.

Do not touch the tool's metal parts while in operation, since they become extremely

hot and can cause personal injury. Also avoid touching already heated and loosened paint, putty and varnish,

which can become hot as well. Always use appropriate safety equipment such as heat-protective gloves.

1. PREVENT FIRE HAZARD:

2. ELECTRIC SHOCK SAFETY:

3 ALWAYS USE A POWER OUTLET WITH A GFCI

4. GROUNDED TOOLS MUST BE PLUGGED INTO A PROPERLY INSTALLED OUTLET:

5. APPROVED ACCESSORIES, PARTS AND SERVICE:

6. ALWAYS USE THE ON/OFF SWITCH:

7. WORK SAFELY:

8. PREVENT BURNS:

6

If the paint is heated for too long and gets overheated the risk

of exposure to toxic gases and fumes increases. Follow the Safety Manual for proper use. Always follow

local laws and regulation.

Contact between the heat from the IR tubes or the gases and the electrical components in the machine may

cause an explosion which may lead to personal injury or death.

Do not let unauthorized people come in contact with this tool or power

cord since this might constitute a fire hazard or risk of injury.

This is to avoid possible toxic gases or other substances that might be in the air

or in the paint waste which might affect the child.

The power tool should never be left unsupervised when in

operation. After use, it should be switched off and allowed to cool to a safe temperature before being left

unattended. Leaving the tool unsupervised might cause fire or damage on other property.

Heating a surface for too long or leaving the power tool unattended may

cause fire or damage the machine or the surface. A surface should be heated only for 20 30

seconds indoors and 20 40 seconds outdoors. Apply only enough heat to make the paint pliable. The paint is

ready to be scraped off when it is both bubbling and smoking at the same time.

Untidy surfaces and work areas increase the risk of fire and

personal injury.

10. DO NOT EXCEED THE HEATING UP TIME.

11. DO NOT USE THE TOOL NEAR FLAMMABLE LIQUIDS OR GASES.

12. KEEP CHILDREN AND PETS AWAY:

13. CHILDREN, PREGNANT OR POTENTIALLY PREGNANT WOMEN AND NURSING MOTHERS

SHOULD NOT BE PRESENT IN THE WORK AREA UNTIL THE WORK IS DONE AND ALL CLEAN

UP IS COMPLETED.

14. NEVER LEAVE THE TOOL UNSUPERVISED:

15. LIMIT THE HEATING- UP TIME: -

16. KEEP THE WORK AREA CLEAN:

TO AVOID THE RISK OF FIRE

17. WE RECOMMEND HAVING A WATER SPRAYER handy to spray mist into cracks and crevices as a

precaution against overheating that may lead to fire. Slightly wetting the painted surface prior to paint removal

is advantageous and will aid the paint removal process and significantly reduce the risk of fire.

The power tool will dry out the moisture you previously introduced, making the wood dry and ready for the

primer coat and paint.

7

Ensure effective ventilation and use a respiratory mask when

working with paint or paint removal. Do this to eliminate the risk of inhaling possible toxic gases and dust.

Follow local laws and regulations.

9. AVOID INHALING FUMES AND DUST:

STOP

STOP

English

8

Always use extension cords approved for the required amperage and environmental

conditions or an electric overload may develop, which might lead to a short circuit.

19 Do not use this tool in damp or wet places.

If the machine gets wet it may cause short circuit.

Never use the cord to carry the tool or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock. Make sure the power cord is not in contact with any of

the hot surfaces on the tool. This could destroy the cord and cause electric shock.

Keep the tool clean and dry. Take special care to ensure that the infrared tubes

and aluminum reflectors are clean and in working order. Dirty tubes and reflectors will reduce efficiency

and can cause fire. Check the power cord, safety shields, and other parts regularly. Replace damaged parts.

The IR tubes are made of quartz glass and must be handled with care. Always use gloves or a rag when

handling the IR tubes. Never touch them with your hands. If an IR tube breaks, immediately switch the

power tool off, pull the plug and replace the tube. Do not operate with only one tube working. Improper tool

maintenance may lead to malfunction, fire hazard, risk of electric shock and thereby personal injury.

Before continuing to use this tool, carefully check all safety systems and

other damaged parts to ensure the tool will function properly for the intended task.

The safety system or other damaged parts should be repaired or replaced immediately.

Although this power tool does not create dust itself, scraping the soft paint might

release dust particles that may contain lead. Clean up all removed paint and dust by wet mopping the floors.

Use a wet cloth to clean all walls, sills and any other surfaces where paint or dust is clinging.

Use an environmentally safe cleaning detergent. Place a drop cloth or tarpaulin under the work area to catch

any paint chips or peelings. Wear protective clothing. At the end of each session, put the paint waste and

debris in a double plastic bag, close it with tape or twist ties and dispose of properly. Follow local laws and

regulation. Use respiratory mask and heat protective gloves. Keep interior work area well ventilated.

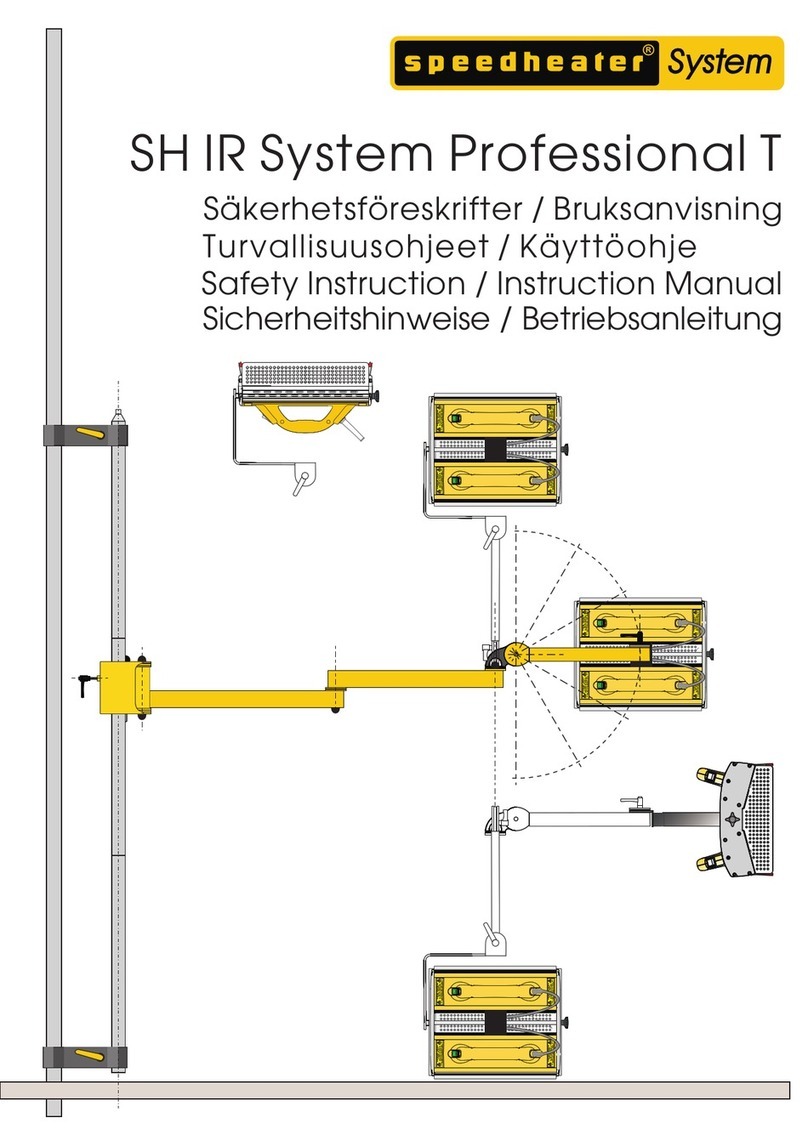

Dropping this tool may cause irreparable damage to the housing and

infrared tubes. IR tubes are the most sensitive parts of this tool and will break if dropped.

Cracked IR tubes and/or damage to the housing void the warranty. It is recommended that a suspension

system be used for removal of paint on exterior walls, which will reduce the risk of dropping the tool and

causing damage to it. Various hands free systems are available from the distributor and/or the dealer

who sold you the Speedheater Infrared Paint Remover, model 1100 S.

18. EXTENSION CORDS:

. DO NOT EXPOSE THE TOOL TO RAIN:

20. DO NOT ABUSE THE POWER CORD:

21. TOOL MAINTENANCE:

22. CHECK DAMAGED PARTS:

23. DUST PARTICLES:

-

24. HANDLING THE POWER TOOL:

-

O T H E R W A R N I N G S

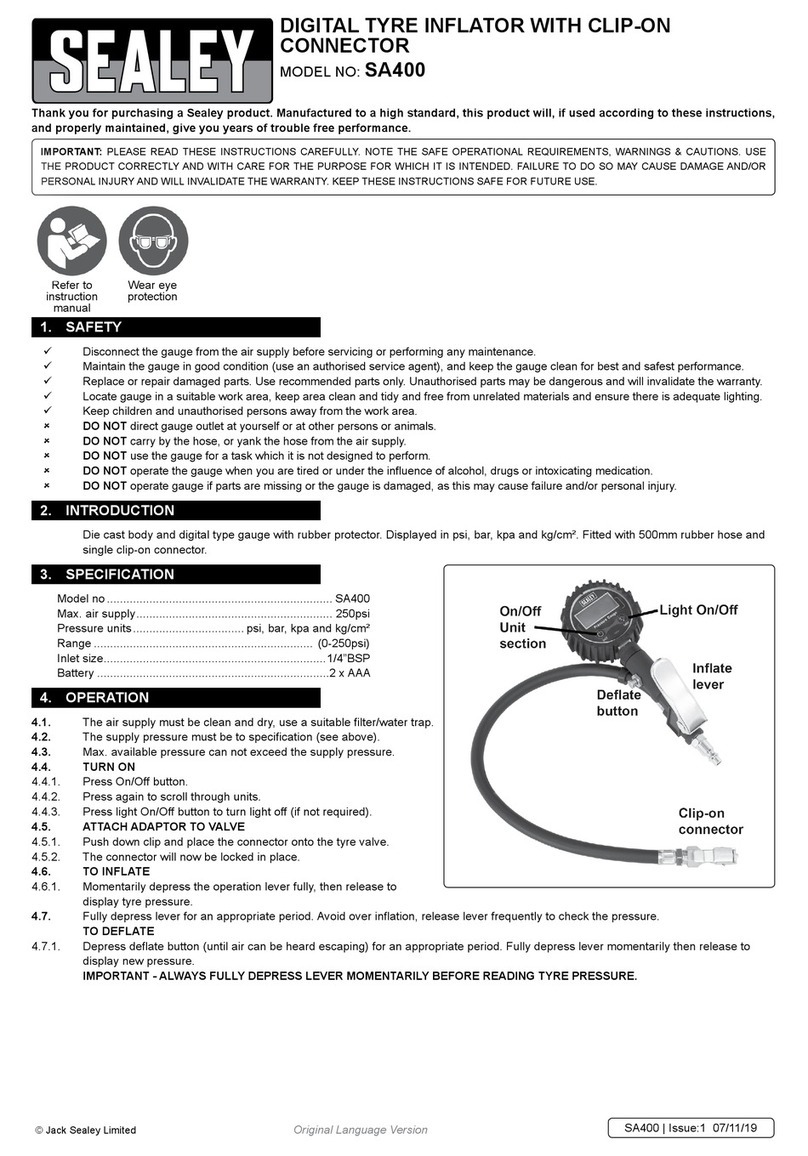

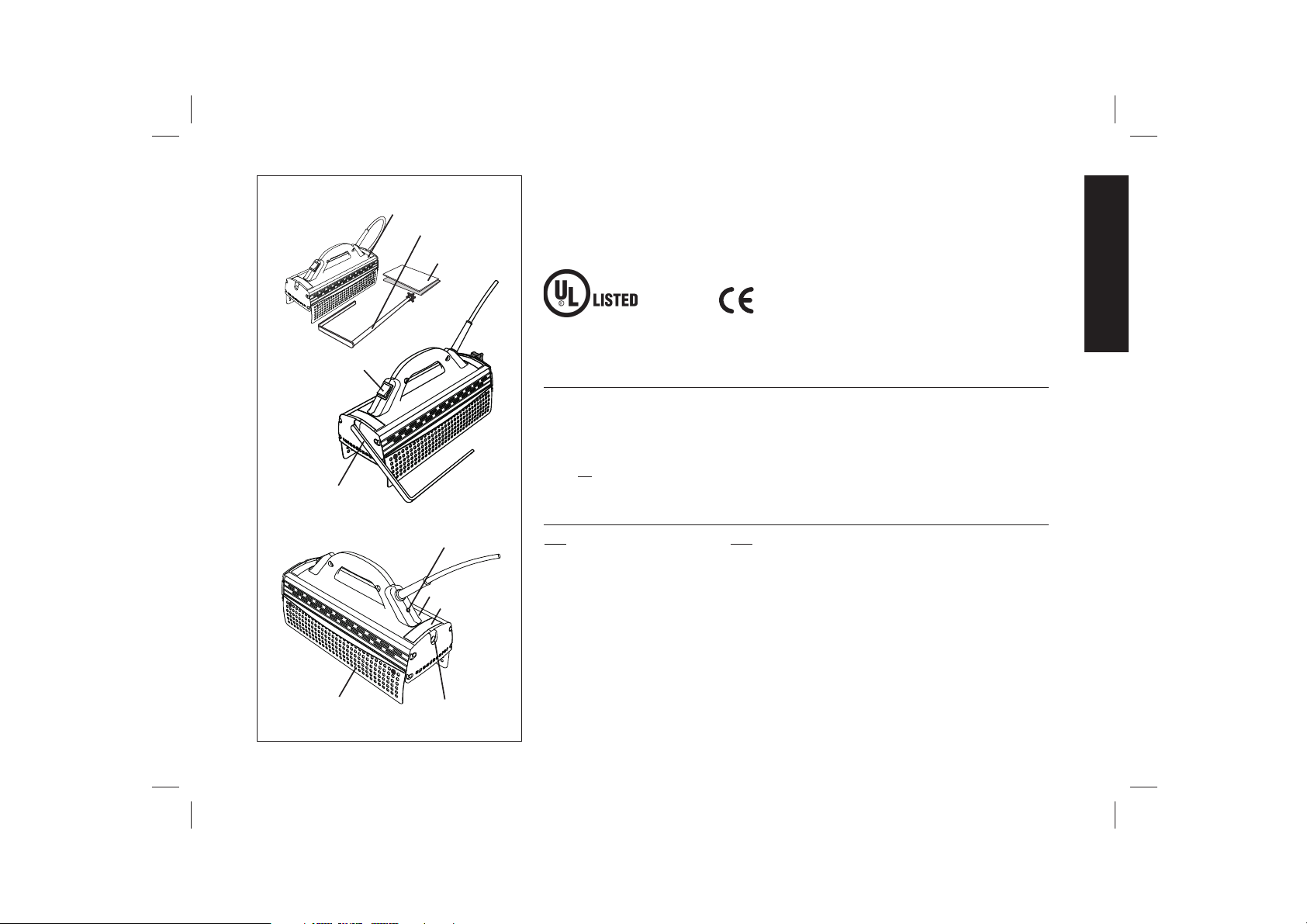

ON/OFF switch

Accessories

attachment point

Protective plates

TECHNICAL SPECIFICATIONS

Speedheater Infrared Paint Remover, model 1100 S

IR Paint Remover

Angle support

Angle support

Operating Temperature

This tool is made in Sweden by Speedheater System AB.

US Patent No. 008442391B2.

Indoors 20 to 30 seconds.

Outdoors 20 to 40 seconds.

The paint is ready to be scraped off when it is both bubbling and smoking simultaneously.

Reset button for

anti-overheat function

SH IR Paint Remover

Storage Box

Total length

idth

eight

:

W:

H:

20”

10 1/4”

9 1/2”

Total :

W:

H:

:

length

idth

eight

Approx. Weight

14 1/2”

6 3/4”

6 3/8”

4 lb 3 oz.

L:

W:

ength

idth

12 1/4”

4 7/8”

in accordance with EN 60335-1, EN 60335-2-45 standards.

Dimensions

Heating surface

Optimum exposure time for paint removal applications

Approximately 200 - 400 F (100-200°C) when used as described in the instructions. Heating for longer than

recommended increases the temperature and may thereby constitute a fire hazard, exposure to lead vapor and

other vapors that may cause severe personal injury.

o

Connection

1 phase standard grounded outlet.

Watts

Volts Amps

120 1100 9.2

Cord

16 gauge 3 wire, 8 feet long.

Anti-overheat function

The anti-overheat feature only protects the components of the tool from being overheated.

It does monitor the temperature of the substrate or protect against fire hazards.not

Serial number

ID # 000000

ELECTRIC PAINT REMOVER

36ER

English

Instruction &

Safety Manual

9

10

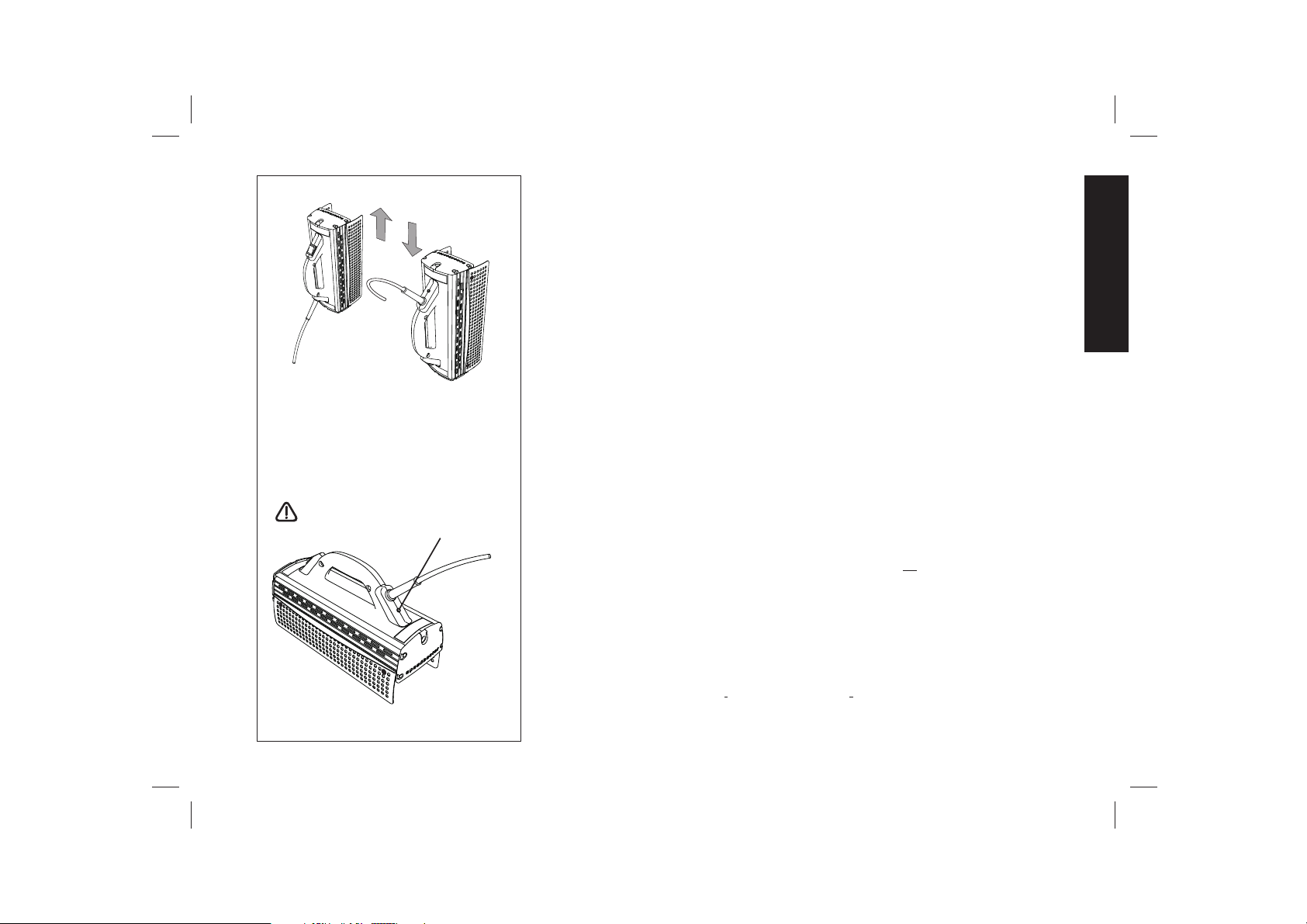

INSTRUCTIONS FOR USE

When heating in vertical angle, turn the

machine around after 2 hours. For keeping

even effect on ir bulbs.

11

General information before you start

Make sure the protective plates are in facing down before you turn the power tool on.

Never obstruct the airflow through the vented shields. Clean the shields if they get obstructed in any way.

The temperature required to remove paint, is significantly less than you may expect. Heat the paint only to

the point when it can be easily scraped off. Indoors 20-30 seconds, outdoors 20-40 seconds. The paint is

ready to be scraped off when it is bubbling and smoking simultaneously.

- Ambient temperature. (Colder temperature will increase time.)

- Wind will increase exposure time. (Outdoor applications.)

- Type of paint. (Acrylic paint needs a shorter heating time.)

- Layers of paint (Many layers will increase heating time.)

The Speedheater Infrared Paint Remover has a shut off function to prevent overheating. The anti-overheat

feature only protects the components of the tool from being overheated. It does monitor the temperature of

the substrate or protect against fire hazards.

If the anti-overheat function is triggered, power to the unit will be cut and the light on the ON/OFF switch will go

out. The safety switch only comes out approximately 1 mm.

Switch the unit OFF, place it with the heating surface facing up and allow it to cool completely. When cool, reset

the anti-overheat function by pressing the button beneath the power cable.

Start the tool up again, according to the Connecting and heating up instructions.

Variables concerning heatingtime

Anti-overheat function

not

“”

When doing a window restoration, place the Speedheater 1100S-15 in an angle with the help of the angle

support. Begin heating paint and putty for about 1-2 minutes. Putty takes longer to soften than paint and even if

the paint surface has bubbled up, it is good to wait close to 2 minutes for the putty to soften.

Reset button for

anti-overheat function

English

- Heating-up time indoors is 20 to 30 seconds and outdoors it is 20 to 40 seconds. To find out how much time

your specific application requires, begin with a short heating time and extend it if needed.

For different variables affecting heating time, see page 11 in the General Information section.

When the paint is smoking and bubbling, move the tool to a new area. Scrape the paint from the first area

while the next area is heating up.

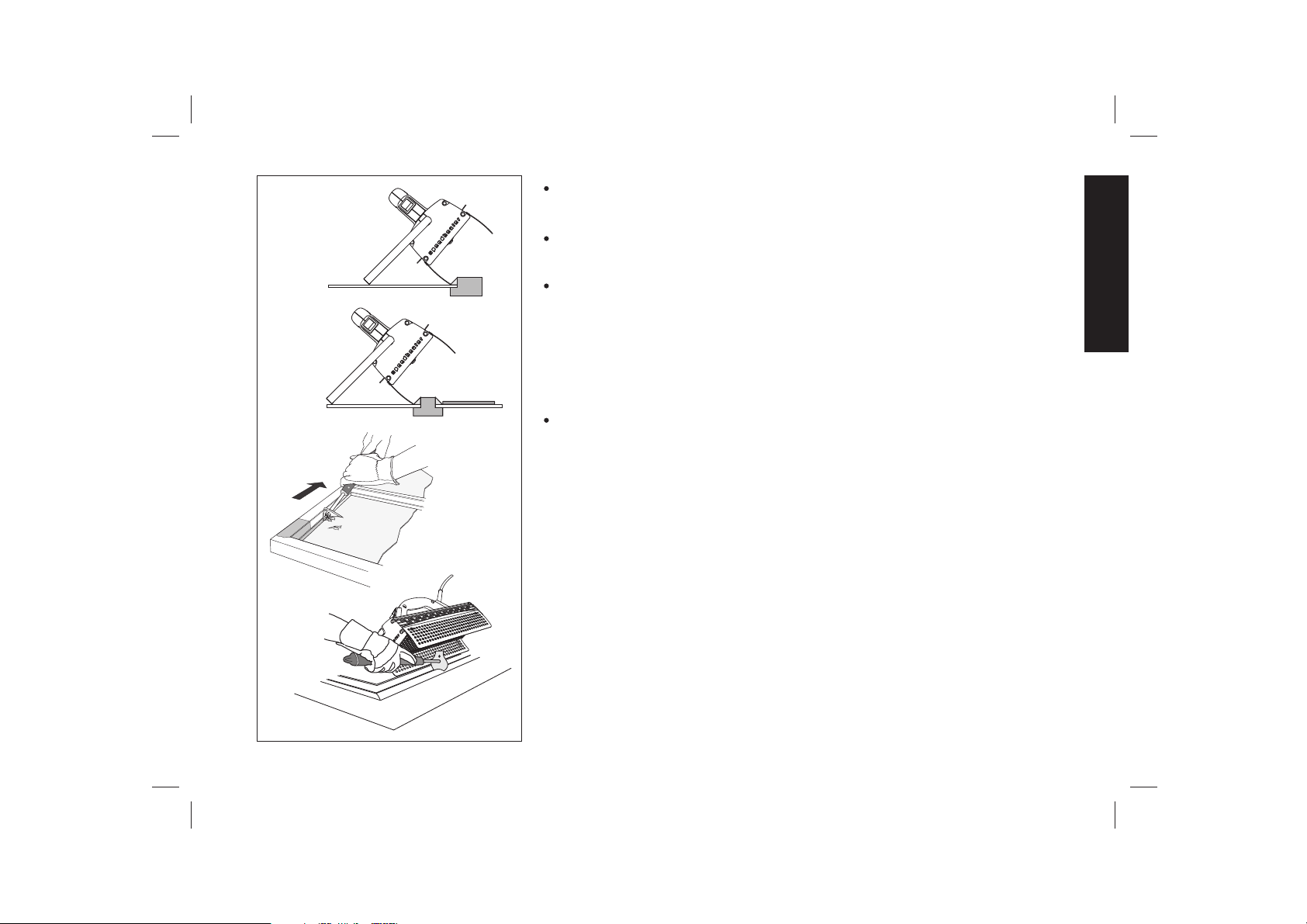

During temporary work breaks, the tool must always be turned upwards

from the surface and never left unsupervised (see diagram).

Connecting and heating up

h

Connect the cord to a 120 V grounded outlet.

- Always use a power outlet with a GFCI (Ground Fault Circuit Interrupter) when working with

the Speedheater Infrared Paint Remover, Model 1100.

- If using an extension cord, ensure it is approved for both the amperage and the environmental conditions.

Move the switch to the ON position, and set the tool down with the heat surface facing up.

Make sure that the tool is placed away from any surface or flammable materials when heating and never leave

it unsupervised.

When the machine is heated up and ready for use, the tubes will glow bright orange.

Heating-up time is approximately 2 minutes.

When the machine is properly warmed up, you can start to eat the paint by turning the Speedheater Infrared

Paint Remover to face the work surface, holding it in position with a firm grip. Wait until the paint

is completely soft, i.e. smoking and bubbling.

Paint stripping

During temporary work breaks, the tool must

always be turned upwards from the surface and

never left unsupervised.

12

Preparations

Ensure the work area is clean and free of flammable materials, liquids and gases.

Make sure ladders, platforms and scaffoldings are properly and safely erected.

- Follow the manufacturer´s mounting and installation instructions meticulously in order to avoid personal injury.

Old dried out paint and

- Paint pigment alone is not sensitive to heat. So to be able to remove very old and dried out paint, a solution

of 80% boiled linseed oil and 20% white spirits Naphtha Hydrotreated Light) can be applied on the dry

surface. Apply the solution using either a paintbrush or spray bottle at least one hour before stripping any paint.

This mixture will help dry paint become more sensitive to infrared heat, making it soft for easier scraping.

(

acrylic paint.

Make sure that the tool is placed away from

any surface or flammable materials when heating

and never leave it unsupervised.

Lay the tool down with the heat surface facing up.

- It is very helpful to always use high quality scrapers for efficient paint removal.

For an even better results, use scrapers that you place on the surface and pull towards you, see Diagram 3.

When removing paint from textured surfaces, use the angle support and scraper as shown in the diagram 4.

- Remember that the metal parts of this power tool are very hot and may cause burns if you come into

contact with them. Always use heat-protective gloves.

- It is important to remember that working on a surface under the Speedheater Infrared Paint Remover

is never necessary but might facilitate scraping heavily profiled surfaces.

13

When working on window sash mountings, use a thin piece of wood covered with aluminum foil

or aluminum tape. It reflects heat radiation and prevents cracking of the facing glass, see Diagram 2.

When restoring windows, be extra gentle in order to protect the glass. Make sure the bottom shield edge of

the tool is placed along the edge of the putty you intend to remove. Avoid directing infrared heat onto the

glass. See Diagram 1.

First remove the paint and then the window putty using a putty chisel, for example. It is possible to reheat the

paint and putty. Heating time depends on the properties of the wood, the putty, type of paint and

climate conditions.

Window pane

Window pane

Wood, 4” wide and

at least the length of

the tool.

Diagram 2.

Diagram 1.

Diagram 3.

Diagram 4.

English

Switching off

Move the switch to the OFF position.

Set the tool down with the heating surface facing up and allow to cool.

- Do not leave the tool unattended until it has completely cooled and make sure that there

are no flammable materials close by.

Disconnect the power cord during breaks and when work is complete.

Do not place the tool in the carrying case before it has completely cooled down.

14

Make sure that the tool is placed away from

any surface or flammable materials when heating

and never leave it unsupervised.

Set the tool down with the heat surface facing up.

15

Problem

Tool does not turn on

Tool turned off after it was on

Fuse blows or circuit breaker trips

Likely cause

Tool not plugged in

The anti overheat function is not reset

The electrical devices in the machine

have been damaged

The fuse has been blown

Tool overheated and the anti-overheat

function shut the tool off

There has been a short circuit caused

by broken tubes or the power iscord

damaged.

-

Solution

Plug the cord into a 15 amp outlet

Reset the anti-overheat function by pressing

the button beneath the power cable.

Check the damage and let an authorized

electrician make the necessary repairs.

Change the fuse that goes to the outlet you

are using.

Let the tool cool down for at least 15 minutes

or until it has cooled and press the small

button below the power cord. You will hear

a clicking sound.

Have the tool inspected by an authorized

person to find out where the short circuit is.

Repair the tool with Speedheater System AB

approved components.

TROUBLESHOOTING GUIDE

English

16

CLEANING AND MAINTENANCE

The IR tubes are made of quartz glass and must be handled with care. If an IR tube breaks,

immediately switch the tool off, pull the plug from the wall socket and replace the tube.

Always use gloves or a rag when handling the IR tubes. Never touch them with your hands.

Repairs should be carried out only by a properly qualified electrician to avoid the

risk of accidents or injury.

The tubes are hot during operation and take some time to cool off. Before changing any tubes, make

sure they have cooled. Always use heat-protective gloves in order to avoid burning and

cutting injuries.

When changing the IR tubes you need to secure the handle of the Power Tool firmly in a vice with a

cloth around the handle so that when you turn the plinth screws you don't move the tool.

To remove the screws for the wires you need a flat head 1/8” wide screw driver.

The wrong size screw driver will crack the ceramic plinth and/or strip the screw heads.

When reassembling, make sure not to over tighten any of the screws.

Always ensure the power cord is disconnected from the electric outlet and the tool is completely

cooled before beginning any cleaning or maintenance work.

In order to maintain the product's safety and efficiency, the IR tubes and reflectors must be kept clean.

The IR tubes and reflectors can be wiped using a cloth moistened with Denatured Ethanol.

Ensure that the Power Tool has completely cooled down.

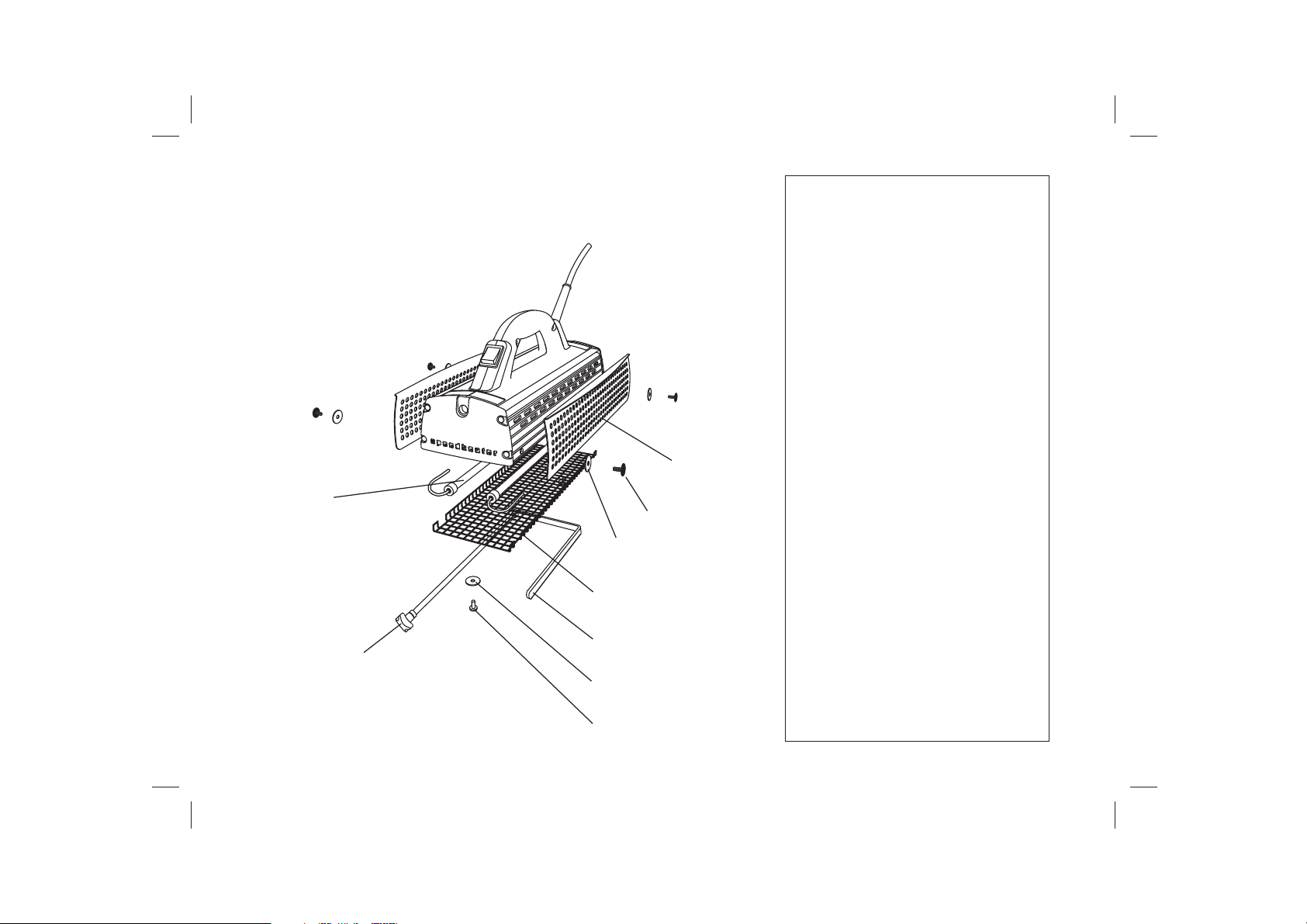

Remove the safety grid by undoing screws 1 at each end.

Carefully wipe accessible parts of the tubes, reflectors and the safety grid.

Replace the grid and ensure that the screws are seated tightly.

Avoid scraping with sharp objects.

Always use protective gloves.

-

-

-

Remove the safety grid by loosening the screws on each end 1 .

Unscrew the safety grid 2 and the reflector flanges 3 .

Detach the IR tube cable connections by undoing the screws on the connection plinths 4 .

CHANGING IR TUBES

Repairs should be carried out only by a

properly qualified electrician to avoid the

risk of accidents or injury.

Flat head 1/8” wide screw driver.

(4 mm)

4

4

1

1

3

2

3

Handle broken tubes very carefully to prevent anyone getting hurt.

Dispose of the IR tubes appropriately.

IMPORTANT!

- Carefully loosen the spring holders 5 in the outer ends in order to loosen the ceramic ends of the IR tubes.

- Turn the tube in the direction shown in the drawing until the tube is released from the middle spring holders 6 .

-

A new IR-tube is inserted in the opposite order from the steps above (6-1).

- Carefully insert and turn the tube into the spring holders in the middle 6 .

- Carefully fasten the outer spring holders 5 on the ceramic ends of the tube.

- Attach the cables to the connection plinths 4 and tighten the screws firmly, but not so hard that they break.

- Make sure the cables are firmly fastened in the right way according to the picture.

- Refasten the reflector flanges 3 , the safety grid 2 and retighten the screws 1 on each end.

Turn the machine on and test warm it with the heating area turned upwards.

The tubes shall have an even soft red/orange color tone.

If you have changed only one tube, a small color difference might occur.

Always use original tubes designed for this model of Speedheater IR Paint Remover.

If you do not have the proper competence for this kind of activity, talk to a professional

or the store where you bought the machine.

17

Flat head 1/8” wide screw driver.

(4 mm)

Make sure to replace the

wires on top as shown

in the picture.

5

6

English

SPARE PARTS LIST

When ordering spare parts, always give the Power Tools

serial number and the part name and number.

The design of the tool is subject to changes

without prior notice.

The Speedheater Infrared Paint Remover, model 1100 S.

Repairs should be carried out only by a properly qualified

electrician to avoid the risk of accidents or injury.

18

11. Protective plate

12. Protective plate screw

14.Safety grid

16. Angle support

18. Protective plate screw washer

19. Grid screw

20.Grid screw washer

10. IR tube

17. Adjustment screw

ONE YEAR LIMITED WARRANTY

DE S

PEEDHEATER

WARRANTY SPE

PEEDHEATER SYS

WARRANTY SPEEDHEA

WARRANTY SPEEDHEATER

RANTY SPEEDHEATER SYSTEM AB WARR

AB WARRANTY SPEEDHEATER SYSTEM AB WA

ARRAN

ER SYSTEM AB WARRANT

EATER SYSTEM AB WARRANTY SP

SYSTEM AB WARRANTY SPEEDHEAT

TEM AB WARRANTY SPEEDHEATER SYSTEM

DHEATER SYSTEM AB WARRRANTY SPEEDHEATER

HEATER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM

SPEEDHEATER SYSTEM AB WARRARNTY SPEEDHEATER S

ER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM AB WARRA

WARRANTY SPEEDHEATER SYSTEM AB WARRANTY SPEEDHEATE

SPEEDHEATER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM WARR

EATER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM AB WARRANTY

M AB WARRANTY SPEEDHEATER SYSTEM AB WARRANTY SPEEDHEAT

SPEEDHEATER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM AB W

HEATER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM AB WARRAN

YSTEM AB WARRANTY SPEEDHEATER SYSTEM AB WARRANTY SPEEDH

SPEEDHEATER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM AB W

ER SYSTEM AB WARRANTY SPEEDHEATER SYSTEM AB WARRANT

AB WARRANTY SPEEDHEATER SYSTEM AB WARRANTY SPEEDH

SPEEDHEATER SYSTEM AB WARRANTY SPEEDHEATER SYS

TEM AB WARRANTY SPEEDHEATER SYSTEM AB WARRAN

ANTY SPEEDHEATER SYSTEM AB WARRANTY SPEEDH

EEDHEATER SYSTEM AB WARRANTY SPEEDHEAT

ATER SYSTEM AB WARRANTY SPEEDHEATE

SPEEDHEATER SYSTEM AB WARRANTY

AB WARRANTY SPEEDHEATER SYST

NDE SPEEDHEATER SYSTEM AB W

SPEEDHEATER SYSTEM AB W

SYSTEM AB WARRANTY

ANTY SPEEDHEATER

SPEEDHEATER SY

ATER SYSTEM A

RANTY SP

SPEED

WA

One Year

Warranty

Speedheater System AB

hereby warrants that the Speedheater

IR Paint Remover, model 1100 S, is covered

by the terms in this limited warranty

against defects in material and workmanship

and it applies to one year from the date

when a sale was invoiced.

The limited warranty does not cover the

normal wear and tear of products.

19

1.

2

3.

4.

5.

6.

.

Speedheater System AB hereby warrants that the Products fully comply with the technical specifications in the

technical manuals and are covered by the terms of this limited warranty against defects in material and

workmanship, provided that any allegedly defective Product has not been altered, misused, neglected or

damaged through causes unconnected with its manufacture.

The limited warranty hereto applies for 1 (one) year from the date when a sale was invoiced. Faults of quality

and hidden defects which cannot be verified immediately upon delivery shall be communicated in writing within 8

(eight) days from discovery thereof. Returns of Products shall be made with proof of purchase to location where

it was purchased, but shall not be made without the authorization of the Dealer/Distributor. The limited warranty

hereto does not cover the normal wear and tear of products.

The limited warranty does not apply to damages caused during transportation (including transport to and from

the owner), or damage due to improper or lack of maintenance, voltage overloads or “undervoltage”, insufficient

or abnormal operation of electrical systems, or in general any cause which does not specifically depend on

defects in material or workmanship, or if the serial number on the product has been removed, altered or defaced.

This limited warranty provides for the replacement of the Products and/or of the assessed defective parts

thereof according to their availability, within about 90 (ninety) business days of receipt by Speedheater System

AB of the defective Products or parts, delivered to the same location and in the same condition and packaging

provided in the original delivery. In case of defects or non-compliance of the Products, Speedheater System AB

shall have up to 90 (ninety) business days to remedy the situation. In no event shall an authorized dealer or

retailer of Speedheater System AB products be entitled to reduce the price of the Speedheater System AB

products as a consequence of defects and/or non -compliance of the products without Speedheater System AB's

written consent.

EXCEPT AS EXPRESSLY PROVIDED IN THIS LIMITED WARRANTY, SPEEDHEATER SYSTEM AB

HEREBY DISCLAIMS ALL WARRANTIES, EXPRESS, STATUTORY AND IMPLIED, APPLICABLE TO

PRODUCTS, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE AND ANY WARRANTY THAT ANY PRODUCT IS DELIVERED FREE OF

CLAIMS OF THIRD PARTIES BY WAY OF INFRINGEMENT OR THE LIKE.

SPEEDHEATER SYSTEM AB FURTHER DISCLAIMS ALL EXPRESSED, STATUTORY AND IMPLIED

WARRANTIES APPLICABLE TO PRODUCTS WHICH ARE NOT MANUFACTURED BY SPEEDHEATER

SYSTEM AB. THE ONLY WARRANTIES APPLICABLE TO PRODUCTS NOT MANUFACTURED BY

SPEEDHEATER SYSTEM AB SHALL BE THE WARRANTIES, IF ANY, OF THE MANUFACTURER OF

THOSE ITEMS.

English

7.

8.

9.

10.

11.

12.

The total liability of Speedheater System AB for any loss, damage or claim, whether in contract, tort (including

Speedheater System AB's active or passive negligence or strict liability) or otherwise, arising out of, connected

with, or resulting from the performance or breach of any distribution agreement, subdistribution agreement, or

sale agreement, or purchase order, or contract of sale accepted or executed by Speedheater System AB, or from

the design, manufacture, sale, delivery, resale, inspection, assembly, testing, repair, replacement, operation,

maintenance or use of any Product or from the performance of any service shall not, in any event, exceed the

price allocable to the product or service which gives rise to the claim, loss or damage.

IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT OR WARRANTY OR ALLEGED

NEGLIGENCE OR STRICT LIABILITY, SHALL SPEEDHEATER SYSTEM AB BE LIABLE FOR INDIRECT,

INCIDENTAL, CONSEQUENTIAL, SPECIAL OR EXEMPLARY DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOSS OF PROFITS OR REVENUE, LOSS OF PRODUCTS OR ANY ASSOCIATED EQUIPMENT,

COST OF CAPITAL, COST OF SUBSTITUTED EQUIPMENT OR PARTS, FACILITIES OR SERVICES, DOWN-

TIME COSTS, LABOR COSTS, OR CLAIMS OF CUSTOMERS OR SUBDISTRIBUTOR.

IF ANY PORTION OF THIS LIMITED WARRANTY IS HELD ILLEGAL OR UNENFORCEABLE BY REASON

OF ANY LAW, SUCH PARTIAL ILLEGALITY OR UNENFORCEABILITY SHALL NOT AFFECT THE

ENFORCEABILITY FOR THE REMAINDER OF THIS LIMITED WARRANTY WHICH IS AND WILL ALWAYS BE

CONSTRUED TO BE LIMITED BY ITS TERMS OR AS LIMITED AS THE LAW PERMITS.

As a prior condition to any obligation of Speedheater System AB under the above limited warranty, the

purchaser of Speedheater System AB's products must have fully and finally paid for the products. The above

warranty does not cover normal wear and tear of the Speedheater System AB's products.

Speedheater System AB shall have no obligation under the limited warranty unless it is established to the

satisfaction of Speedheater System AB that the Speedheater System AB' product (i) has not been altered or

modified without the prior written consent of Speedheater System AB, (ii) has been assembled, maintained,

operated and used at all times in accordance with Speedheater System AB's current, applicable operation,

maintenance and other written instructions issued from time to time by Speedheater System AB, and (iii) has

been used only with parts specifically approved by Speedheater System AB for use with Speedheater System

AB's product.

This Limited Warranty distributes the risk of product failure between purchaser and Speedheater System AB,

and Speedheater System AB's product pricing reflects this distribution of risk and the limitations of liability

contained in this Limited Warranty. The agents, employees, distributors, and dealers of Speedheater System AB

are not authorized to make modifications to this Limited Warranty, or make additional warranties binding on

Speedheater System AB. Accordingly, additional statements such as dealer advertising or presentation, whether

oral or written, do not constitute warranties by Speedheater System AB and should not be relied upon.

20

Table of contents

Languages:

Other Speedheater Power Tools manuals